Maintenance

·

19 min read

What Are the 4 Types of Maintenance?

When someone mentions to you the word maintenance, what pops into your head first? For many people, it’s the image of a machine breaking down and someone rushing in with a toolbox. It’s that classic “uh-oh, something’s gone wrong” moment.

But here’s the thing: maintenance isn’t only about reacting to problems. It’s also about preventing them. In short, that is the, let’s say, quiet work that keeps production lines moving, offices safe and costs under control.

For better understanding, think of it the same way you think about your own health. You don’t wait until you’re really sick before caring for yourself (at least, you shouldn’t). You go for check-ups, you eat better, maybe you even try to exercise. Those small, ongoing habits save you from bigger issues later. Maintenance works exactly like that. Just, in this case, we are not talking about your body, we’re rather talking about machines, vehicles, or entire facilities.

Over the next sections, we’ll break down the four main types of maintenance: reactive, preventive, predictive and condition-based. Each of these 4 types has its pros and cons. Stick with me, and you’ll see how the right approach to maintenance isn’t just about saving money. It’s about making your day-to-day run with a lot less drama.

The 4 Types of Maintenance Definition

You know how it goes—maintenance doesn’t really come in a one-size-fits-all package. Different teams handle it in different ways, usually depending on the type of equipment they’ve got and how much time or budget they can spare. Some folks push things to the limit and only deal with it when something finally gives out. Others plan regular check-ups. And then there are those who lean on data and sensors to tell them when to act.

Usually, we group it into four buckets:

- Reactive – something breaks, you fix it.

- Preventive – you don’t wait for the break; you check and service things on schedule.

- Predictive – you use data to guess when something might break.

- Condition-Based – you watch the actual condition of the equipment and step in only when the signs say it’s time.

None of these is “the best” in every situation. Sometimes quick fixes are fine. Other times, planning ahead saves a lot of stress. What really matters is knowing what these types are and then figuring out which one (or which mix) fits your world.

Let’s look at Reactive Maintenance first. The one where the “fix it when it’s broken” approach is taken.

Reactive Maintenance: The "Run-to-Failure" Approach

Reactive maintenance is exactly what it sounds like. You wait until something breaks and then you fix it. Simple as that.

Most of us have lived this one in everyday life. The car won’t start on a Monday morning, so you call the mechanic. The office printer jams in the middle of a big project and suddenly you’re shaking it like that’ll magically fix the problem. That’s reactive maintenance.

Advantages of Reactive Maintenance

It’s easy and it makes sense. No planning, no scheduling. You just deal with issues as they come up. For small, low-cost equipment or maybe when things aren’t that critical, this approach can actually be fine. Why waste time doing check-ups on a $20 fan when you can just buy another one?

The downside of Reactive Maintenance

If and when something important goes wrong, it usually happens at the worst possible moment. Now, that is the problem. Suddenly you’ve got downtime, a pile of stress and sometimes even a safety headache. And fixing it in a rush? Yeah… that usually costs more than if you had just kept an eye on it from the start.

Where Reactive Maintenance works best

Reactive maintenance has its place, though. It’s fine for non-essential gear or maybe for things that are cheap and easy to replace. But if you’re running machines that are expensive, complex or vital to your operation, relying only on reactive maintenance can feel like gambling. You never know when it’ll let you down.

Reactive vs Corrective Maintenance

Sometimes you’ll also hear the term Corrective Maintenance. This is basically fixing something after it fails — which is why many people use it interchangeably with Reactive Maintenance. The difference is that corrective can also include smaller, planned fixes that aren’t urgent breakdowns.

Preventive Maintenance: Staying Ahead of Problems

So, next up is preventive maintenance. This is the type where you take care after things before they break. We are sure you go to the doctor for an annual check-up, even when you feel just fine. Why? Because you might need some additional checkup or some medicine. In that way you could avoid complicated surgery in the future, or longer sick leave. You can think of preventive maintenance as an annual checkup for your equipment.

With preventive maintenance, you set up a plan. That might mean giving the machines a quick look every week, swapping out a filter now and then or changing a part before it starts acting up. The whole point is to spot problems early, so things keep running and you don’t suddenly get stuck with a big breakdown.

Advantages of Preventive Maintenance

The big win? Peace of mind. You know your gear is being looked after and surprises are much less likely. Less stress, fewer emergency calls and often lower overall costs than reactive maintenance.

The downside of Preventive Maintenance

Of course, it’s not perfect. Preventive maintenance takes time, planning and sometimes costs money for things you might not even need to replace yet. Some companies find themselves overdoing it. Changing parts that are still fine, just to stick to a schedule. That’s where balance comes in.

Where Preventive Maintenance works best

Preventive maintenance works best for equipment that’s expensive, essential or just plain tricky to fix if it breaks. Things you can’t afford to have go down unexpectedly. By keeping a routine, you avoid the panic and extra costs that come with reactive fixes.

Predictive Maintenance: Using Data to Stay Smart

Next up is predictive maintenance. This one is a bit smarter than preventive because it doesn’t follow a fixed schedule. Instead of checking things just because it’s “time,” you pay attention to what the machines are telling you.

The secret is sensors. They watch things like heat, vibration or even the noise a motor makes. All that info gets collected and checked. If the numbers start looking strange, that’s your sign that something might be broken soon. Basically, your equipment is giving you a heads-up.

Advantages of Predictive Maintenance

The nice thing is you don’t swap parts that are still fine. You only take the action when the data says it’s needed. Most of the time, it just means fewer surprises, less time stuck waiting for fixes, and, best of all, saving some money along the way. Plus, it makes planning repairs easier. You get a warning before something actually goes wrong.

The downside of Predictive Maintenance

It’s not perfect for everyone. You need sensors, software and someone who can read the numbers. That can get pricey and a bit complicated for smaller teams or businesses with simpler machines.

Where Predictive Maintenance works best

Predictive maintenance is great for places where a breakdown costs a lot. Examples include factories, airlines, energy companies or transport. Catching a problem before it causes a shutdown can save a ton of time, stress and money.

Condition-Based Maintenance: The Middle Ground

The last type is condition-based maintenance. This one is kind of predictive, but even simpler. Instead of checking on a schedule or analyzing a bunch of data all the time, you keep an eye on the equipment and act only when it shows signs of wear or trouble.

Picture a machine with a simple gauge or some kind of indicator. When it comes to a certain point, that’s your signal to step in. Maybe a belt is getting loose, a pump is making more noise than usual or the oil looks dirty. You only do maintenance when the signs show it’s needed.

