CMMS

·

8 min read

CMMS vs Excel: Choosing the Right Tool for Maintenance Efficiency

You use Excel for maintenance management? You update rows, track assets, and assign tasks? Errors happen every week? Work orders get lost? Preventive maintenance slips through the cracks? You re fed up because every delay costs time, money and productivity and your team struggles to keep up? You keep going because you are in your comfort zone; used to that way of managing the business? But are you, though?

Excel cannot scale with your operation.

You spend hours fixing mistakes. You wait for updates from your team. You guess which assets need attention. Stress and inefficiency build up. Oversight disappears. Decisions are delayed. Problems grow unnoticed.

CMMS software solves these issues. Serwizz centralizes maintenance. Tasks schedule automatically, assets are tracked, and reports are generated instantly. You get control and visibility over every job. No more lost work orders. No more manual updates. Your team works efficiently, and your equipment stays reliable.

In a few days, your team adapts. Preventive maintenance happens on schedule. Work orders log automatically. You track progress from any device. Operations become predictable. Downtime drops. Costs fall.

Why Excel Falls Short

Excel works for small, simple tasks. It handles minimal operations. But it collapses as you grow.

- Manual updates increase errors

One wrong formula, one missed row, and your schedule is off. Work orders get lost.

- Limited collaboration

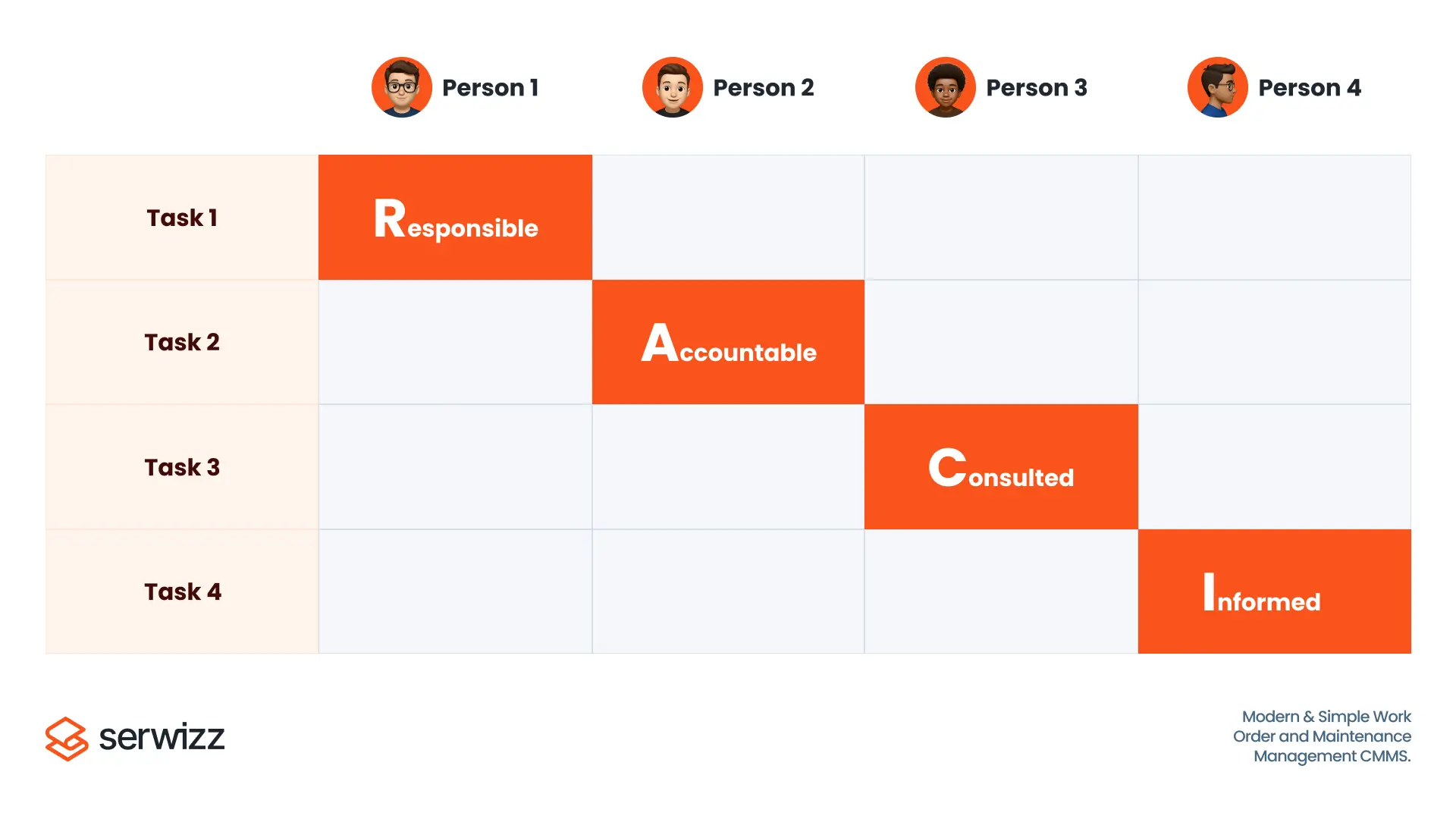

Multiple technicians editing the same sheet at once. Teams in different locations cannot see live updates. CMMS provides a source of truth. You know what’s scheduled, assigned, and completed.

- No automated preventive maintenance

Excel doesn’t alert you when maintenance is due. Tasks are delayed or missed. Serwizz sends reminders and schedules tasks automatically.

- Slow reporting

Generating reports from Excel takes hours. Serwizz gives instant insights with actionable data.

- Scaling is difficult

Excel cannot manage hundreds of assets efficiently. Adding dozens of tasks becomes chaotic. Serwizz grows with your operation. You manage machines across multiple locations without losing accuracy.

Work Orders in Excel

A work order is a kind of document that describes a maintenance task for a specific asset. In Excel; each task is represented as a row in a spreadsheet. Each row contains the machine name, task description, assigned technician, scheduled date, status, and completion notes. The process is entirely manual. You must update the row whenever a task is completed or rescheduled. Tracking history requires scrolling through multiple sheets or files. Errors happen easily, and missed tasks lead to downtime.

Pros: It is simple, familiar, no new software needed.

Cons: Time-consuming, it is prone to errors, no automatic notifications, asset history is incomplete.

