Maintenance

·

16 min read

What is MTBF?

To start with, MTBF or by its full name - Mean Time Between Failures is a quite important measurement in preventive maintenance.

If you’ve ever managed various devices or any kind of equipment, you probably faced the fact that there is no perfect system. As time goes on, machines might stop working, parts fail and unexpected downtime happens when you least want it, or expect it. This is where MTBF can help you and make your life easier.

MTBF measures how long (on average)a piece of equipment runs before it experiences a failure. Think of it as the “trust score” of your machinery: the higher the MTBF, the more reliable the system is likely to be.

It’s important to remember that MTBF will not predict the exact moment something will break. It will rather provide you with statistical data. With this data, you can optimize your maintenance process and operations. Additionally, you can make decisions with more confidence.

For better understanding, let’s take a look at one example. A ship’s main generator has an MTBF of 2,000 hours. Will it stop working after exactly 2000 hours? We don’t know that. But we know that around that time we should do the inspection, maybe replace the spare parts. We know that we have to allocate the team for that. That we have to order those spare parts. Now you see the way this leads?

MTBF should be your tool that helps businesses like yours save time, reduce costs and minimize unexpected downtime.

How to Calculate MTBF

Let's try to calculate MTFB. MTBF calculates the average time a piece of equipment runs before it fails. In formula form, it looks like this:

MTBF=Total Operational Time / Number of Failures

Going back to our ship example. During the last year, the main generator on a vessel has been running for a total of 10,000 hours. We’ve noticed it failed five times during that year. To calculate the MTBF, we divide the total operating hours by the number of failures:

MTBF=10000 hours / 5 failures=2,000 hours

So, on average, the generator runs for about 2,000 hours between failures.

A few things to keep in mind:

- MTBF gives you the average number, not the precise one. Some failures may occur sooner, while others may happen much later than the calculated MTBF. The number helps you plan and prepare.

- If you know your MTBF, you can schedule inspections, order spare parts and allocate the team on time.

- Good records are key. Accurate operational logs and failure reports make MTBF calculations meaningful. Without reliable data, the number becomes less useful.

- MTBF is like a weather forecast for your equipment. It doesn’t tell you the exact minute a storm will hit, but it tells you to pack your umbrella.

Common Problems and Challenges in MTBF Calculation

MTBF is a powerful tool, but like any other tool it is not perfect. Here are some common bumps in the road when using MTBF:

1. Failures aren’t always random.

MTBF works on the idea that failures happen randomly, but anyone who’s worked on a ship knows that’s rarely true. Sometimes a part just breaks down faster. Maybe the air is too salty or the engine has been working overtime. One engine might fail sooner than another just because it’s near a slightly leaky pipe. That means MTBF can only give you a rough idea — it’s a guide, not a guarantee.

2. Bad or incomplete data.

Pure MTBF is nothing, unless you store and keep data. You should keep track of when and why failure happened, and how often. If you skip some data, you will most likely get a wrong picture. Think of it like trying to figure out your average speed on a road trip when you forgot to start the odometer a few times. The number just won’t make sense.

3. Small sample sizes.

If a piece of equipment hasn’t been used much yet, calculating MTBF can be tricky. One early failure can make the MTBF look awful, even if the system is actually quite reliable. The more hours and failures you record, the more accurate the number becomes.

4. MTBF doesn’t account for human factors.

MTBF can not predict human factors. We’ve seen that sometimes the engineer forgets one step in installation or during the routine check. Despite that, MTBF is still there to help, by remaining us to keep good habits, teach a team and double check the work.

