Work Orders

·

8 min read

What Is a Work Order? Tips & Best Practices

What Is a Work Order?

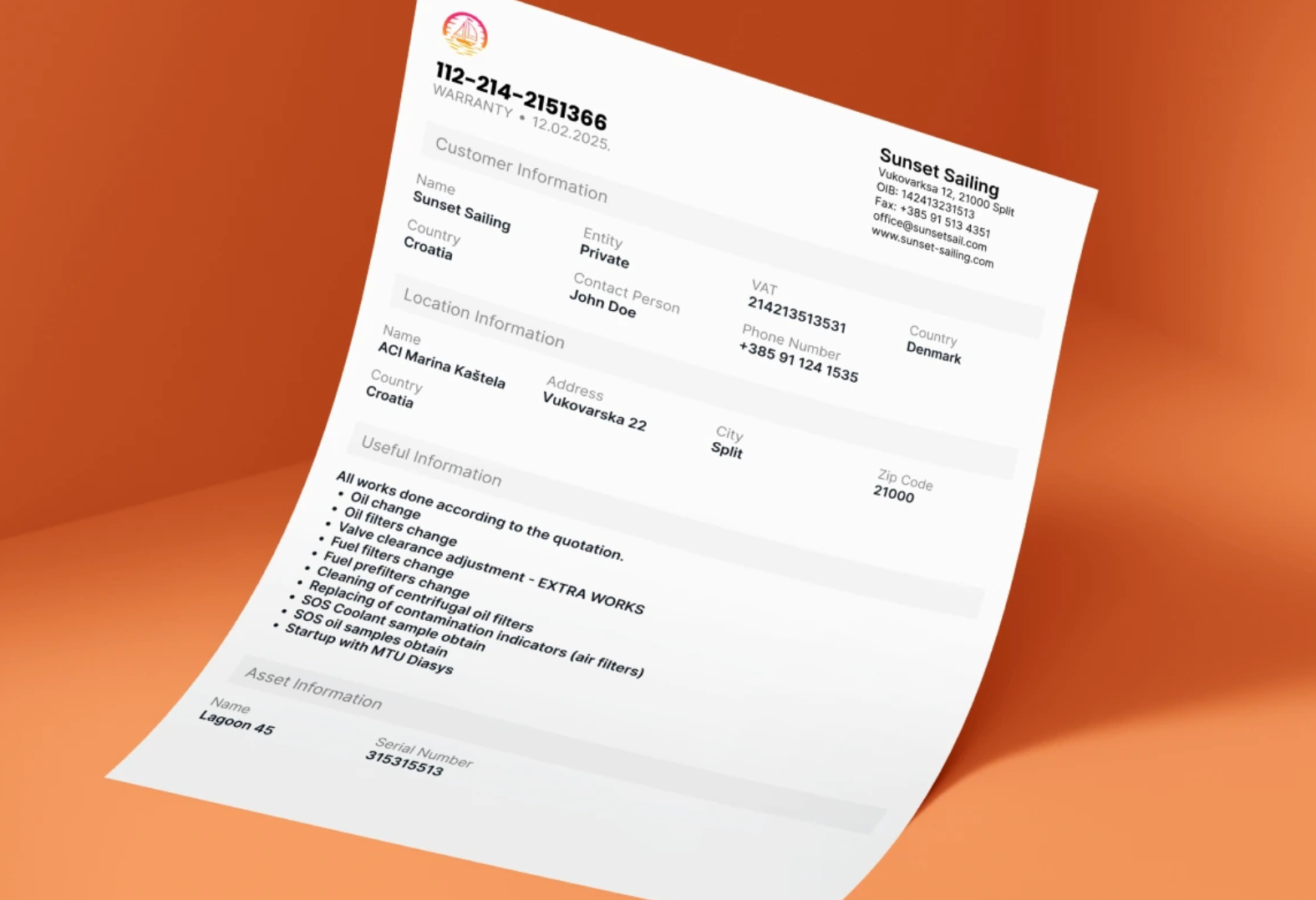

A work order is a central document in business operations—it’s an official instruction for a worker to carry out a specific task assigned by their supervisor. The document contains all the necessary information for the job: it clearly states who requested the task (and for whom), where it should be carried out (e.g. office building at Dummy Address 5), and what exactly needs to be repaired or replaced (e.g. air conditioning unit).

