CMMS

·

28 min read

What Is a Work Order? Tips & Best Practices

What Is a Work Order?

A work order is a document that has details related to a maintenance task like clear instructions for technicians. It’s an official permission to go ahead and get the job done. Usually, it’s created after someone submits a work request like reporting a breakdown.

Once that request is reviewed and approved, typically by a manager it becomes a work order. That’s when the job becomes scheduled, assigned and tracked.

A good work order makes the job easier. It gives the technician what they need to plan, get the work done and wrap things up without confusion.

Work order contains:

- Task description – what exactly needs to be done

- Who requested it – name or department

- Location of the work – building, room or asset

- Assigned technician or team – who’s responsible for completing it

- Target completion date – expected timeframe for the work

- Required parts or tools – anything needed to do the job

- Additional notes or documents – safety info, manuals or photos

All of this helps the team:

- Understand what’s needed

- Gather the right resources

- Stay on schedule

- Estimate costs (parts, labor, time)

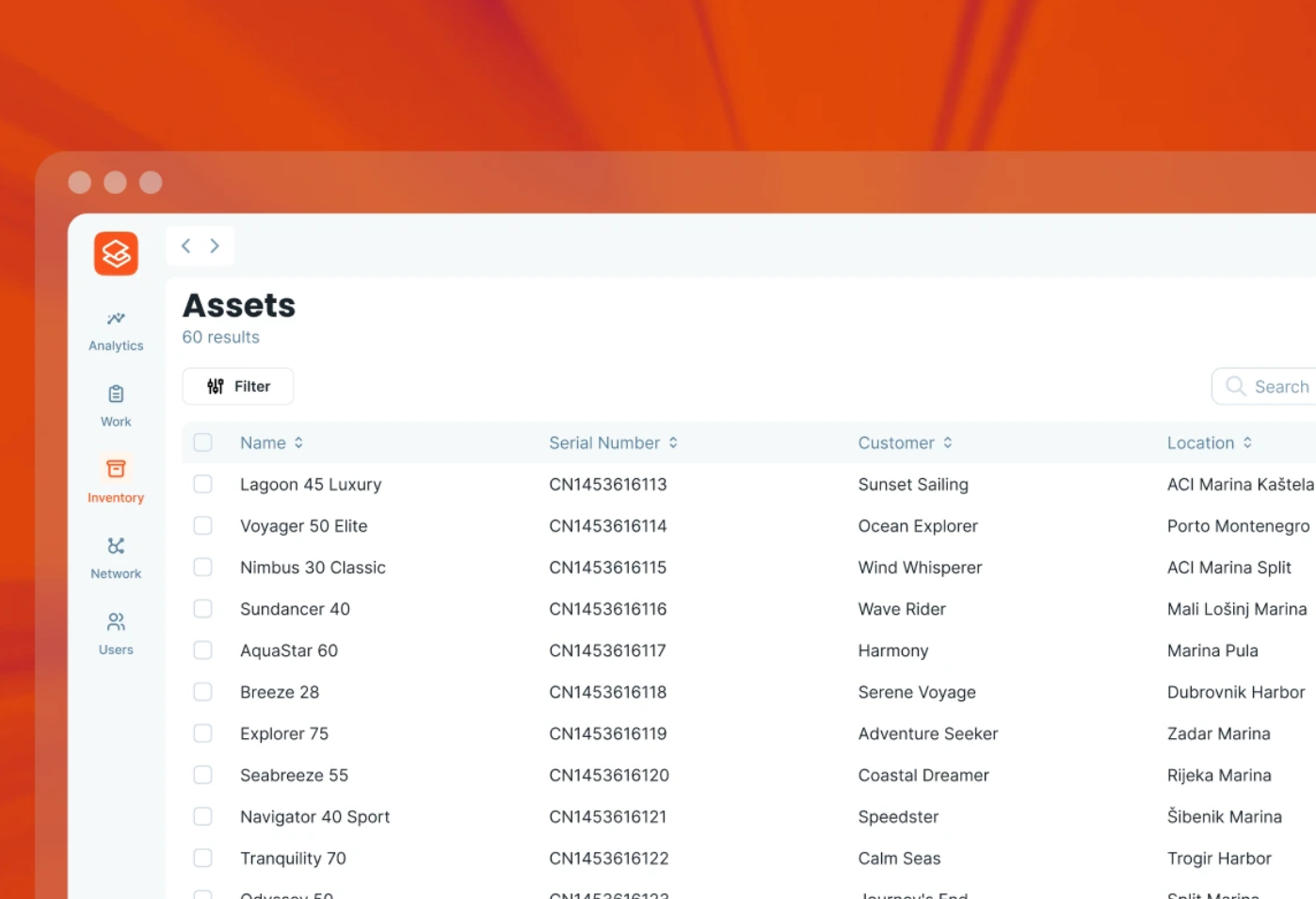

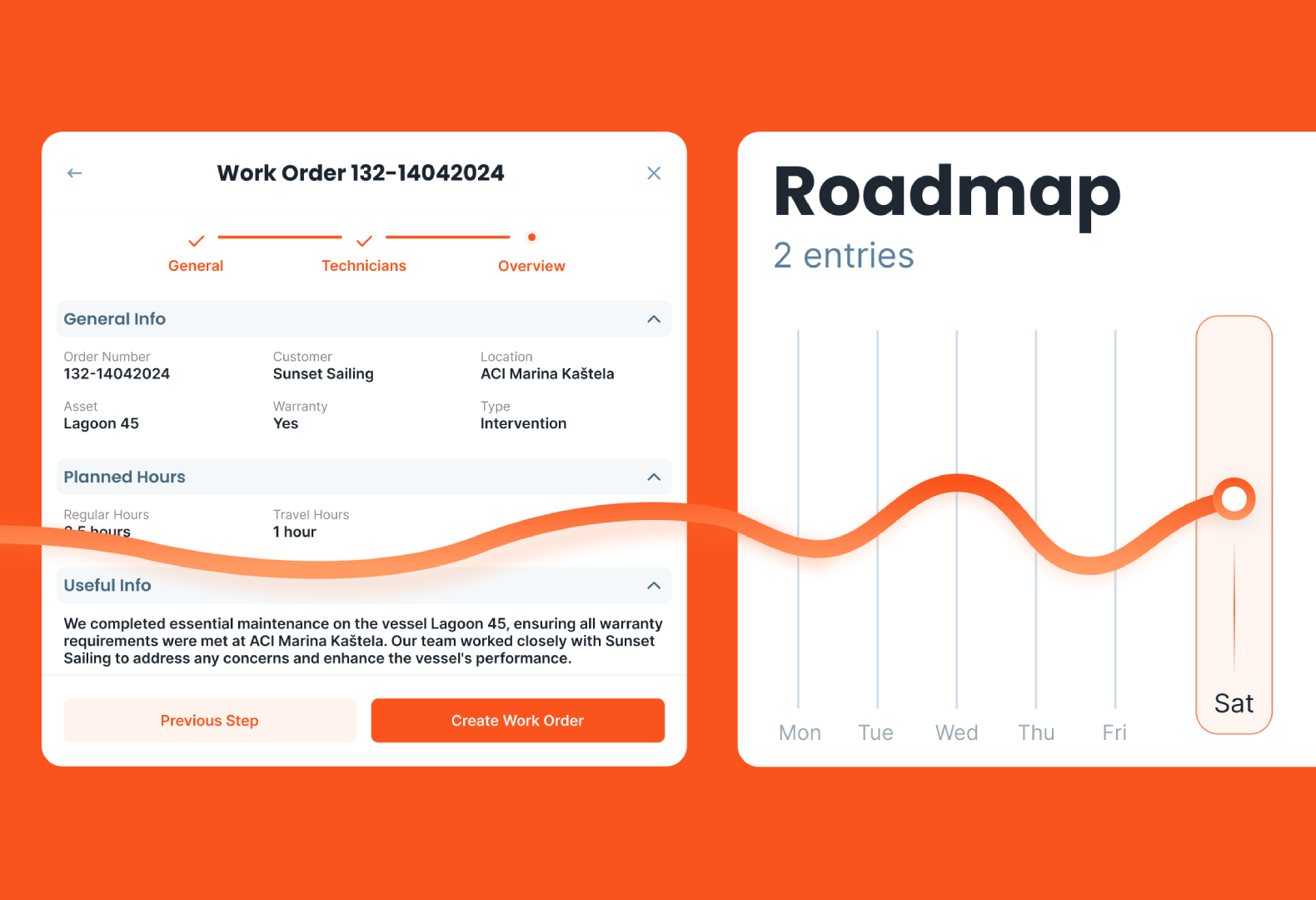

In platforms like Serwizz CMMS, most of these fields are built right into the work order form. That means no one forgets important info, and everything’s logged from the start, so the job flows smoothly from request to resolution.

From Paper Work Order to Digital Work Order

Work orders are still commonly used in paper form, and often stored in office archives once completed. People are used to using pen and paper—we’ve grown up with it. If you know how to write, you know how to fill in a work order.

If you prefer paper form work orders, we offer you a free work order template.

But this method brings a number of risks: illegibility, physical damage or complete loss of the document. This leads to dissatisfaction for both the managers but also clients. Not everyone has nice, readable handwriting and sometimes it’s hard to understand what someone wrote. Paper forms can get lost, storage space is needed for physical archives and copies are required for everyone involved in the process, the technician, the client and finance. In some cases, additional staff are needed. All of these costs can be reduced by digitalization.

The Serwizz app allows a smooth transition to digital work orders.

Key Benefits of Digital Work Orders

Increased Efficiency

Digital work orders are available to everyone involved the moment they are created. Unlike paper orders that must be physically delivered to technicians, digital work orders appear instantly on the devices of the assigned workers.

This is particularly useful for field employees who work far from company HQ. Any updates or comments are immediately visible to everyone. Supervisors and workers can communicate via in-app comments, reducing the chance of human error.