Advantages of Condition-Based Maintenance

The big advantage? You’re not wasting time or parts. You fix things when it actually needs fixing, which can save money and reduce unnecessary work. It’s also less stressful because you know the machine is fine until it gives you a clear sign.

The downside of Condition-Based Maintenance

Of course, it’s not perfect. You need someone paying attention and checking the equipment regularly. If you miss a warning or don’t interpret it right, problems can sneak up on you. It also works best for machines that have clear indicators you can rely on.

Where Condition-Based Maintenance works best

Condition-based maintenance fits well for equipment that’s not too complex but still important. Think pumps, motors, or vehicles where a small problem can get bigger if ignored. You get the benefits of planned care without the cost or complexity of full predictive systems.

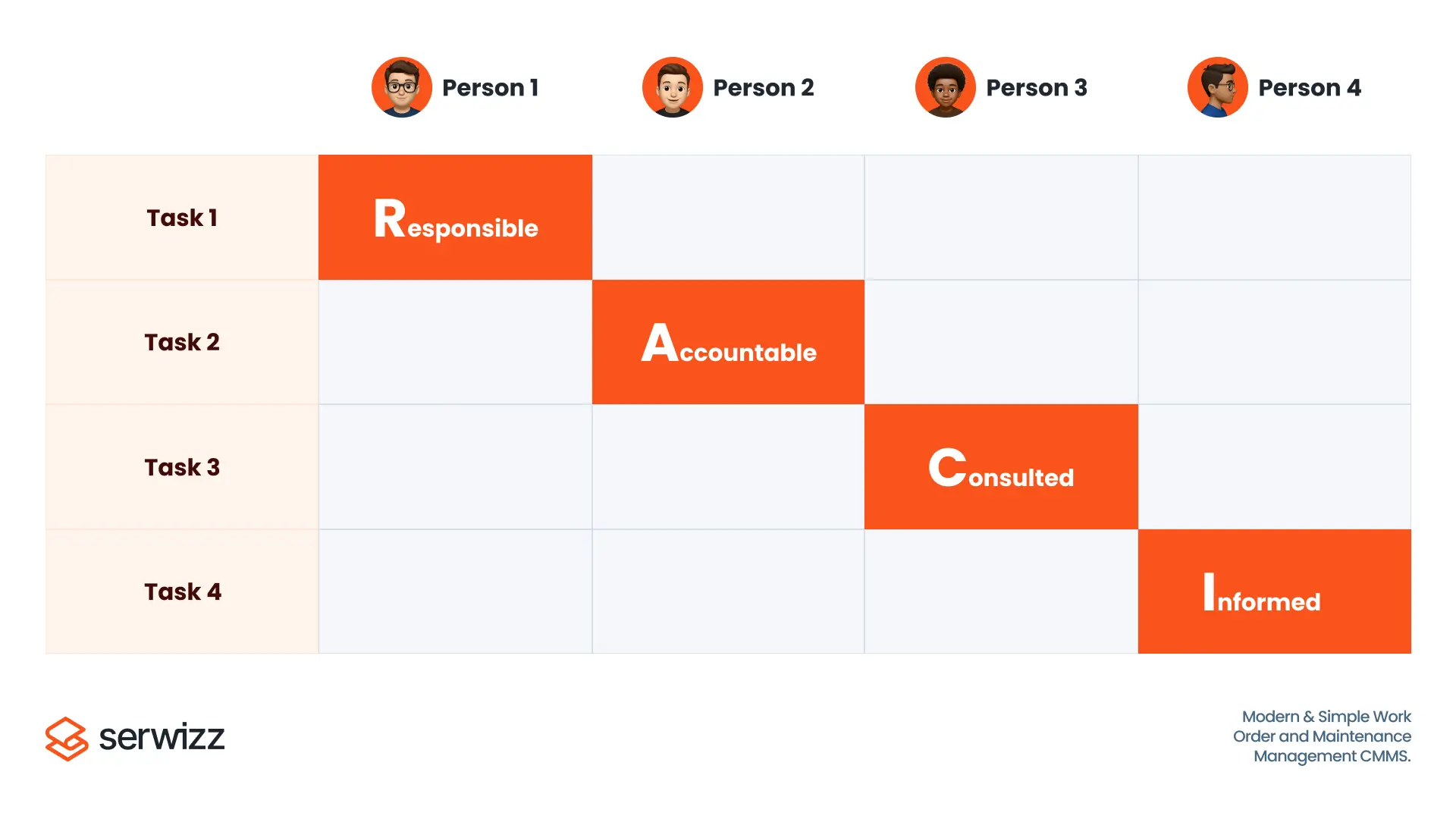

Choosing the Right Maintenance Strategy for Your Business

Choosing the right maintenance method isn’t about finding the “one best method.” It’s more about figuring out what fits your team, your equipment and your budget.

Some equipment might be fine with reactive maintenance, because they are cheap, and easy-to-replace machines don’t need fancy monitoring. Other machines, especially the expensive or critical ones, do better with preventive, predictive, or condition-based approaches.

A lot of businesses end up using a mix. Maybe reactive for small stuff, preventive for routine checks, and predictive for the really important machines. Try tp focus on balance, rather than perfection.

To make it easier to see the differences, here’s a table overview:

| Maintenance Type | When to Use | Pros | Cons |

|---|---|---|---|

| Reactive | Small, cheap, easy-to-replace equipment | Simple, no planning needed | Surprises, downtime, higher emergency costs |

| Corrective (sub-type of Reactive) | Planned or unplanned fixes after a fault is found | Planned repairs, extends equipment life | Can still cause downtime if not addressed quickly |

| Preventive | Important machines, regular wear parts | Fewer surprises, smoother operations | Can replace parts unnecessarily, needs planning |

| Predictive | Critical, expensive, complex machines | Fixes only when needed, less downtime | Needs sensors, software, and trained staff |

| Condition-Based | Machines with clear indicators | Cost-effective, fixes only when needed | Requires monitoring, can miss hidden issues |

You can think of it like picking the right tool for the job. Some things are fine with just a hammer (that’s reactive). Others need a whole toolkit (like predictive). The table just helps you get a quick idea of what fits where.

We will also share examples of each type, for better understanding.