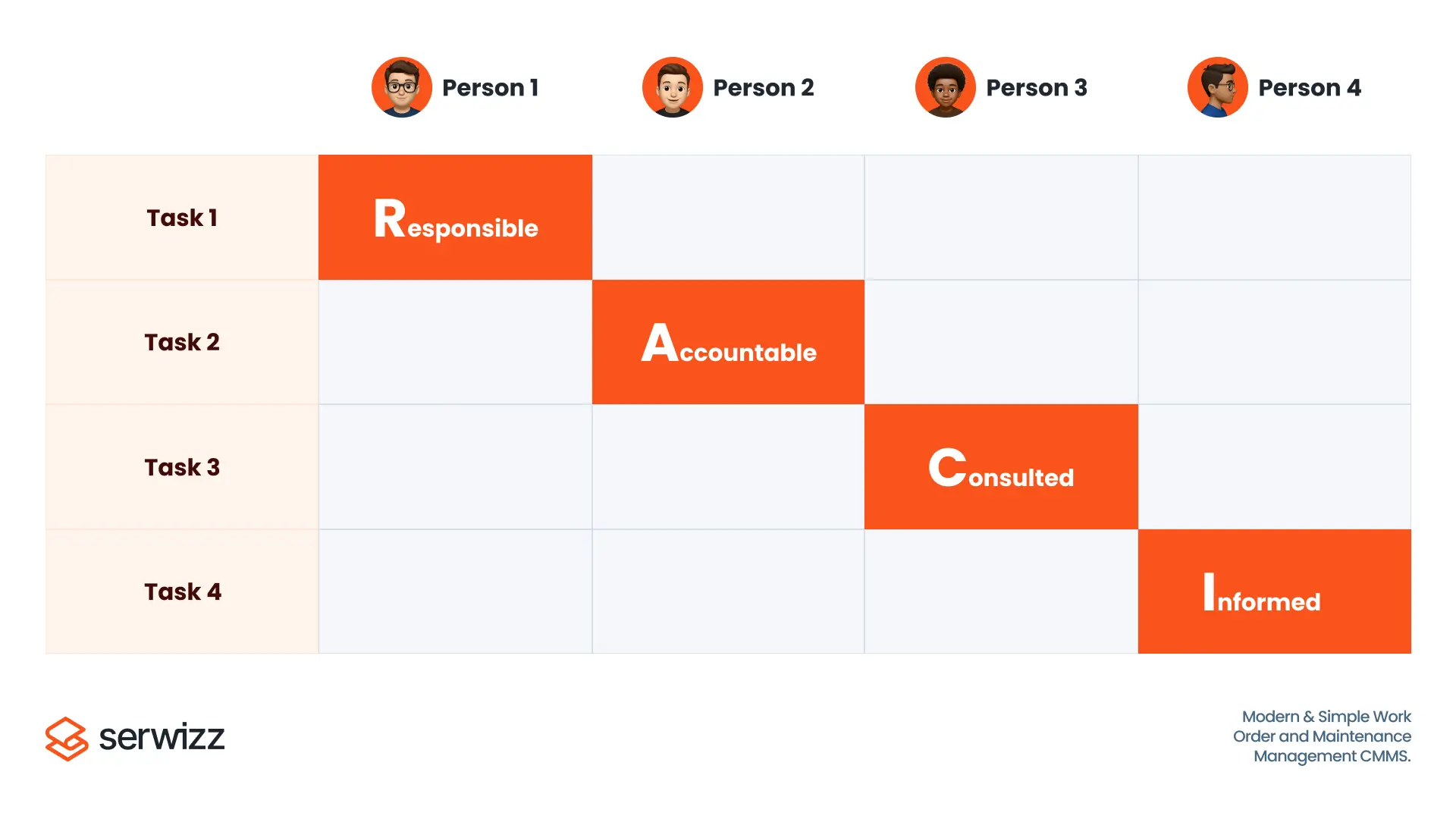

MTBF vs MTTF vs MTTR

If you are working in any maintenance intrustry, you know there are other terms, beside MTBF, such as MTTF and MTTR. We will now explain each of these and compere them for better understanding.

MTBF (Mean Time Between Failures)

This is the main topic of this blog. MTBF is just the average time your equipment runs before it needs a little care. It’s the number that helps you decide when to check in on it, when to stock spare parts and when to call the crew for maintenance.

