Maintenance

·

21 min read

What is MTTF?

Introduction: Why reliability metrics matter in maintenance

If you are coming from an industry that deals with machines or any kind of equipment, you are probably aware that sooner or later the component will stop working. The idea is not to prevent failures, because that is obviously impossible, but rather to understand when failures happen. We would like to know if there is any pattern or frequency when failure occurs. That’s why we use reliability metrics.

Metrics like MTBF (Mean Time Between Failures), MTTR (Mean Time to Repair) and MTTF (Mean Time to Failure) help you deal with failures. They provided you enough info to calculate when failure might occur, and help you create maintenance plans, schedule interventions and reduce the downtime.

If you’ve read our earlier article on MTBF, you already know how valuable it is to measure these things. However, MTBF is not always applicable, as some assets and equipment can not be fixed. Examples include light bulbs or batteries. In short, once they stop working, they are done. That’s why for those assets we use MTTF.

In this blog we will explain what MTTF means and show you the difference between other measures. We will explain how to calculate it and how to use it in everyday work. We’ll also look at how modern CMMS software (like Serwizz) can help you track MTTF more easily and make smarter decisions for your business.

Once you read the blog, you’ll have a clear picture of how MTTF works and how to use it as a tool, especially in the maintenance world.

What is Mean Time to Failure (MTTF)?

Mean Time to Failure (MTTF) is a quite important measurement in preventive maintenance. It tells you the average expected lifetime equipment that can not be repaired, before it fails. To compare, MTBF is more applicable on components that can be, and should be repaired. MTTF examples include light bulbs, batteries, fuses or certain electronic components.

The main idea behind MTTF is to predict the lifespan. Once you know approximately when something might stop working, you can organize the team and ensure you have the spare parts in the warehouse ready. So similar to MTBF, you are taking a proactive approach and you prepare your team for failure, before it even happens.

It’s important to emphasize that MTTF can not determinate the exact moment when the asset will stop working. It’s a statistic number that can give you good enough estimate to plan your work. For example, if you test 100 light bulbs and record the time until each ones stops working, the MTTF is the average lifespan of those bulbs. Some may fail earlier, some late and the MTTF gives you a good enough benchmark.

In the real world, by using this benchmark, you help businesses reduce costs by ordering spare parts on time, avoiding rush shipping and preventing downtime. You can also improve the quality of your equipment because this measure helps you reveal poor-quality components.

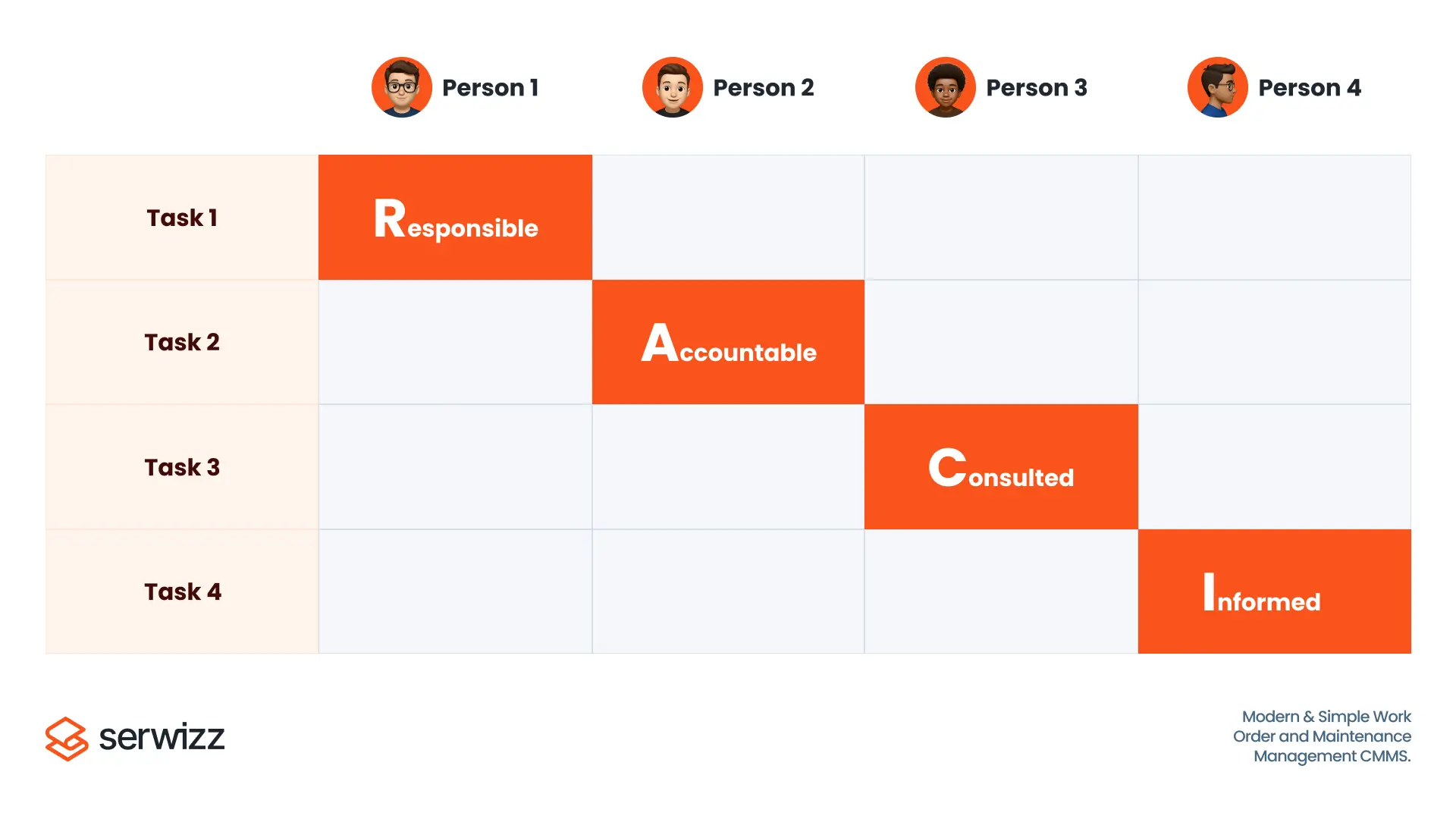

MTTF vs. MTBF vs. MTTR – Clearing the confusion

If you’re new to maintenance metrics, these three acronyms (MTTF, MTBF and MTTR) can confuse you. All of these metrics can help you with equipment that stopped working, but each metric has its own specifics. Understanding the differences is key to using them correctly.

