Maintenance

·

11 min read

SOP for Maintenance Organizations

What is SOP

While working with different companies from the maintenance world, we have noticed one pattern. Different companies handle the same task in a completely different way. But not only that, even the two technicians from the same company handle the same task in completely different ways. One technician turns off the HVAC unit properly before cleaning the filters. The other one skips a safety step to “save time.” After the job is done, the system seems to work fine, but a week later HVAC stops working and no your team is not sure why.

That’s where Standard Operating Procedures (SOPs) come in. In simple terms, an SOP is just a clear, step-by-step way of doing a task.

The purpose of SOPs is not to create extra paperwork but rather to create consistency. SOP should help you and your team, that no matter who performs the task, it should meet the same standard of safety and quality.

In the world of maintenance, SOP can help you prevent small issues, which could cost you a lot. They help your team create good practices and make into daily habits. By using SOP your team should be more organized, accountable and safe.

What is Maintenance SOP?

A maintenance SOP is a detailed guide that provides specific steps for performing maintenance tasks. It sets standards for work quality and safety. If you start using SOP, everyone in your team will know exactly what to do, in what order and why. This consistency doesn’t just prevent mistakes. It keeps your team safe and your equipment running smoothly.

Imagine you’re managing a production line. One of the machines in the line stops working. You ask your team why this happened (and how) and each person on the team gives you a different answer. One technician skipped a step, another used an old procedure. This issue could cost your company more than a thousand euro.

This situation is common in companies where there is no SOP. SOP should be like a cookbook for your team. It’s also great training material. A new technician can follow a well-written SOP and perform a task on his own, without asking more experienced team members or being afraid of possible error. SOP is also a key for compliance, helping your team meet safety standards and internal audits.

Accountability is one of the SOP’s characteristics. When your team logs each step, you can quickly tell who handled which task, which saves time when issues pop up.

To sum up, SOPs turn chaos into order, mistakes into learning. In maintenance it removes uncertainty and brins. predictability.

Key Elements of a Good Maintenance SOP

A good SOP is a guide that anyone on your team can follow, on a daily basis. Here’s what makes an SOP effective:

1. Title and Scope

Give the SOP a clear title and define what it covers. Avoid ambiguity. with a clear title and define what the SOP covers. Example: “HVAC Filter Cleaning: Monthly Preventive Maintenance.” Include which assets and equipment the SOP applies to.

2. Purpose

Explain why the task needs to be done. Understanding the reason behind each step makes the work faster and safer. In our HVAC example, the purpose could be: “Maintain indoor air quality.”

3. Tools and Materials

List everything you need for the task. Gloves, filters, screwdrivers... If you can, ask the regular technician for help. They could remember some not obvious items.

4. Step-by-Step Instructions

This is the core. Create small tasks and numbered steps. For HVAC filter cleaning, it might include:

- Turn off the unit and lockout the power switch.

- Remove the front panel.

- Take out and inspect filters.

- Clean or replace filters.

- Put back the front panel.

- Restore power.

5. Safety Notes

Include Personal Protective Equipment (PPE) requirements. Safety should be priority.