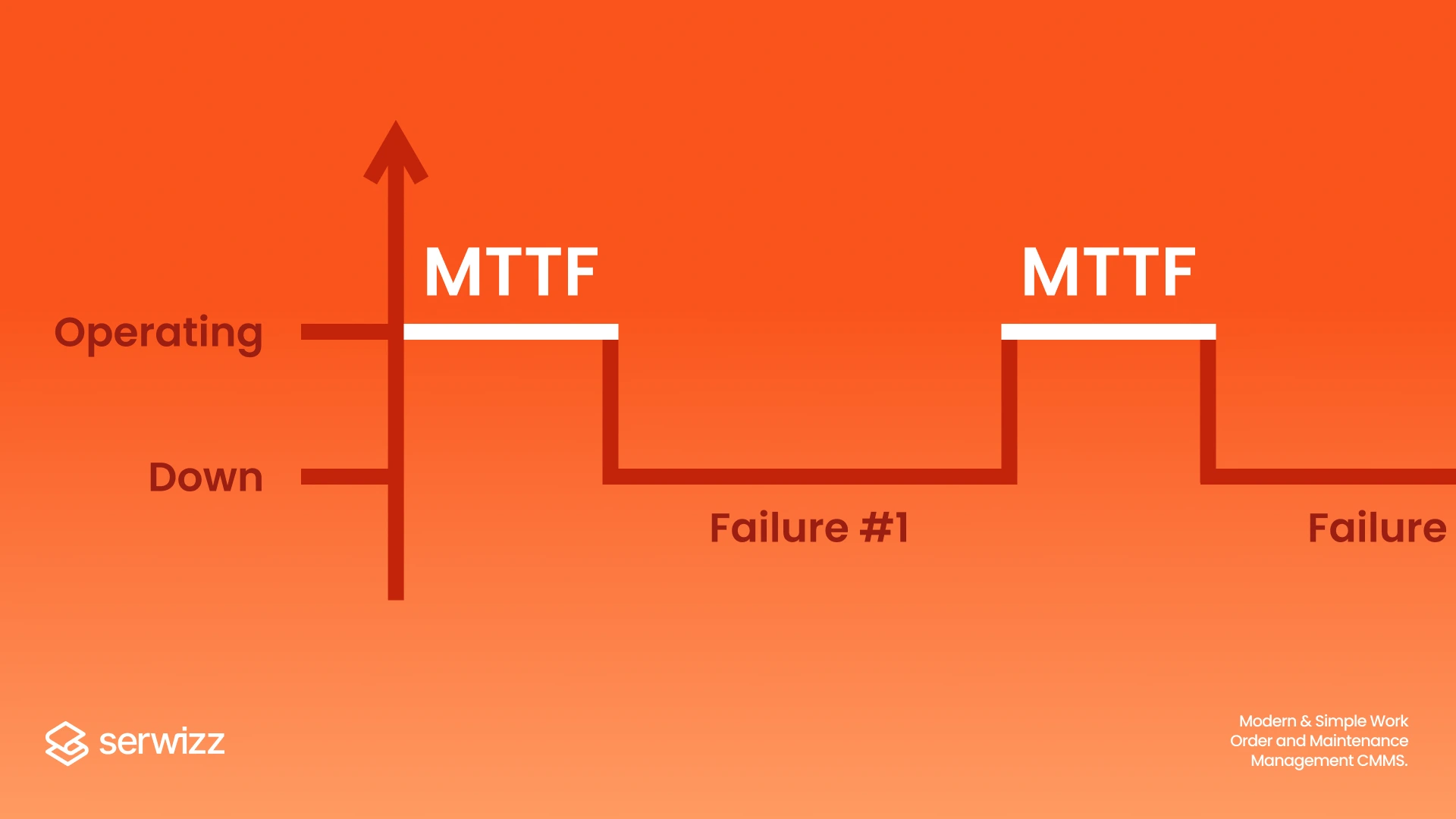

MTTF (Mean Time To Failure)

MTTF is close to MTBF but has a small difference. It usually applies to items you don’t repair, you replace them once they fail. Examples include cabin light bulbs or sensors. MTTF gives you an idea of how long these parts are expected to last before they give out.

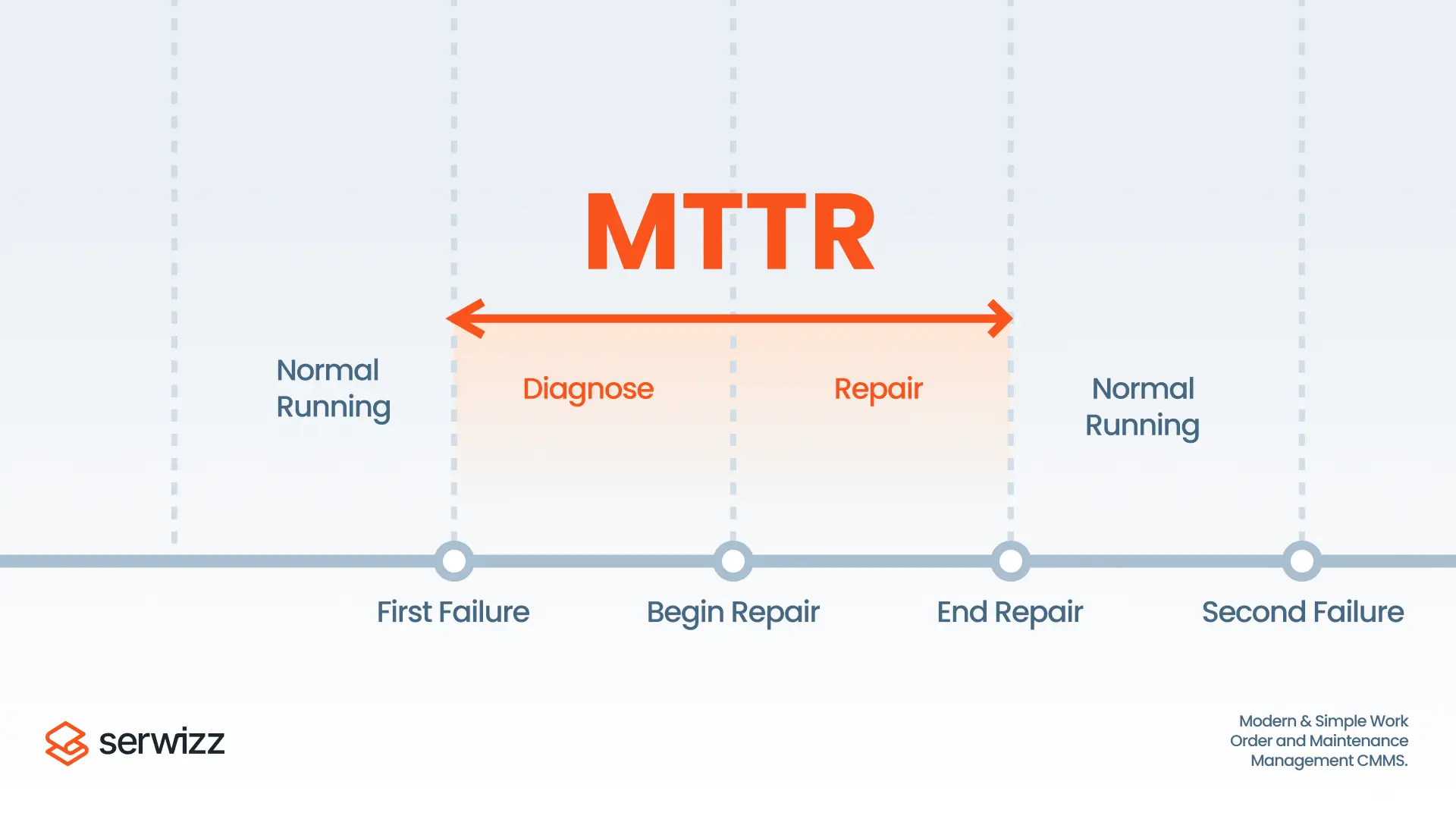

MTTR (Mean Time To Repair)

MTTR is simply about how long it takes you to get something running again once it breaks down. While MTBF and MTTF talk about how long equipment usually keeps going, MTTR looks at the downtime: the hours between “it stopped” and “it’s back in service.”