MTTF (Mean Time to Failure)

MTTF, the main topic of this blog, is used for components that can not be repaired. It will tell you the average time when the asset will stop working and after that it can not be fixed. Use MTTF when dealing with items like light bulbs, batteries or electronic chips. Once they stop working, you will have to replace them.

MTBF (Mean Time Between Failures)

MTBF, that we covered in our previous blog, is forced on components that can be repaired. It will tell you the average time when the assed will stop working, but after that you can repair it. It assumes that equipment will be fixed and returned to work. For example, a production machine that breaks down occasionally, but can be repaired and put back to work, could be measured with MTBF.

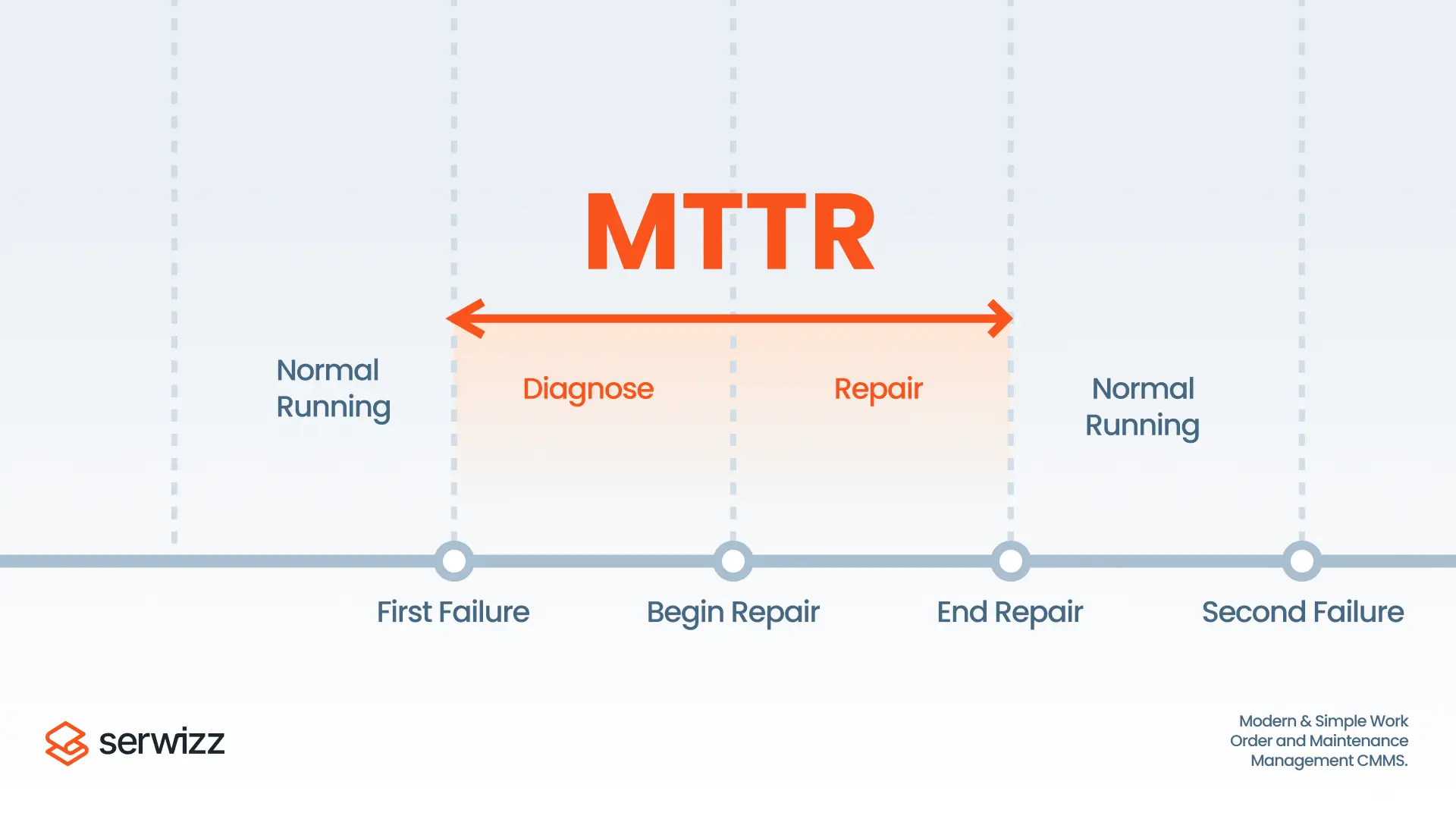

MTTR (Mean Time to Repair)

MTTR is different from the other two. It’s more connected to MTBF; as it will tell you how long it would take to repair the equipment that has stopped working. MTTR helps you understand how quickly your maintenance team can fix the issue.

Why it matters

Using the wrong metric can lead to poor decisions. If you use MTBF for a light bulb it will make no sense, as the bulb can not be repaired after it stops working. Also, if you ignore MTTR, you might wrongly allocate your team.