Example Table (expanded with examples)

| Type of Maintenance | What it means | Simple example |

|---|---|---|

| Reactive | Fix it after it breaks | A pump stops working and you repair it on the spot |

| Preventive | Regular, scheduled checks | Change air filters every month |

| Predictive | Use data to predict failures | Vibration sensor shows a motor is wearing out, so you replace it before it fails |

| Condition-Based | Act when warning signs appear | Replace a belt when you see it’s visibly frayed |

| Corrective (extra note) | Planned or unplanned fixes after a fault is found | During inspection, you see a cracked valve and schedule it for replacement next week |

The important part is noticing how your machines behave and what would really cause trouble if it failed. Which ones could handle a surprise breakdown? Which ones would cost a lot if they went down? Just thinking about that helps you figure out a plan that actually works for your team.

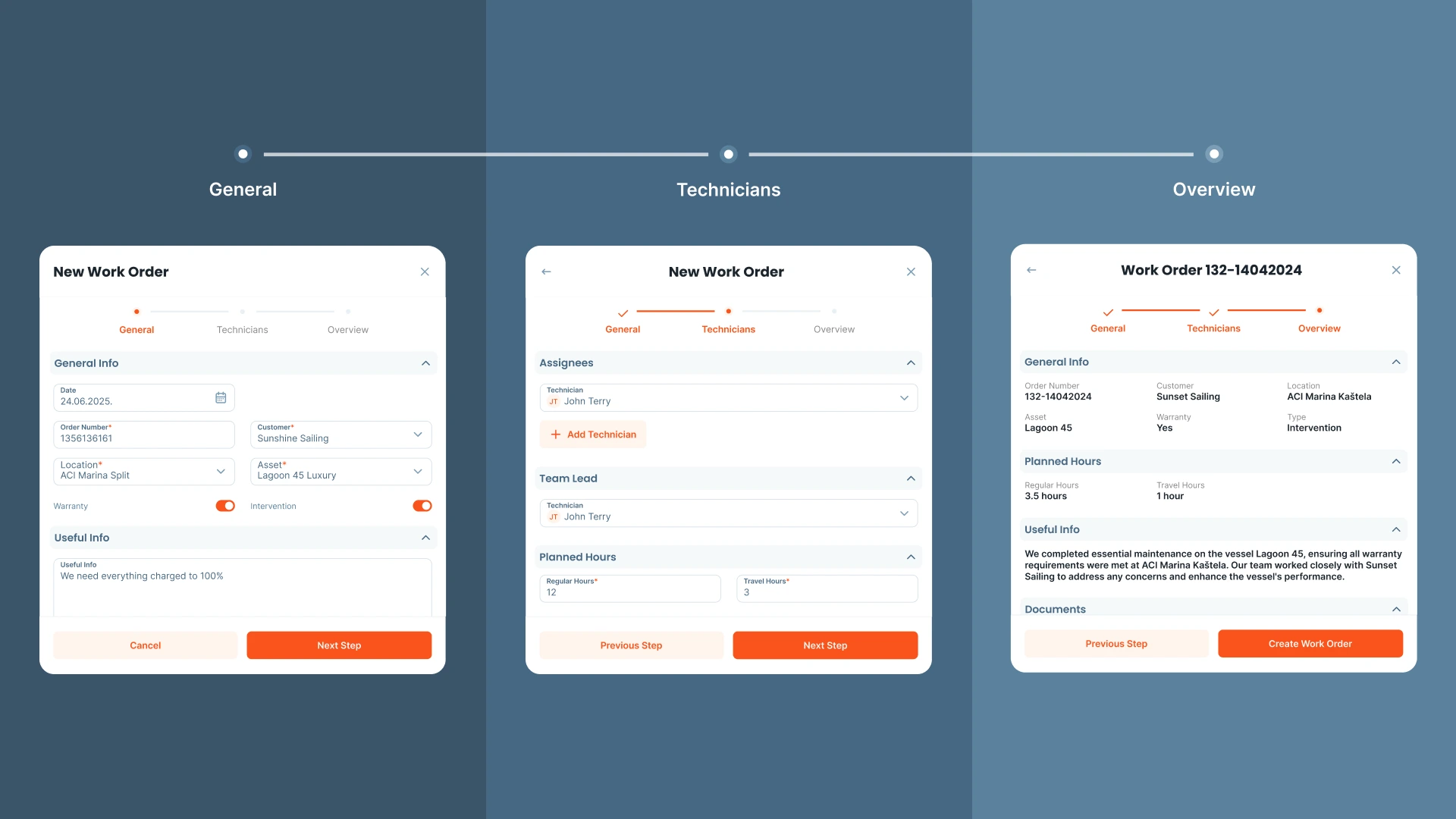

How CMMS Supports Every Type of Maintenance

Keeping up with all the different maintenance types? It can get confusing. You’ve got reactive stuff, preventive checks, predictive data, and condition-based signals. Each one acts differently.

