Maintenance

·

24 min read

FMEA Analysis: Practical Guide for Maintenance Teams

Why Predicting Failures Matters

The Everyday Challenge of Unplanned Downtime

Some of the clients we are working with, told us more or less the same experience they’ve faced in their career. It was a normal working day, their maintenance team were working on preventive tasks, like panned.Then, without warning, one piece of equipment stopped working. The issue soon escalated and the pressure was there. So as higher costs.

If you’ve worked in maintenance or operations, we are quite sure you had the similar experience. Unexpected failures are part of the job. Each of them comes with hidden costs: wasted labor, lost production time and sometimes even safety risks.

We all know this could’ve been avoided. That’s exactly where FMEA (short for Failure Mode and Effects Analysis) can help.

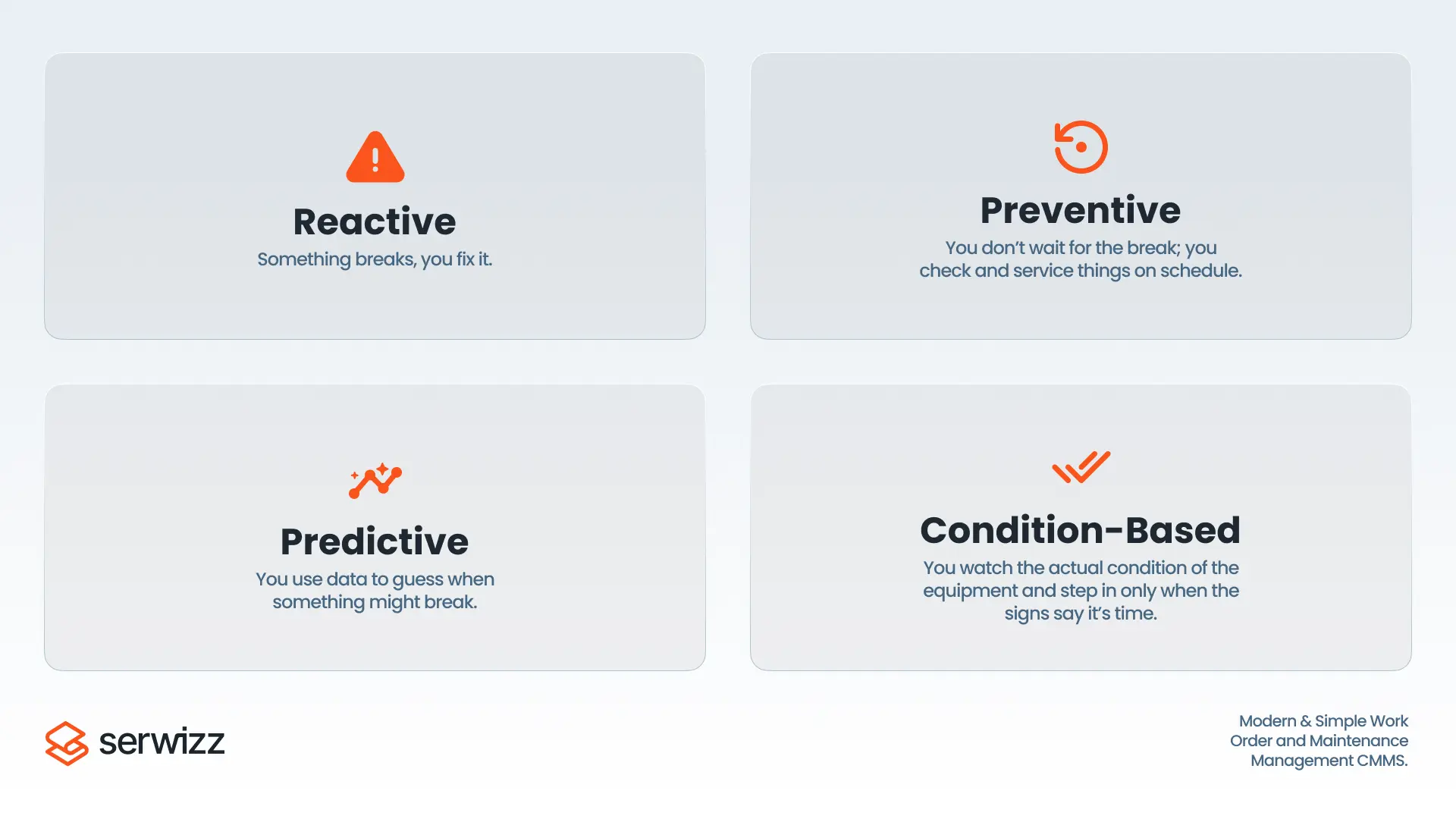

From Reaction to Prevention

You should treat FMEA like a way of thinking, because it’s more than just a technical process. Take some time, write down your equipment and assets, and ask following questions:

- “What could fail here?”

- “Why would it fail?”

- “And what would happen if it did?”

If you use this structured method, you will be able to detect the possible problems before they happen. If you have a large building with an HVAC system, you could perform FMEA and maybe detect that fan motors have more issues when air filters aren’t changed regularly. That insight lets you adjust your maintenance schedule and avoid downtime.

The Human Side & Culture of FMEA

At first you might only see the technical benefits from FMEA. But, if you take a deeper look, there is also a human touch. Ask your team the question: What could go wrong?. By doing that, they will now know you care.

FMEA works best when it becomes part of the culture. It encourages everyone to prevent small issues, to avoid bigger ones. It’s a continuous loop: observe, predict, act, review. This loop builds trust and confidence.

What Is FMEA (Failure Mode and Effects Analysis)

Breaking Down the Concept

FMEA is a structured way to think about how things can stop working and what we should do if that happens. The name might sound complicated, but the idea behind it is quite simple:

- List all way one component might fail

- Assess the effect on your system

In short:

- Failure Mode = What could go wrong?

- Effect = What happens if it does?

Try to understand both and then prioritise the issues that require more attention.

The Purpose Behind FMEA

The main goal of FMEA is to raise awareness. It helps maintenance and reliability teams in better prioritisation and usage of their time.

A simple example: We helped perform FMEA for one of our clients. They had several air-handling units in different facilities. Analysis showed that if one small sensor stopped working, the system would still be able to work for a while. That’s a low-impact issue. Analysis also showed that if a compressor stopped working, the entire HVAC system stops. Now that’s a high impact.