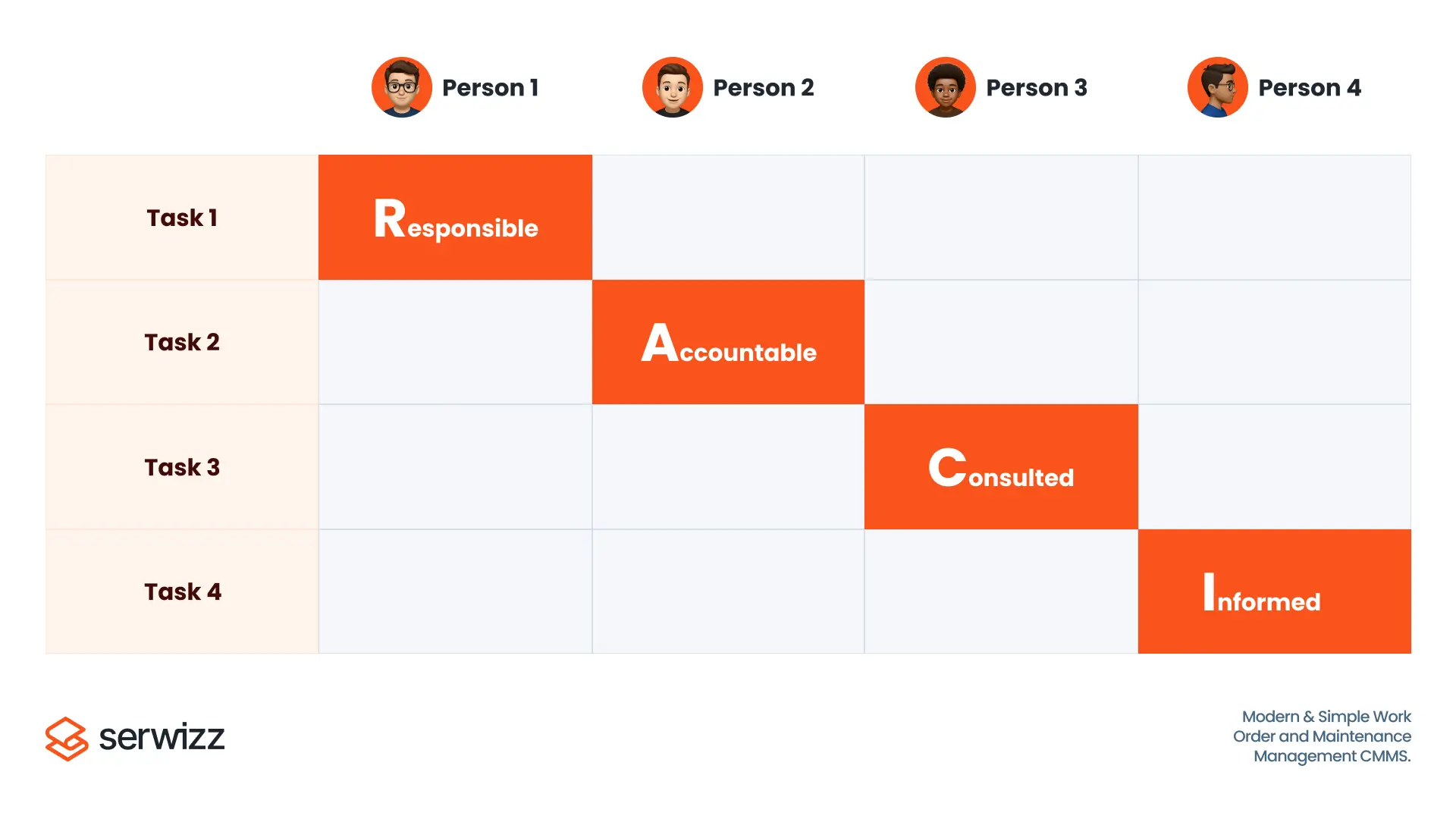

6. Responsibilities and Documentation

Who performs the task? Who verifies it? Where should it be logged? For example, note that the technician logs completion in the maintenance software.

How to Create a Maintenance SOP

Writing a maintenance SOP is like you take the best practices from your team and turn it into instruction. SOP should be easy to follow for all team members, juniors to principals. Here’s a simple way to approach it:

1. Choose a task that needs standardization

Think about a task your team does regularly. For example, every month someone has to clean the HVAC filters. It seems simple, but without a clear SOP, the task could be done differently (and with issues).

2. Watch and talk to the people doing the work

The best SOPs come from the technicians who actually do the job daily. Watch them, ask them questions and note what steps they do.

3. Write clear, simple instructions

Use short sentences and everyday language. Number your steps.

4. Include safety reminders

Don’t assume anyone will remember safety procedures. Note PPE requirements, lockout procedures or anything else needed to stay safe.

5. Test the SOP

Have one team member follow the SOP exactly as written. Ask for feedback: Was there any confusion or missed step. Then adjust instruction accordingly.

6. Review and approve

Have a supervisor or maintenance lead review it. Make sure it matches best practices and safety rules.

7. Keep it updated

Equipment and procedures change. Set a schedule to review your SOPs so they stay accurate.

Common Mistakes to Avoid When Writing SOPs

SOP should be written and used thoughtfully. Here are some common mistakes you might face:

1. Making SOPs too long or complicated

You want to make sure that your team uses the SOP. Try to make it simple and concise. Rather than having long text explanations, use short, clear steps.

2. Ignoring the technicians’ perspective

Your team is the one doing the work, on a daily basis. You should keep them included, or you might miss crucial steps or practical tips. Watching and asking your experienced technicians is the right way.