In short, a work order provides everything the worker needs to understand and complete the task. It also includes details about the person who performed the work, client confirmation that the job was done—successfully or not—and supervisor approval, which includes a review of how long the technician was on site and what materials were used for repair or replacement.

In industries like ship maintenance, HVAC servicing, and facility management, work orders are an everyday essential. They are at the center of operations—everything starts with a work order.

A Guide for Organized Work

A work order helps get the job done clearly and efficiently. It’s used across industries and always includes important task execution details.

In manufacturing, it might include: a short task description, required materials, production steps, time estimates per step, and technical drawings.

In maintenance, it usually includes: fault descriptions, what needs to be repaired or replaced, spare part details, and required materials/time.

In service, you’ll find: service description, client information, task specifics, and execution instructions.

In construction, it includes: project description, required materials, and instructions on how the work should be carried out.

From Paper to Digital

Work orders are still commonly used in paper form, and often stored in office archives once completed. People are used to using pen and paper—we’ve grown up with it. If you know how to write, you know how to fill in a work order.

But this method brings a number of risks: illegibility, physical damage, or complete loss of the document. This leads to dissatisfaction not only among managers but also clients. Not everyone has readable handwriting, and sometimes it’s hard to decipher written numbers. Paper forms get lost, storage space is needed for physical archives, and copies are required for the technician, the client, and finance. In some cases, additional staff are needed—these are all costs that digitalization can eliminate.

The Serwizz app allows a smooth transition to digital work orders.

Key Benefits of Digital Work Orders

Increased Efficiency

Digital work orders are available to everyone involved the moment they are created. Unlike paper orders that must be physically delivered to technicians, digital work orders appear instantly on the devices of the assigned workers.

This is particularly useful for field employees who work far from company HQ. Any updates or comments are immediately visible to everyone. Supervisors and workers can communicate via in-app comments, reducing the chance of human error.

With no need for phone calls or paperwork exchange, tasks get done faster. All necessary data is available in real time. Also, digital work orders can’t be lost or damaged like paper forms, so project delays are minimized. After completing a job, the technician can email a copy of the work order directly to the client.

Legibility and Multilingual Support

Notes written by hand can be hard to read—especially when done in a rush. Numbers can be misread, which becomes a problem during work reviews or audits. Digital work orders remove the risk of illegible or unclear entries—everything is typed, clean, and standardized.

One big advantage of Serwizz digital work orders is that they support both Croatian and English, and additional languages (like German) can be introduced if needed.

Better Process Integration and Full Transparency

In HVAC servicing, miscommunication between office staff and field technicians often leads to errors or delays. For example, if the technician doesn’t get the correct part list or fails to report extra work that’s needed, this might lead to multiple visits, job delays, and frustrated clients.

With digital work orders:

- All stakeholders—from customer service to field techs—access the same real-time information.

- As soon as a work order is created, the technician sees everything: client address, fault description, required parts, and notes.

- They can also enter their own notes immediately after completing the task.

- Service managers can instantly track job status—whether it’s in progress, completed, or needs follow-up—without additional communication. Data is always up to date, and it's easy to monitor time, materials used, and team productivity.

Types of Work Orders: Client and Internal

1. Client Work Orders

This type refers to jobs performed for a specific client. A client work order is always linked to clearly defined elements:

- Client location

- Client asset

- Client equipment

These orders usually include:

- Problem descriptions

- Repair instructions

- Required spare parts

- Expected duration

- Task priority

2. Internal Work Orders

Unlike client orders, internal work orders are not linked to external clients—they refer to tasks carried out within the company.

Examples include:

- Workshop or warehouse cleaning

- Servicing internal equipment

- Training

- Admin tasks

Internal work orders help with scheduling, planning, and resource optimization.