How FMEA Supports Modern Maintenance Teams

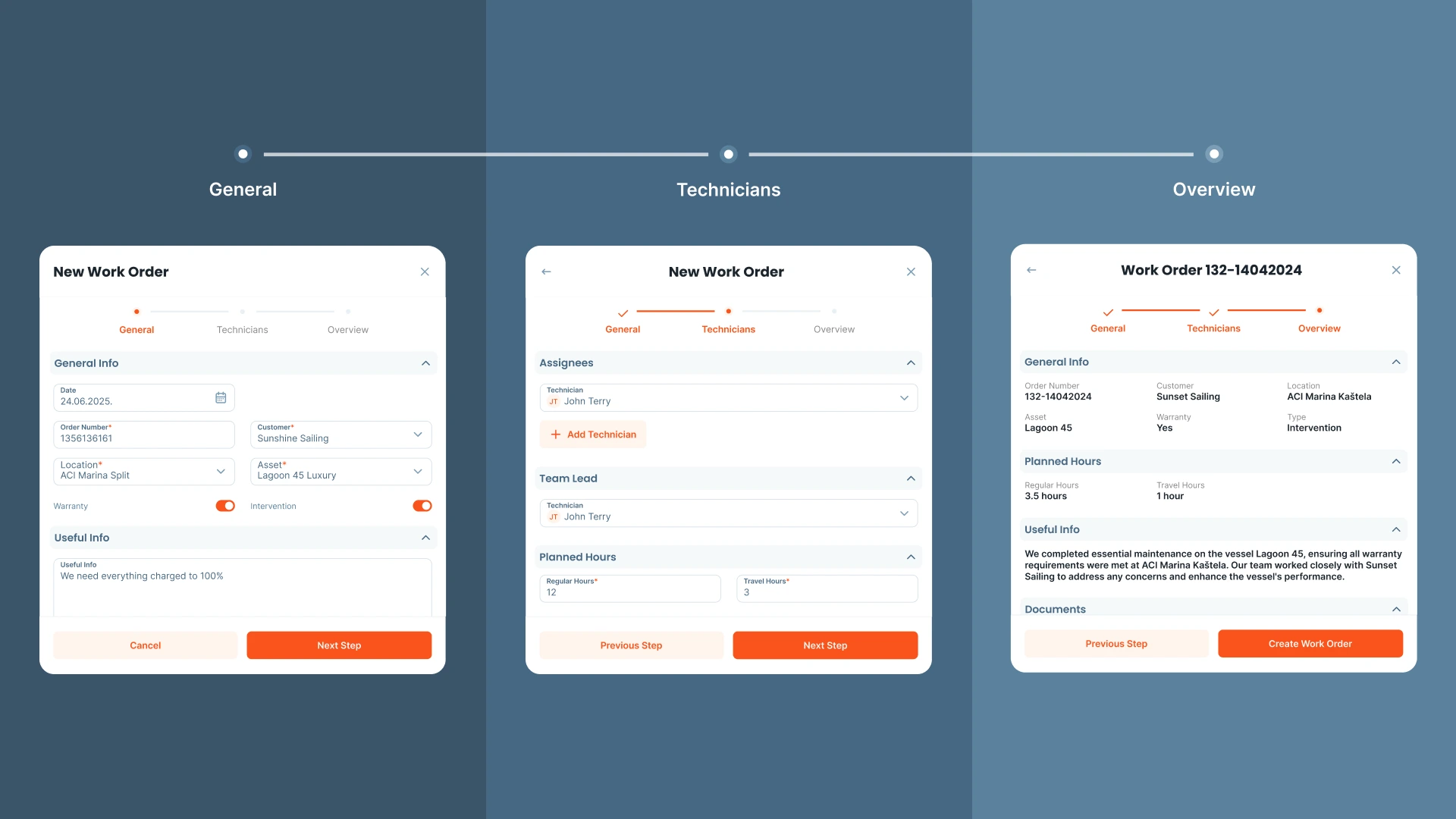

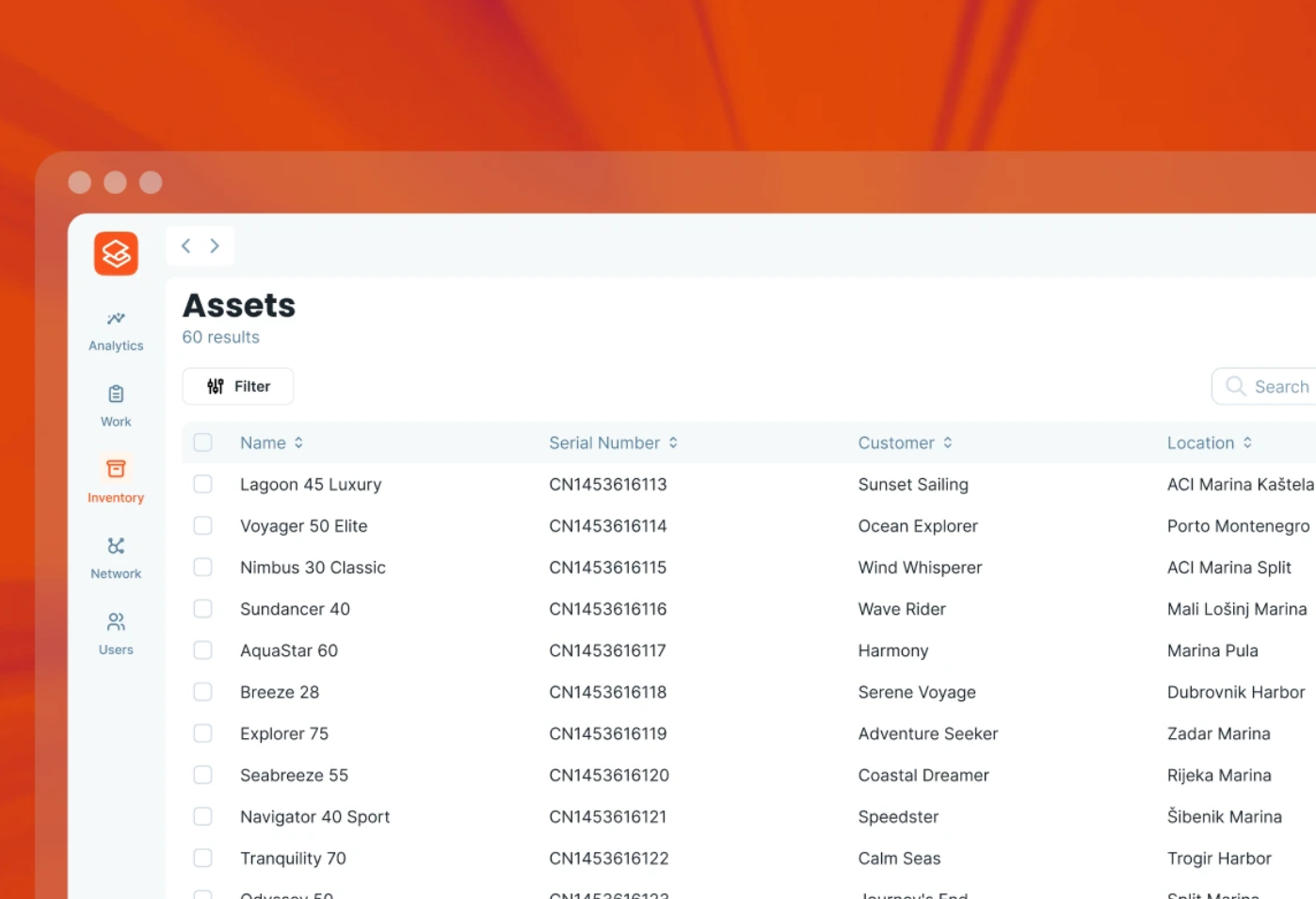

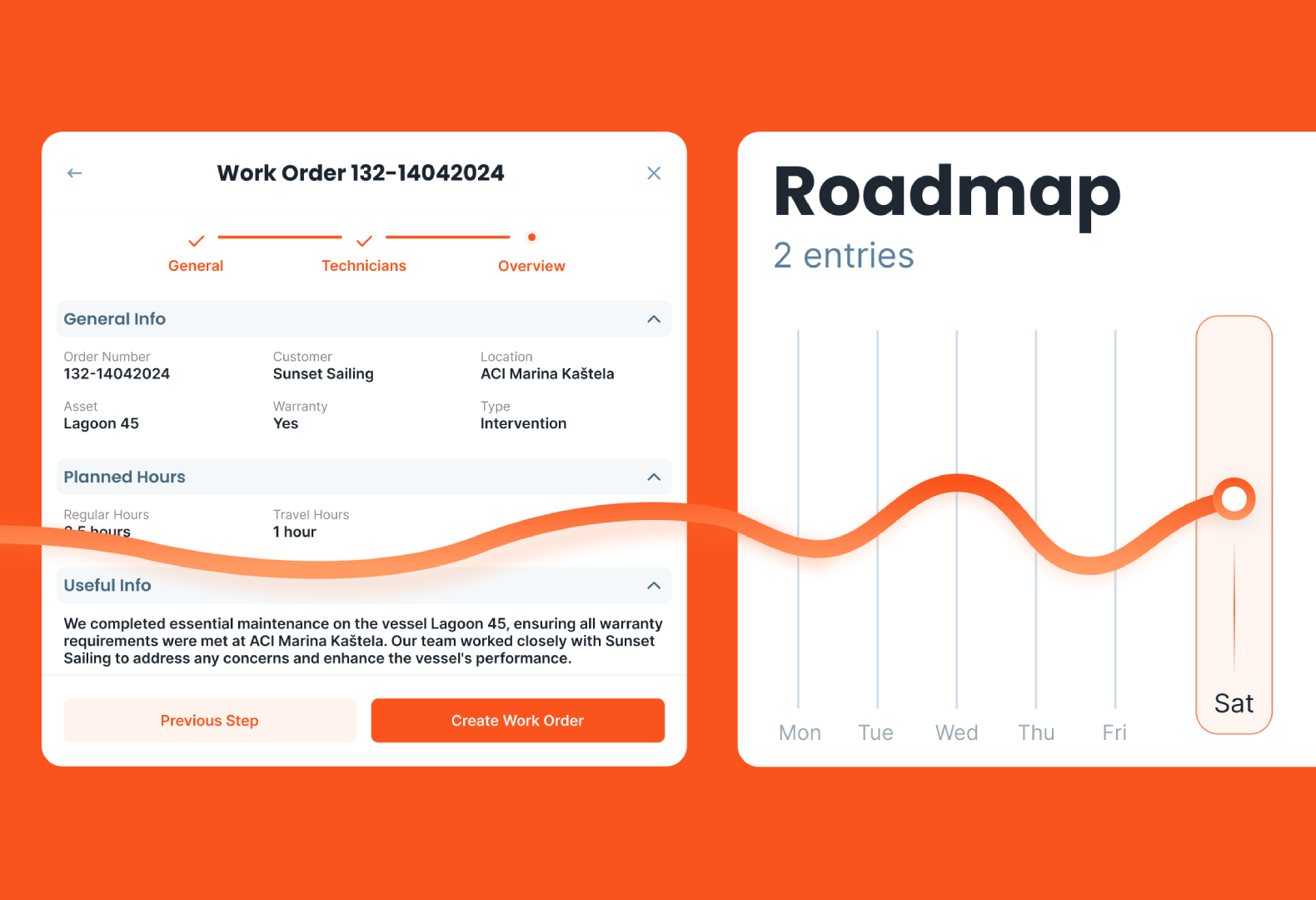

