Preventive Maintenance

·

6 min read

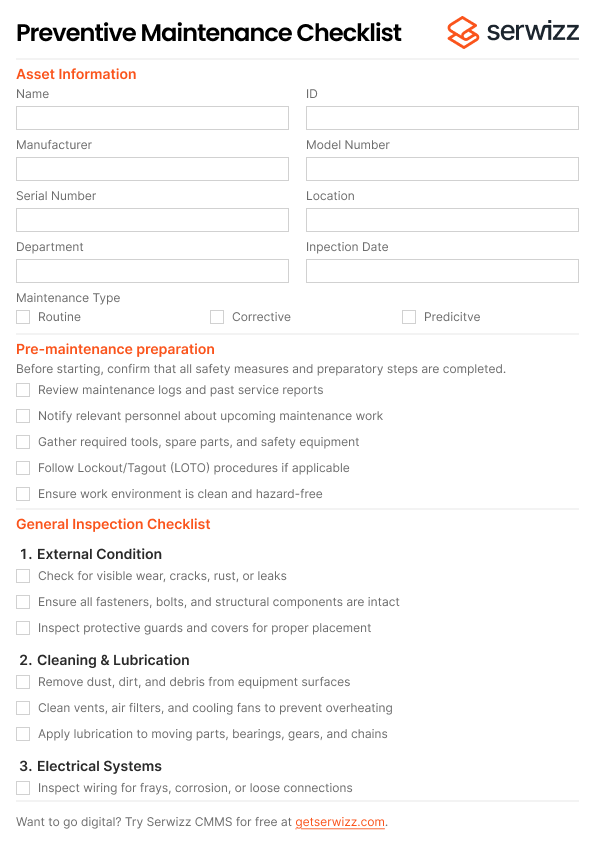

Free Preventive Maintenance Checklist

Keep your equipment and systems running smoothly with this easy Preventive Maintenance Checklist. Regular checks and simple fixes help you catch problems early, reduce downtime, and save money on costly repairs. Whether you manage vessels, facilities or field equipment, this checklist has you covered.

Download Free Preventive Maintenance Checklist

Below you can download a practical and customizable preventive maintenance checklist for free. The document comes in PDF format, with the possibility of editing and adapting it to your needs.Click the button below and start using it immediately – completely free.

Looking for an Excel Preventive Maintenance Checklist? Contact us via email or via the contact form and we will send you a Preventive Maintenance Checklist in Excel format ready for even more detailed editing.

Preventive Maintenance Checklist – Field Descriptions

Asset Information Section

| Field | Description |

|---|---|

| Name | The name or title of the asset/equipment (e.g., HVAC Unit 1, Generator A). |

| ID | Unique internal ID or tag number assigned to the asset. |

| Manufacturer | Company or brand that produced the asset. |

| Model Number | Official model number listed on the asset. |

| Serial Number | The unique serial number from the manufacturer. |

| Location | Where the asset is located (room, floor, vessel, site, etc.). |

| Department | Which team or department the asset belongs to. |

| Inspection Date | The date this maintenance check is being performed. |

Maintenance Type:

- Routine: Regular, scheduled maintenance

- Corrective:Repairs or fixes after a fault is found

- Predictive: Based on condition monitoring or data trends

Pre-Maintenance Preparation Section

This section helps ensure everything is in place before work begins. Especially useful for safety-critical environments.

General Inspection Checklist Section (Summary)

Before starting any maintenance, it’s important to take a few key steps to ensure safety and avoid delays. This section helps you confirm that the work area is safe, the right tools are ready, and everyone involved is informed.

- External Condition: Check the asset for physical damage like rust, leaks, cracks or missing parts.

- Cleaning & Lubrication: Clean the unit and apply lubrication to moving parts to ensure smooth operation.

- Electrical Systems: Inspect wiring, test electrical components, and confirm there are no loose or damaged connections.

- Mechanical Components: Check belts, gears, bearings, and hydraulics for wear, tension, leaks and proper function.

- Safety and Compliance Checks: Verify emergency stops, alarms and safety systems work and meet local regulations.

- Functional Testing: Power up the equipment and confirm it runs properly without noise, delays, or errors.

Repairs and Corrective Actions Section

| Field | Description |

|---|---|

| Issues Identified | List any faults or irregularities found during inspection. |

| Immediate Actions Taken | What was done right away to fix or secure the issue. |

| Additional Repairs Required? | Yes / No – Will more work be needed later? |

| Replacement Parts Needed? | Yes / No – Do you need to order/install new parts? |

| Technician Notes | Any observations, suggestions, or comments from the technician. |

Next Maintenance Schedule Section

| Field | Description |

|---|---|

| Next Inspection Due Date | When the next maintenance is planned. |

| Maintenance Frequency | Choose one: Weekly / Monthly / Quarterly / Annually |

| Responsible Personnel | Who is assigned to perform the next maintenance? (Name/Title) |

| Technician Signature | Signature of the person completing this checklist. |

How to Create an Effective Preventive Maintenance Checklist

Creating a good preventive maintenance checklist doesn’t have to be complicated. Follow these simple steps to build one that works:

-

Identify all equipment and assets.

Make a list of everything that needs regular maintenance. -

Determine maintenance tasks.

Figure out what checks and services each piece of equipment requires to stay in good shape. -

Set maintenance frequency.

Decide how often each task needs to be done: daily, weekly, monthly or yearly. -

Keep it simple and clear.

Use simple, everyday language and break tasks into easy smaller steps. -

Include space for notes and sign-offs.

Let technicians record findings, issues and confirm they completed the tasks. -

Review and update regularly.

It’s not a one time thing. Make sure the checklist stays accurate and effective by updating it based on feedback and new equipment needs.

Using these steps, you’ll create a checklist that keeps your maintenance organized and efficient.