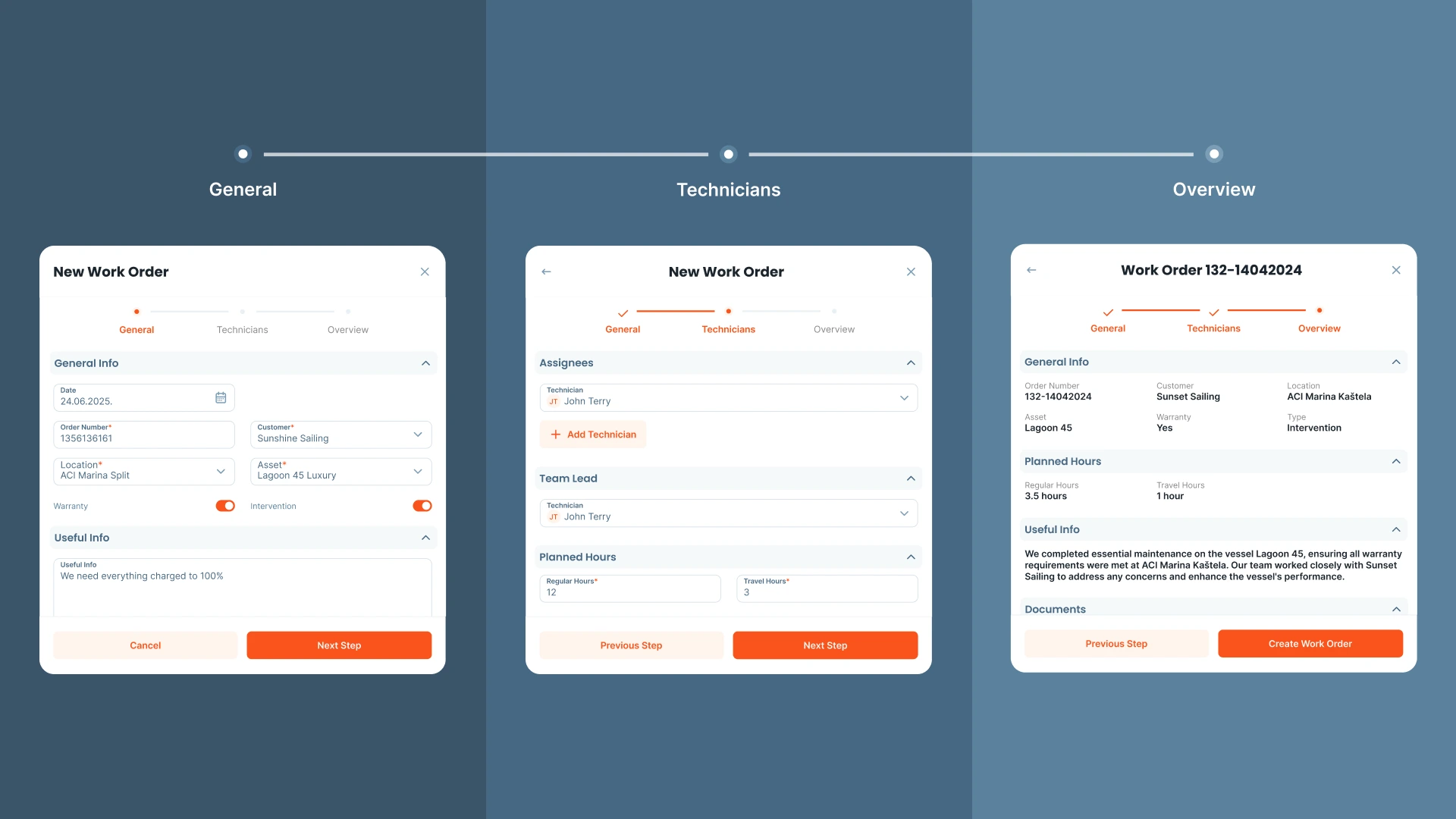

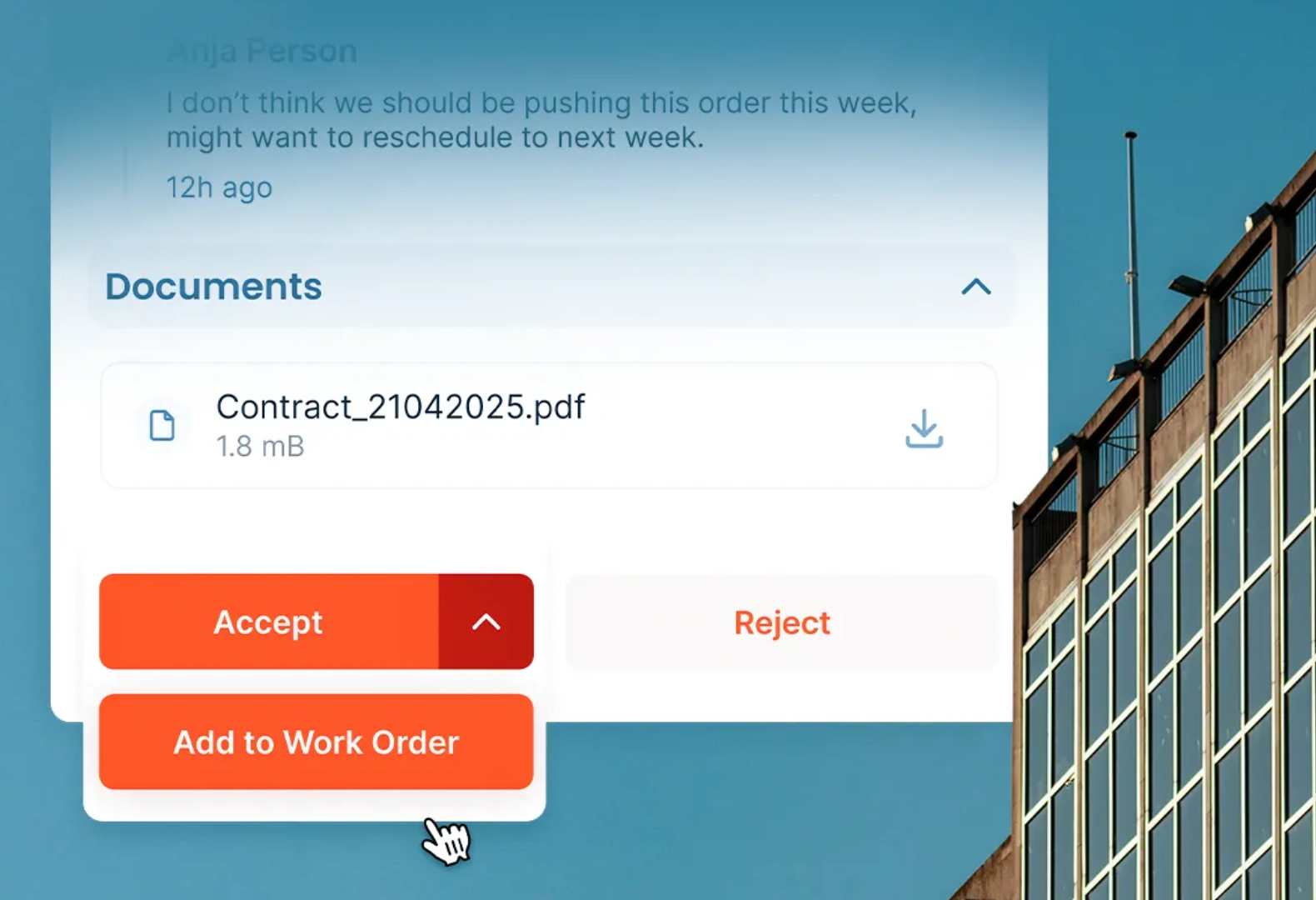

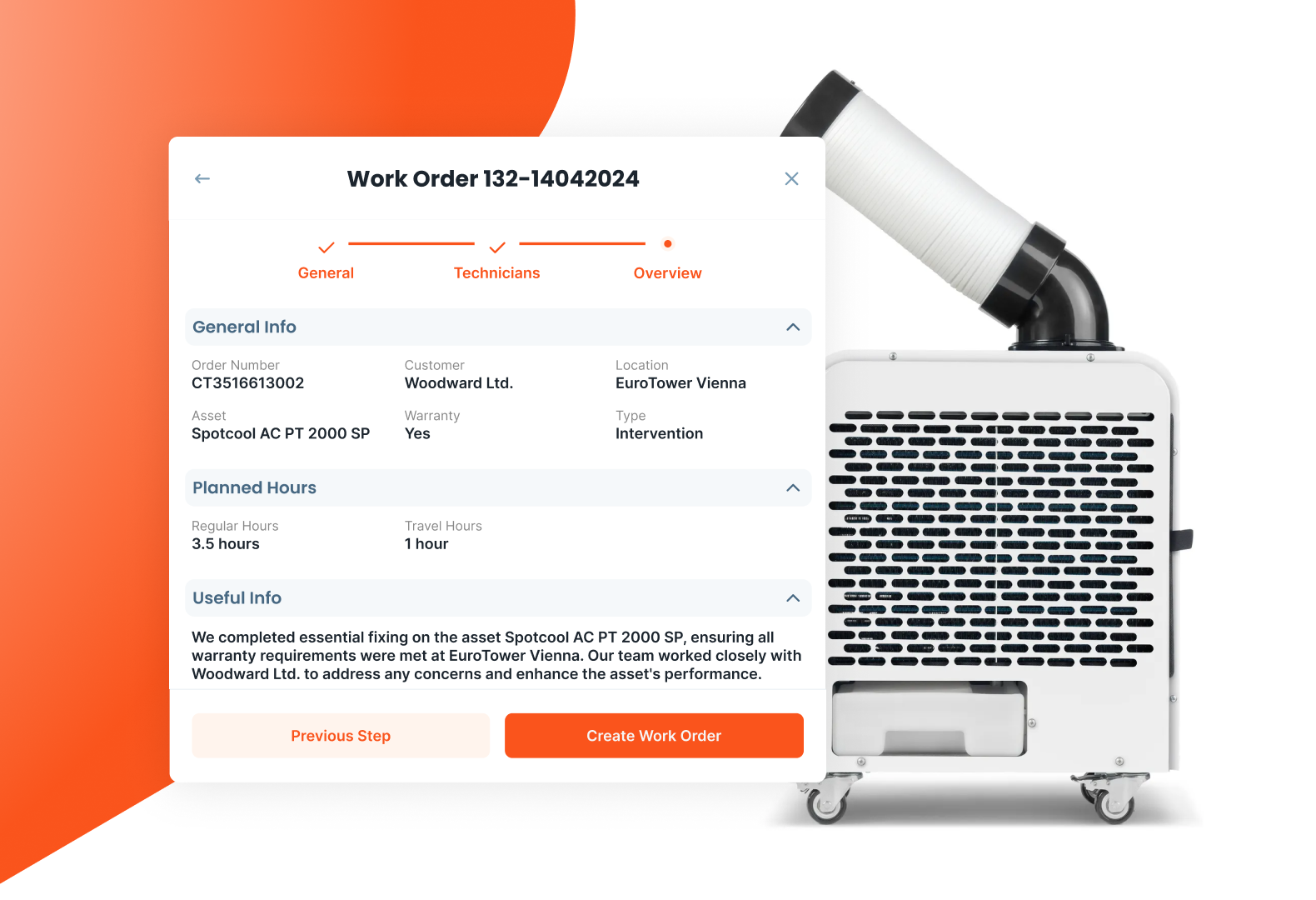

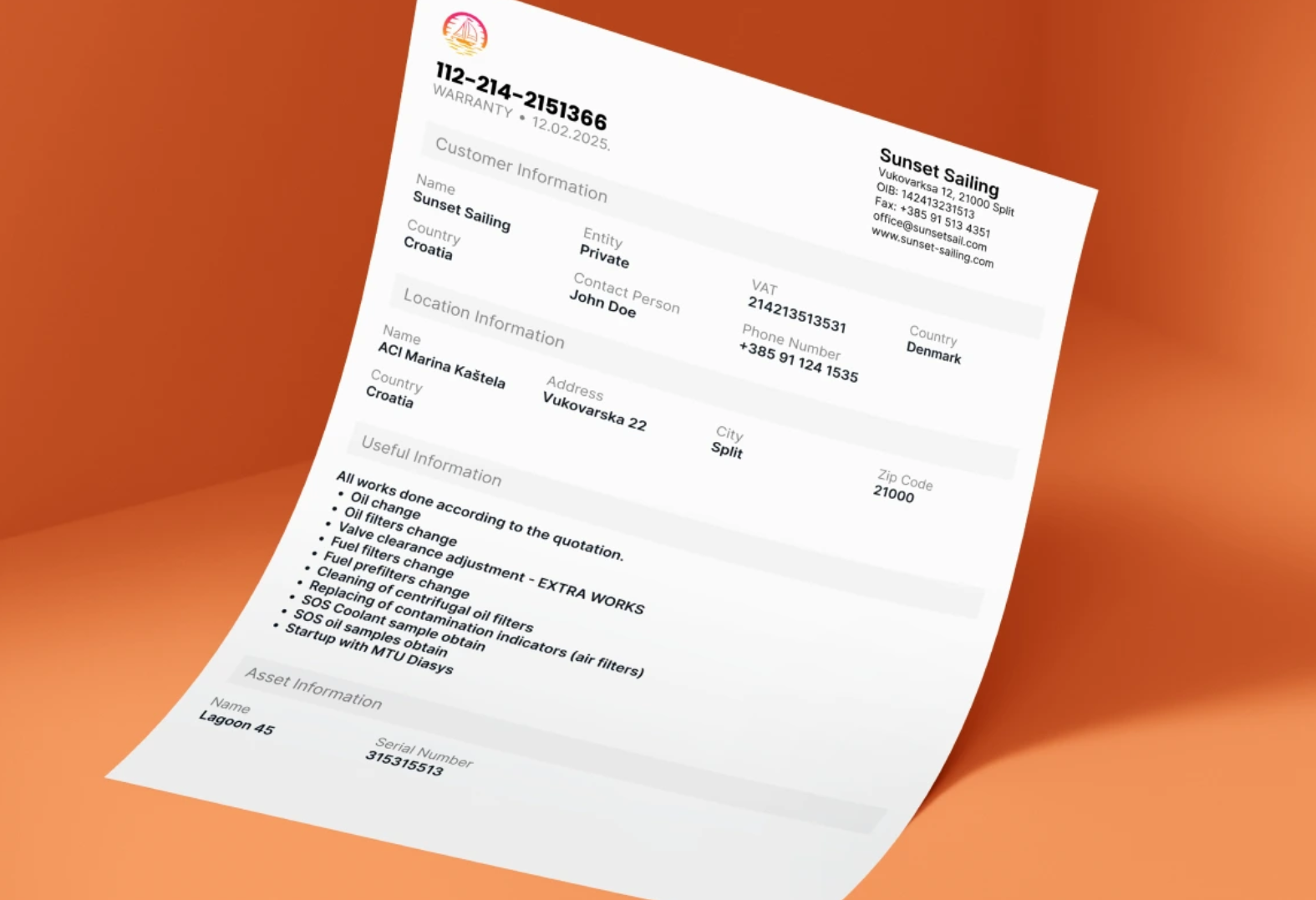

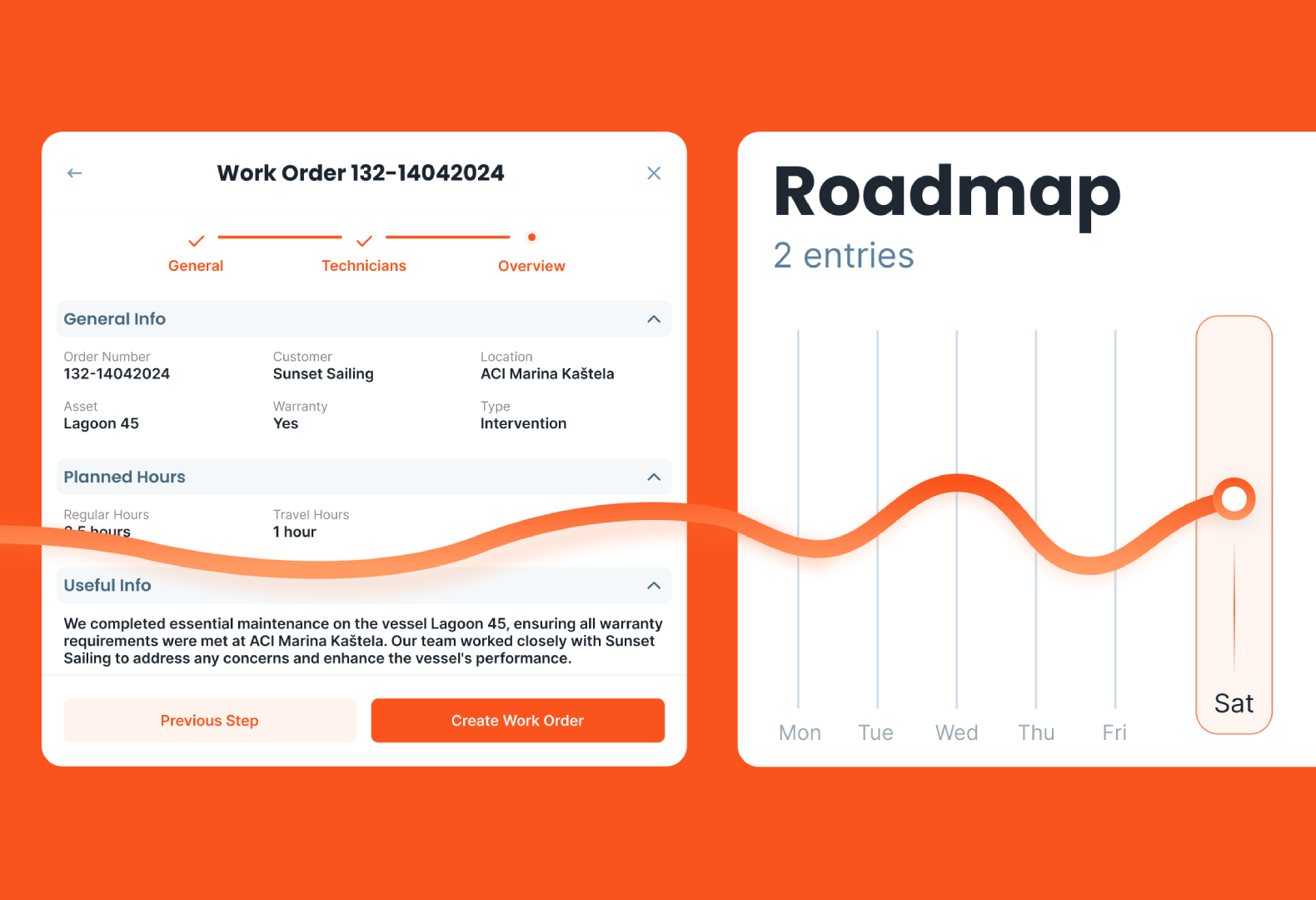

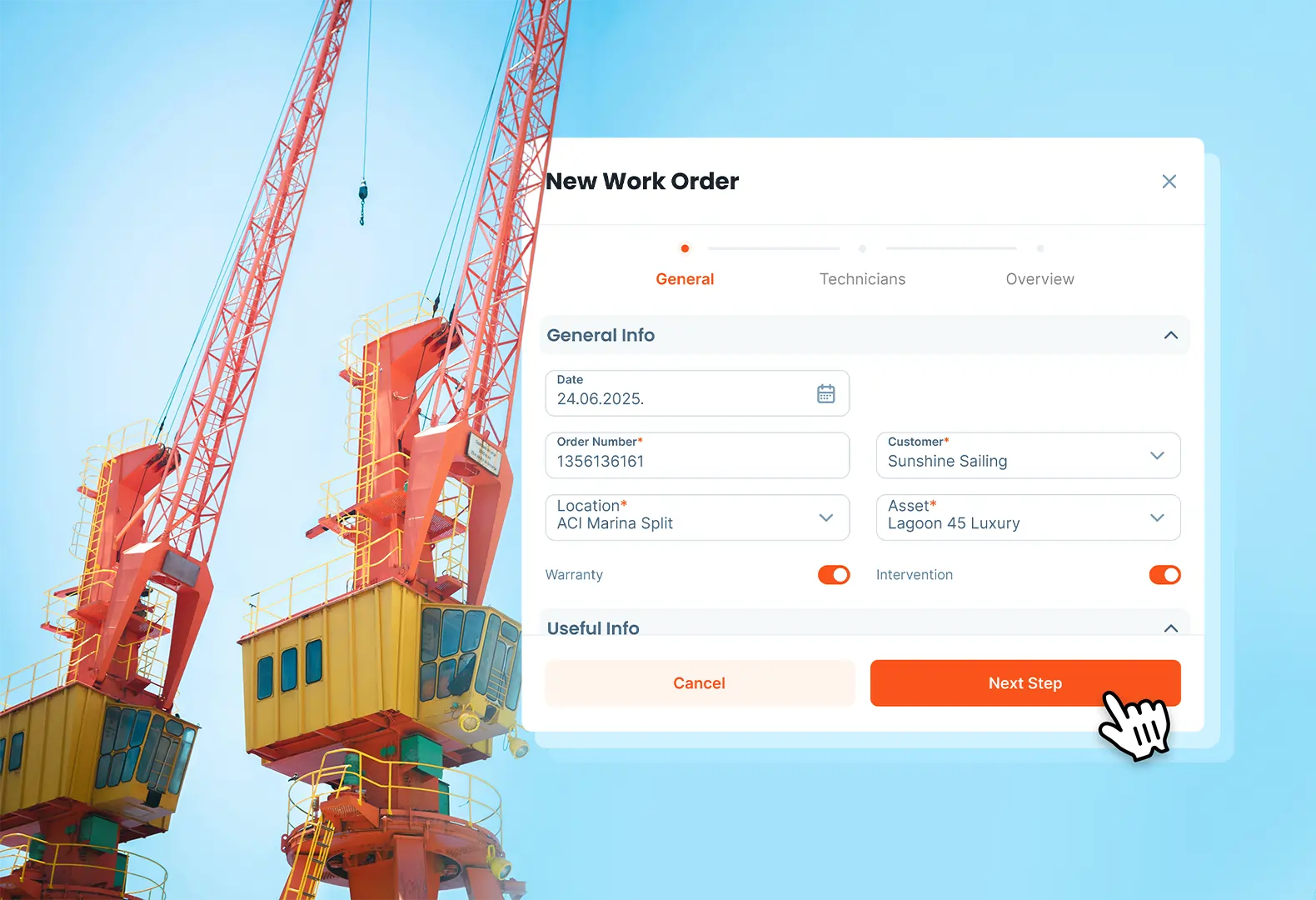