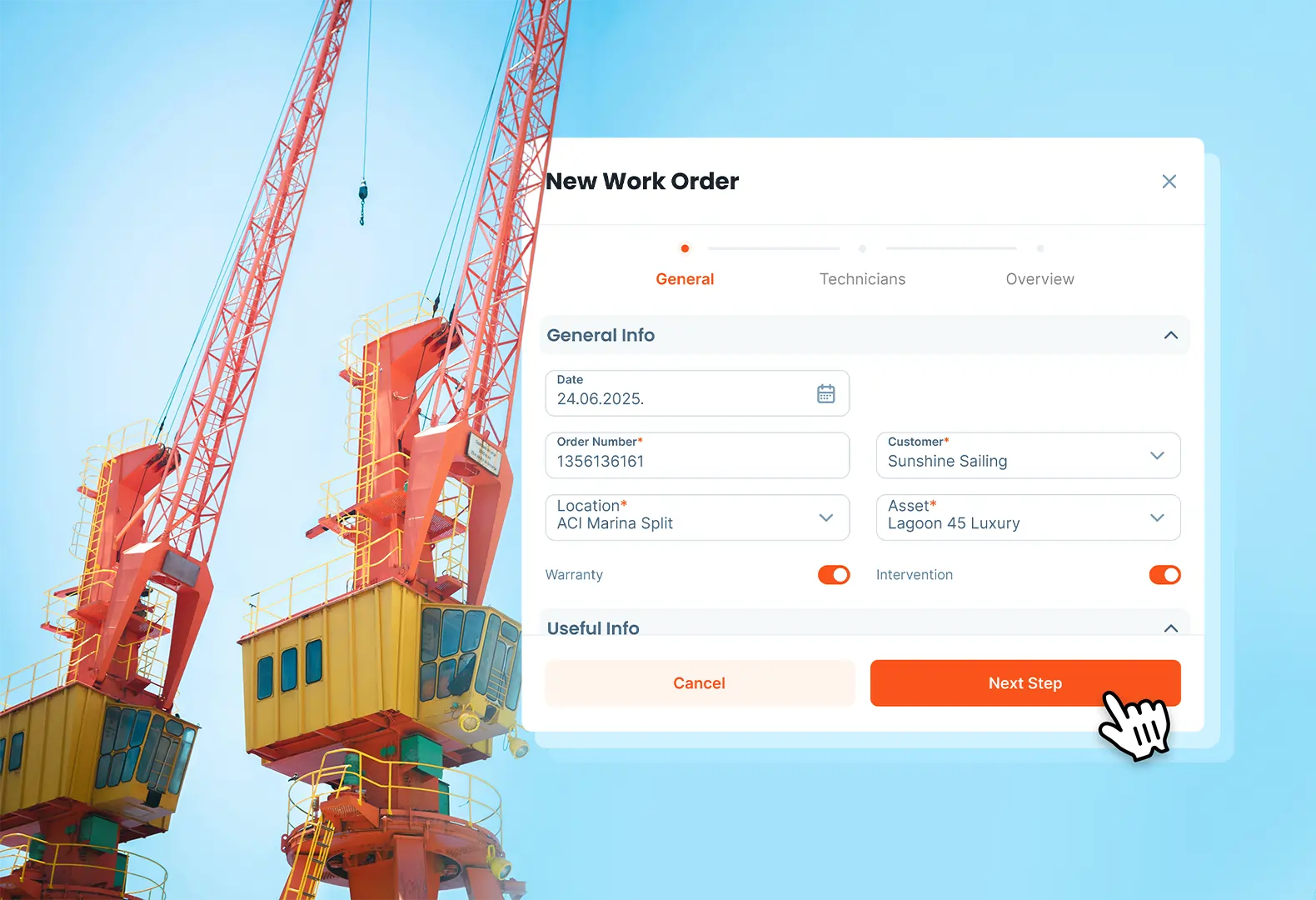

In practice, FMEA combines great with modern maintenance tools like CMMS platforms (for example, Serwizz). It can help in:

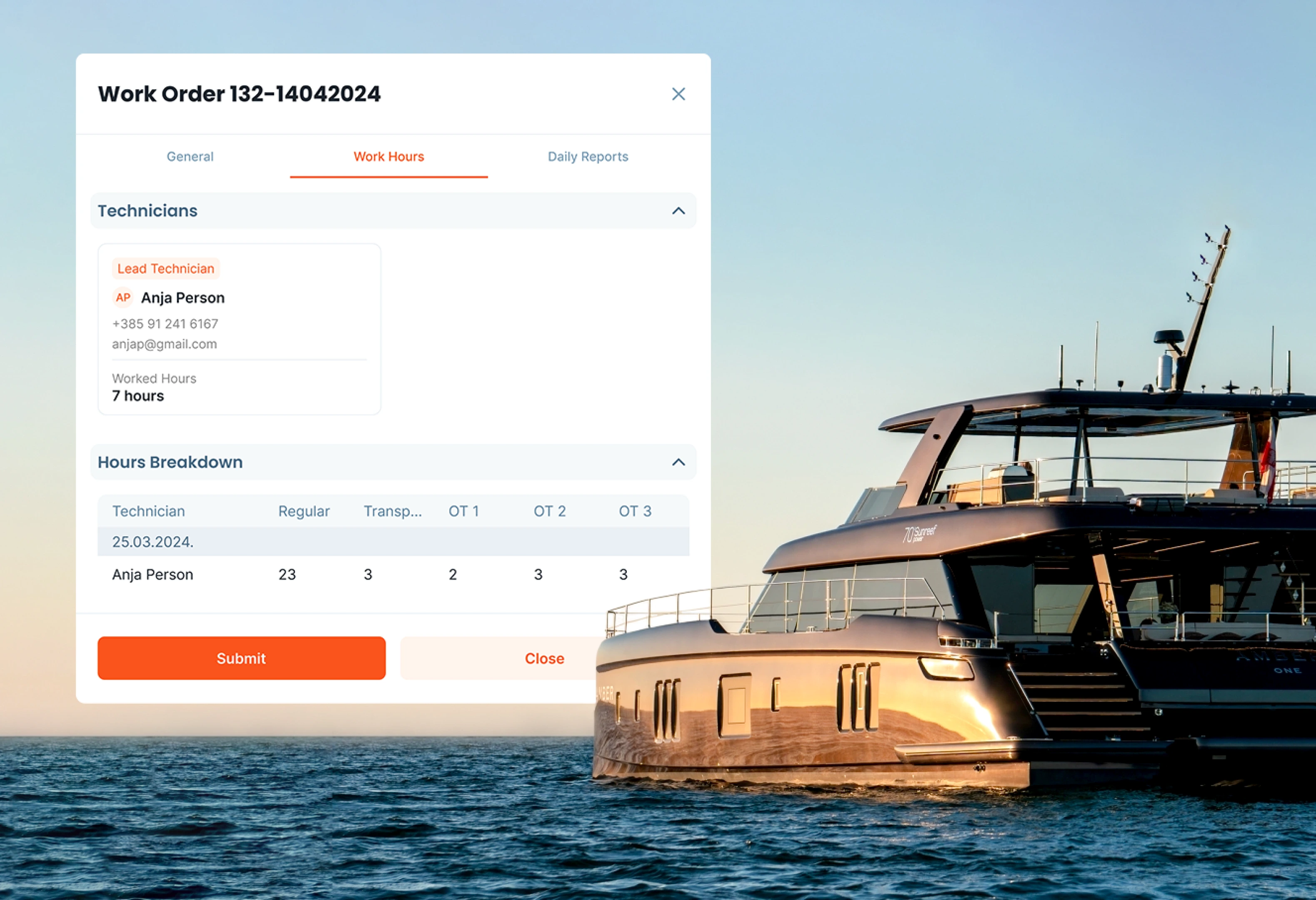

- Data collection: A CMMS records every work order, failure note and inspection detail. That is a valuable input for FMEA.

- Prioritization: You can rank equipment by failure frequency or cost impact and target those first.

- Action tracking: When you decide to act on a potential risk, your CMMS helps schedule and verify those preventive tasks.

Combining CMMS and FMWA, FMEA becomes part of everyday work, not just isolated analysis.

A Simple Way to Remember It

Think of FMEA as three steps:

- Find the weak spots.

- Understand what happens when they fail.

- Plan to prevent or reduce the risk.

Why FMEA Matters in Maintenance

Preventing Failures Before They Happen

In the maintenance world, one goal is common, to avoid surprises. If you equipment or asset stops working when you didn’t expect it, you will have chain reaction:

- Delays in production

- Overtime

- Unhappy client

- Frustrated team

FMEA helps you stop that chain before it starts. Try to identify which assets are critical and focus your time and budget on those. Your preventive maintenance plan will become smarter, as you will not do multiple things at the time, but rather risky work.

Linking FMEA to CMMS and Preventive Maintenance

If you already use a CMMS (like Serwizz), FMEA is a great add on to your preventive maintenance strategy. Your CMMS gives you valuable data: failure frequency, downtime hours, repair costs. FMEA helps you use that data:

- Identify patterns: FMEA shows you which components stop working more often.

- Plan actions: The CMMS helps you schedule preventive tasks.

- Track improvements: You can compare performance data and see real results. Detect if you will have less issues and lower costs.

Tangible Benefits for Teams and Operations

At first, FMEA might feel like extra paperwork. However, research showed that maintenance teams that use FMEA have noticed following improvements:

- Fewer emergency repairs

- Better teamwork

- Improved safety

- Lower costs

The Different Types of FMEA

Understanding That Not All Failures Are the Same

We distinguish 3 types of FMEA, as this process isn’t a one-size-fits-all. Based on type of your analysis, the approach could be different. There are 3 main types of FMEA:

- Design FMEA (DFMEA) - when you analyse the a product

- Process FMEA (PFMEA) - for processes

- System FMEA - when you analyse the whole system.

They have different purposes, but the same goal. To predict what might go wrong and how to prevent it.

Design FMEA (DFMEA)

Design FMEA focuses on the product or component itself. It’s used before you build anything, in the design phase. The goal is to identify design-related risks: ie: weakness in materials or not stable connections between the assets.

Example:

Your company designs new air-handling units. A DFMEA might show that a specific type of unit overheats faster. If your team knows this early enough, they will choose better material or add extra cooling features before production even starts.

Process FMEA (PFMEA)

Process FMEA focuses on how something is made or maintained. PFMEA studies the steps in your process: from manufacturing to to maintenance tasks.

Example:

In your company, you have a maintenance procedure that involves replacing filters on an HVAC system. A PFMEA could detect that technicians sometimes skip one small inspection step because it’s hard to reach. That small skipped step could cause a fan motor to stop working. If you identify this process risk, you can improve the work instruction and make the task easier and safer.

System FMEA

System FMEA is used to analyze how different components or subsystems interact within a larger system. The focus is on interconnections: how one failure can trigger another.

Example:

In your company you have the HVAC system that consists of fans, compressors, thermostats and sensors. They all work together. If one temperature sensor sends the wrong data, it might cause the compressor to overheat and stop working. A System FMEA helps you see those links and prevent the issues.

How to Choose the Right FMEA Type

If you’re not sure where to start, here’s a simple rule:

- If you’re designing something new → use DFMEA

- If you’re working on processes or procedures → use PFMEA

- If you’re looking at an entire operation or system → use System FMEA

Many companies usually combine all of them. They start with a System FMEA to identify overall risks. Then they proceed with PFMEA or DFMEA for specific areas.