Quick example:

A vessel motor lasts 1000 hours before it stops working. It can be repaired in 5 hours and then after another 1000 hours it will stop working.

- MTBF = 1,000 hours

- MTTR = 5 hours

A batch of 100 batteries lasts an average of 800 hours before they stop working.

- MTTF = 800 hours

By understanding the differences, you can choose the right metric for the right asset, plan maintenance more accurately, and optimize costs.

| Metric | Applies To | Measures | Key Takeaway | Example |

|---|---|---|---|---|

| MTTF | Non-repairable components | Average time until failure | Predict lifespan for replacements | Light bulbs, batteries |

| MTBF | Repairable equipment | Average time between failures | Plan maintenance and reduce downtime | Conveyor motors, machines |

| MTTR | Repairable equipment | Average time to repair | Understand repair efficiency and team response | Time to fix a broken machine |

Why is tracking MTTF important?

You should treat MTTF like it is more than just a number. Why? Because it gives you details about lifespan of components that can not be repaired and reliability insights. By knowing and using this information, you can save time and money and optimise your team utilization.

1. Proactive maintenance planning

Once you know the average lifetime of your component, you can plan replacement before it stops working. This is crucial for important parts, such as medicine equipment, where failure can cost someone's life. MTTF allows you to plan ahead instead of reacting to issue.

2. Cost reduction

If your equipment stops working when you don’t expect it, that can cost you a lot. You need to allocate the team asap, order the parts that stopped working, maybe pay more for faster shipping. If you use MTTF as a benchmark, you can ensure you have the right parts available in the warehouse.

3. Improved asset quality

Monitoring MTTF can also help you detect poor-quality components. If your equipment stops working before the expected time, it can indicate supplier problems, so you might switch to a more reliable one.

4. Enhanced reliability and safety

For some industries, having stable equipment is crucial. Ie. in medicine, if equipment stops working, it is not just a money problem, but also safety. Tracking MTTF ensures that risky components are replaced before they stop working, improving safety and reliability.

5. Better decision-making

MTTF helps you make business decisions based on data, rather than gut feeling. You can make maintenance plans and schedule, order spare parts and decide about your team allocation by reading this statistical data.

How to calculate MTTF

Calculating MTTF is quite simple.You are looking for statistical average lives of components that can not be replaced. Once you have that number, you can use it to plan maintenance, create schedules and order spare parts.

The basic formula

The general formula for MTTF is:

MTTF=Total operational time of all units / Number of failures

To simplify, you sum up the total hours all assets have worked before they’ve stopped working. Then divide that by the number of assets that stopped working.

Example:

Imagine you have 5 batteries that fail after the following hours: 700, 800, 900, 850, and 750.

-

Add all the the working time together:

700 + 800 + 900 + 850 + 750 = 4,000 hours -

Divide by the number of units (5):

4,000 ÷ 5 = 800 hours

So, the MTTF for these batteries is 800 hours.

Important points to keep in mind:

- MTTF is only for non-repairable components. Don’t try to use it for machines that you repair after failure.

- It’s an average, not a guarantee. Some items may fail earlier, some later.

- The more units you test, the more reliable your MTTF calculation will be.

MTTF calculation example

Now that we showed you the formula, let’s assess one example, for better understanding. We will show you a real life example where MTTF helped one maintenance team in planning.

Example scenario: industrial fans

We recently worked with a company that had 50 cooling fans in their facility. Thing was, once the fan stopped forking, it could not be repaired. Each fan had to be replaced. In order to calculate the reliability, the company measured the lifespan of 10 fans. Based on the data they took corrective actions and adjusted their planning.

Here’s the data you collected from 10 fans that stopped working:

| Item name | Working time in hours |

|---|---|

| Fan 1 | 28 000 |

| Fan 2 | 31 000 |

| Fan 3 | 29 500 |

| Fan 4 | 30 000 |

| Fan 5 | 32 500 |

| Fan 6 | 29 000 |

| Fan 7 | 30 500 |

| Fan 8 | 31 200 |

| Fan 9 | 28 800 |

| Fan 10 | 30 200 |

- Sum all the working times in hours, and you will get number: 300 700 hours

- The number of failures is 10.

- Divide that sum by the number of failures: 300 700 / 10 = 30 070 hours

- The result was 30 700. That is your MTTF for fans.

What does this mean in practice?

Each fan will work on average for approximately 30 070 hours, before it stops working. If we re-calculate that in years, that is about 3.5 years of non-stop working. Based on this information you can do the following:

- Schedule replacements after 3 years to avoid downtime.

- Ensure you have a spare fan in warehouse in advance

- Compare your MTTF with manufacturer’s data, to see if the quality is as good as promised.

This example shows how a simple calculation can help you in everyday decisions. With MTTF data, there is no more guessing, rather proactive work.

Practical applications of MTTF in maintenance

So we have shown you how to calculate the MTTF, but I guess you are wondering how to use it in your everyday maintenance work? Knowing the formula is nice to have, but the real work is applying that knowledge.