Picture this: the ship’s generator suddenly shuts down mid-voyage. MTTR that tells you how long the crew will likely spend troubleshooting, replacing parts and bringing it back to life. The exact time can vary but having an MTTR figure helps you plan ahead and avoid disruptions.

Quick Comparison Table

| Metric | What it Means | Typical Use | Marine Example |

|---|---|---|---|

| MTBF | Average time between failures | Repairable equipment | Ship’s main generator — average hours it runs before needing a repair |

| MTTF | Average time to failure | Non-repairable parts | Cabin light bulb or disposable sensor — expected lifespan before replacement |

| MTTR | Average time to repair | Any failed equipment | Time it takes the crew to fix the generator and get it running again |

To sum up: All these measurements together give you the full picture of reliability. MTBF and MTTF tell you how long things keep working, while MTTR tells you how long you’ll be stuck when they don’t.

Benefits of MTBF - main helper in Preventive Maintenance

MTBF real value comes when you start using it in your daily operations. This is not just a number, but a tool that can help you optimize business and save money.

1. Smarter Maintenance Planning

Preventive maintenance is basically giving your equipment some regular TLC. You check it, service it, and make sure everything’s in good shape so it doesn’t suddenly quit on you. If you know the MTBF, you will have a better idea when to do the service and inspection. .

2. Reducing Downtime

Breakdowns at sea are never fun. If you are regularly tracking your MTBF you will be prepared and probably avoid surprises. If your team is ready and spare parts are available, downtime should be increased, a lot.

3. Improving Reliability

Over time, MTBF shows you which equipment is strong and which isn’t. Maybe one type of pump keeps failing while another keeps humming along. Those numbers tell you where to invest, which suppliers to trust and where to be extra careful.

4. Managing Risk

MTBF data enhances broader risk assessment efforts. It provides concrete numbers to support risk analysis and decision-making. Risk managers can use MTBF to:

- Quantify the likelihood of equipment failures

- Estimate the financial impact of potential downtime

- Prioritize risk mitigation efforts

MTBF Example

Let’s make MTBF concrete with a simple example, and we will try to avoid formulas, for those who are not fans of numbers.

The cargo ship has a small pump that keeps the engine room dry and it prevents water damage. That pump has been running for 4800 hours during the last year. In that period it had issues 4 times. To calculate the MTBF, you should ask yourself: On average, how long does this pump run before it stops working?

In our case MTBF is 1200 hours. How did we got to this number? Divide the total number of hours 4800 by the number of failures 4.

How to use this number in the real world. Knowing MTBF is 1200 doesn’t mean your pump will stop after 1200 hours. Issue may occur after 900 or in better case after 1500 hours. Remember that MTBF number is a guideline that helps you plan maintenance tasks. With this knowledge, you can:

- Use preventive maintenance techniques to schedule inspections before the pump reaches its average failure time.

- Make sure spare parts are available.

- Assign your engineers to check and service the pump proactively, rather than reacting to emergencies.

Improving MTBF

MTBF calculations are useful, especially in preventive maintenance. However, you should strive to improve that number, because higher MTBF means your equipment will work longer. If equipment lasts longer, you will spend less money buying spare parts, and your team can focus on other tasks.

Steps to improve MTBF in practice

1. Stick to preventive maintenance

Use preventive maintenance, it’s your friend. Do regular check-ups such as oil changes, filter replacements. These scheduled tasks keep equipment lasting longer and they prevent small issues from turning into big ones.

2. Keep good records

Remember to track when issues happen - how often, and how did you fix it. Data is your friend here. If you don’t log these data, your MTBF numbers won’t mean much. Accurate records help you define patterns: maybe a certain supplier doesn’t last as long as the others.

3. Train and support the crew

Machines do stop working, but remember, that sometimes a huge factor is human error. You should educate your team - give them access to needed manuals. Also, set standard procedures and make sure the team is familiar with them.

4. Use quality parts and suppliers

This is also important. You may purchase cheaper parts, but in the end you might regret, as they will stop running earlier. Invest in quality parts, because you will increase the reliability and extends MTBF

5. Monitor operating conditions

Your machines do not work in perfect stereo conditions. They face polluted air, vibrations ect. You should monitor these conditions and adjust your operations. In that way you can prolong the life of equipment.