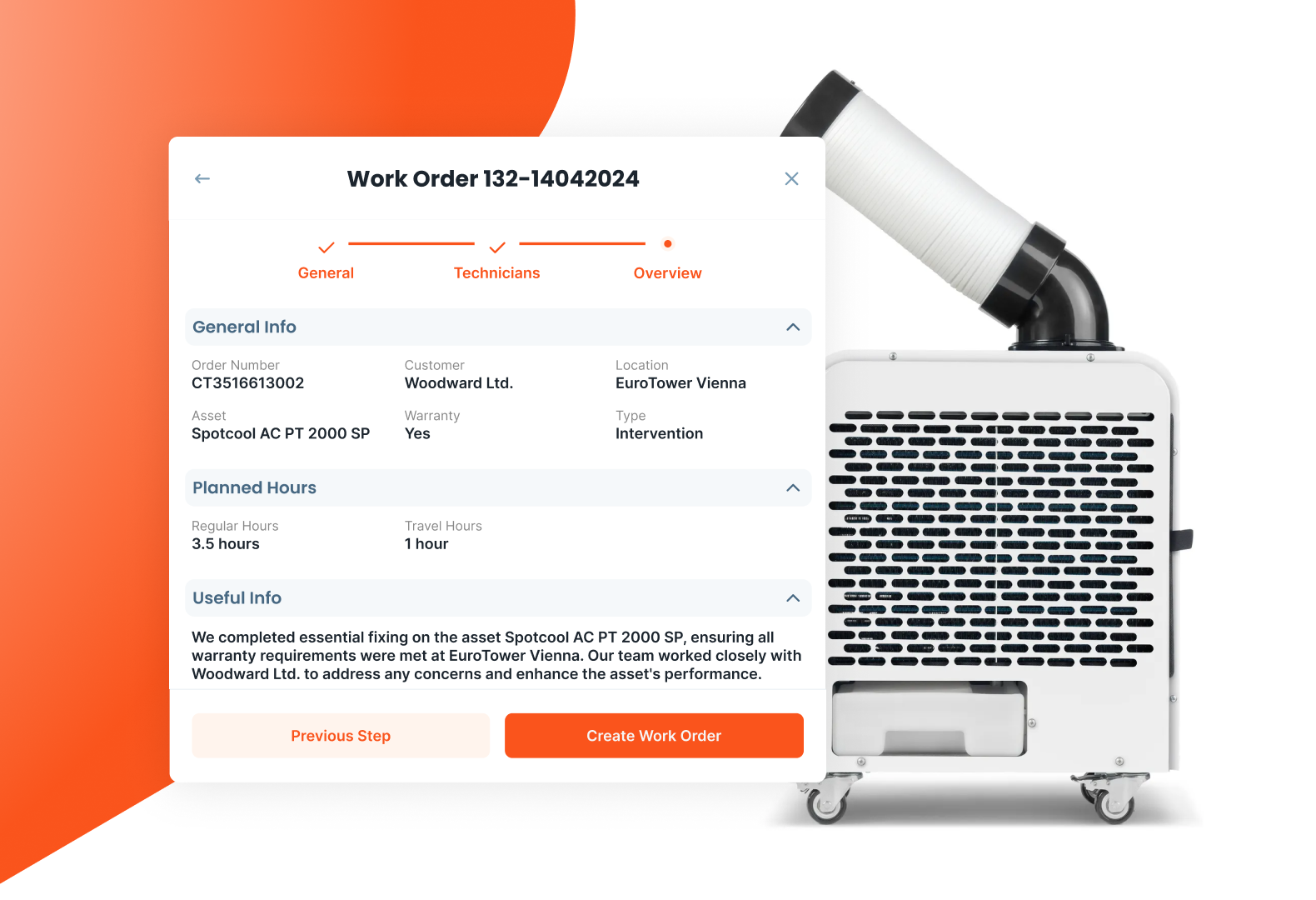

The FMEA Process Step-by-Step

Why Following a Clear Process Matters

Once you understand what FMEA is and its benefits, the next question is always the same: “How do we start?”

FMEA follows a logical and simple process. You can start by gathering your team and by using a plain spreadsheet (in case you don’t use CMMS).

Step 1: Define the Scope and Build a Team

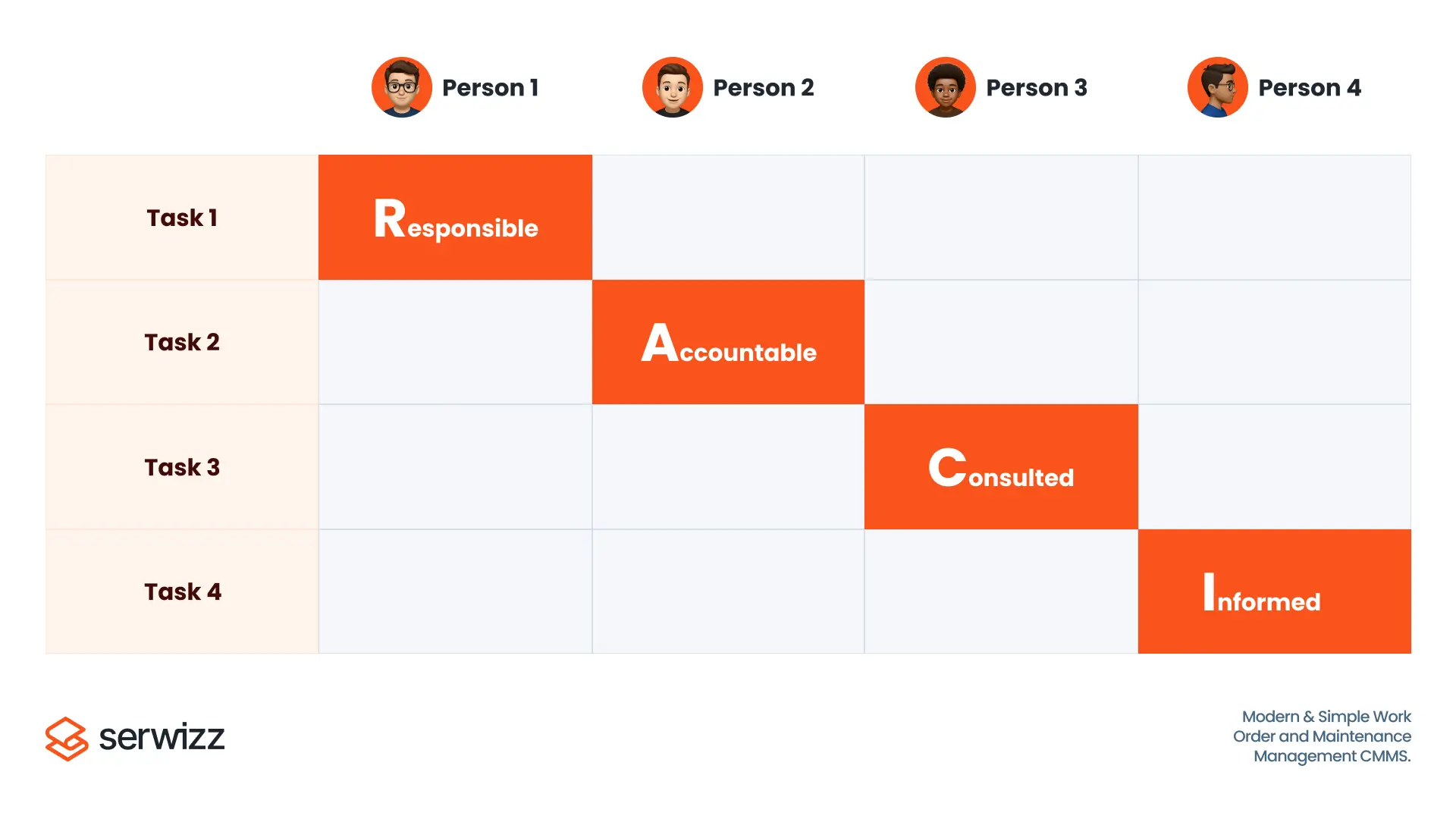

Define what you want to analyze. Whole system, a process or one piece of asset? Make sure that the scope is clear. Next, gather a small cross-functional team ie: maintenance, production, engineering and safety. Each team member sees the system differently. Their different perspectives could help identify hidden risks.