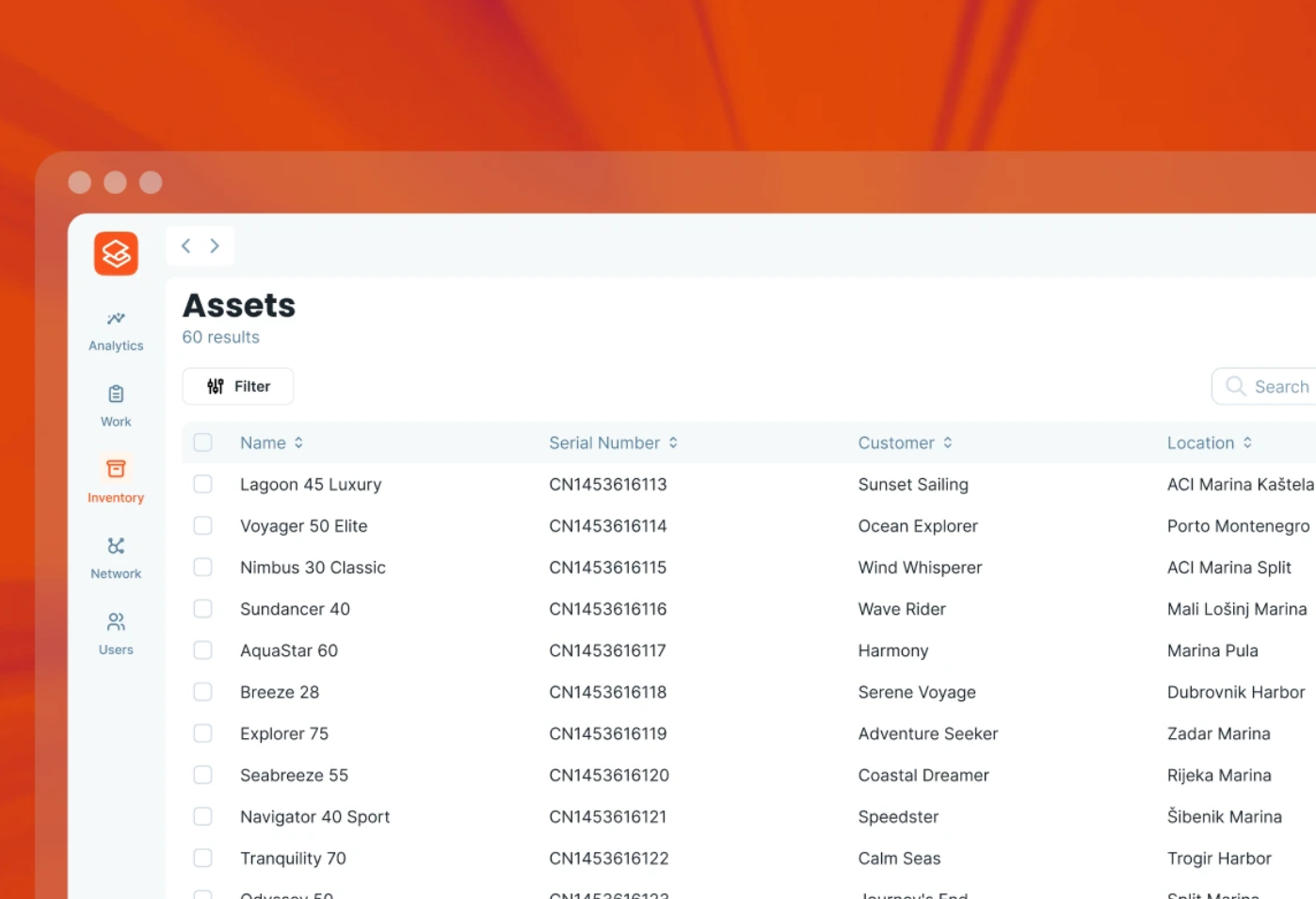

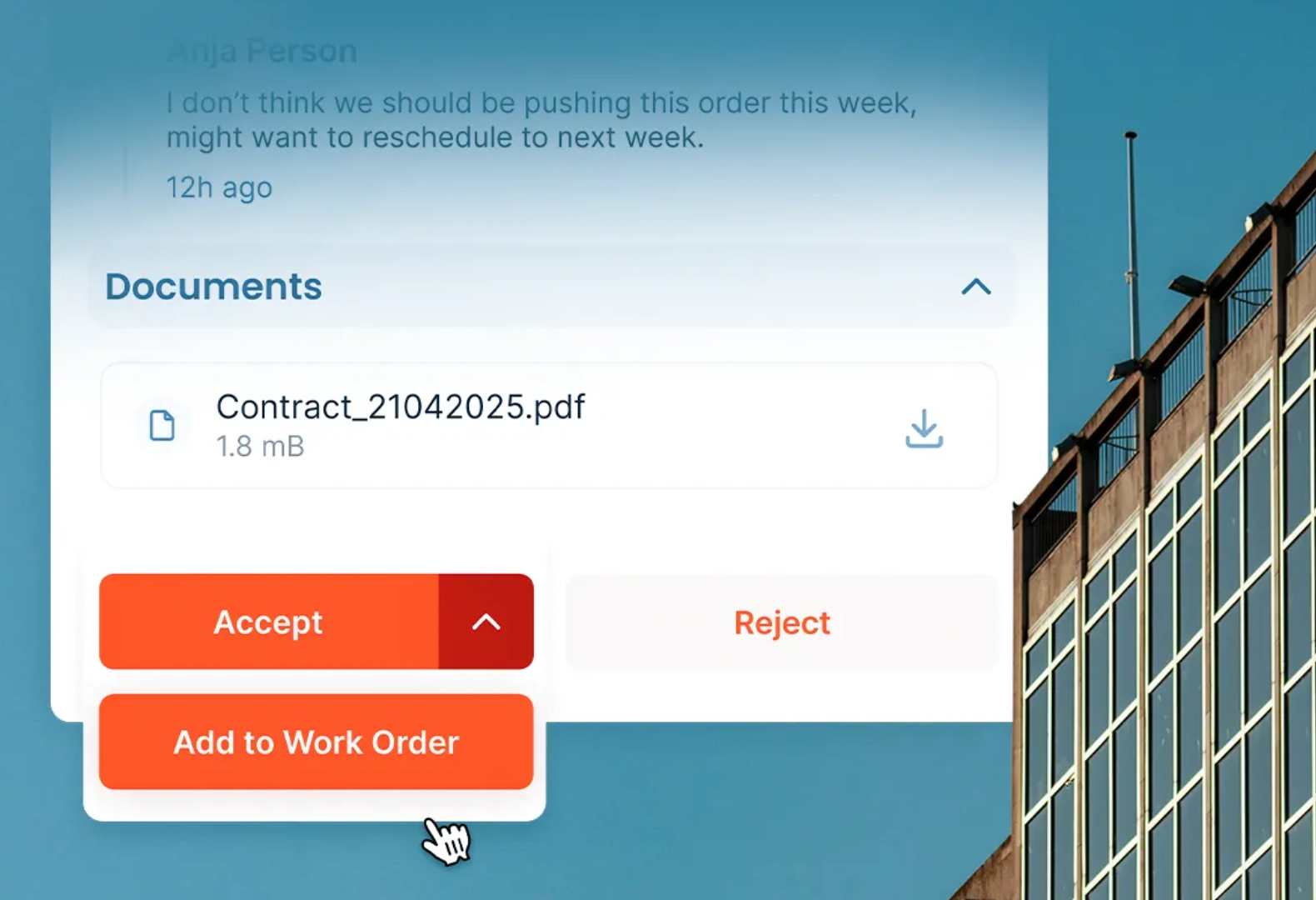

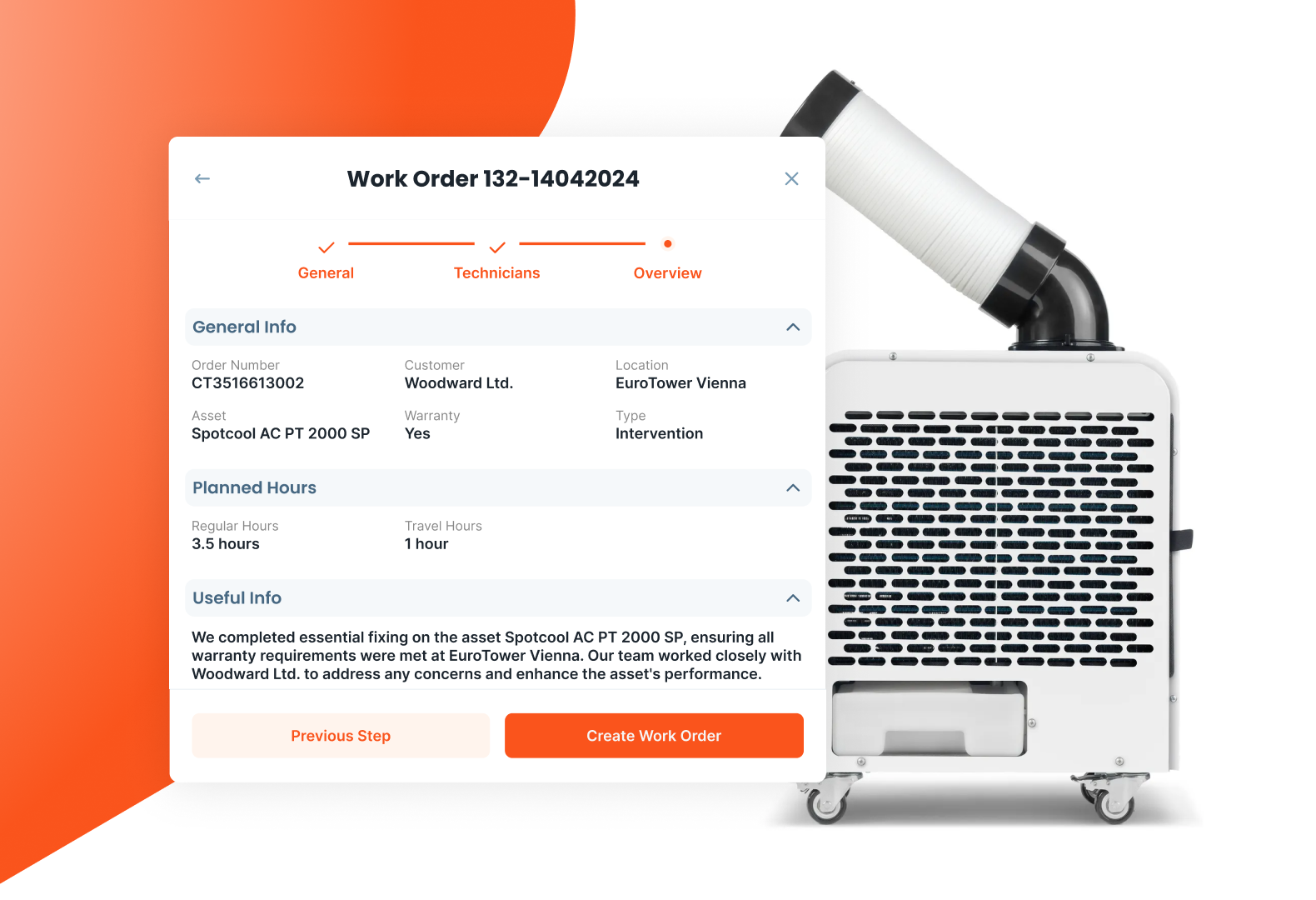