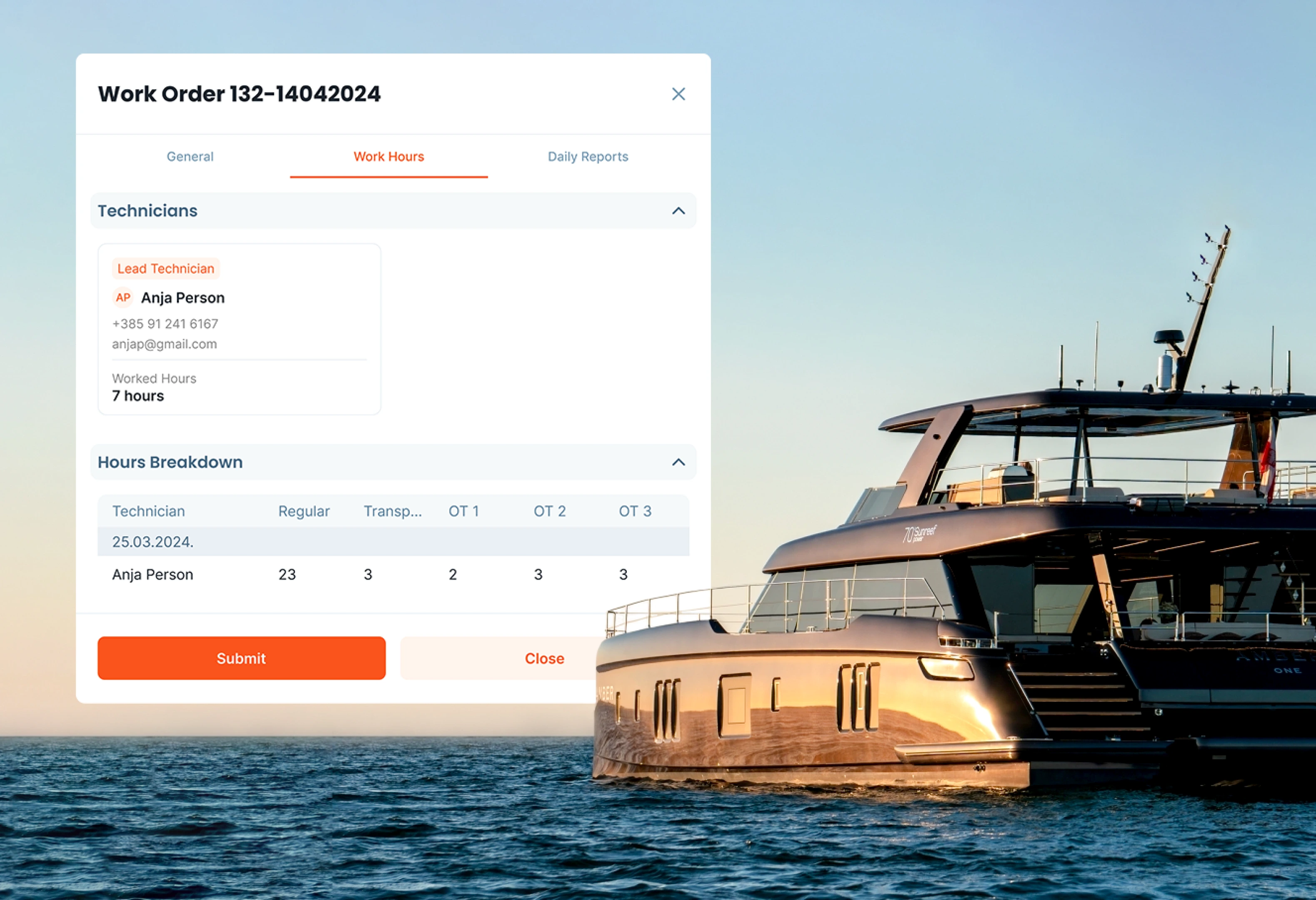

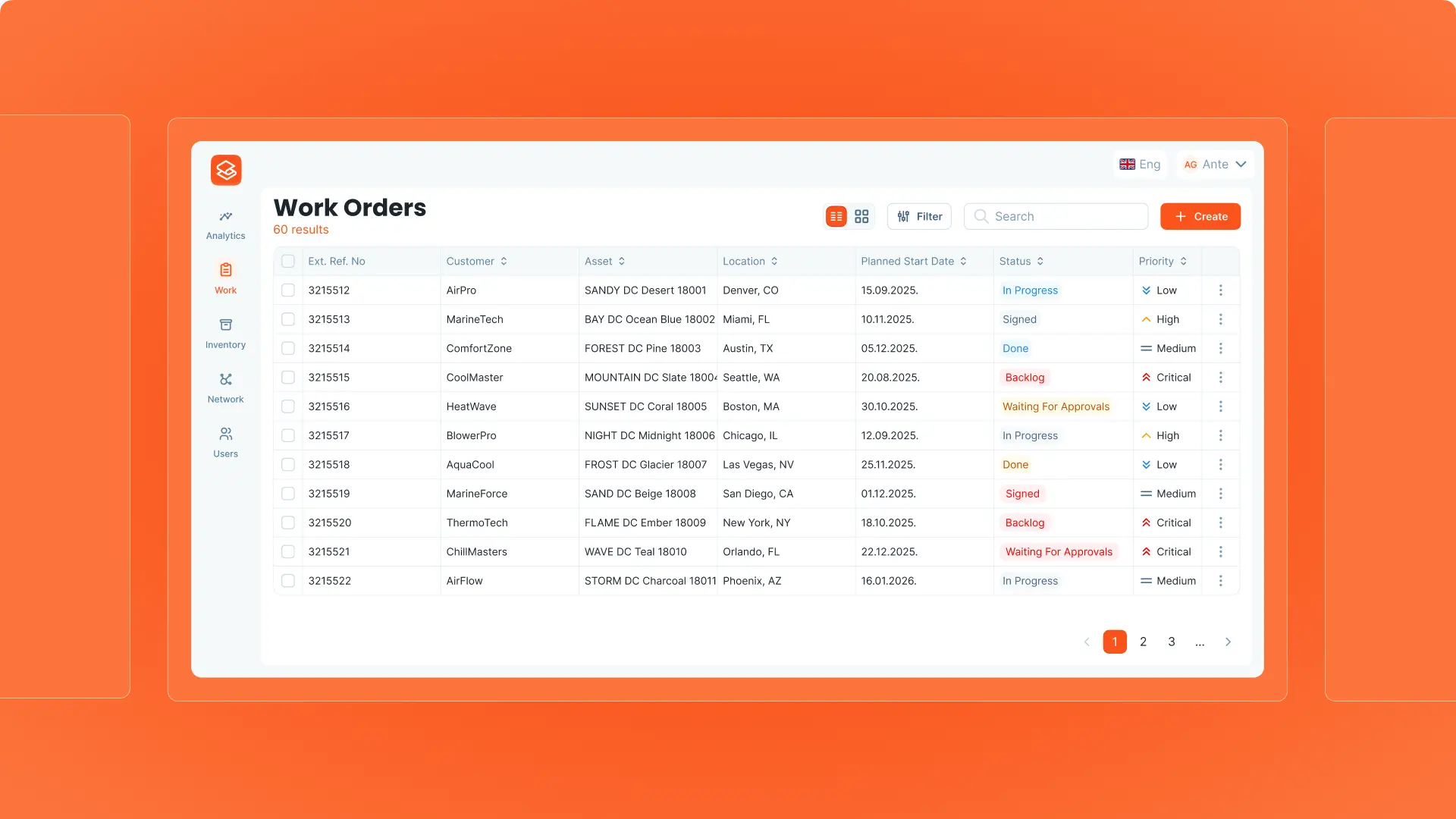

Work Orders in Serwizz

Serwizz automates work orders. You create a task once and the system schedules it, notifies technicians, and logs completions automatically. You see all tasks at a glance. Asset history is complete and accessible instantly. Teams spend time doing maintenance, as they should, instead of updating spreadsheets.

Pros: Automation, accurate logs, all kind of notifications, complete history, scalability.

Cons: Requires initial setup and training.

Comparison Table: Excel vs Serwizz CMMS

| Feature | Excel | Serwizz CMMS |

|---|---|---|

| work Order Creation | manual input per row | automatic task generation |

| notifications | none | instant alerts to technicians |

| Asset history | scattered and incomplete | centralized and continuous |

| error risk | high due to manual edits | low, automated tracking |

| scalability | limited for large operations | supports multi-location management |