Step 2: Identify Failure Modes

Ask your team to brainstorm their ideas. The goal is to identify all the possible problems with your equipment or process.

Tip: Look at your maintenance logs in your CMMS. If you see the same issue showing up in work orders, that’s a start to add it to your FMEA list.

Example:

For an HVAC system possible issues include:

- Fan motor stops working

- Air filter gets dirty

- Thermostat sends wrong data

- Compressor overheats

Each of these becomes one “failure mode” to evaluate.

Step 3: Evaluate the Risks (Severity, Occurrence, Detection)

Assess risks and calculate potential failure ratings:

- Severity (S): How big is the impact if this issue occurred?

- Occurrence (O): How likely is it to happen?

- Detection (D): How easy is to catch the issue before it becomes a problem?

Each is typically rated from 1 to 10. Once you’ve assigned the ratings, calculate:

RPN = Severity × Occurrence × Detection

A higher RPN means the issue needs more attention and action.

Step 4: Plan and Take Action

The goal is to lower the RPN. When you know which risks are most critical, you want to reduce them. You can reduce risk in several ways:

- Redesign the component

- Adjust the maintenance schedule

- Improve the inspection checklist

- Add better sensors or monitoring

Step 5: Review and Update Regularly

FMEA should be done regularly. Machines change and so do processes. Review your FMEA regularly, once or twice a year. After the review, you can adjust your findings and plans.

Understanding the FMEA Scoring System

Making Sense of the Numbers

In the previous chapter we’ve mentioned: Severity, Occurrence, Detection and RPN. Let’s explain these numbers in more detail.

Severity, Occurrence and Detection Explained

Severity (S)

Ask yourself - if the issues happen, how big are the consequences. For example, if a small LED light on your control panel stops working, that’s not a big deal. If a compressor stops working that’s serious.

Occurrence (O)

How often does this issue happen, or how likely is it to happen again?

Look at your CMMS data. You might detect that dirty air filters are a common issue, while a complete motor failure happens once a year.

Detection (D)

How easy is it to notice the problem before it happens?

If your team can easily see or measure the issue, that’s good. But if the issue is difficult to detect, the detection rating should be high.

Calculating the Risk Priority Number (RPN)

Once you’ve rated Severity, Occurrence, and Detection on a scale from 1 to 10, you multiply them together:

RPN = Severity × Occurrence × Detection

The higher the RPN, the bigger the risk.

Let’s take a small example:

| Failure Mode | Severity (S) | Occurrence (O) | Detection (D) | RPN |

|---|---|---|---|---|

| Fan motor overheating | 8 | 6 | 5 | 240 |

| Dirty air filter | 4 | 7 | 3 | 84 |

Here, the fan motor overheating has a much higher RPN, so it’s your top priority.

You can now plan preventive tasks based on this information and introduce more frequent inspections.

Using Data to Drive Better Decisions

When you have the numbers, focus on trends, not single values.

If RPN is high, act. If RPN becomes lower after an improvement, you’re moving in the right direction.

For example:

- You might notice that your compressor failures dropped by 40% after adjusting maintenance intervals.

- Or that certain components, once considered “low risk,” start showing more frequent issues in your reports.

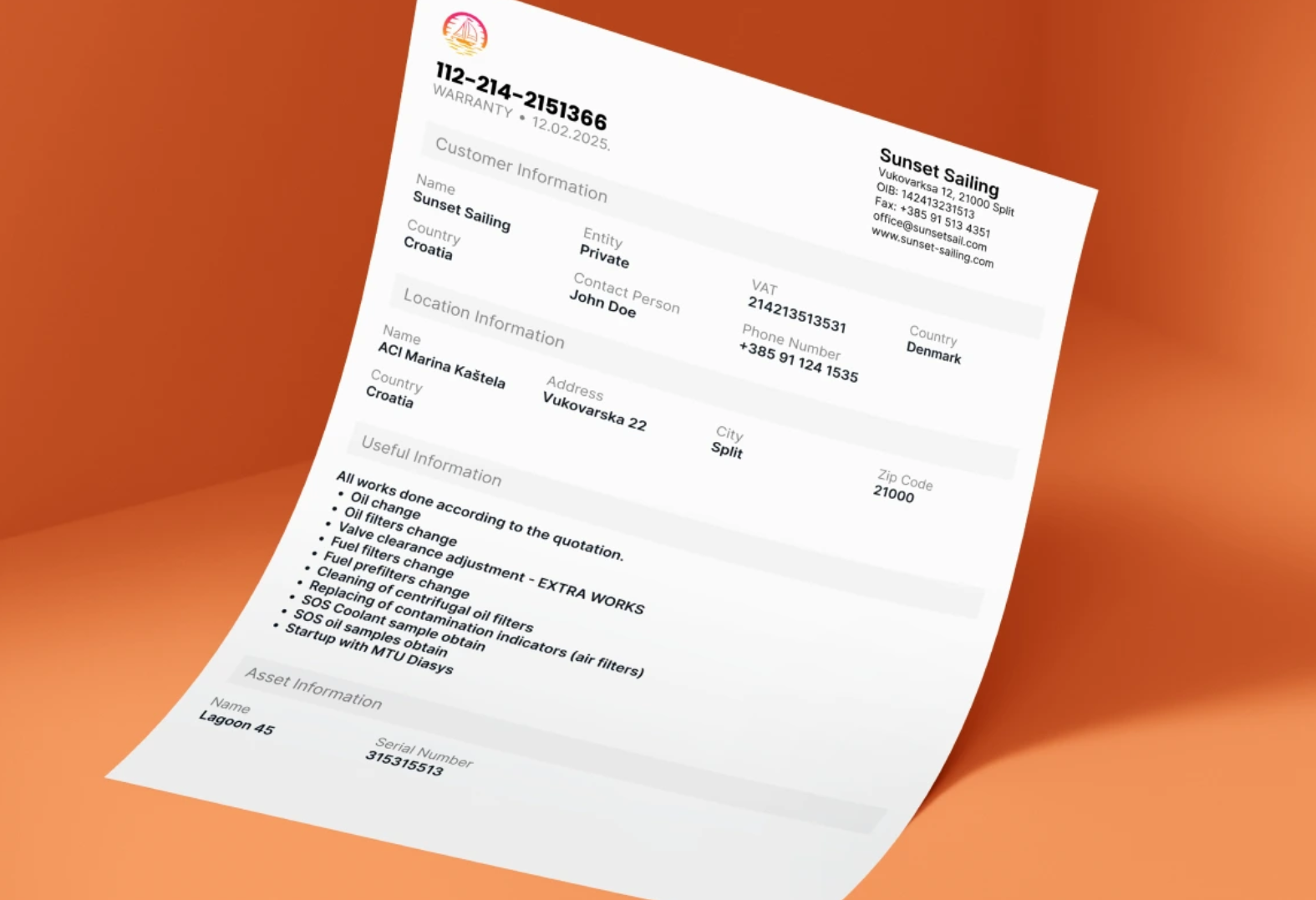

Real-World FMEA Examples

Turning Theory Into Practice

You know the FMEA theory, but let’s see how it applies in the real world. We have prepared a few simple examples that your team might face already. The goal here is to show how small changes can lead to big improvements.