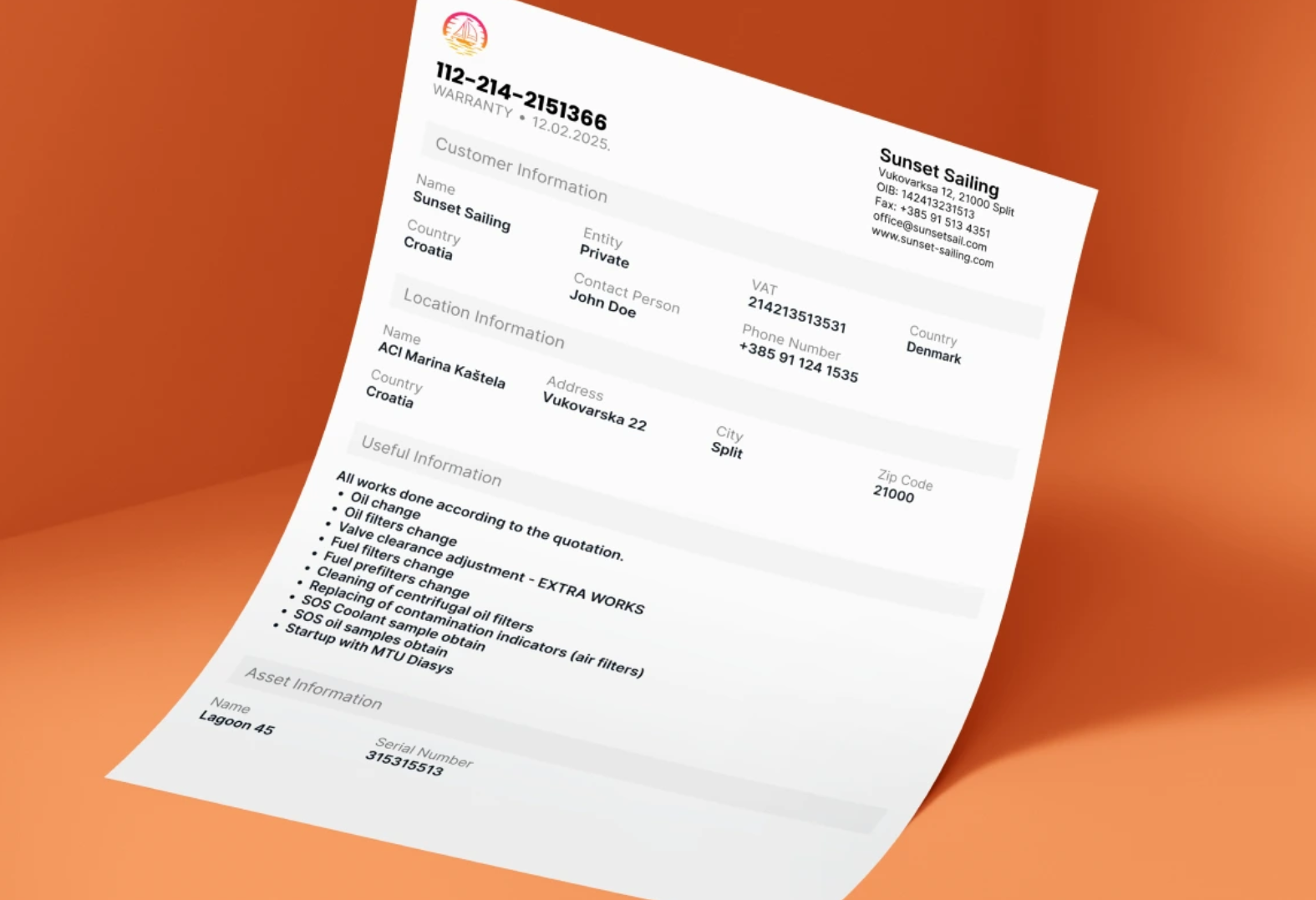

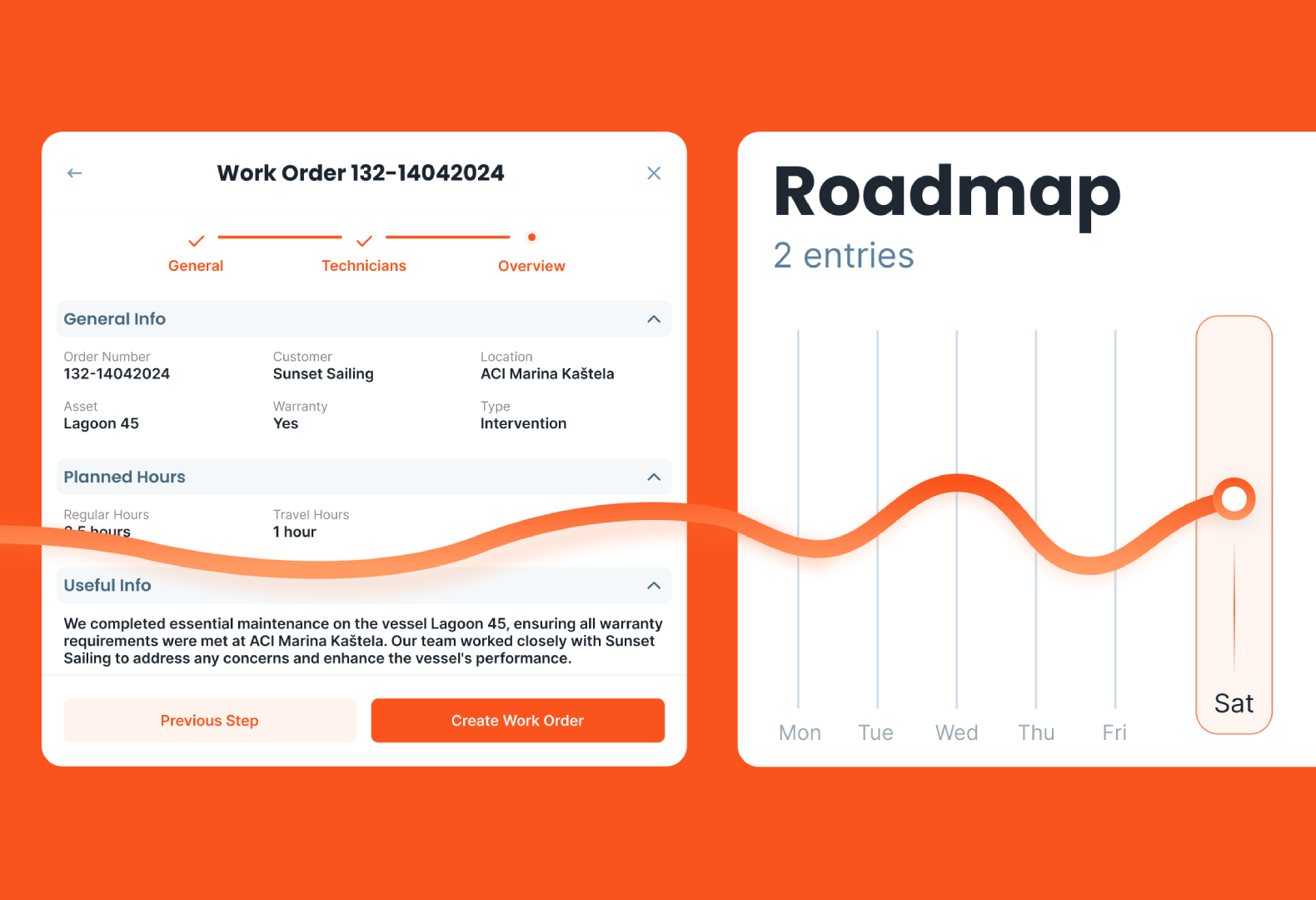

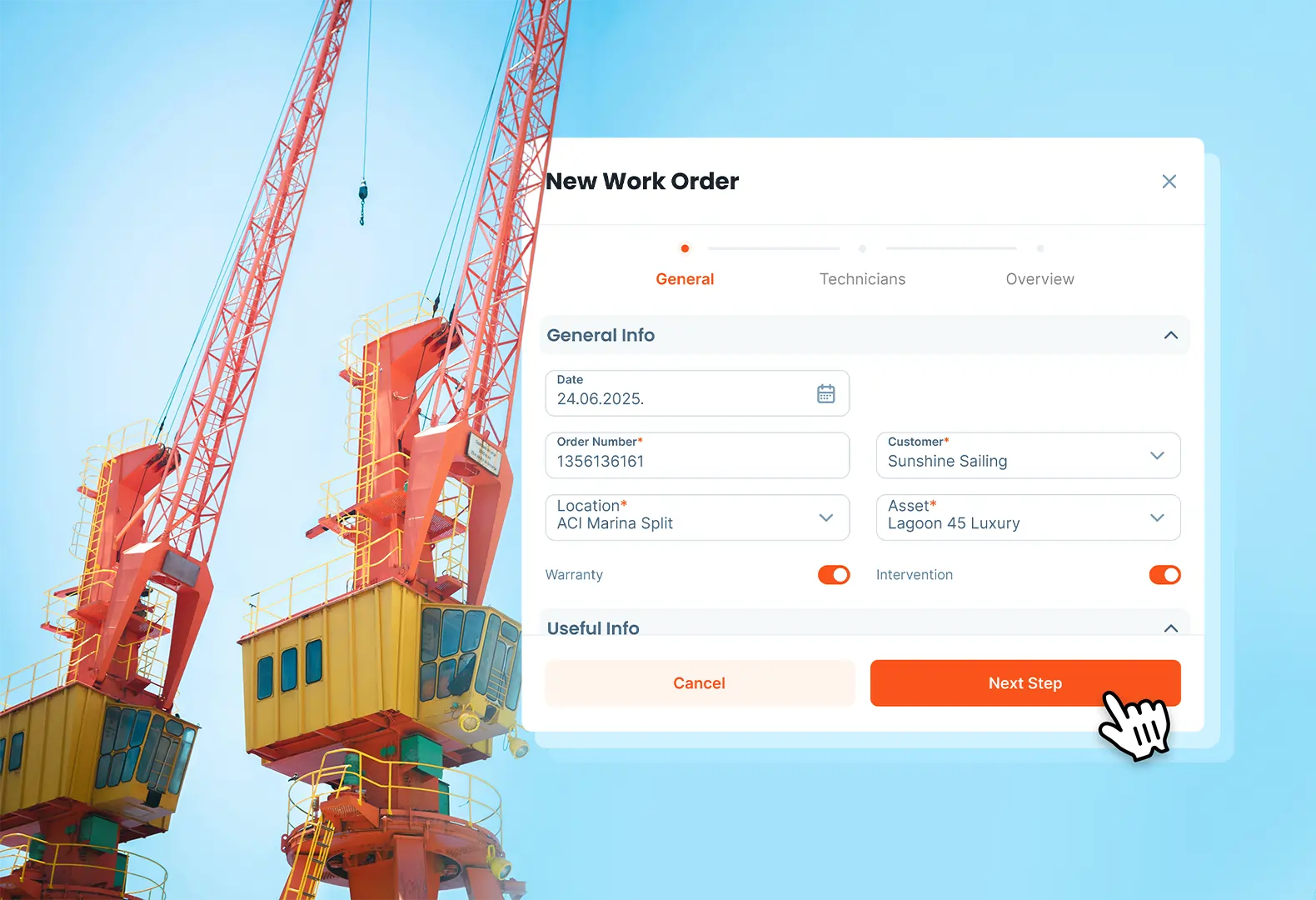

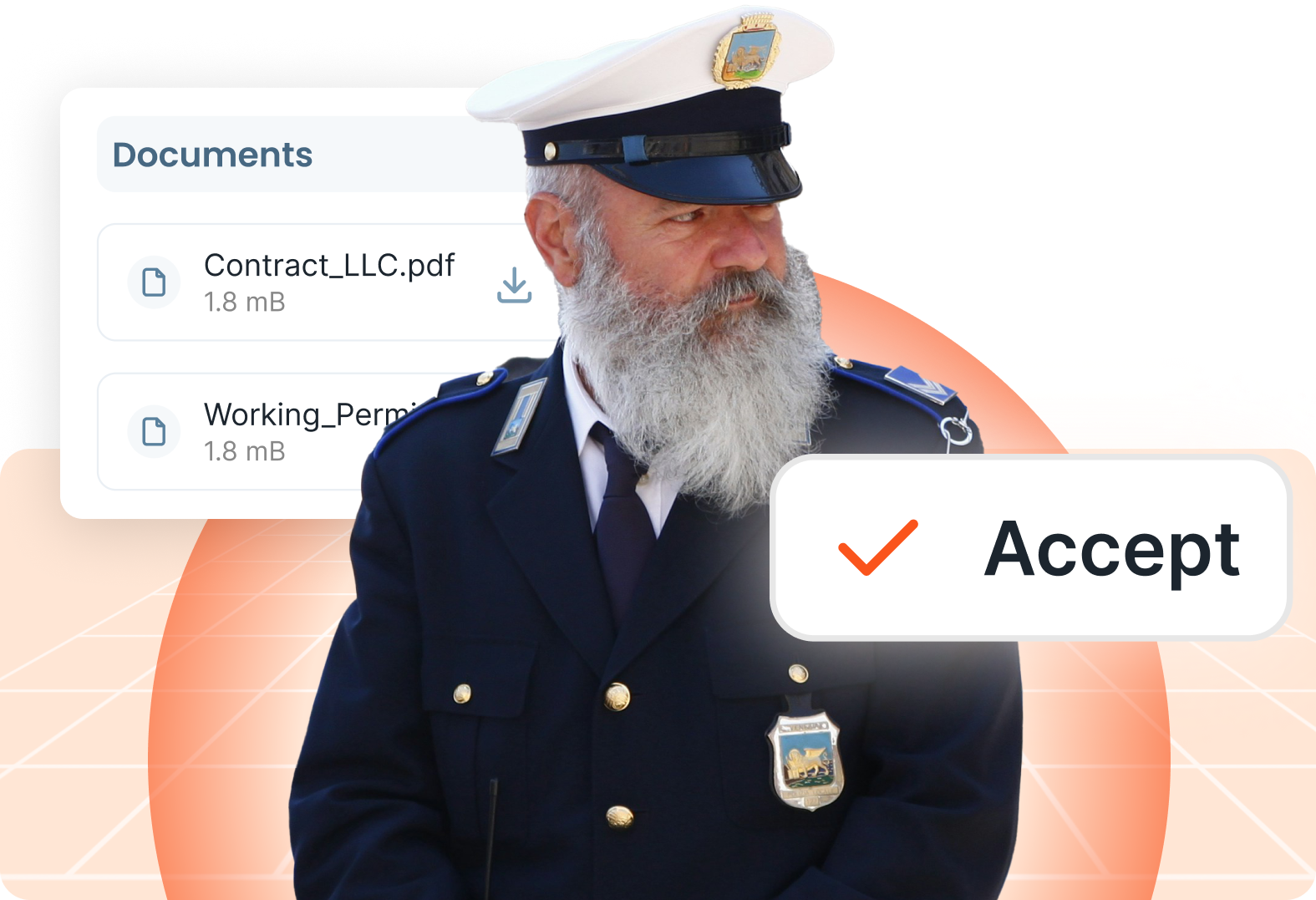

That’s where Serwizz CMMS helps. Think of it as a helper that keeps an eye on what needs doing. Who should do it. When it should happen. It helps you keep on top of things and makes sure nothing slips through the cracks.

With Serwizz, you can stay on top of maintenance without much effort.