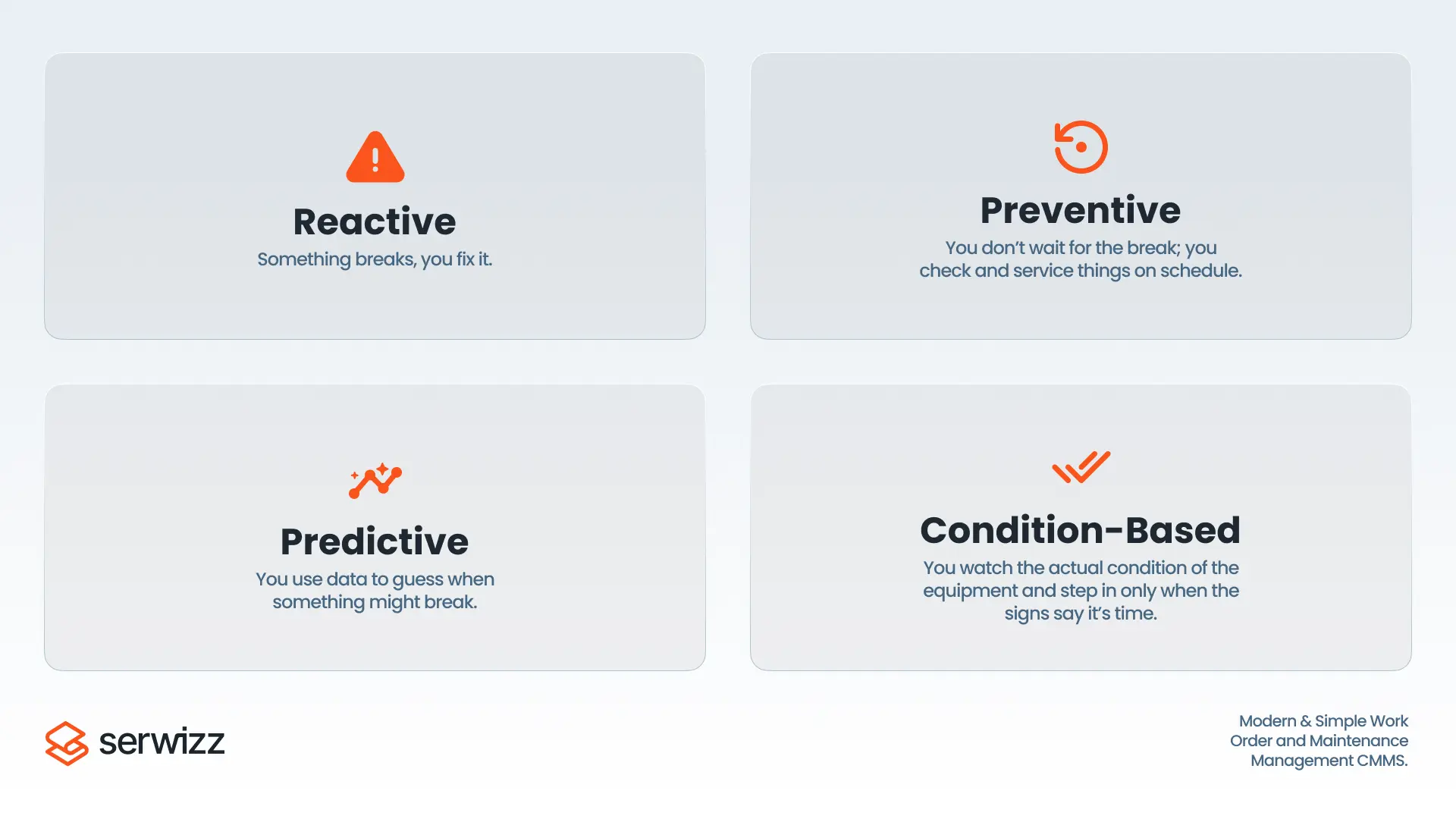

Preventive Maintenance Strategies

In theory, preventive maintenance tells us to check things before they break. In the real world it will need to include your team, proper planning and discipline. Preventive maintenance can help you to increase MTBF.

Here are a few strategies that work well:

1. Schedule around operating hours

MTBF can help you create maintenance plans. Use it to determine inspection or service date. By doing this, you are switching from reactive to proactive mode.

2. Use checklists for routine tasks

Each team member is dealing with a bunch of tasks and responsibilities. Due to that it’s easy to forget some steps. Use a checklist that you avoid missing steps.

3. Stock smart, not heavy

Using MTBF might lead you to another problem. Having each and every spare part ready in your warehouse. Having all the spare parts isn’t realistic. Rather focus on having critical spare parts ready, or those who are hard to get. In that way, you will maintain your warehouse clean and reduce the costs.

4. Rotate crew in inspections

If you do the same tasks over and over, you might do it on autopilot mode. That could lead to human error. Plus, you heavily depend on one person. Try to rotate responsibility so more people are trained. This also ensures coverage if someone is unavailable.

5. Track and adjust

MTBF numbers are not set in stone. Review them and adjust if needed, based on new data.

Future Trends in MTBF Analysis

MTBF is evolving. In today's world, it is not just a number and formula. Usage of technology is making it more useful.

1. Real-time monitoring

Sensors and connected devices can track equipment in real time. They spot early signs of problems, so you can react before equipment stops working.

2. Predictive maintenance powered by AI

AI will play an important role in MTBF analysis. Instead of your team doing analysis, they can use AI to predict when the equipment will stop working. It’s still important that your team collects historical data and other conditions. MTBF and AI can bring preventive maintenance to the next level. You act only when it’s needed, rather than following a schedule.