Example 1: HVAC System: Avoiding Compressor Failures

HVAC systems are something our clients in maintenance are familiar with. One of our clients owned a building with several large air-handling units. His team noticed that every few months, a compressor shuts down unexpectedly. Repairs were quite expensive.

They performed FMEA and these were the findings:

- The failure mode was the compressor overheating.

- The cause was restricted airflow from dirty filters.

- The effect was full system shutdown and loss of cooling.

The RPN was high because it’s both severe and somewhat common.

Action taken:

The company adjusted their maintenance plan and replaced filters more frequently.

Result:

Compressor failures dropped by over 60% in the next six months. This small adjustment, which was the result of FMEA saved money in repair costs.

Example 2: Manufacturing Line: Reducing Downtime

A client in manufacturing told us about an issue with their packaging line. Machines were stopping mid-shift and they didn’t know why.

They've performed FMEA and identified one failure mode: the conveyor motor frequently overheated.

Analysis detected two main causes:

- Dust due to poor cleaning.

- Overloaded motor during peak production hours.

The RPN confirmed it was a high-priority issue.

Actions taken:

- They have improved the cleaning schedule.

- They adjusted production speed settings during long shifts.

Result:

Downtime related to motor failures almost disappeared. Technicians could also complete cleaning tasks in half the time.

Example 3: Facilities Maintenance: Small Sensor, Big Impact

One of our partners detected that in one facility they have temperature fluctuations in a critical storage area. After performing an FMEA, they discovered that a temperature sensor occasionally failed due to humidity exposure.

The issue seemed minor, but the effect was serious: it could cause damaged materials and compliance problems.

Actions taken:

- Replaced the sensor with a sealed model.

- Added a visual indicator for early detection.

Result:

After taking the action temperature sensors are working normally and storage humidity was normal. This is a good reminder that FMEA can be performed on small assets in the system, not just the large ones.

The Benefits of FMEA in Maintenance

Beyond Theory: Real Value for Maintenance Teams

In the maintenance world one goal is common: to improve predictability. With FMEA you can change the way your team thinks and works. The idea is to move from reactive to preventive mode. Here are some of other FMEA benefits:

1. Less Unplanned Downtime

When your system is not working, the cost can be huge. You have to pay the repair hours, overtime and additional parts. It affects both your team and the clients.

If you manage to identify high-risk assets and understand how they fail, you will be able to adjust your preventive maintenance plans. It’s simple math: One hour of prevention can save days of emergency work.

2. Smarter Use of Maintenance Time and Budget

FMEA helps you in asset management. With FMEA you can prioritise assets that need more attention. Those would be the one with the highest risk and impact. Instead of doing “everything for everyone,” your team will focus on the most critical items.

3. Stronger Team Collaboration

When a team performs FMEA together their communication improves. Technicians, engineers and managers start to see the bigger picture. Everyone shares their ideas and experience. This creates a sense of shared ownership.

4. Improved Safety

FMEA helps you create a safety net for both people and machines. With FEMA you can identify dangerous failures and detect the unsafe conditions.

5. Continuous Improvement

You should keep in mind that FMEA is not a one time thing. Perform it regularly. Each review of FMEA gives you new data and insights. You can track how your actions improved the process and adjust again. Consider FMEA as cycle of improvement:

Observe → Predict → Act → Review → Improve

6. Better Use of CMMS Data

When combined with a CMMS (like Serwizz), FMEA can be even more powerful.

CMMS contains work orders and reports and with which you can use FMEA finding to make better decisions.

You can:

- Detect recurring failure patterns

- Adjust maintenance schedules

- Track how risk levels change over time

Common FMEA Mistakes (and How to Avoid Them)

Learning From Experience

FMEA is a great tool but it works well when used correctly. When we talked with people from the field, we noticed one pattern. Teams start doing FMEA with enthusiasm but then they introduce overcomplicated steps. Here are some of the most common mistakes and simple ways to avoid them.

1. Making It Too Complicated

One of the biggest mistakes is trying to make FMEA perfect.

Teams start discussion and spend time in long meetings and they focus on theory. In the end they don’t implement anything.

How to avoid it:

Start simple.

Pick one asset or one process. Let your team get familirat with FMEA before implementing it in a complicated system. It is better to have an imperfect FMEA for one asset rather than a perfect theory for the whole system.

2. Doing It Once and Forgetting About It

When you introduce FEMA to the team, people will be happy to perform it. Once they perform the FMEa, they forget about it. It’s important to explain to them it is not a one time thing, as assets and processes change.

How to avoid it:

Schedule reviews at least once or twice per year. Every time you install new equipment or change a process, perform the FMEA again.

3. Skipping the Team Approach

FMEA should be done within the team, not just by one person. One person might not have the full picture and might miss something.

How to avoid it:

Include people from different areas: maintenance technicians, engineers and managers. Each person sees problems from a different angle. That mix of experience will improve your FMEA.

4. Focusing Only on High-Tech Failures

Some teams focus only on the big issue and they ignore small risks.

How to avoid it:

When you do FMEA, include simple human or process-related causes too. They often have low cost but high impact when ignored.