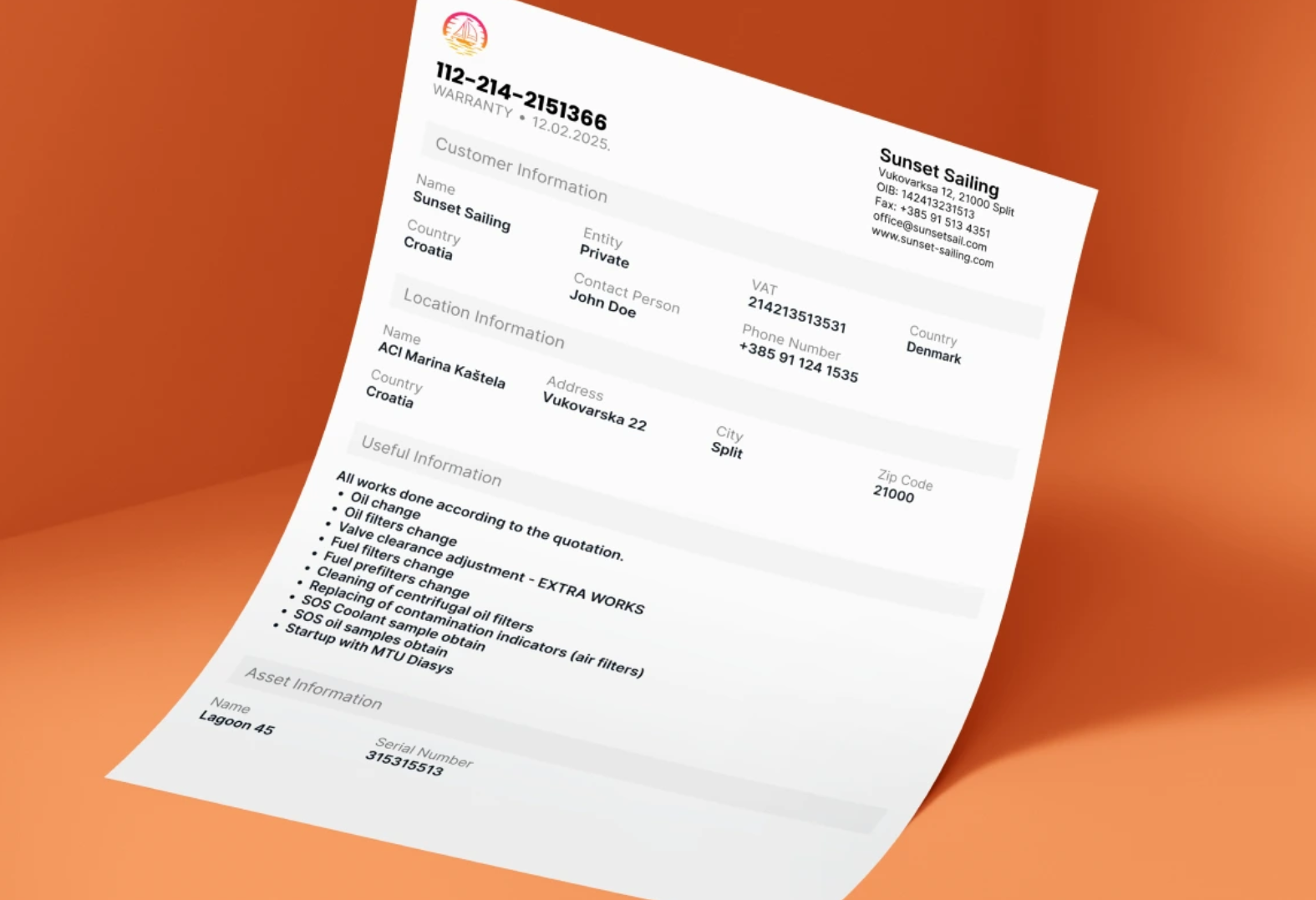

With no need for phone calls or paperwork exchange, tasks get done faster. All necessary data is available in real time. Digital work orders don’t get lost or damaged like paper ones, so projects usually stay on track. Once the job’s done, the technician can just email the work order straight to the client.

Legibility and Multilingual Support

When notes are written by hand they can be hard to read. Numbers get mixed up, which can cause problems later during checks. Digital work orders remove the risk of illegible or unclear entries: everything is typed, clean and standardized.

One big advantage of Serwizz digital work orders is that they support both Croatian and English, and additional languages (like German) can be introduced if needed.

Better Process Integration and Full Transparency

In HVAC work, mix-ups happen when the office and field technicians aren’t synced. Like, if the technician doesn’t have the right parts list or forgets to say there’s extra work, it ends up meaning extra trips, delays and unhappy customers.

With digital work orders, everyone has the latest info. As soon as a work order is created, the technician can see everything: the address, what’s wrong, what parts are needed and any notes. They can also add their own notes as soon as they finish the job.

This way of working offers greater control over service processes, aids planning for future jobs, and ultimately improves both team efficiency and customer satisfaction.

Main Types of Work Orders: Client and Internal

Work orders can be grouped into two main categories: Client Work Orders and Internal Tasks. Each type has its own purpose and workflow within the company.

1. Client Work Orders

This type refers to jobs performed for a specific client. A client work order is always linked to clearly defined elements:

- Client location – the address where the service will be performed (e.g. HVAC repair in a commercial or residential building),

- Client asset – the client’s owned infrastructure or system (e.g. refrigeration system, boiler room, heat pump),

- Client equipment – the specific device or component being serviced, repaired, or replaced.

These orders usually include:

- Problem descriptions,

- Repair instructions,

- Required spare parts,

- Expected duration,

- Task priority.

The goal is to equip technicians with all necessary information for fast and efficient on-site service.

2. Internal Work Orders

Unlike client orders, internal work orders are not linked to external clients—they refer to tasks carried out within the company. These activities support business operations, maintenance, and growth, without client involvement.

Examples include:

- Workshop or warehouse cleaning,

- Servicing and calibrating internal equipment,

- Employee training,

- Internal meetings or organizing materials,

- Admin tasks.

Internal work orders help with:

- Better staff scheduling,

- Time planning,

- Tracking internal performance,

- And optimizing use of human and material resources.

Additional Types of Work Orders

Not all work orders are created equal. Depending on the situation, the type of work order you use can help define urgency, scope and who needs to be involved. While we’ve already covered the basics client vs internal there are a few more types worth knowing about.

Here are some of the most used work order types:

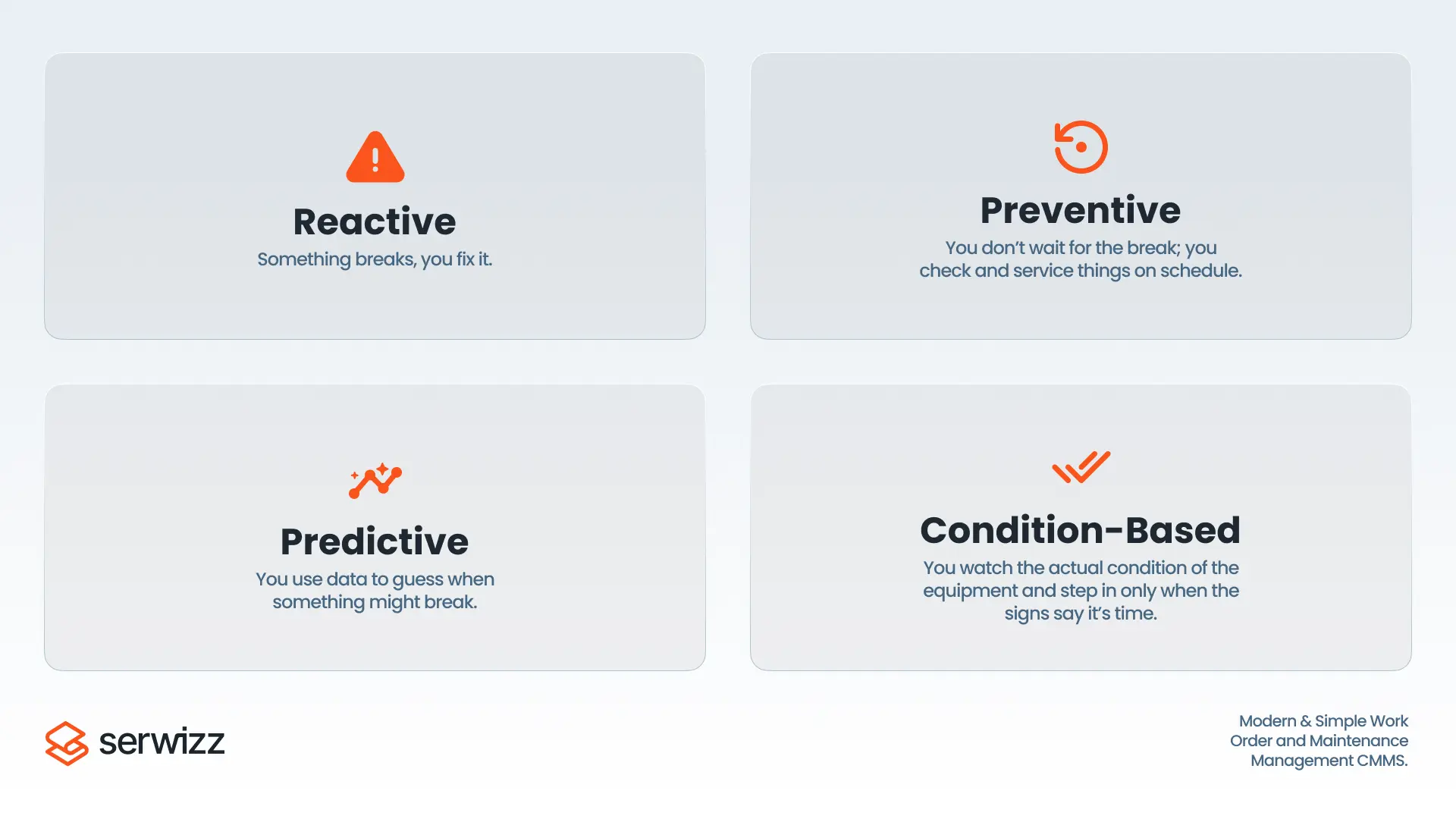

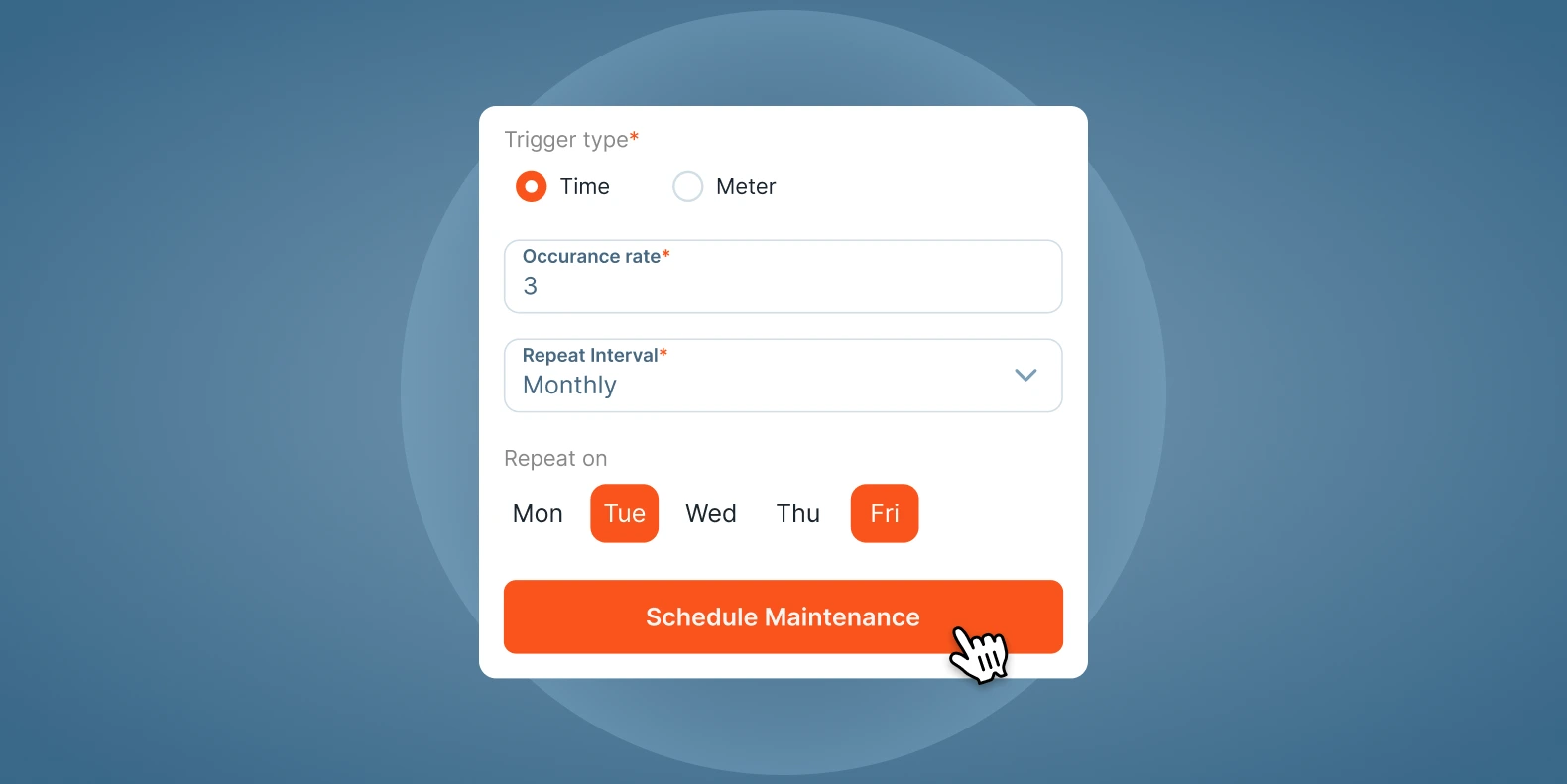

Preventive Maintenance Work Orders

These are created to prevent something from breaking in the first place. These work orders are scheduled in advance. Examples include routine inspections, filter replacements, daily cleaning, etc.

Example: “Monthly check-up of all aircondition units. Clean unit, replace filters and check cooling and heating performance.”

Preventive work orders help avoid costly breakdowns and reduce emergency calls. In Serwizz, you can set them up as recurring tasks, so you never miss them.

Corrective (Reactive) Work Orders

These come in when something has already gone wrong. Maybe there’s a leak, a system failure or something just stopped working. Corrective work orders are about fixing the issue as soon as possible.

Example: “Water pump leaking in basement. Shut off unit, replace damaged seal, test pressure.”

These are the most common type in many industries and they often show up as “urgent” in the app.

Inspection Work Orders

Used to verify the condition of equipment or facilities. With these work orders you can identify issues before they turn into problems.

Example: “Inspect electrical panel in Unit B. Check for corrosion and overheating.”

Technicians can mark inspection results in Serwizz using notes, checklists and uploaded photos.

Emergency Work Orders

High priority, time-sensitive jobs that require immediate action. These work orders are blockers in the normal work and are marked as critical.

Example: “Emergency AC repair at hospital wing. Unit failure during heatwave.”

In Serwizz, you can flag these as “High Priority” to make sure they’re seen and assigned fast.

General Service Work Orders

These cover regular jobs that aren’t emergencies or part of a schedule. Installations, small repairs, new equipment setups—anything that just needs to be done.

Example: “Install new ceiling fan in meeting room 2. Client provided hardware.”

These are perfect for day-to-day requests and quick tasks that still need documentation.

Internal Work Orders (Tasks)

These are tasks that help you keep the company work smooth. Work orders can include warehouse cleanup or employee training.

Example: “Clean and reorganize parts storage area. Dispose of old filters. Inventory check after.”

Even if they don’t involve a client, internal work orders are key for keeping things in order behind the scenes.

When you assign the correct type of work order, you help your team:

- Understand what’s expected

- Prioritize the job correctly

- Prepare the right tools and materials

- Report and track results more accurately

And with Serwizz, you can easily define the type when creating a new work order—so nothing gets lost in translation.

How to Write an Effective Work Order

Writing a work order isn’t just ticking boxes. It’s about making sure the job actually gets done the right way. If it’s written poorly, things can easily go the wrong way. People will get confused, work will be delayed and the job will be done poorly. In the end, the client will be unhappy. But when a work order is clear and detailed, everyone involved in the team technicians, managers and even the clients will know what’s happening and what needs to be done. It just makes everything smoother.

Tips to write better work orders:

Be Clear and Specific

Avoid vague task descriptions like “fix A/C.” Instead, write something like:

“Replace clogged air filter on rooftop HVAC unit 2. Check for ice buildup and test cooling function after install.”

This helps technicians show up with the right tools, parts and expectations. In short, it reduces back-and-forth.

Use Consistent Terminology

If your team uses terms like Asset, Equipment or Component, make sure they’re used the same way in every work order. This consistency avoids confusion, especially across larger teams or multi-site operations.

Serwizz helps here with dropdown menus and linked assets, so terminology stays clean and consistent.

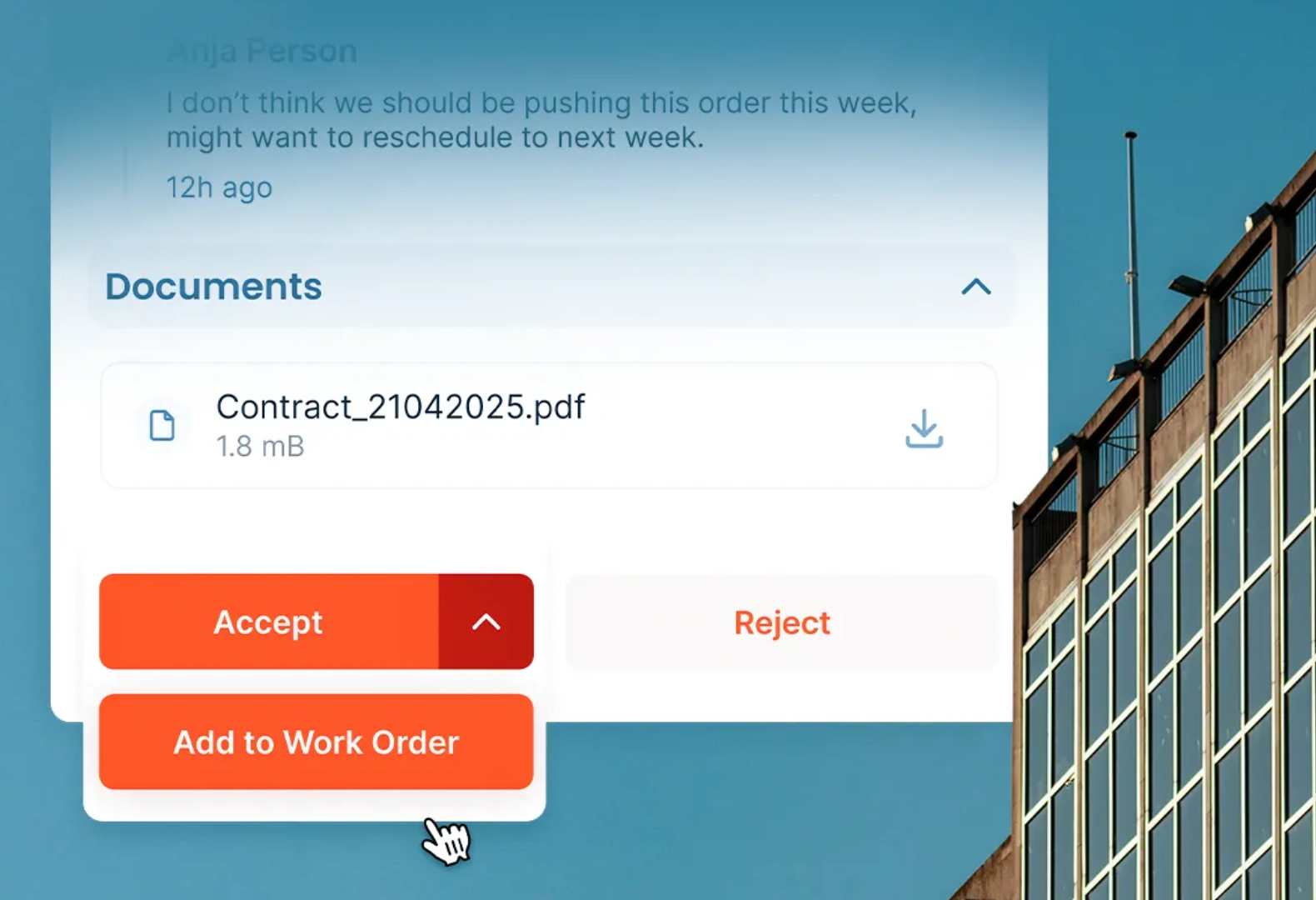

Attach Visuals and Supporting Docs

One picture can tell a thousand words, especially when troubleshooting.

- Add photos of the issue (e.g., broken part).

- Attach PDF manuals from clients.

- Upload floorplans or equipment diagrams when available.

In Serwizz, file uploads are a built-in feature, easy to add from your phone or tablet.

Estimate Time and Set Priority

Don’t forget about the planning. Add:

- Estimated hours (and travel time, if needed)

- Task priority (low, medium, high, emergency)

This helps with scheduling and makes sure urgent issues are not forgotten.

Make It Actionable

Each work order should answer these basic questions:

- What needs to be done?

- Where is the task located?

- Which equipment or asset is involved?

- When should it be completed?

- Who is responsible?

The more details you provide, the less problems you will have.

Use Templates and Required Fields

Templates help standardize work orders. In such a way, no important detail is forgotten. With Serwizz, managers can set required fields like:

- Location

- Asset

- Work description

- Safety check

- Materials used

This ensures that no work order goes out incomplete and no technician goes out unprepared.

Best Practices for Managing Work Orders

Just having work orders isn’t enough. If they’re not managed properly, things slip. But with the right process, you avoid delays and keep everything running smoother.