Some of the most common applications of MTTF in maintenance:

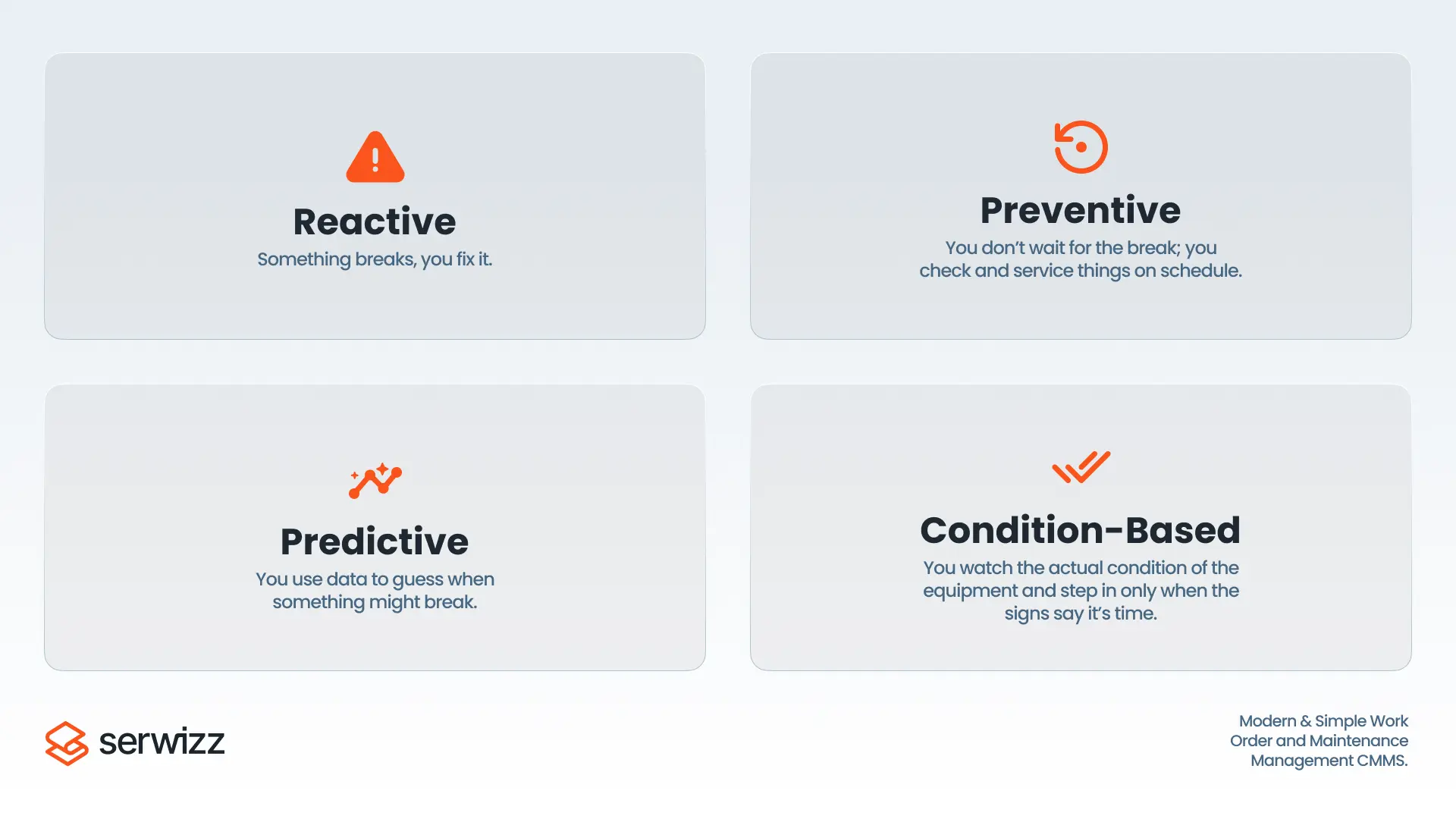

1. Preventive maintenance scheduling

If you know your MTTF, you know when to expect your equipment to stop working. That helps you schedule preventive maintenance. You assign the team to replace the parts before they stop working.

2. Predictive maintenance strategies

MTTF can be used together with sensors. If you know your MTTF and if your device starts making strange noises or has a higher temperature, that could be an indication of an end. You can then compare actual data with the expected MTTF to predict the optimal replacement time.

3. Spare parts inventory management

One common problem with predictive maintenance is having spare parts ready in the warehouse. If you have too many spare parts, you are wasting the space and the money. If you don’t have spare parts, you can have a problem once equipment stops working. MTTF helps you find the balance. If you know when some equipment will stop working, you can order spare parts on time.

4. Procurement and vendor evaluation

As said before, MTTF can help you verify if the equipment is working as long as promised by the supplier. If your equipment stops working before MTTF indicates, you might have a problem with the quality of that vendor.

5. Asset lifecycle planning

MTTF can help you decide if you will replace or repair the equipment. If you understand the average lifespan of components, you can make better investment decisions.

6. Risk management and safety

In some industries like medicine or aviation, equipment that stops working can cost someone’s life. If you use MTTF, you can reduce the risk and make sure that equipment is always up and running.

Limitations of MTTF as a metric

Like any other tool, MTTF has its own limitations. MTTF is just one piece of a puzzle that helps you make the decisions.

Here are some of the main limitations you should keep in mind:

1. It’s an average, not a guarantee

MTTF number tells you the average time that equipment will stop working. In short, some components might stop earlier, some will work longer. The truth is, that no one can tell you the exact moment something will stop working.

2. Doesn’t apply to repairable equipment

MTTF is not applicable for all the components. It’s applicable for components that can not be repaired. For components that can be repaired, use MTBF. If you mix up these two values, you might end up with wrong plans.

3. Testing conditions may differ from real life

MTTF is often calculated in perfect conditions. However in real life equipment might face high temperatures, dust or humidity. Those conditions might affect MTTF and make it lower.

4. Doesn’t capture the cost of failure

MTTF can be the same for two components, but the impact if they both stop working is not the same. In example, if your light bulb stops working after 500 hours, that’s not an issue. You will replace it and move on. If your crucial machine stops working after 500 hours, that is a problem, as costs of replacement are high. MTTF doesn’t calculate the cost factor.