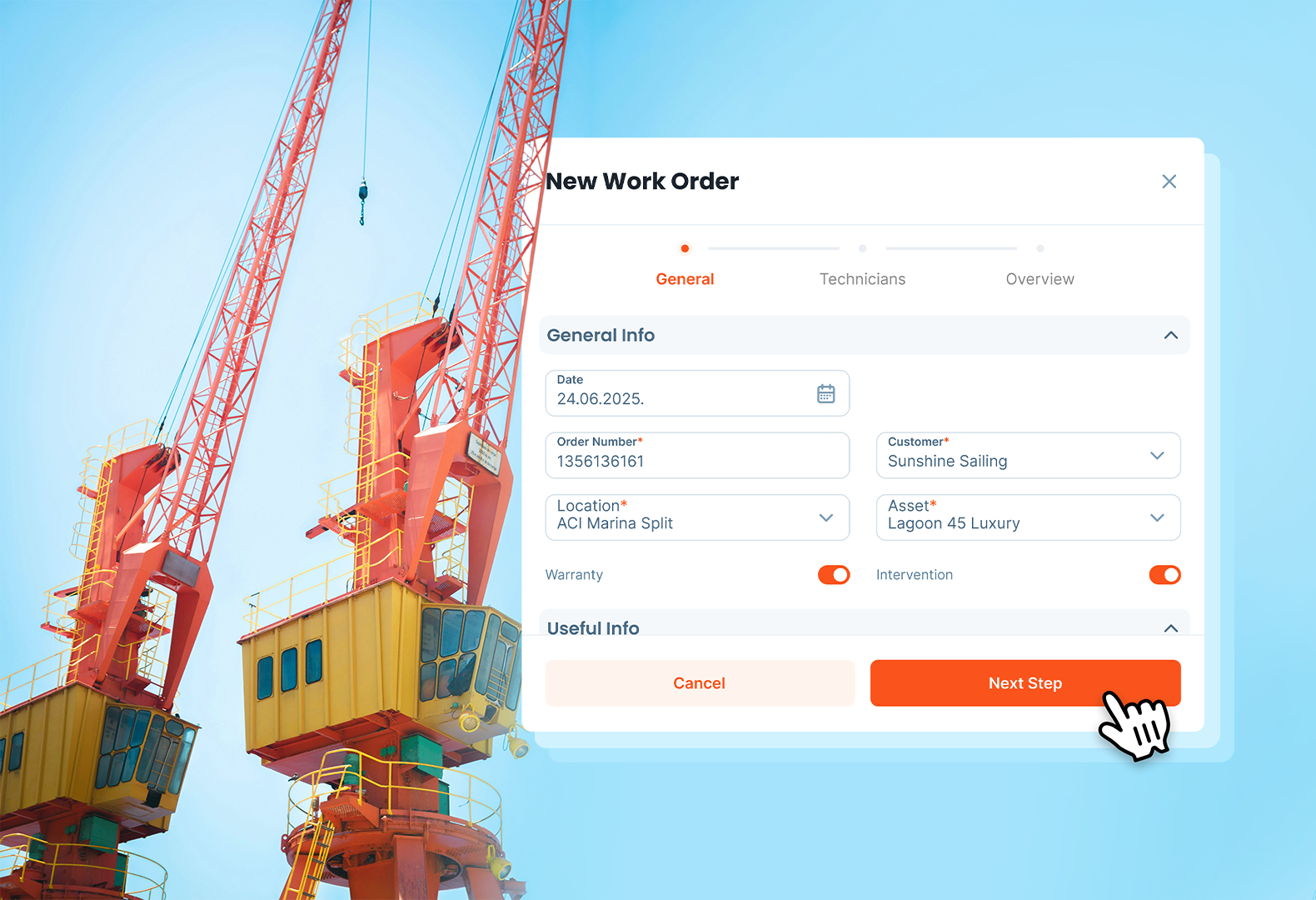

Who Can Create a Work Order in Serwizz?

Only users with the following roles:

- Manager

- System Administrator

can create and assign work orders.

Roles that cannot create work orders:

- Approver

- Technician

- Other field staff

This ensures better access control and clearer responsibilities.