Here are a few effective practices:

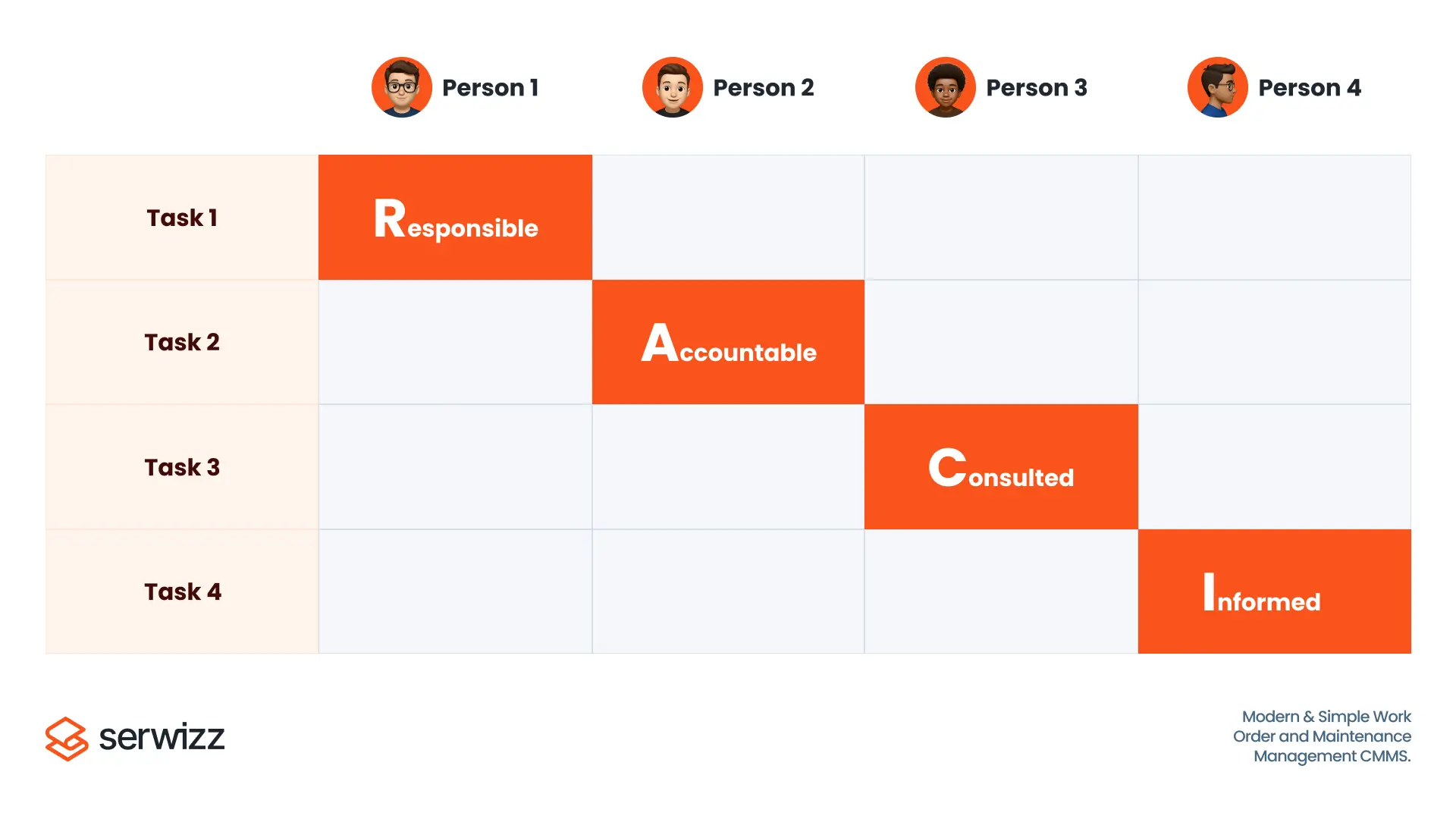

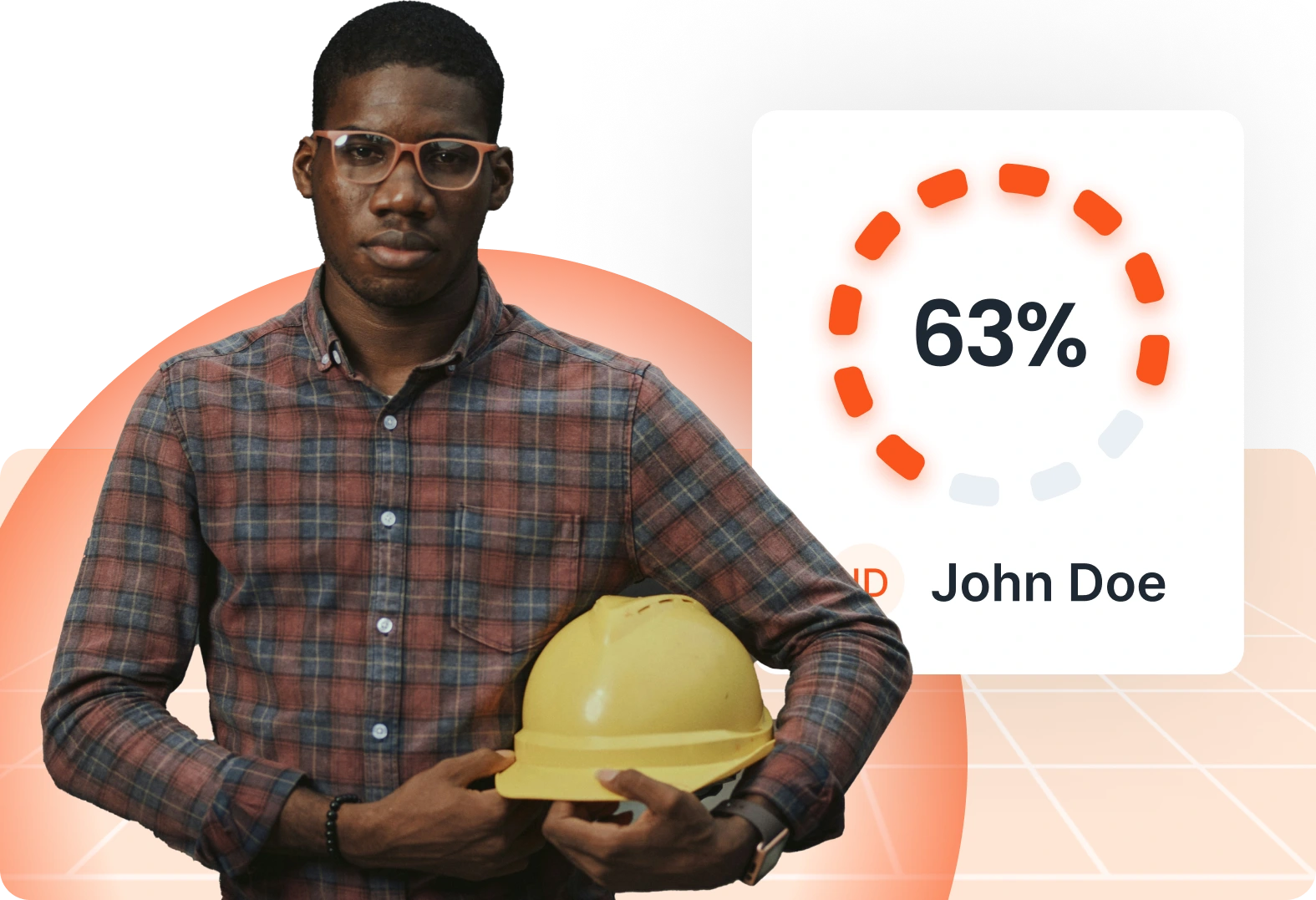

1. Always assign a clear owner

Every work order should have someone responsible for it. Even if a team is working on the job, one person should be accountable whether that’s the assigned technician or a team lead. Read more in our RACI blog post.

In Serwizz, you can assign a primary tech and even tag a tech lead when multiple people are involved.

2. Keep the information complete and clear

Work orders should never be vague. Include what needs to be done, where, by when and with what tools or parts. If something’s missing, the technician will waste time figuring it out.

Tip: Use templates and required fields so nothing important gets skipped. Serwizz can help with that.

3. Update statuses in real-time

Work that’s “in progress” for a week with no updates? That’s a red flag. It’s helpful to use clear statuses throughout the job—like Scheduled, In Progress, or Ready for Approval—so no one’s left guessing. In that way everyone sees where things stand without sending emails or making calls.

4. Don’t forget close-out steps

Work doesn’t end when the job is done, it ends when the work order is closed. Make sure the technician:

- Logs hours

- Adds used materials

- Uploads any supporting files

- Gets the client’s signature

And that a manager reviews and approves it. In Serwizz, this is all built into the workflow, so it’s easy to track and confirm.

5. Review your data regularly

Work orders give you valuable data, only if you use it. Look at:

- How long jobs are taking

- Where delays happen

- Which assets break down the most

- Who’s logging the most overtime

Over time, this helps you improve scheduling, reduce costs, and spot patterns before they become problems.

6. Make it easy for techs to report from the field

The easier it is for techs to fill out work orders, the more accurate your data will be. If they have to wait until they’re back in the office or rely on memory, details will get missed.

Serwizz is built for mobile, so techs can upload photos, log hours and update statuses right from their phone.

Work Order Examples: Good vs. Bad

It’s one thing to create a work order, but it’s another to write it well. A good work order saves time, reduces confusion and makes the job easier. A bad one? Brings confusion, missed details and delays.

Here’s a simple side-by-side comparison to show how small things can make a difference:

| Field | Bad Example | Good Example |

|---|---|---|

| Task Description | “Fix AC” | “Replace clogged air filter on rooftop unit 2, then test cooling.” |

| Location | “Main Office” | “Main Office – Building B, Roof – Unit #2” |

| Materials | “Screws” | “6x stainless steel screws, M6 – part #A29” |

| Working Hours | “3h” | “2h work, 1h travel – no overtime” |

| Notes | “It’s done” | “Cleaned coils, replaced filter, tested. Cooling normal.” |

| Attachments | None | Before/after photos uploaded + filter part code |

Why the “bad” one doesn’t work:

- Too vague, “fix AC” doesn’t say what was wrong or what was done.

- Missing detail, technician might show up with the wrong tools or parts.

- No context, no way to track quality, duration or cost.

Why the “good” one works:

- It’s specific, any technician reading it knows exactly what to do.

- It includes the “where” and “how”, no time wasted figuring things out.

- It’s easy to review, approve and follow up later.