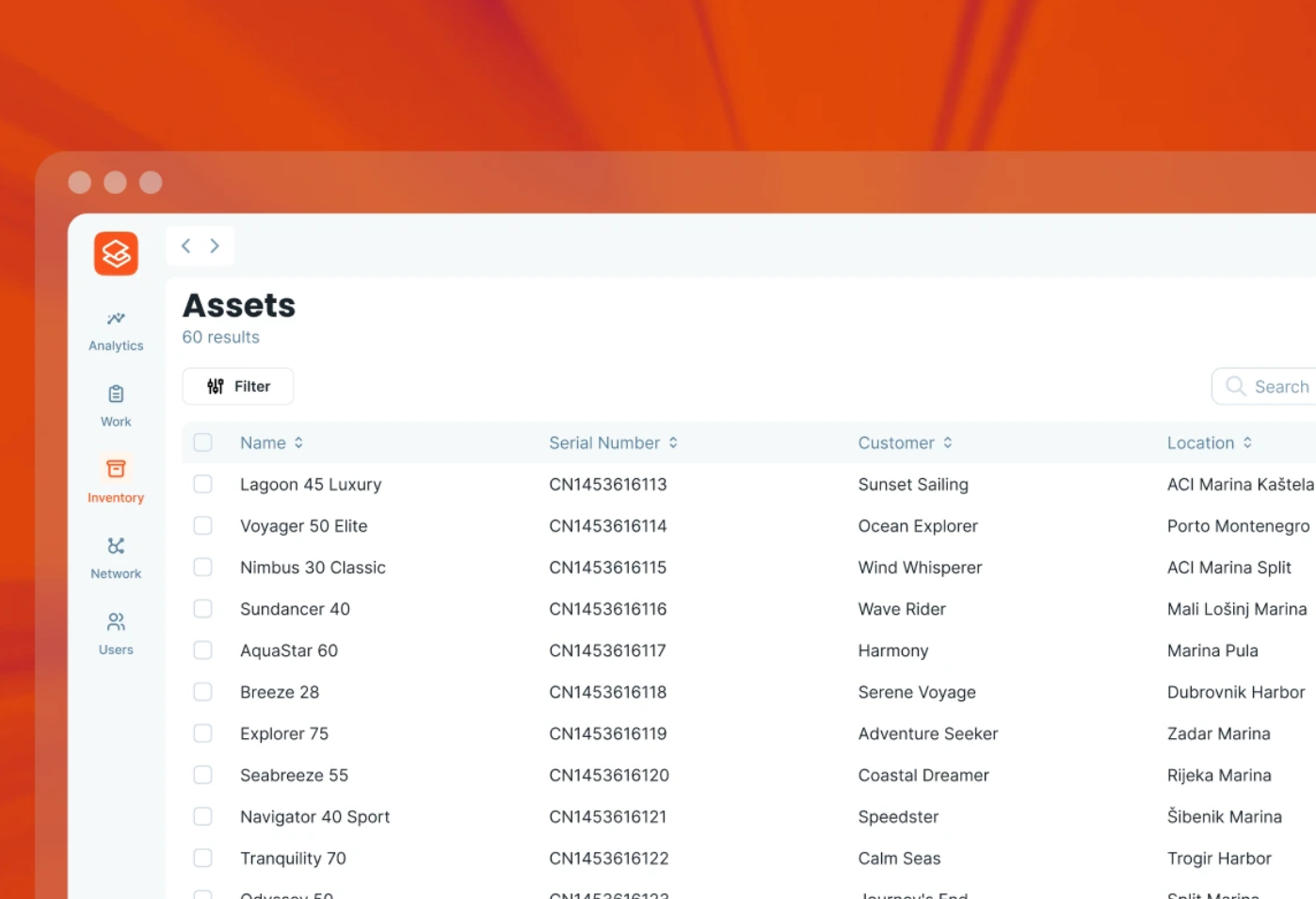

Serwizz Analytics and Asset History

Recurring issues are logged automatically. You know which machines need attention immediately. Analytics give a clear view of downtime, costs, and completed tasks. Problem areas appear before they escalate.

Costs

Updating Excel sheets manually takes so much time every week. Missed preventive maintenance also causes unplanned downtime. Mistakes increase repair costs. Serwizz schedules tasks automatically and logs completed work instantly. Your team spends time on maintenance, not spreadsheets. Most teams recover the subscription cost within weeks.

Industry Applications

- Manufacturing

A factory with 60 machines schedules weekly and monthly checks with Serwizz. Tasks log automatically. Teams get notifications instantly. Using Excel would require constant manual updates. Mistakes are likely.

- Facilities Management

Try to picture this: a manager overseeing five buildings assigns tasks and tracks completion in real time. Excel would require multiple files and that is increasing the risk of missed tasks.

- Shipping and Service

A company managing 20 vessels schedules inspections and logs repairs in Serwizz. Technicians are notified immediately, in real time. Tasks are tracked in real time across all locations. Excel cannot provide live updates or track remote tasks efficiently.

- Healthcare

A hospital managing MRI machines, ventilators, and lab devices uses Serwizz to keep preventive maintenance on schedule. Downtime decreases, and staff rely on equipment availability.

- Logistics

A warehouse with 50 forklifts assigns maintenance and logs completions in our Serwizz; reports are generated automatically; Excel would require daily updates and still risk missed tasks.

Practical Examples: Excel vs Serwizz

Just try to picture this: ten machines need weekly checks. In Excel, updates are manual. Rows are missed. Tasks get delayed. Problems appear after a machine breaks down.

With Serwizz, tasks schedule automatically. Technicians get notifications. Completions log automatically. Reports appear weekly. Downtime decreases. Productivity increases. Work orders don’t get lost.

Another example: a medium-sized company tracks HVAC, elevators, and lighting maintenance in Excel. Work orders are duplicated, tasks missed. Switching to Serwizz, schedules are automatic, tasks log in real time, and managers spot problem areas immediately.

Transitioning from Excel to Serwizz

Start small; import your data into Serwizz. Assign tasks to your team. Set preventive maintenance schedules. Train your team with Serwizz guides. The system adapts to your operation. Efficiency improves in days, it doesn’t take months.