3. Letting SOPs gather dust

An SOP is only useful if it’s actually followed. Post it in an accessible place, whether that’s a CMMS like Serwizz or a visible binder on the shop floor.

4. Forgetting to update

Equipment changes, and processes evolve. A monthly HVAC filter cleaning SOP that hasn’t been updated in two years might include outdated steps, leading to mistakes or downtime.

5. Being too rigid

SOPs should be your guideline, rather than constrain. You should allow some flexibility for technicians: Keep the core steps, but allow them to adapt in not common situations.

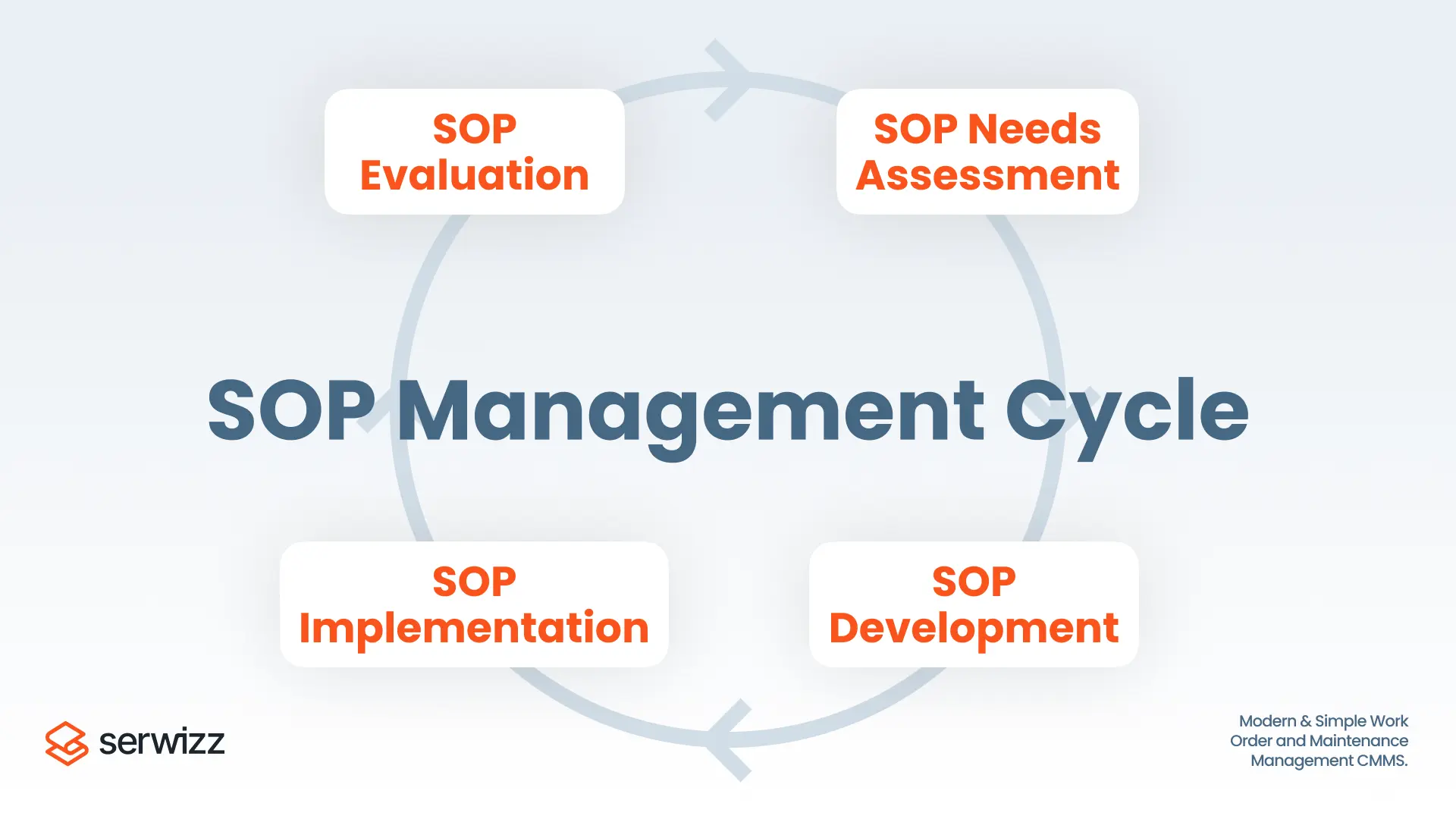

How to Implement and Manage SOPs Using a CMMS

Creating a well-written SOP is only half the job. If you want your team to be effective, they have to have easy access to SOP and they have to update it regularly. To make your life easier, we suggest using a Computerized Maintenance Management System (CMMS), such as Serwizz.