How Serwizz Helps You Get to “Good”

With Serwizz, most of these fields are structured, so no one has to guess what to write. You can:

- Choose assets and locations from dropdowns

- Add materials from your catalog

- Upload photos on the go

- Break down working hours (regular, travel, overtime)

- Include technician notes

- Include client signatures

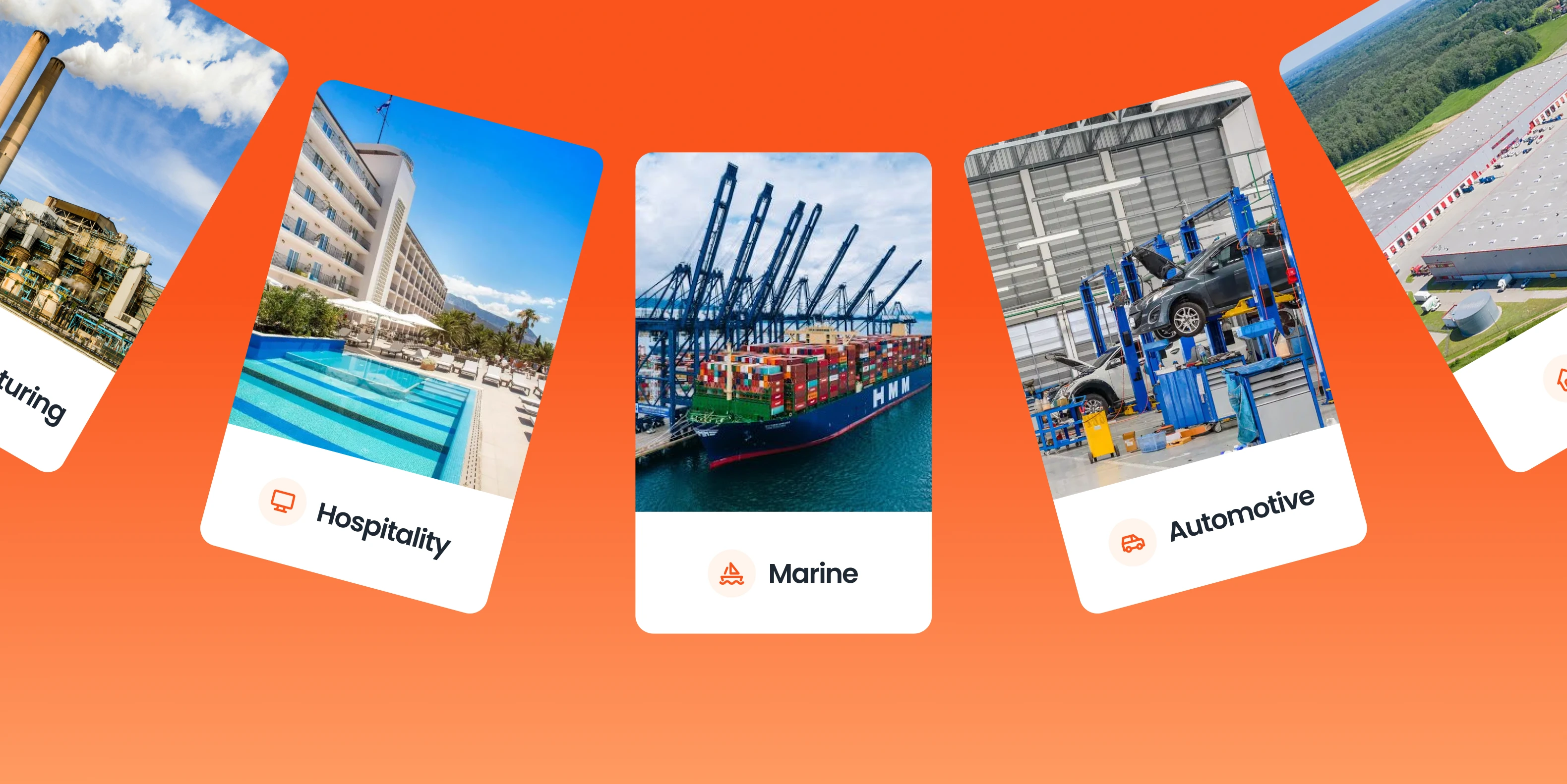

Work Orders across Industries

A work order helps get the job done clearly and efficiently. It’s used across industries and always includes important task execution details.

- In manufacturing, it might include: a short task description, required materials, production steps, time estimates per step, and technical drawings.

- In maintenance, it usually includes: fault descriptions, what needs to be repaired or replaced, spare part details, and required materials/time.

- In service, you’ll find: service description, client information, task specifics, and execution instructions.

- In construction, it includes: project description, required materials, and instructions on how the work should be carried out.

In short, a work order is a guide that ensures the job is done properly—regardless of industry.

Industry-Specific Use Cases for Work Orders

Work orders aren’t just for facility teams or maintenance crews. You’ll find them in all sorts of industries, wherever there’s gear to handle, jobs to finish or services to provide. While the basic setup stays pretty similar, the specifics and what matters most shift depending on the kind of work involved.

Here’s how different industries use work orders in real life:

HVAC & Facility Maintenance

Probably the most common use case: HVAC teams rely on work orders every day for repairs, preventive maintenance, filter replacements and inspections.

Example:

“Check HVAC Unit #3, Building B. Replace filters, test heating function. Note any irregular noise or vibration. Submit before Friday.”

Manufacturing

In manufacturing, work orders often focus on machine servicing, quality checks or equipment calibration. Timing and documentation are critical here to avoid production downtime.

Example:

“Monthly calibration of laser cutter on Line 4. Use calibration tool set B, log readings in attached form. Notify QA upon completion.”

Digital work orders help maintenance teams keep track of recurring tasks and respond faster when equipment breaks down.

Marine / Maritime

In marine settings, work orders help with routine upkeep as well as urgent repairs, covering everything from bilge pumps to navigation equipment.

Example:

“Inspect generator cooling system on vessel A45. Clean intake, replace coolant filter, run pressure test.”

Hospitality

Hotels and resorts use work orders for everything from room repairs to event setup to routine inspections.

Example:

“Replace broken shower head in Room 204. Check water pressure and log parts used. Notify front desk when done.”

Healthcare

Hospitals and clinics depend on work orders to take care of important equipment and make sure they follow all the necessary rules.

Example:

“Service defibrillator in ER Unit 3. Perform battery check, firmware update, and test charge cycle. Attach service log.”

Construction & Projects

In construction, work orders help coordinate subcontractors, track progress and manage daily tasks across multiple teams.

Example:

“Install light fixtures on 2nd floor hallway. Reference blueprint section E2. Confirm with site supervisor before marking complete.”