5. Needs a large enough dataset

MTTF is the better, the more failures you have. So it can be tricky to calculate it with expensive components or those that work for a long time. If you only have one or two failures, the result won’t be accurate.

6. Doesn’t predict how something will fail

MTTF tells you when a component might stop working, but it doesn’t tell you how. Ie will it overhead or have electrical error. For deeper analysis, you need other tools like Failure Mode and Effects Analysis (FMEA).

How to improve MTTF in your organization

MTTF will tell you for how long your components that can not be repaired work. But don't worry, there are some steps you can do to prolong their life.

Ways to improve MTTF:

1. Use higher quality parts

In manufacturing, cheaper often means lower quality. Invest in quality (but maybe expensive parts). They will most likely last longer and save your money long-term.

2. Optimize operating conditions

Some environmental factors might affect your MTTF, such as heat, dust and humidity. Do small improvements, by keeping lower temperature and equipment clean, and you can extend the life of your components. That also means higher MTTF.

3. Perform regular inspections

Use the power of preventive maintenance. Schedule regular inspections and detect the issues early, before they happen.

4. Train your staff

It’s important to educate your team. If they know how to handle the components and keep them clean in good conditions, they will prolong the life of equipment, and make sure that MTTF is higher.

5. Use data to refine replacement schedules

If you manage to have enough data, you can have a solid base for preventive maintenance schedules. You don’t need to check the manufacturer data, but you can rather rely on your own data.

6. Work with reliable vendors

If your MTTF is higher than the manufacturer indicates, you are lucky. You have a good vendor. In case your equipment stops working before the MTTF suggests, you might consider a vendor switch.