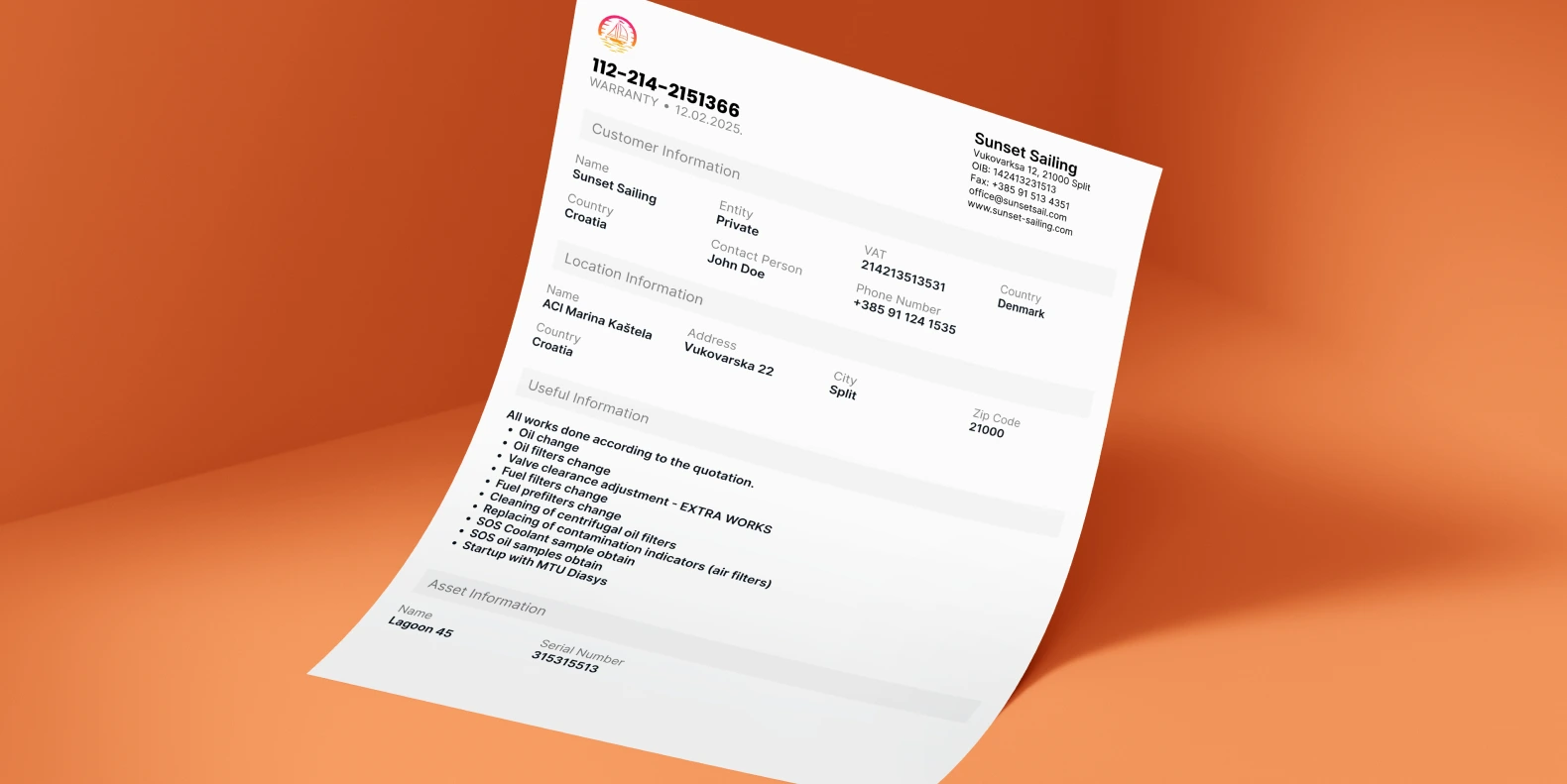

Work Order Fields

When creating a work order, managers fill in:

- External reference

- Customer

- Location

- Room

- Assets

- Warranty

- Intervention type

- Useful information

- Upload files

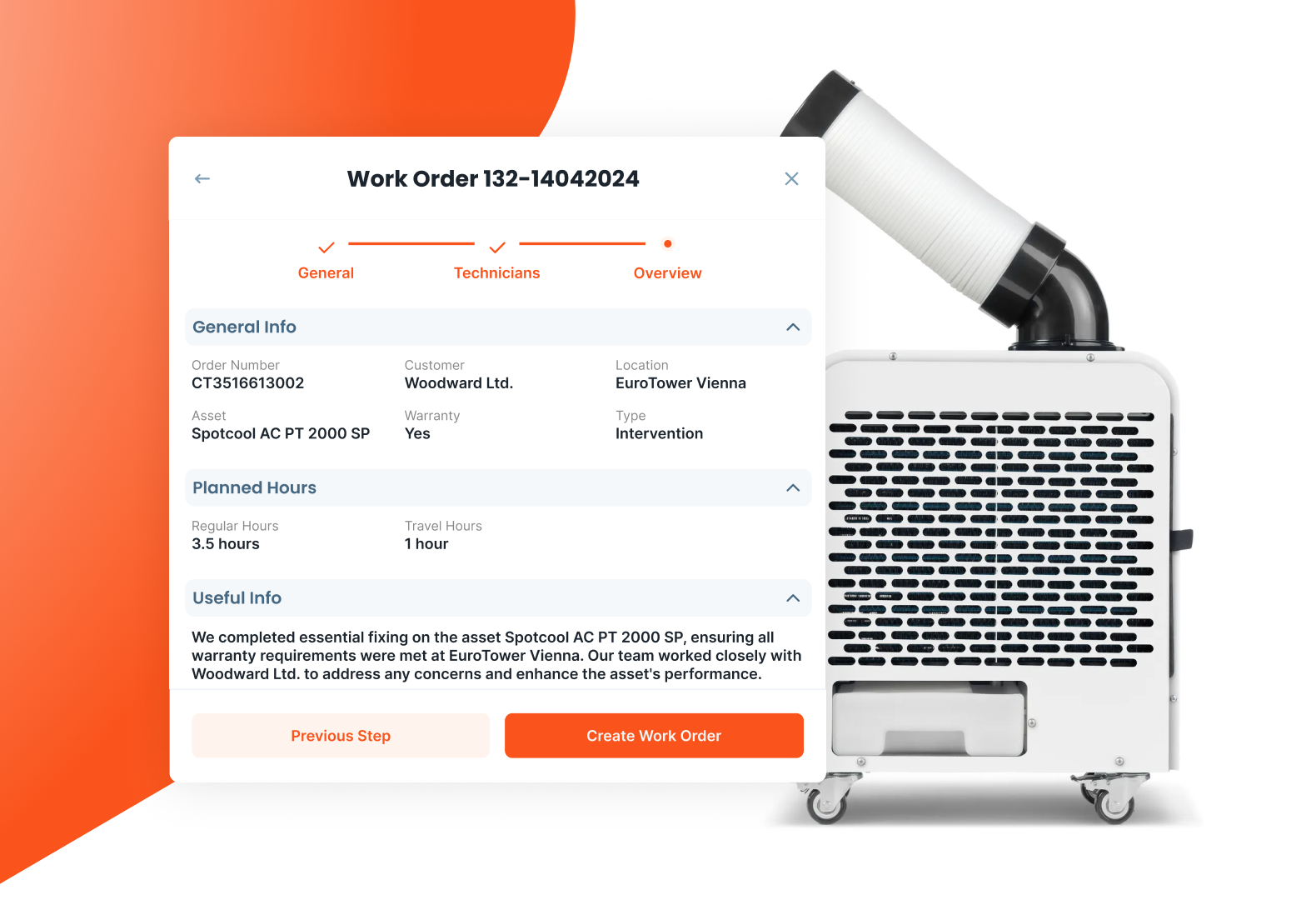