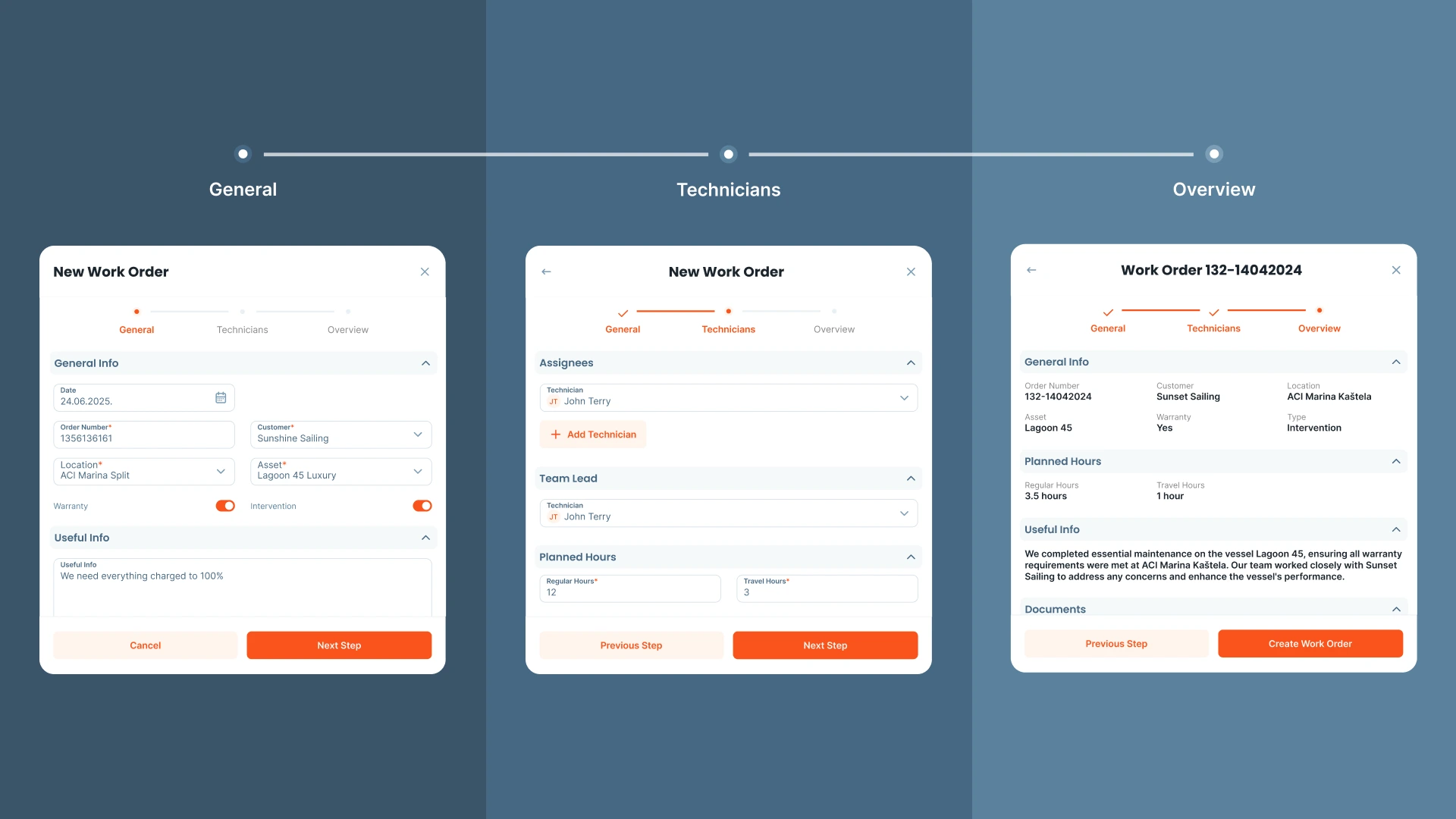

Creating a Work Order with Serwizz

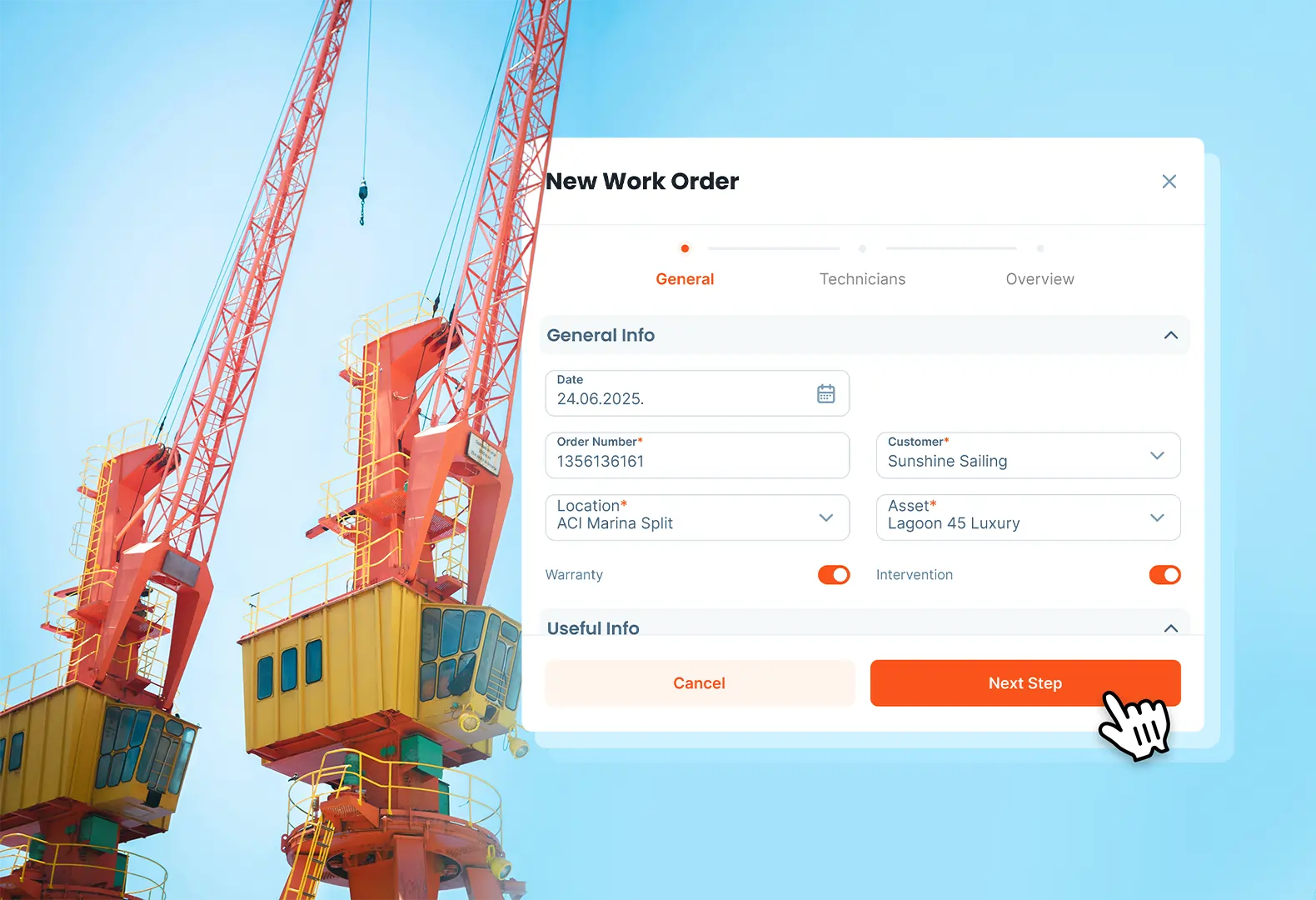

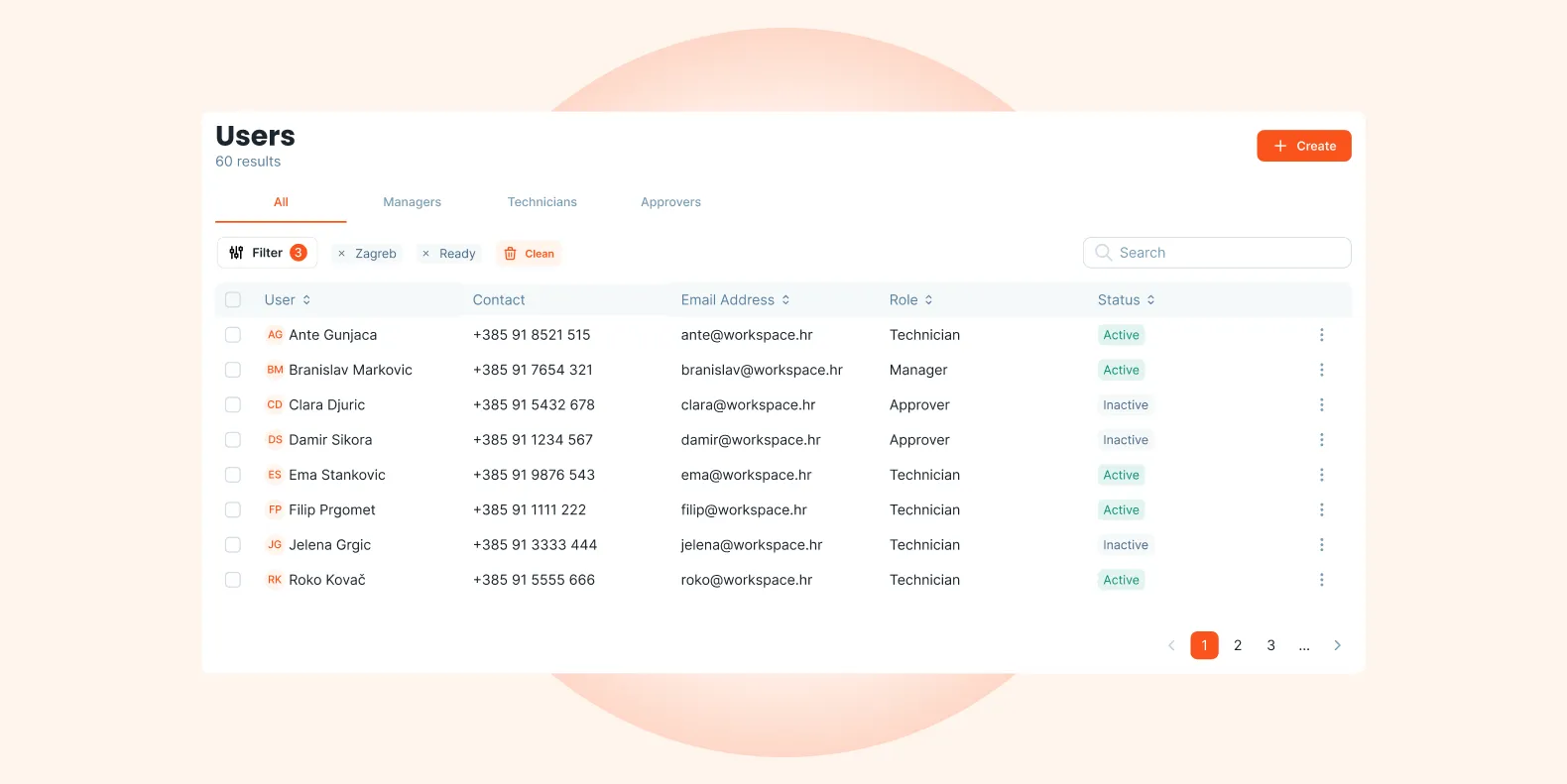

In the Serwizz app, access rights and permissions are clearly defined to ensure data security and efficient task management.

Only users with one of the following roles:

- Manager or System Administrator

Can:

- Create new work orders,

- Assign technicians,

- Set priorities,

- Monitor progress,

- Enter all relevant task details.

Users with the following roles:

- Approver

- Technician

- Other field staff

can not create new work orders. Their access is limited to tasks explicitly assigned to them. With this implementation, we ensure that each team member only sees information relevant to their role.

Access Security and Privacy

Setting up roles makes things more secure and helps everyone know what they’re responsible for. Technicians and field staff only see the work orders meant for them, so there’s less chance of someone messing with the wrong job by accident or seeing info they shouldn’t.

Work Order Fields

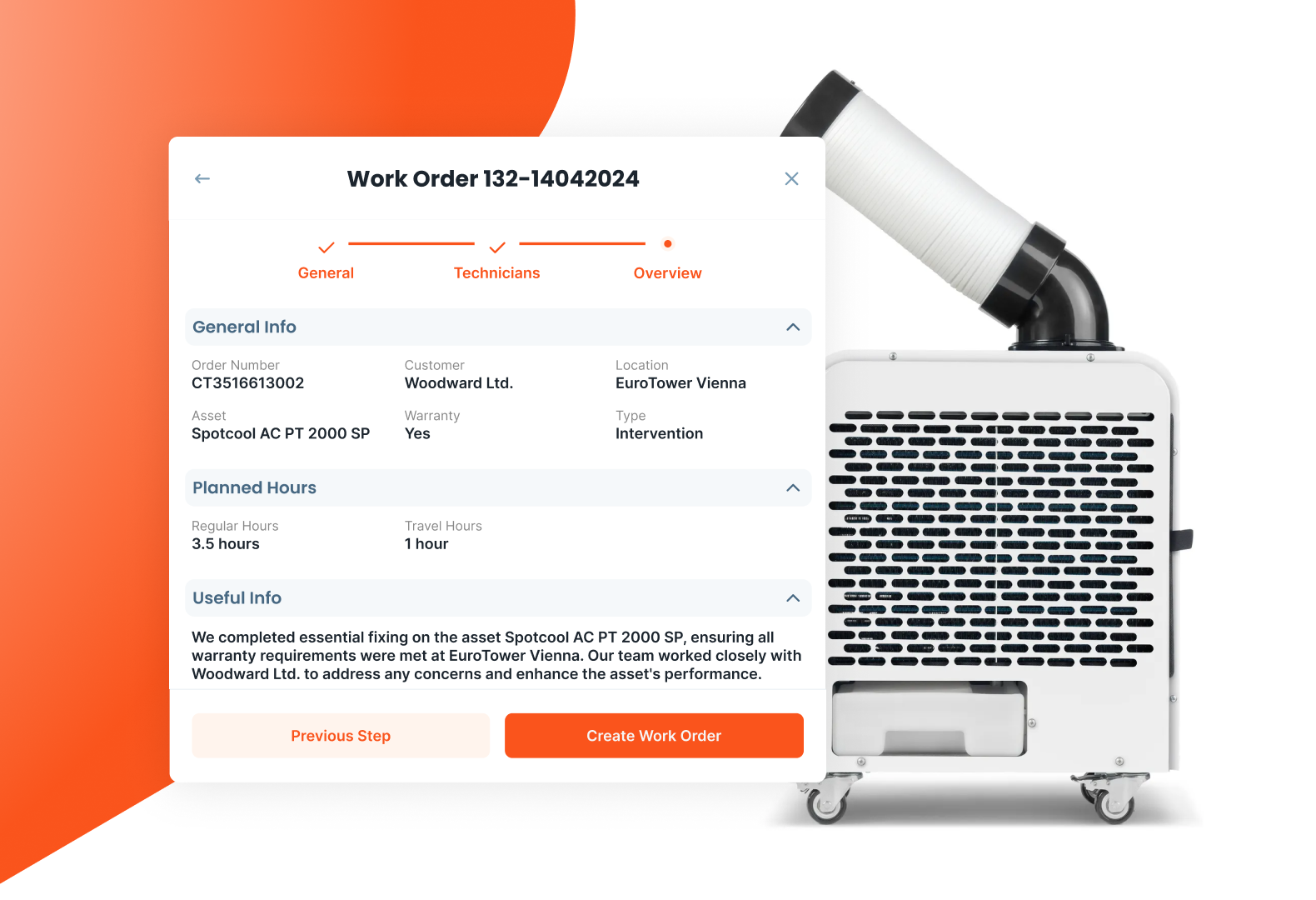

When a manager creates a new work order, they first complete the General section, which includes:

- External reference – order number if it’s from an external system (e.g. Pantheon),

- Customer – the client for whom the order is created,

- Location – the client site where the equipment is located,

- Room – specific area where the problem is (used mostly in facility management),

- Assets – the equipment or system involved (e.g. AC unit, boat for marine management),

- Warranty – is the equipment under warranty?