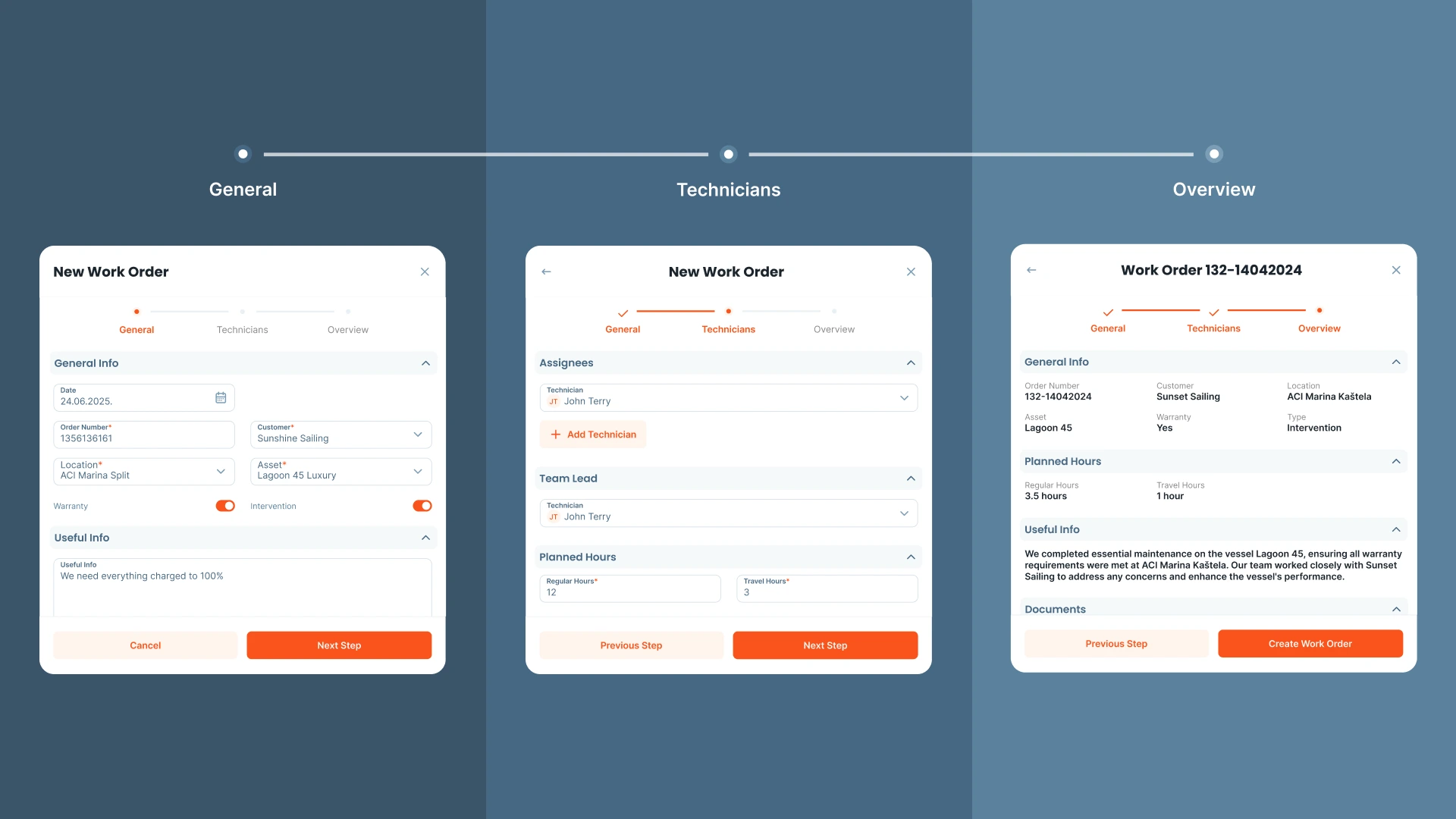

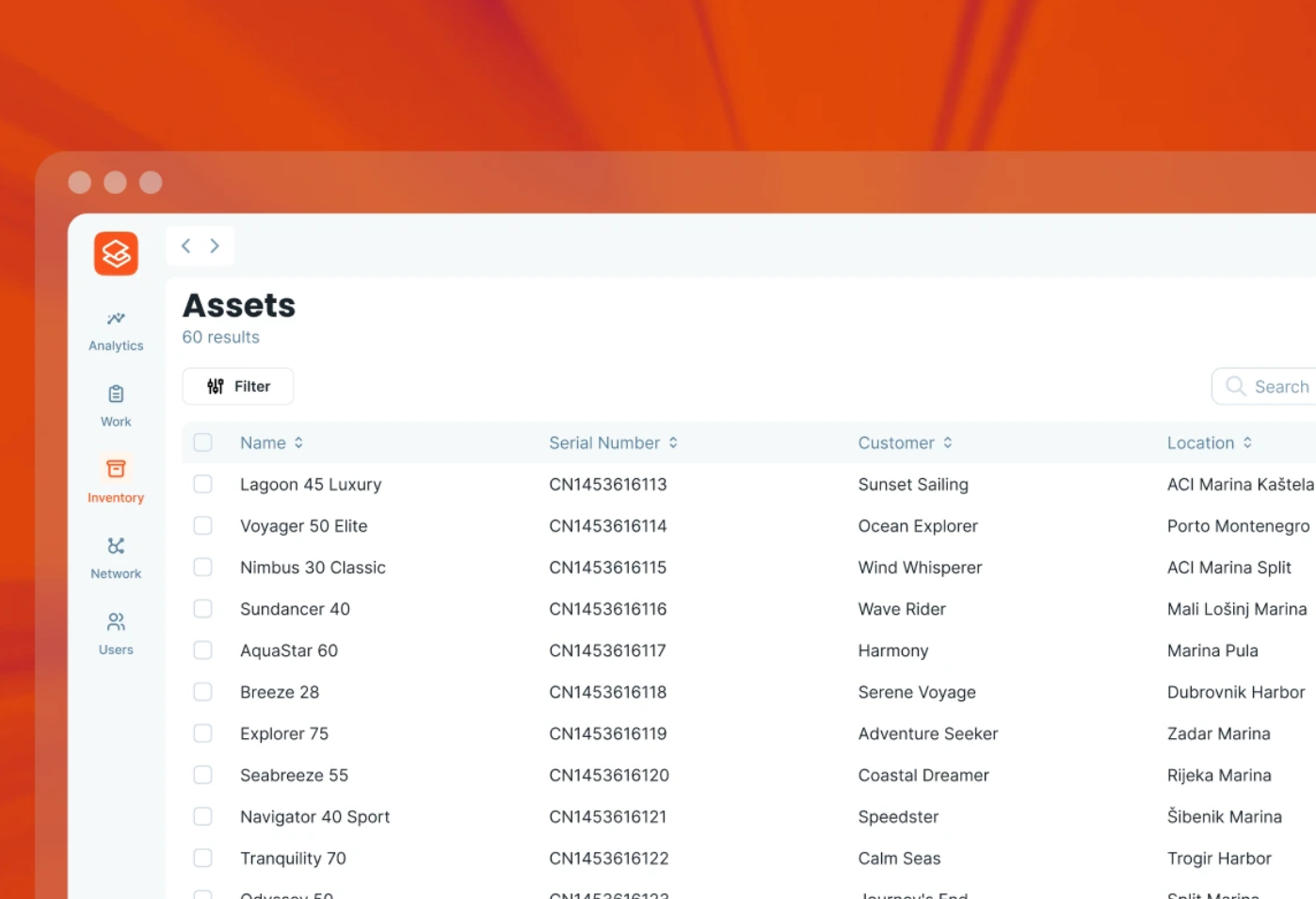

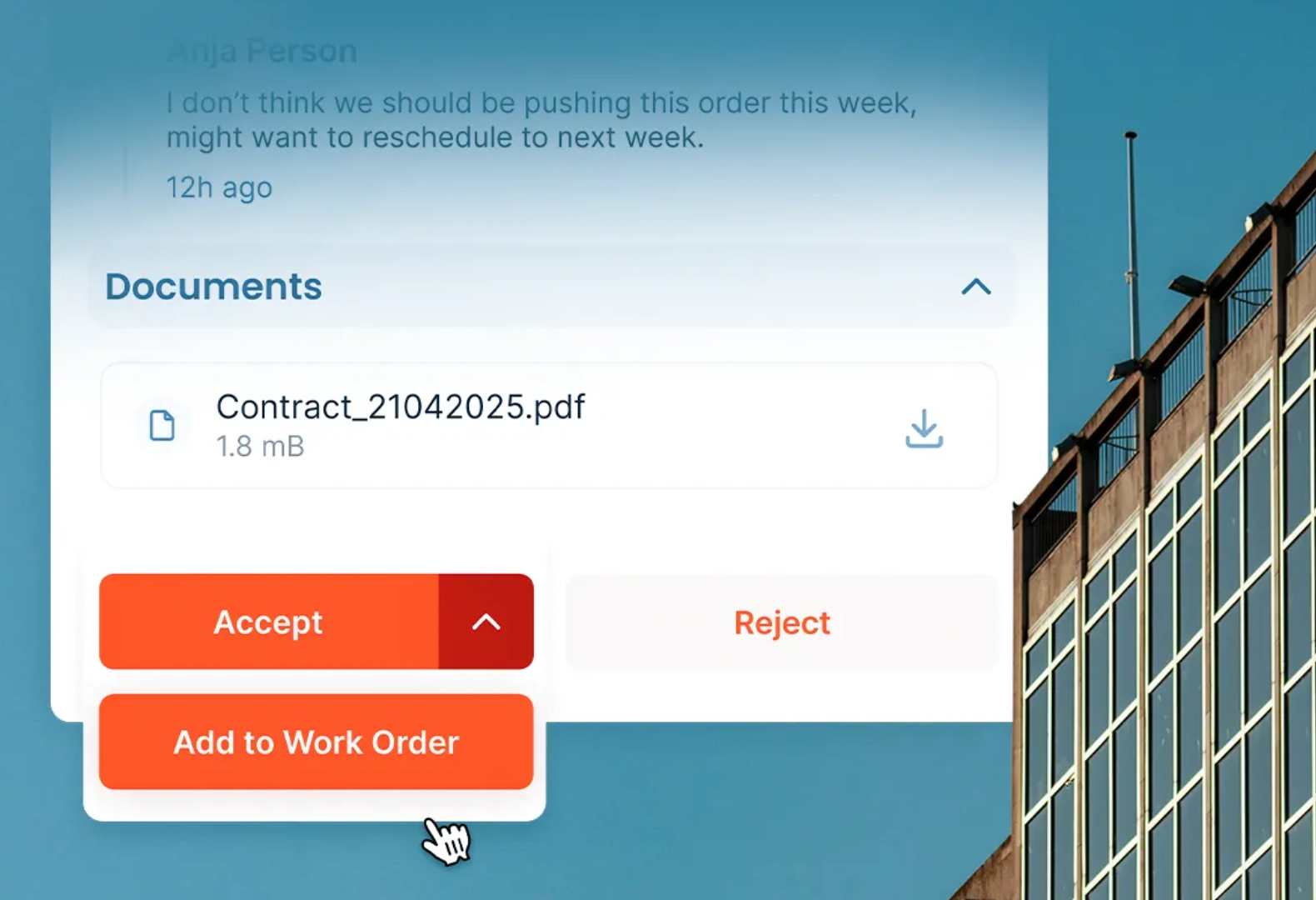

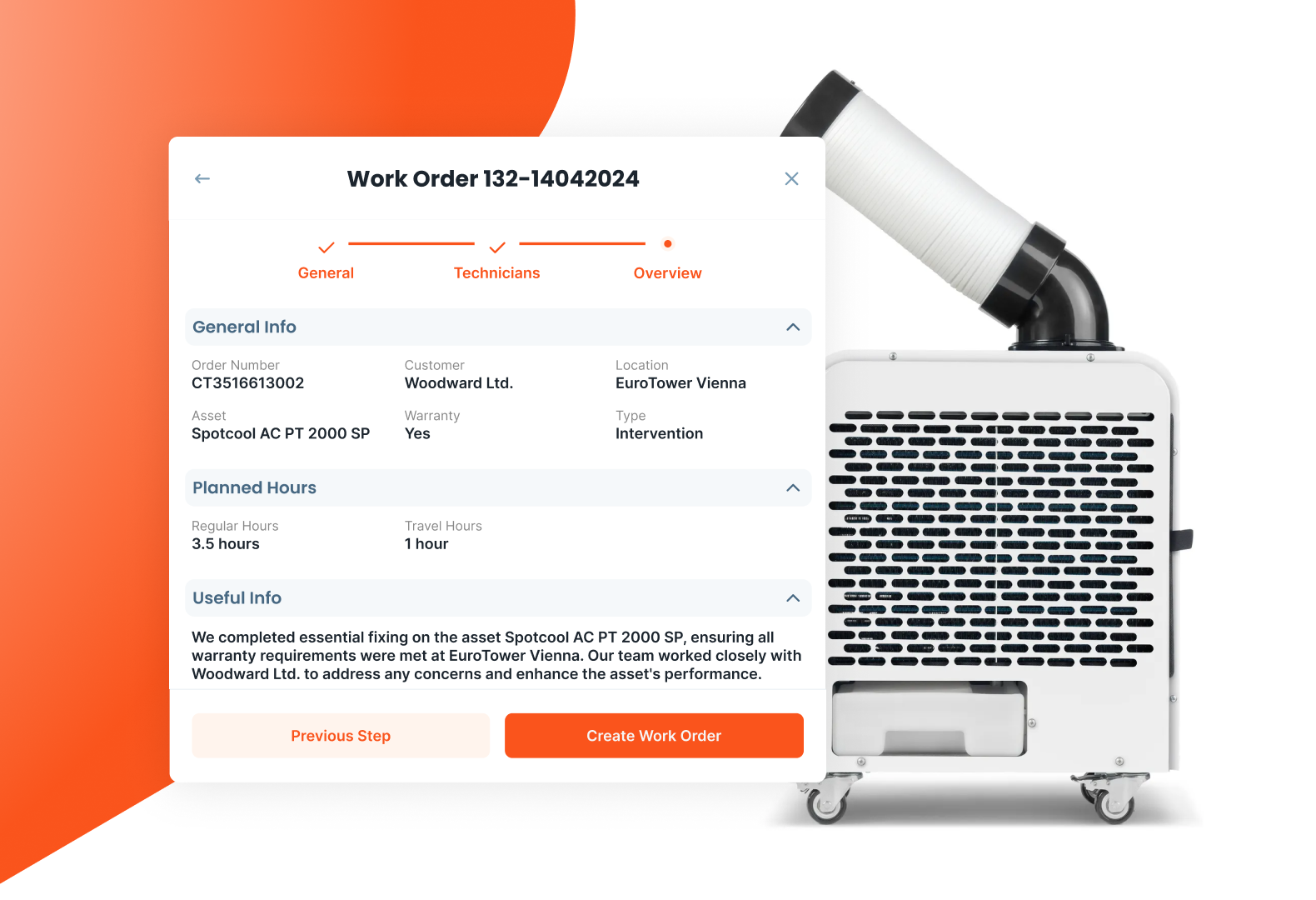

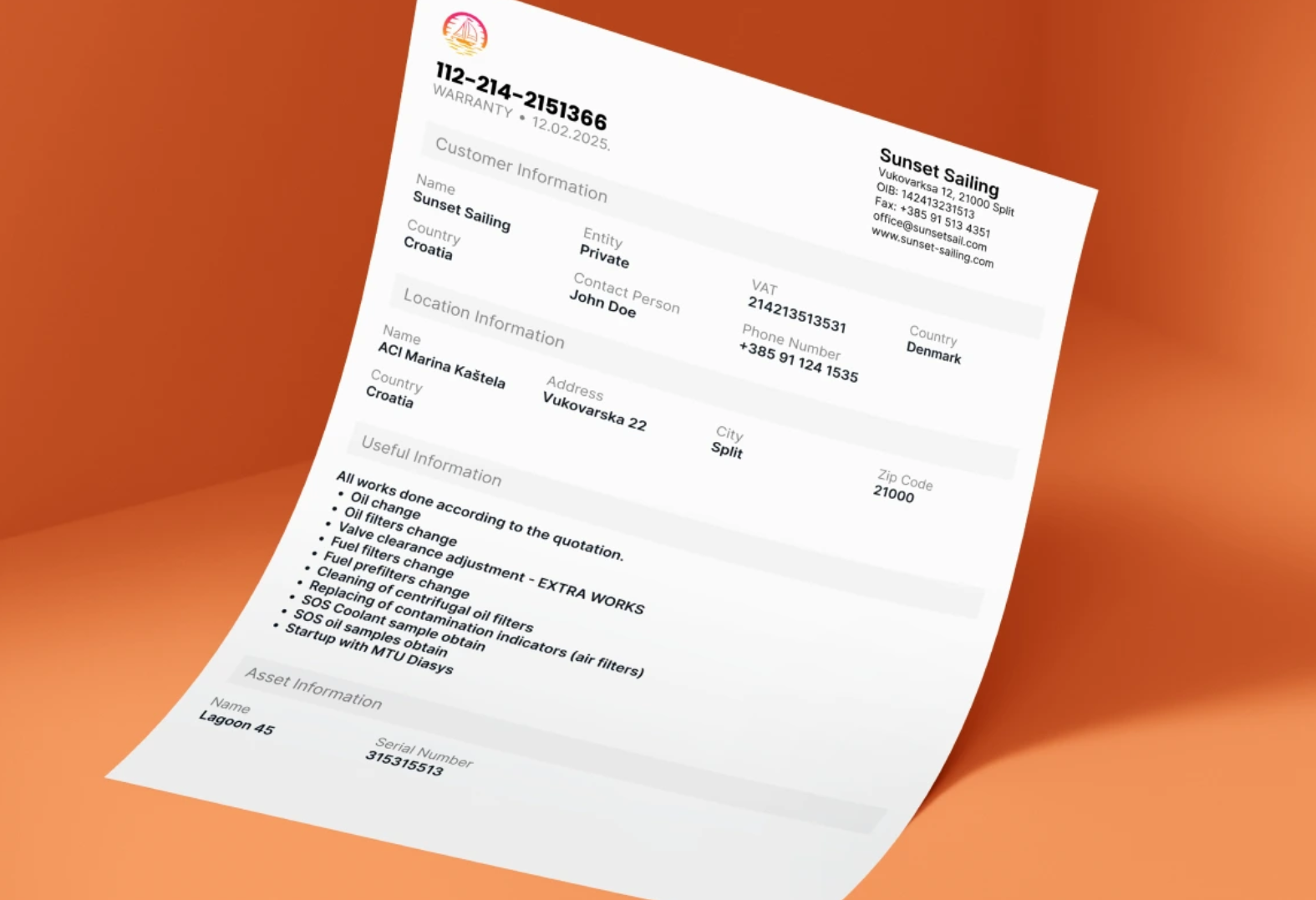

Using CMMS software to track and optimize MTTF

Calculating MTTF manually can be simple if you don’t have that much equipment. If you have hundreds of components tracking failures, logging hours and calculating averages can be complicated with spreadsheets. That’s why we suggest using CMMS (Computerized Maintenance Management System) software.

Advantages of CMMS:

1. Automated data collection

CMMS automatically detects the failures and records asset usage, downtime and replacement history. In that way you can have the data in real time, without the manual work.

2. Easy calculation of metrics