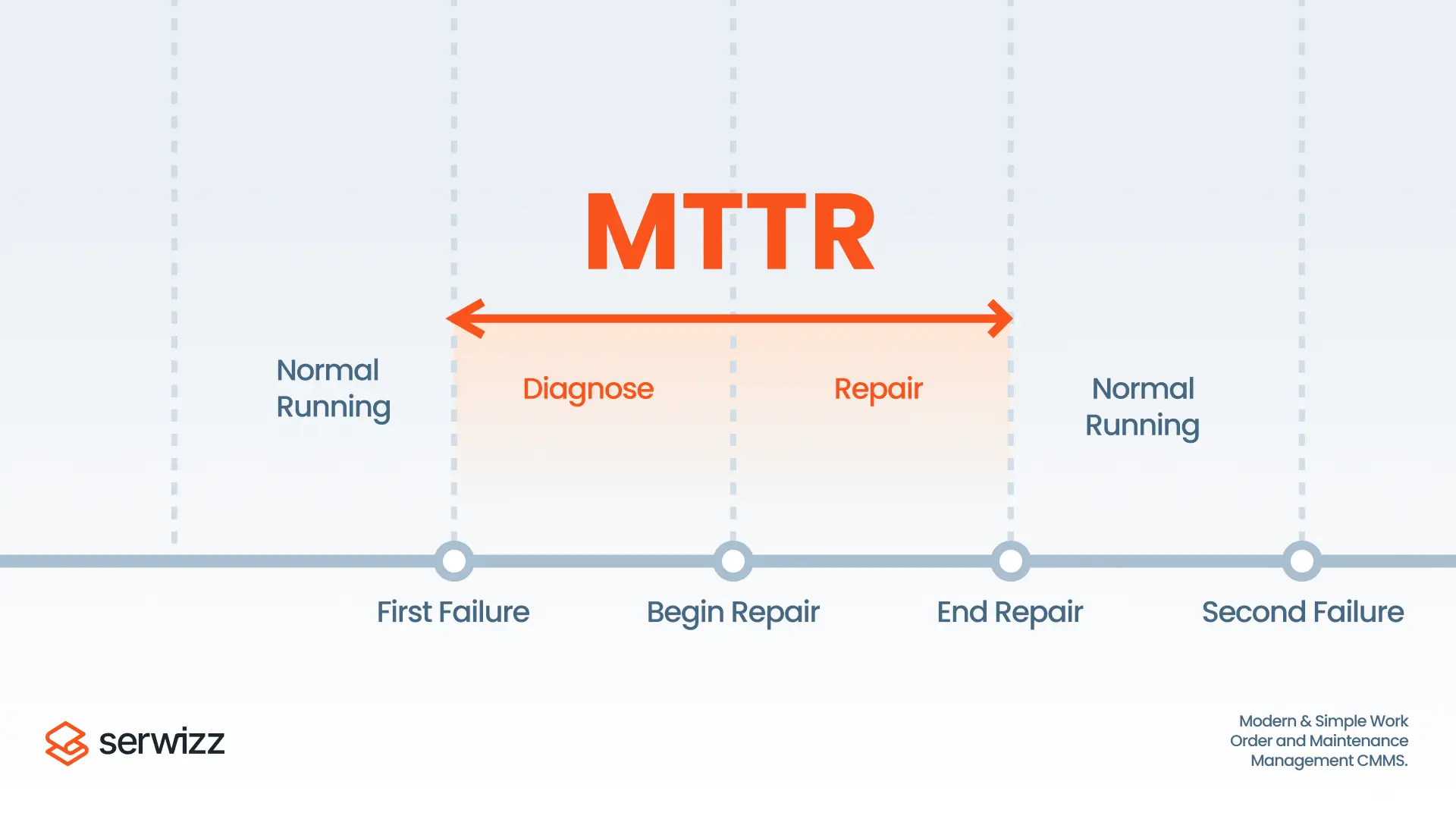

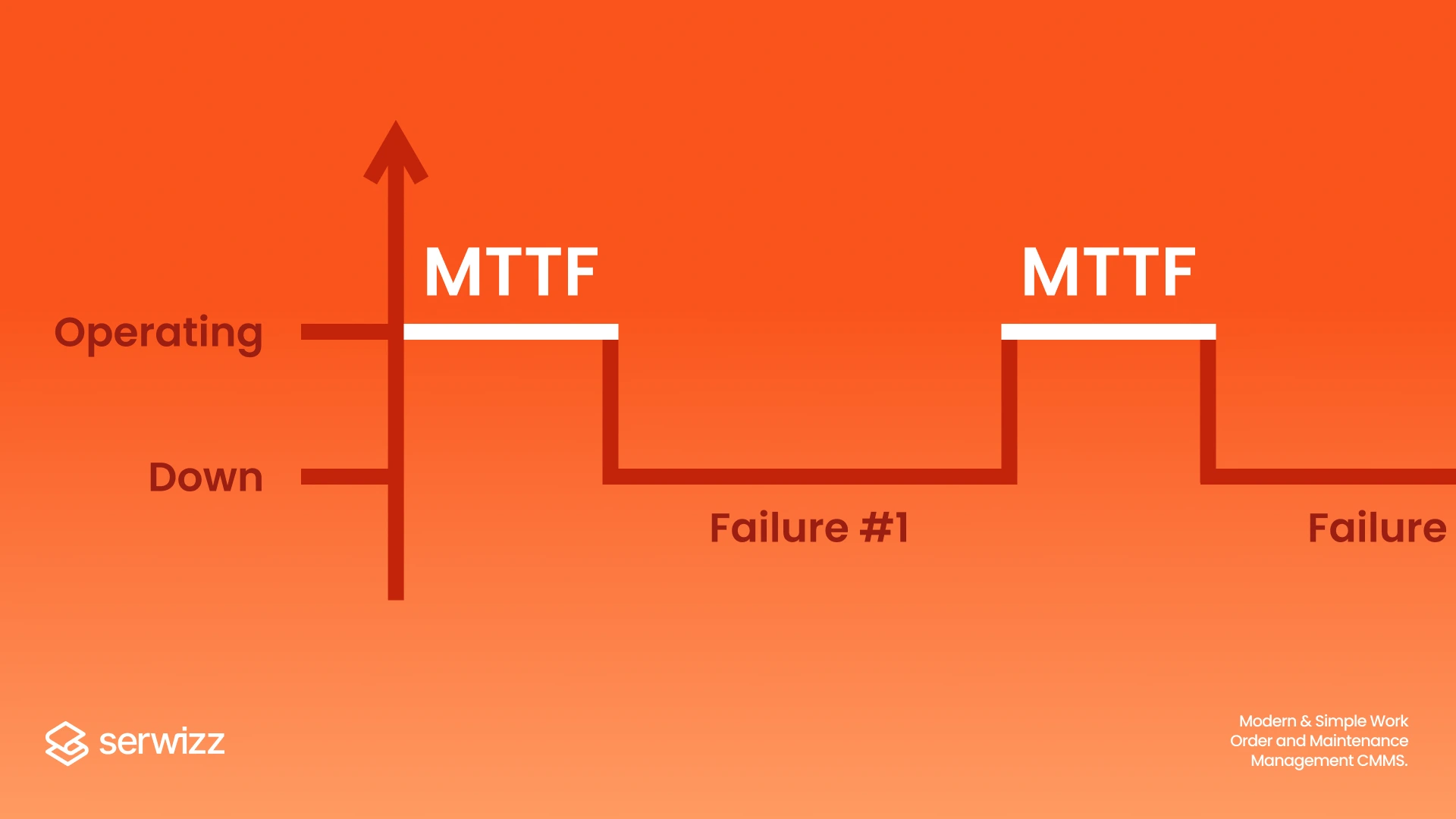

Measuring Success

Track completed vs scheduled tasks, downtime, hours saved, and maintenance costs. Serwizz dashboards show data instantly. Decisions happen faster. Problems are caught early. Equipment stays operational. Maintenance finally becomes predictable, measurable, and controlled as well.

Final Thoughts

Excel handles numbers. It does not handle maintenance.

CMMS gives visibility, control, and efficiency.

Serwizz makes the transition easy. Automated tasks, asset tracking, work orders, and performance analysis save time and reduce errors. Equipment stays reliable.

Switching to Serwizz CMMS is a decision for efficiency, accuracy, and growth, so take control of your maintenance today.