- Intervention type – is this an unplanned task?

- Useful information – technician instructions (e.g. which screws to replace),

- Upload files – fault photos, PDF guides from the client, etc.

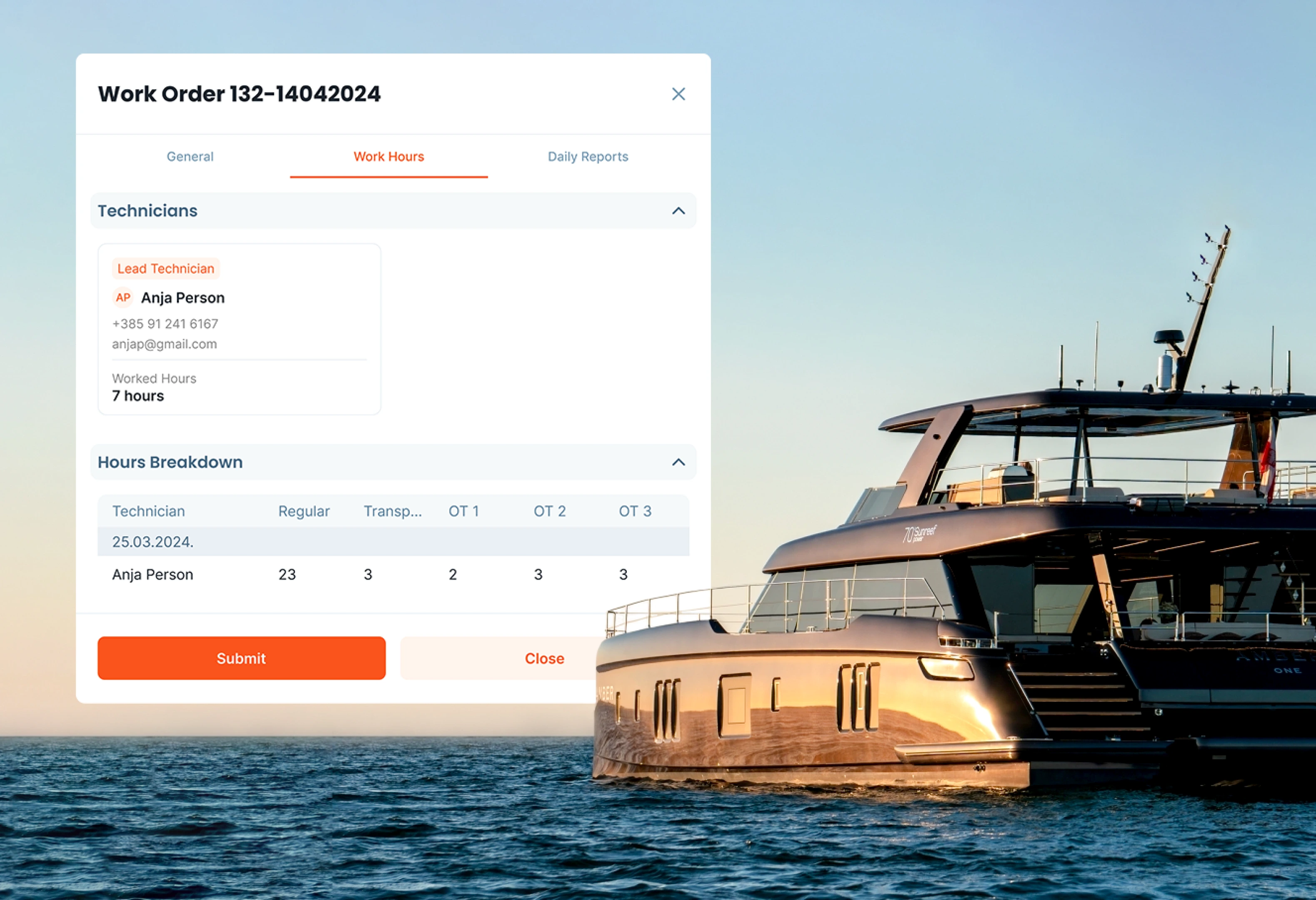

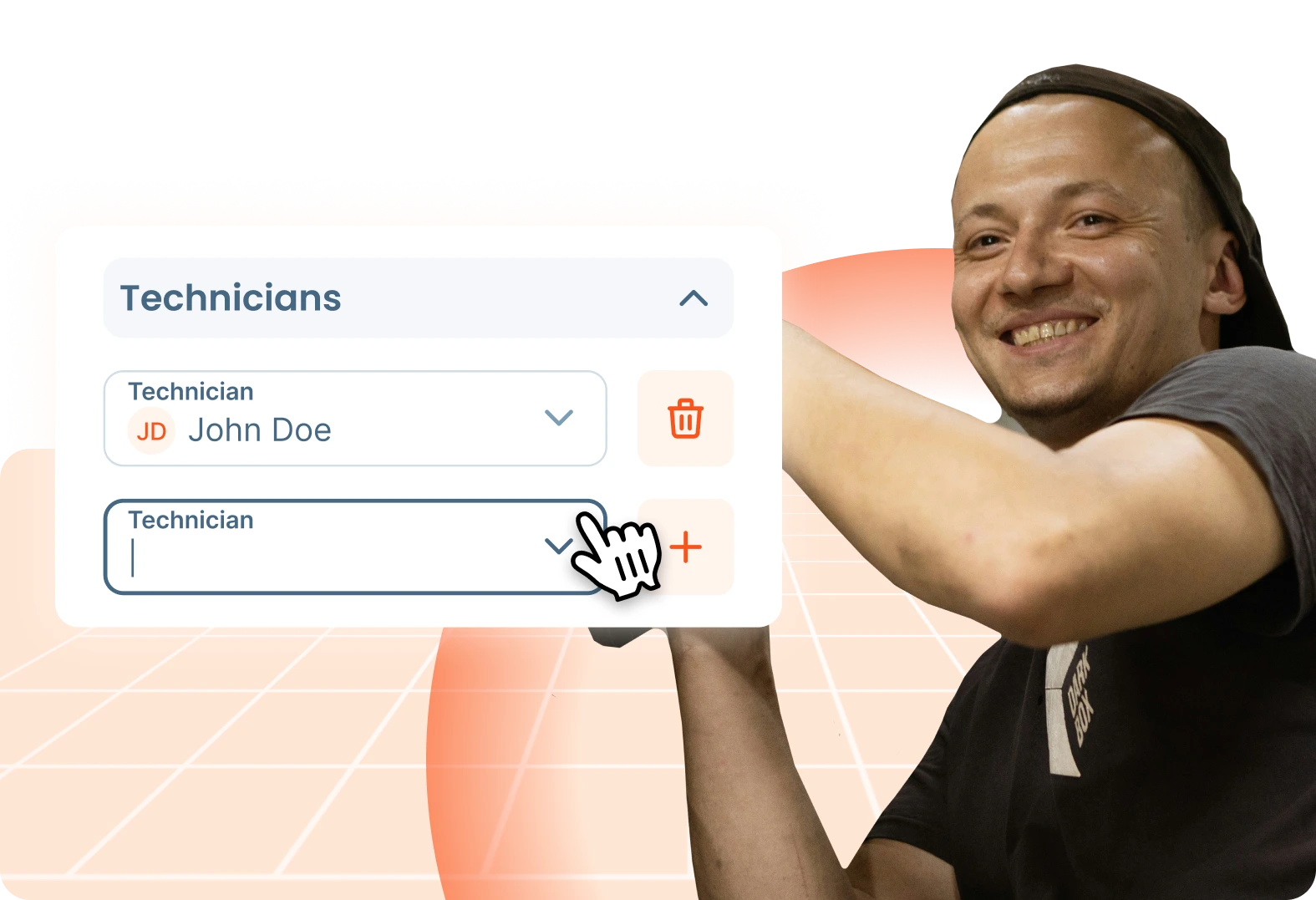

Assigning Work Orders

Once the general fields are completed, the manager assigns:

- A technician,

- A tech lead (if multiple people are involved),

- Planned work hours and travel hours, if the task is off-site.

Technician Workflow: From Daily Reports to Final Approval

Once a work order is assigned to a technician, they can view it in the Serwizz app and begin working on it. Each day, they are expected to complete a Daily Report. That is a structured entry that acts like a technician’s work diary, capturing all tasks performed that day.

Since multiple technicians can work on the same work order, the system supports multiple daily reports under the same job. This ensures full visibility into each team member’s contribution.

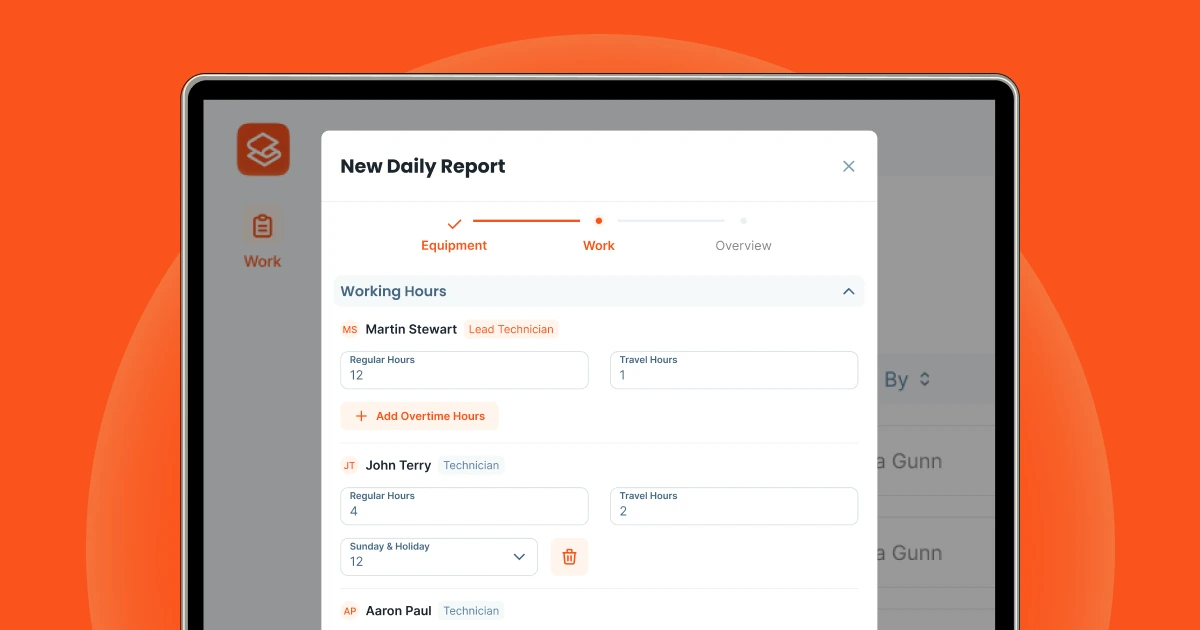

Daily Report Fields

Before filling out a report, the technician must first read and acknowledge the General Safety Guidelines. Technicians confirm they are fully aware of any job-related risks and safety procedures. This confirmation is mandatory before proceeding.