CMMS and Reactive Maintenance

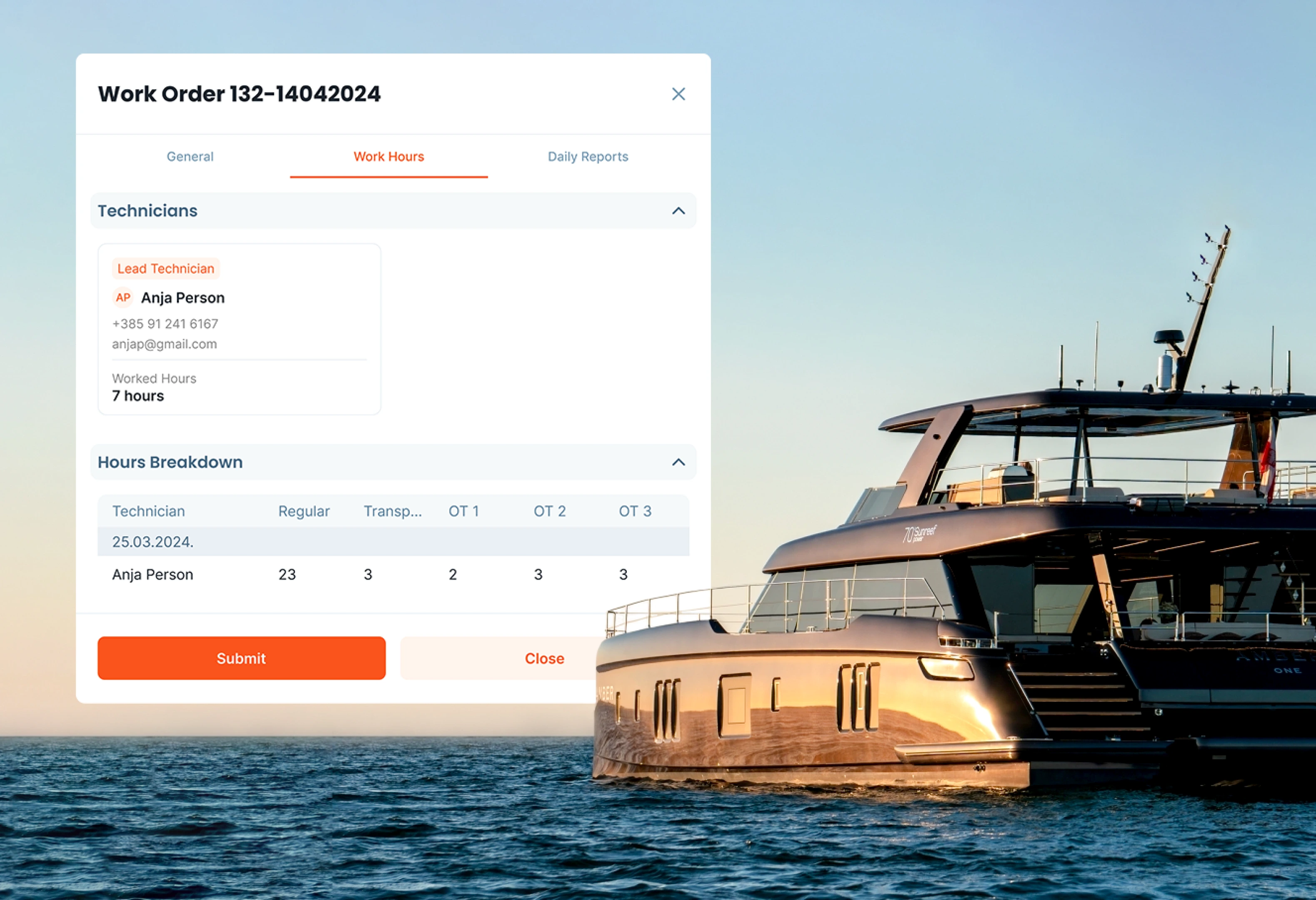

Even if your team mostly reacts to breakdowns, a CMMS can make a difference. You can log each repair, see which parts keep failing and spot patterns over time. Stuff that felt random starts to make more sense. You might even notice a particular machine keeps acting up, so next time you can fix it before it turns into a big headache.

CMMS and Preventive Maintenance

Preventive maintenance is mostly about keeping a schedule. Serwizz can help with that. You can set a reminder, a checklist,or just do a quick inspection. No need for sticky notes or old school spreadsheets. You get a rough idea of what’s coming up and what really needs attention. Things run better and you dodge those last-minute scrambles.

CMMS and Predictive Maintenance

Predictive maintenance relies on data and Serwizz makes it easier to keep track. You can connect sensors or just jot down readings yourself. After a bit, patterns start to pop up. When a machine starts working abnormally, you notice early and can fix it before it becomes a bigger headache. Fewer breakdowns, less stress and less wasted parts.

CMMS and Condition-Based Maintenance

For condition-based maintenance, a CMMS helps you notice the signs your equipment gives. Maybe a gauge hits a warning point or a part starts making unusual noises. Serwizz keeps all these notes in one place so nothing gets forgotten. You only fix what really needs fixing, which saves time and money.

Benefits Across All Types

The best part? A CMMS works with every type of maintenance. Whatever type of maintenance you’re doing, a CMMS keeps an eye on everything. Less stress, fewer surprises and your team can make better decisions. It’s like having a helper looking out for your machines and making life a little easier for everyone.

Future Trends in Maintenance Practices

Maintenance isn’t standing still. Technology is changing the game and the ways we take care of machines are evolving too.

More and more, data is driving decisions. Sensors, IoT devices and smart monitoring tools are helping teams spot problems before they even happen. Predictive maintenance is getting sharper and condition-based approaches are becoming easier to manage.

Automation is another big trend. Machines can now do part of their own checks, send alerts, or even schedule small tasks. That doesn’t replace people. It just takes some of the repetitive stuff off your plate so your team can focus on the tricky bits.

There’s also a push for sustainability. Teams are thinking not just about keeping machines running, but about using parts and energy more efficiently. Fewer wasted resources, less downtime and smarter planning all go hand in hand.

And of course, software like Serwizz is only going to get smarter. Better analytics, easier scheduling, and clearer insights will make it easier for teams to handle any maintenance strategy..

The bottom line? Maintenance is getting a lot more hands-on and less of a headache. Watch these trends, and your team and machines will be ready for whatever pops up.

Conclusion: Finding Balance in Maintenance

Maintenance doesn’t have to be stressful. Each maintenance type has its own pros and cons. The secret is knowing your equipment, how your team works, and which breakdowns would really cause trouble.

The right mix of approaches can save time, money and of course, a lot of unnecessary stress. You don’t have to do it perfectly, just smartly. Keep an eye on your machines, plan where you can, react when you must, and let tools like Serwizz give you a hand when things get tricky.

At the end of the day, good maintenance makes life easier. Machines run better, your team stays calmer, and your day-to-day just flows a little smoother