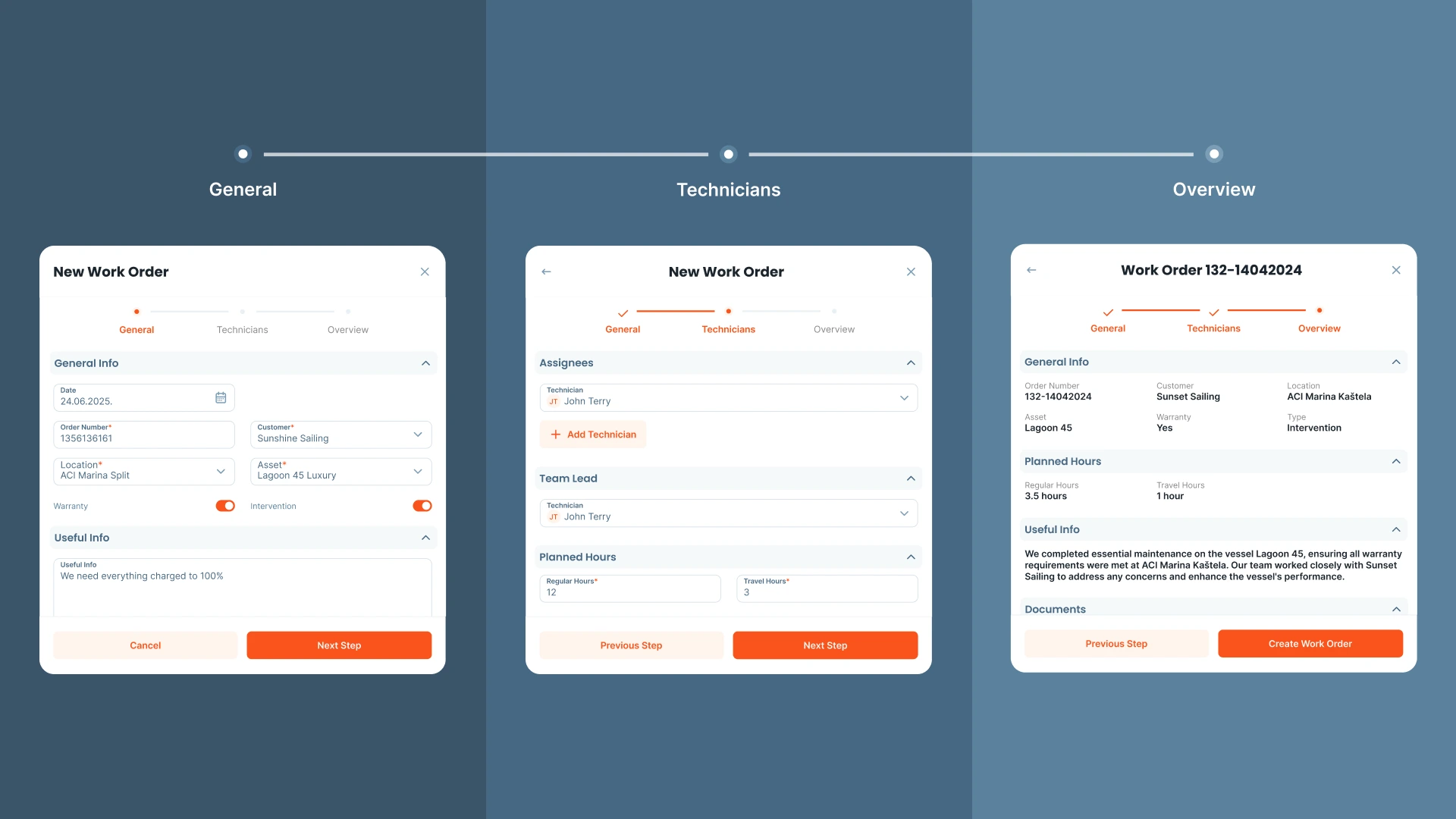

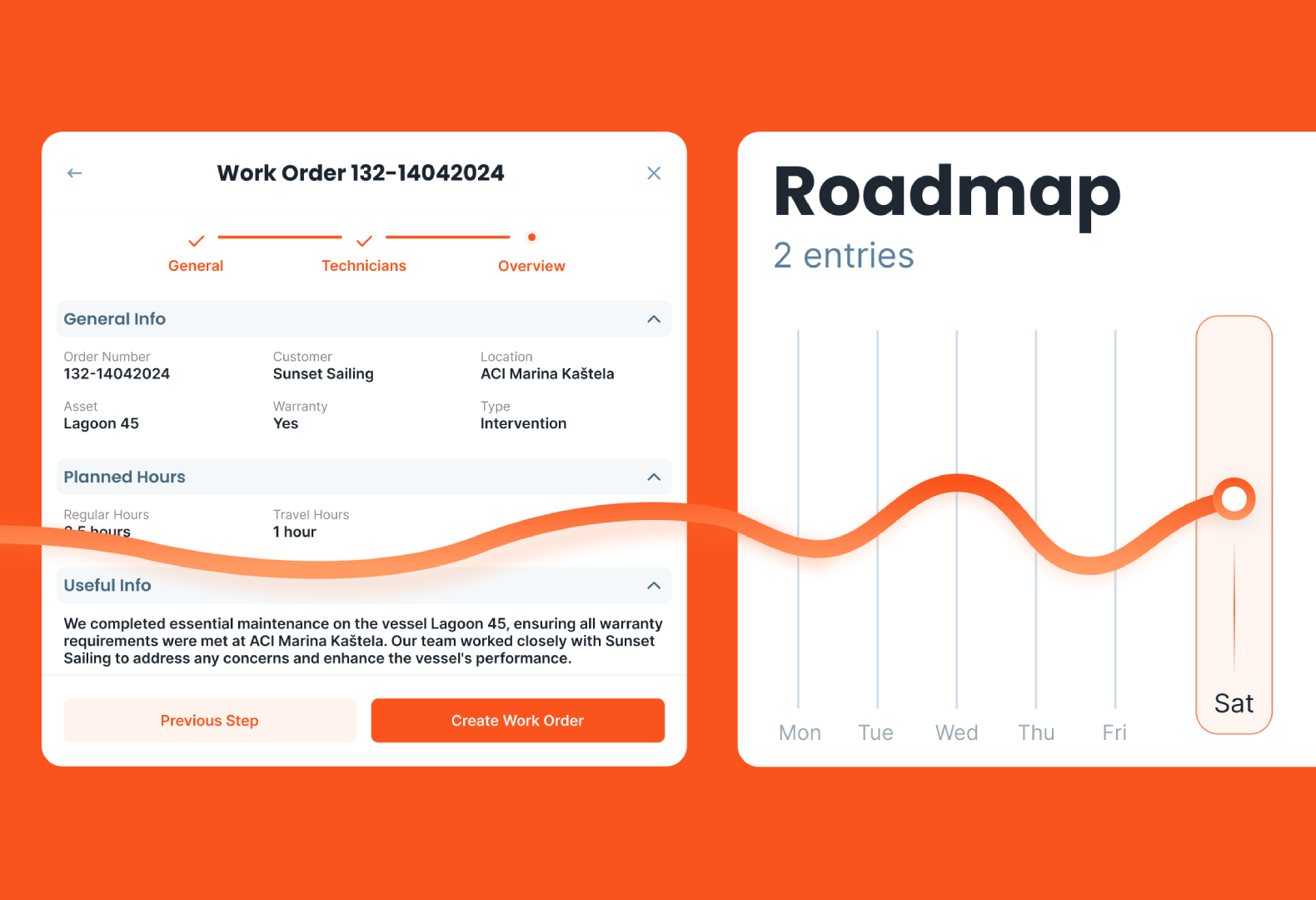

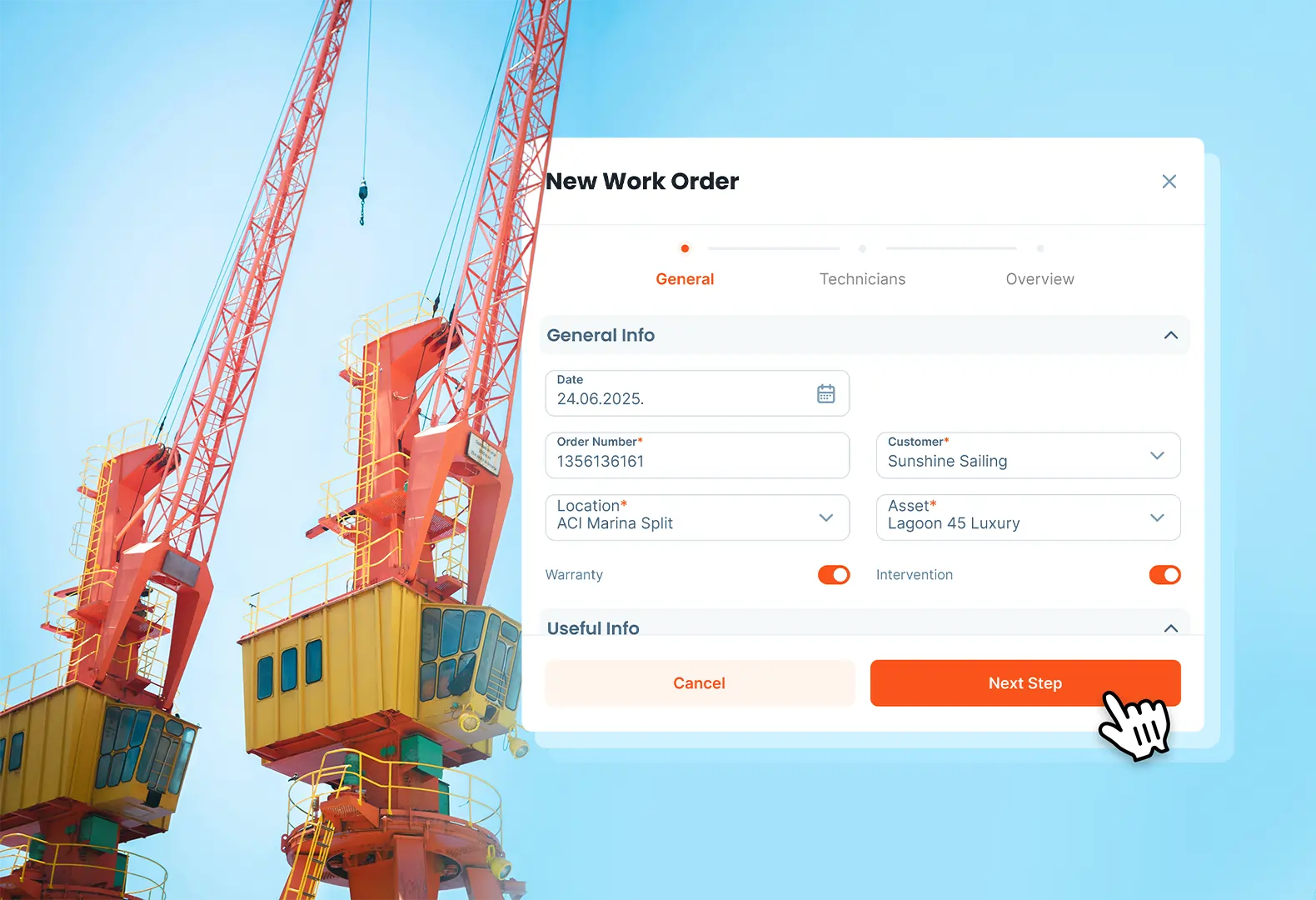

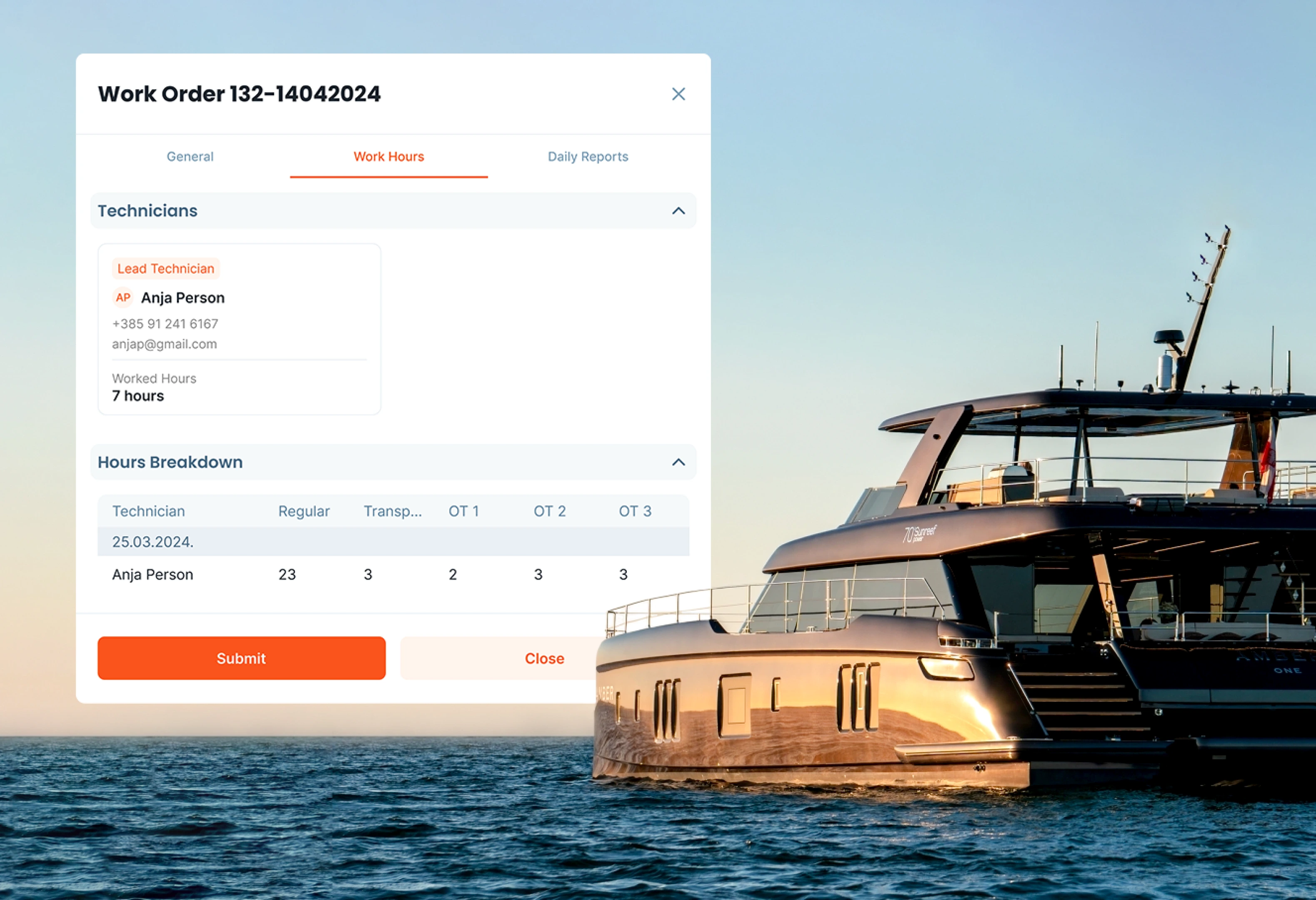

3. Smarter software tools

With digital transformation, we have more and more tools that combine MTBF, MTTR and MTTF values, to give you the full picture. AI can help you identify patterns that we as humans might not be aware of.

4. Data-driven decision making

Data analysis is getting better with AI. With better data you can make better decisions such as when to buy spare parts or when to schedule a maintenance.

Conclusion

MTBF is your little helper in making plans. It doesn’t tell you exactly when something will break, but it shows you where bumps might appear on the road. With that knowledge you can plan inspections, schedule maintenance and have spare parts ready.

Combine MTBF with preventive maintenance, a well organized team and well organised data and you will have one powerful tool to plan your work. On top of that, use modern technology tools such as Serwizz and AI and you are completely in proactive mode, rather than reactive.

The takeaway? MTBF isn’t about perfect predictions. It’s about staying one step ahead, reducing surprises and keeping business smooth.