In the Daily Report, technicians can enter:

- Notes: A free-text summary of what was done that day.

- Attachments: Upload photos or documents as proof of work (e.g., broken parts, completed installations).

- Equipment: Select which asset was worked on, or add new equipment if necessary.

- Materials Used: For example: screws, bolts, filters—along with quantity and unit of measure.

- Working Hours: Regular hours, travel hours, and overtime (if applicable).

- Expenses: Choose from predefined categories:

- Transportation

- Accommodation

- Parking

- Insurance

- Other Expenses

For each expense, the technician can upload supporting documents, which include a photo of a parking ticket, fuel receipt or hotel invoice.

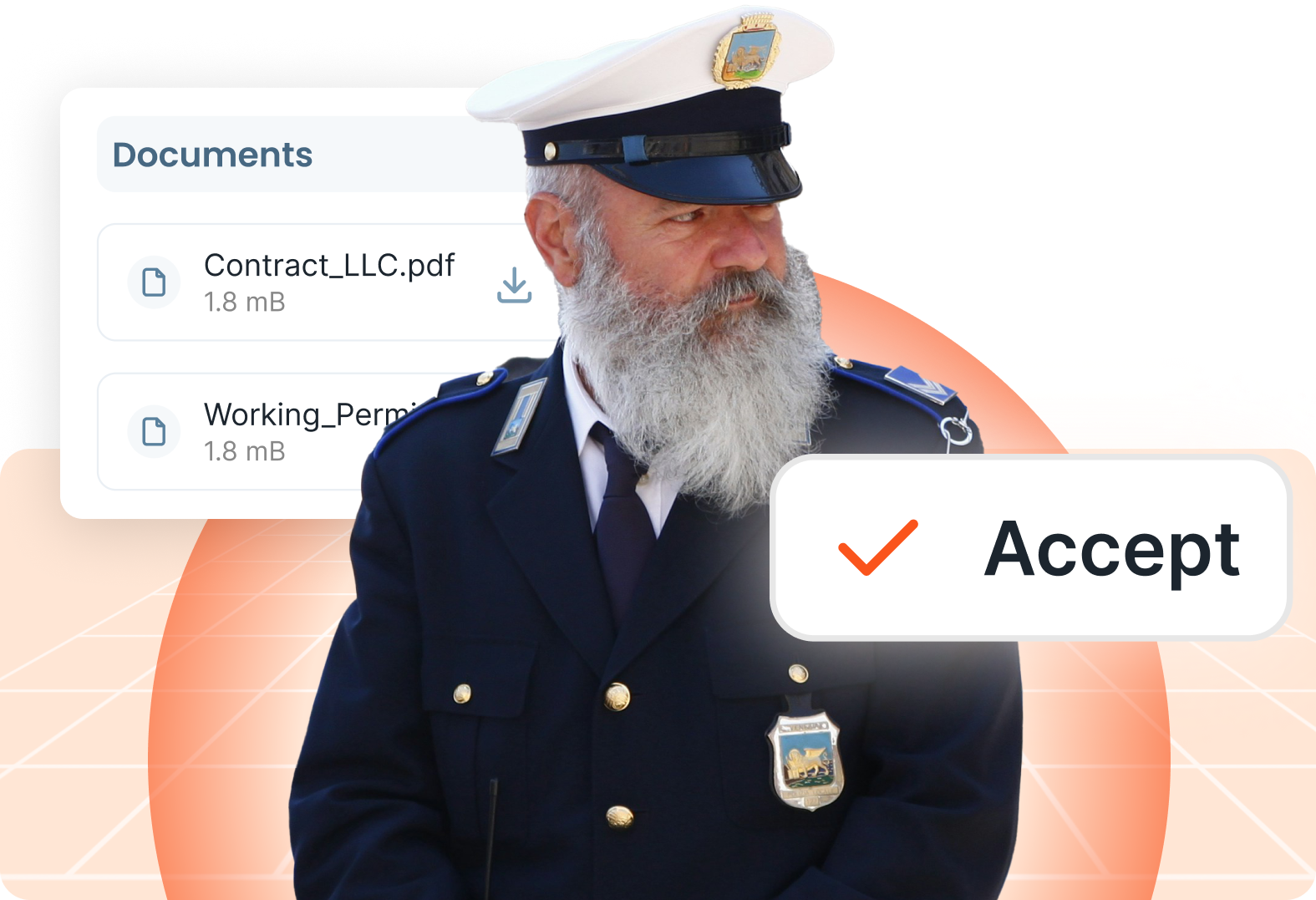

Finalizing the Work Order

Once all job tasks are completed, the technician sends the work order for approval. Before doing so, the app opens two signature fields:

- One for the client’s confirmation that the work was successfully completed,

- And one for the technician’s own signature.

This step is key for transparency and accountability. It ensures both sides formally acknowledge the task completion before any administrative closure.

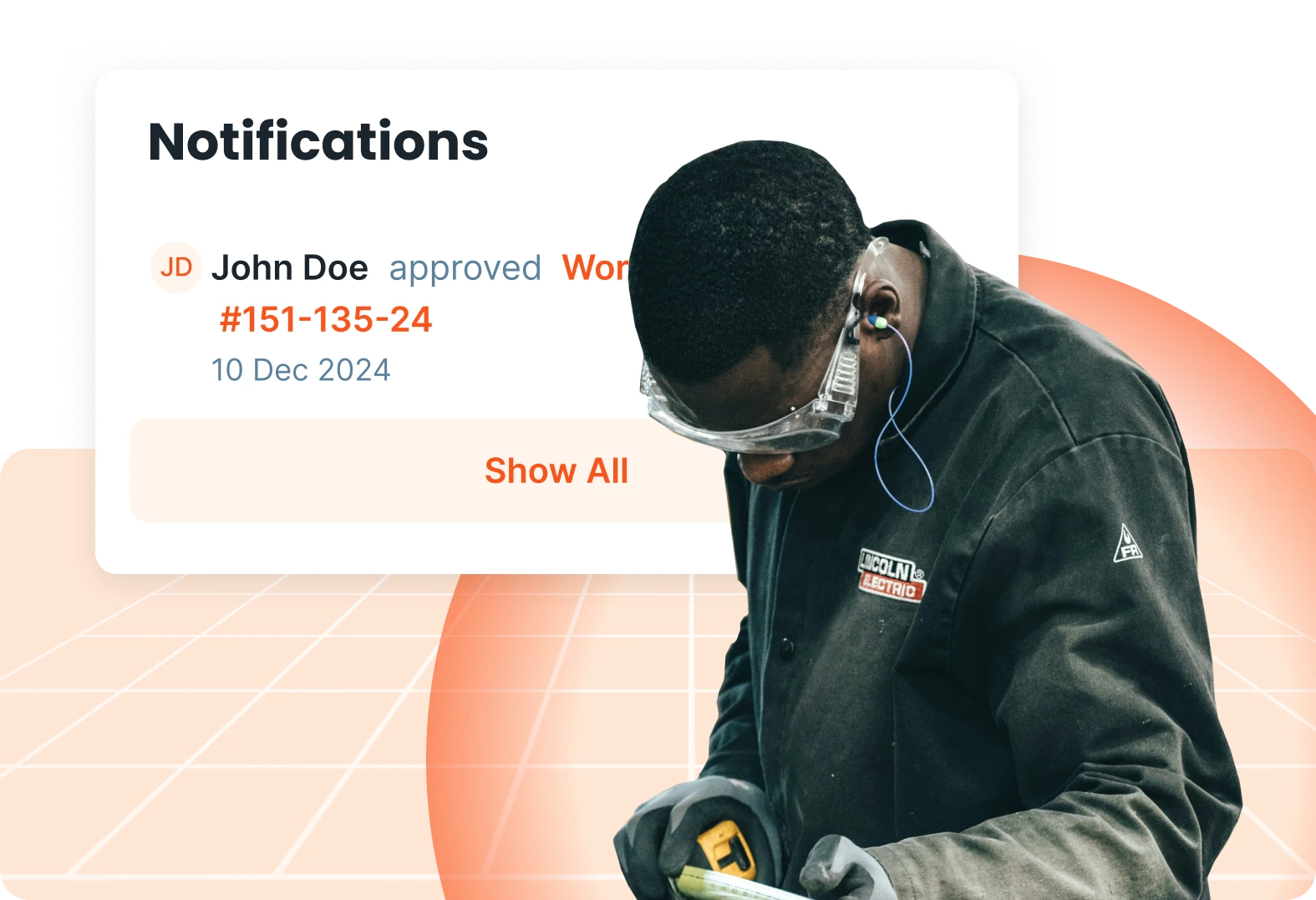

What Happens After Submission?

Once the technician sends in the work order for approval, it gets locked, no more changes allowed.

If something was missed, like forgetting to list materials, a manager can reopen it to make updates, but only when really needed. This helps keep the records clean and accurate.

Normally, the manager just reviews the order, adds any notes or feedback if needed and signs off. Once approved, the job’s officially marked as done.

Work Order Lifecycle Summary

Let’s summarize the full lifecycle of a work order in Serwizz:

- Backlog – The work order is created by a manager, but not yet started. It remains in this state until the technician begins work.

- In Progress – Once the technician submits the first Daily Report, the work order status moves to in progress. It stays in this state while the task is being executed—this could span several days.

- Ready for Approval – After completing all work, the technician collects the client’s signature and submits the order for approval.

- Done – The manager reviews the work, adds final comments if needed, and approves it. The work order status is now done.

This structured process helps ensure clarity, compliance, and control at every stage—from planning and execution to billing and documentation.

Conclusion

Work orders have always been part of how stuff gets done. They connect what’s planned with the actual job. But nowadays, paper work orders just don’t cut it. They’re kind of a pain: easy to lose, slow to fill out and not exactly great when you need to find info fast.

Going digital just makes more sense now. It’s way easier for everyone to stay on the same page: techs, managers, the customer. No more guessing what’s going on. Things move faster and there’s less ambiguity.

Take Serwizz, for example. It’s got stuff like support for different languages, safety checks built in, tracking for materials, and you can sign things digitally. Saves you time and headaches.

A good work order system gives your customers a better experience, helps them cut costs and gives them opportunity to grow.

At the end of the day, if your team’s got clarity, they’ll feel more confident. When they are confident, the job gets done better, and clients get happier.

Next Steps

👉 Learn more about Serwizz CMMS

👉 Book a demo or get started free