The CMMS systems calculates metric numbers based on your input. So instead of calculating MTTF, MTBF and MTTR, you focus on reading and interpreting those numbers.

3. Smarter scheduling

CMMS helps you create inspection plans. If you know MTTF is 9000 hours, you will take action after 8000 hours. You will order spare parts and allocate the team for inspection.

4. Inventory and spare parts planning

CMMS can indicate you when you might need the spare part. That info helps you do the purchase and have spare parts ready.

5. Vendor and asset performance tracking

CMMS often offers analytics, so you can easily compare suppliers that have quality parts, and those that don’t.

6. Real-world example

With a platform like Serwizz CMMS, you can track every failure, replacement and maintenance activity in one place. The application tells you how your equipment behaves. That helps you to improve planning and cut costs.

Final thoughts on MTTF

Mean Time to Failure (MTTF) is a simple metric. If you use the right way, you can have better preventive maintenance schedules, optimize your team allocation and reduce the costs.

We’ve explained what MTTF is and how to calculate and use it. We also showed the difference between MTBF and MTTR, and described its limitations and showed you the way to improve it. The biggest takeaway is that MTTF should never be seen as an isolated number. It’s part of a bigger picture. If you combine MTTF with other numbers and use it with a CMMS like Serwizz, it will become an important tool to help you optimise your business.

Keep in mind that MTTF can not predict the future with 100% accuracy but it can give you enough information to make better decisions.