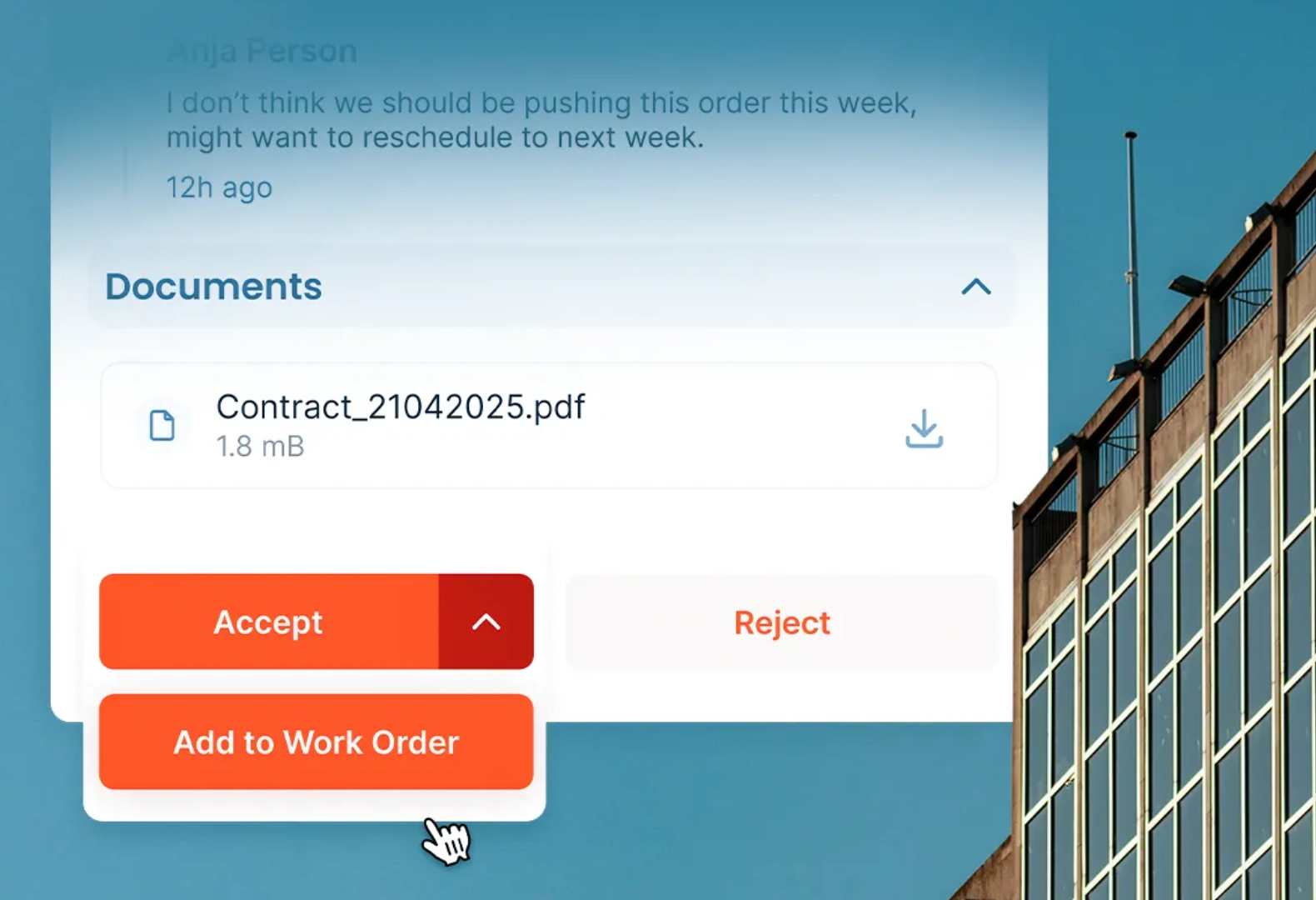

5. Ignoring the “Action” Part

Some teams see FMEA as paperwork: Fill the table, calculate RPN and stop. They forget the most important part - the action,

How to avoid it:

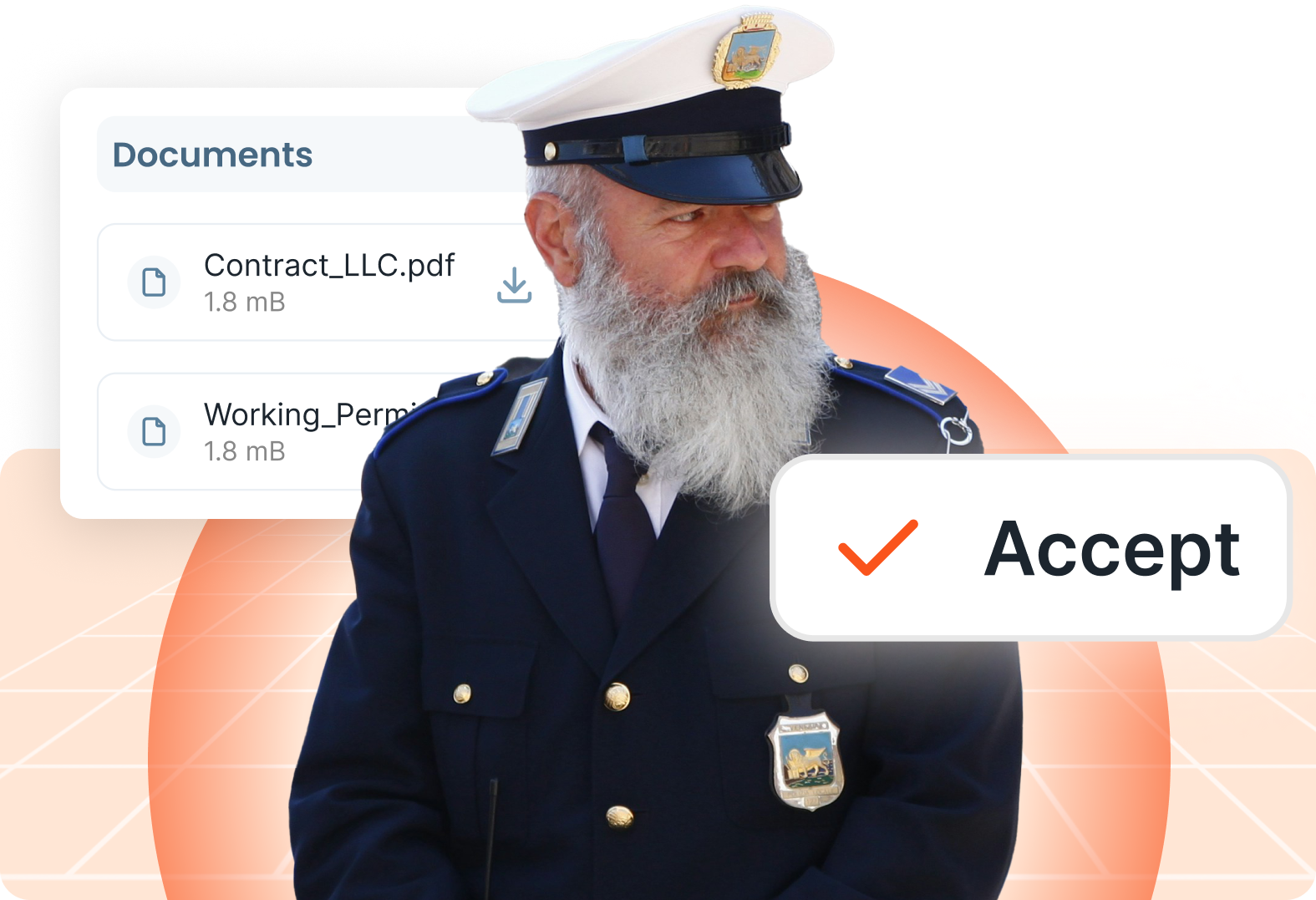

After finishing the analysis, assign responsibilities and deadlines. Use CMMS (like Serwizz) to track these action as tasks.

6. Not Linking FMEA With Real Data

Sometimes, FMEA scores are based on assumptions, not actual data.

How to avoid it:

Use your CMMS history to guide your scoring. Check how often failures happen and how long it takes for repairs. Real data will help you in prioritisation.

Conclusion & Final Thoughts

FMEA as a Practical Habit, Not a Paper Exercise

If there’s one idea to keep from this blog, it’s this: FMEA works when it becomes part of how your team thinks. If you perform it regularly, FEMA should help you switch the mindset from reactive to proactive.

You’ve seen how simple actions: changing filter intervals, adding sensor, improving cleaning can stop repeated failures. FMEA doesn’t have to be costly or complicated to be effective.

What Success Looks Like

When FMEA is doing its job, you’ll notice practical changes:

- Fewer unexpected breakdowns and less overtime.

- Clearer priorities

- Better conversations between technicians, engineers and managers.

- Measurable improvements in repair costs.

Small Steps You Can Take Tomorrow

You don’t need a big system to start FMEA. Try one of these right away:

- Pick a single asset the team knows well and run a quick FMEA session.

- Use CMMS history to check how often that asset fails.

- Choose one action that’s cheap and fast (e.g., replace a suspect sensor).

- Track the result in your CMMS and share the win with the team.

A Final, Human Note

Maintenance is as much about people as it is about machines. FMEA helps you bring those two parts together. Keep the process simple and involve the right people. With addition of CMMS FMEA will become one of your most useful tools.