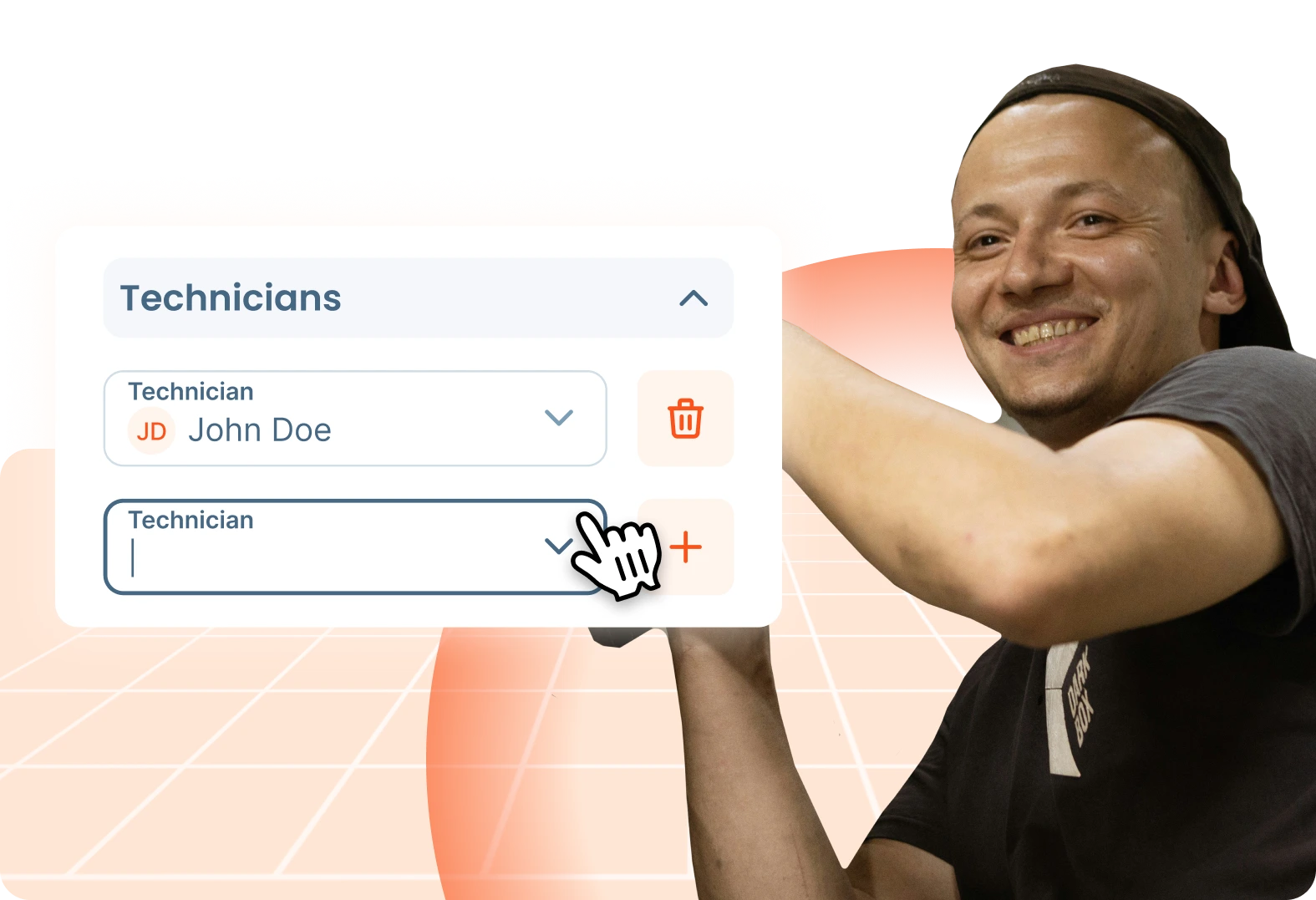

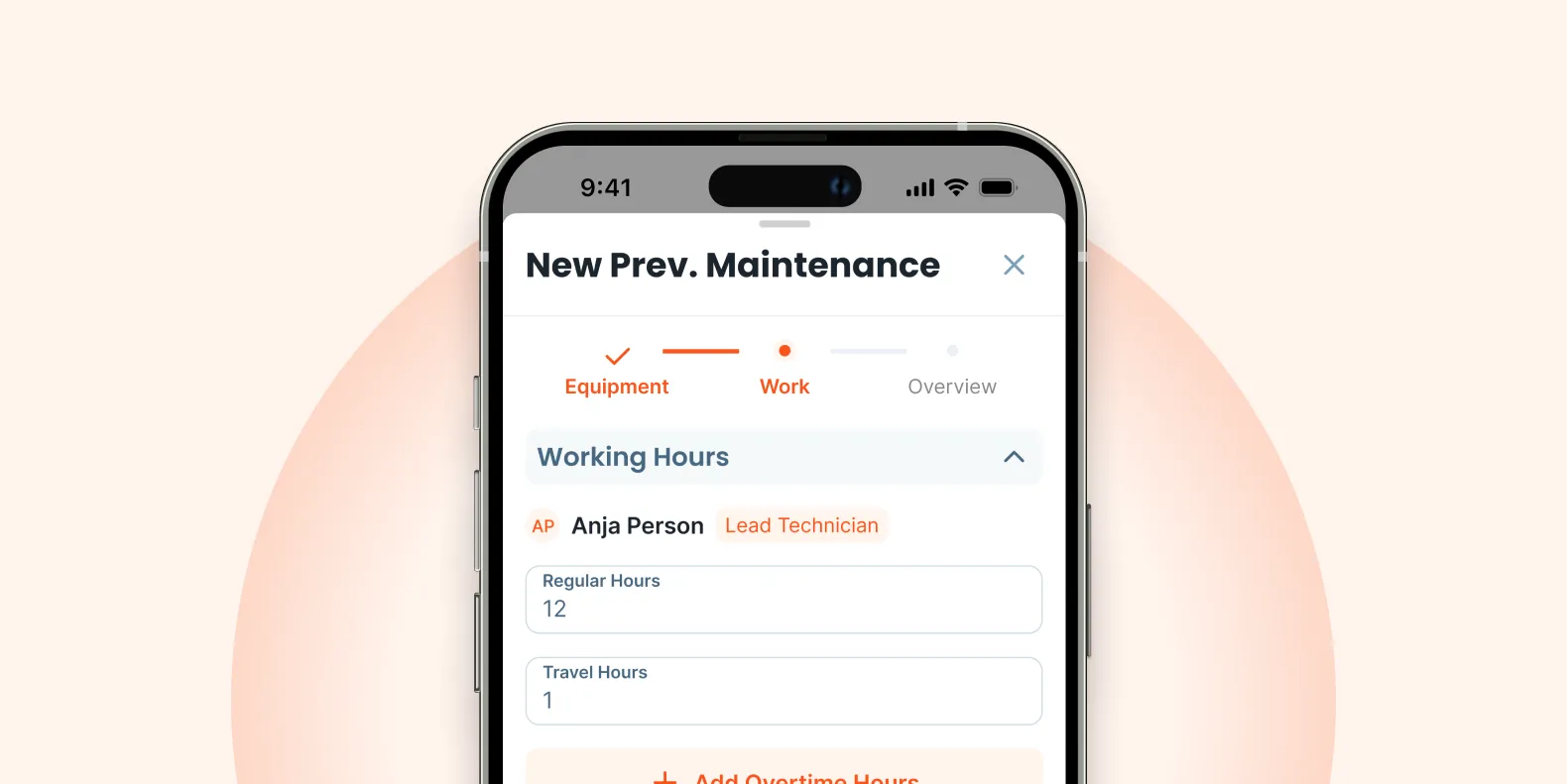

Assigning Work Orders

Managers assign:

- A technician

- A tech lead

- Planned work hours and travel hours

Technician Workflow: From Daily Reports to Final Approval

Each technician completes a Daily Report for their tasks, including:

- Notes

- Attachments

- Equipment

- Materials Used

- Working Hours

- Expenses with receipts

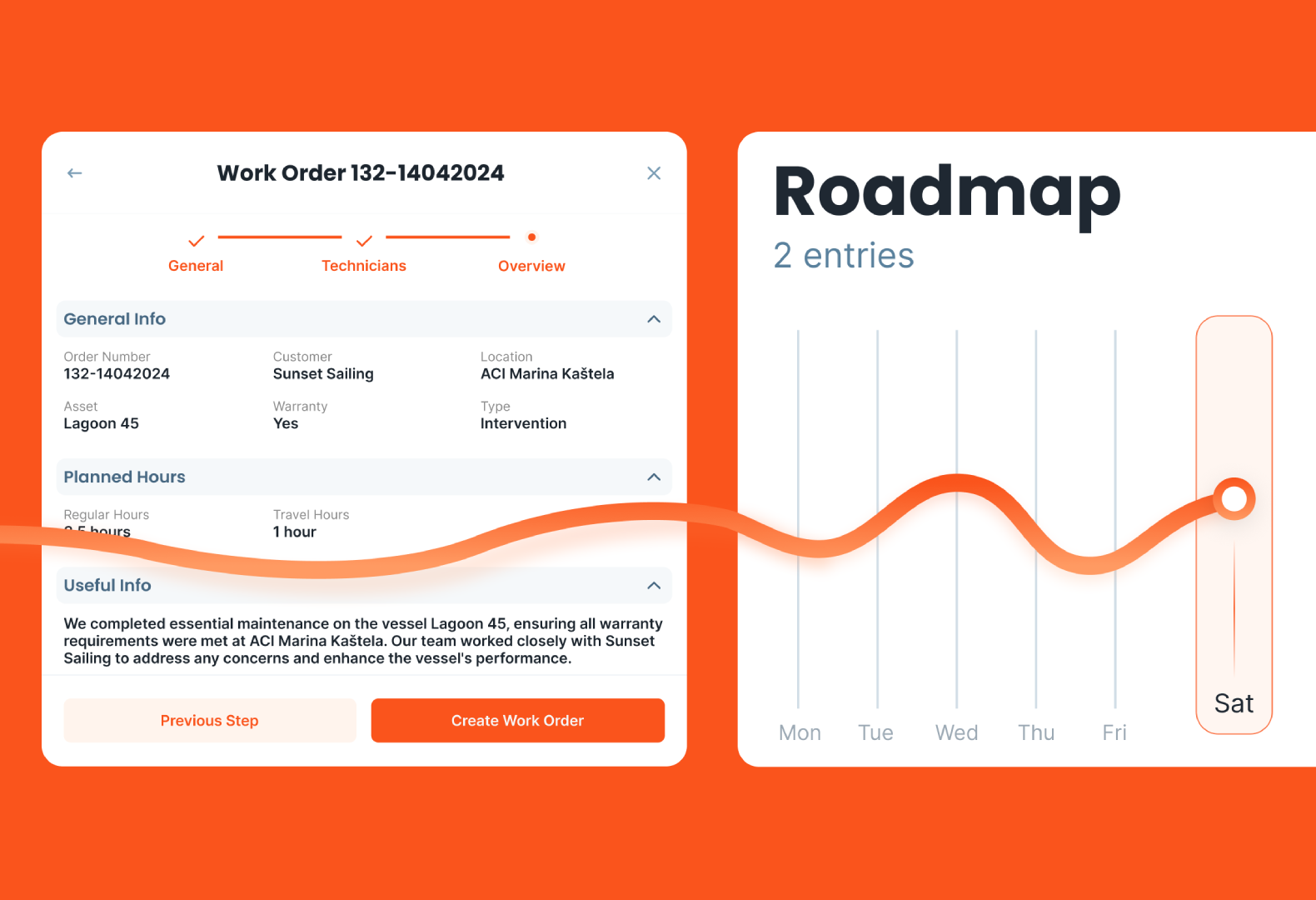

Finalizing the Work Order

Before submission, both technician and client sign off digitally. The system then locks the record for review and approval.

Work Order Lifecycle Summary

- Backlog – Created, not yet started

- In Progress – Work started

- Ready for Approval – Work completed, submitted

- Done – Manager approval completed

Conclusion

Work orders have always been part of getting things done—but paper-based ones don’t keep up. Digital work orders improve clarity, reduce delays, and increase satisfaction for both teams and clients.

With features like multilingual support, material tracking, and digital signatures, Serwizz makes field service smarter and more scalable.

Clarity creates confidence—and confidence builds trust.