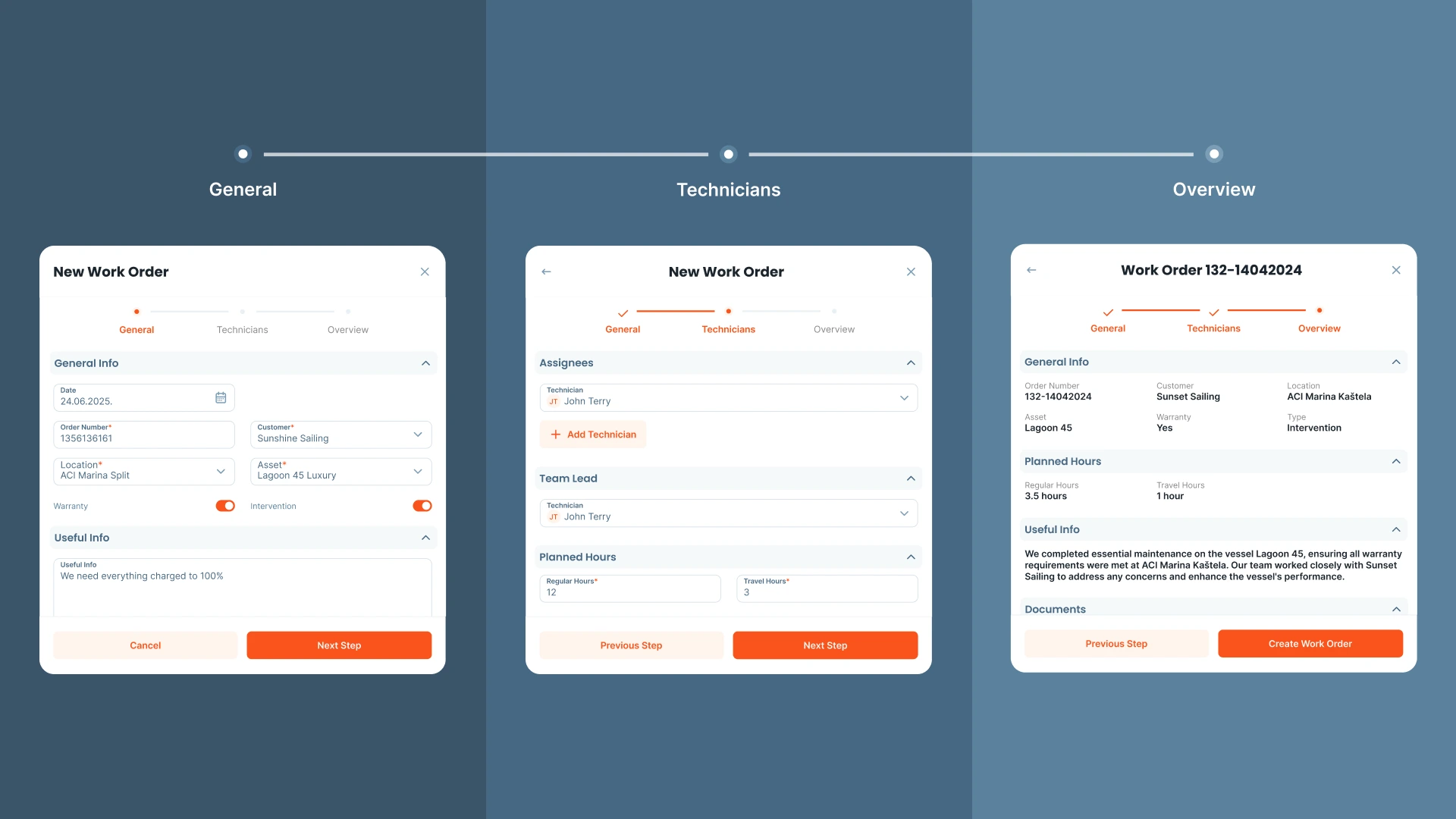

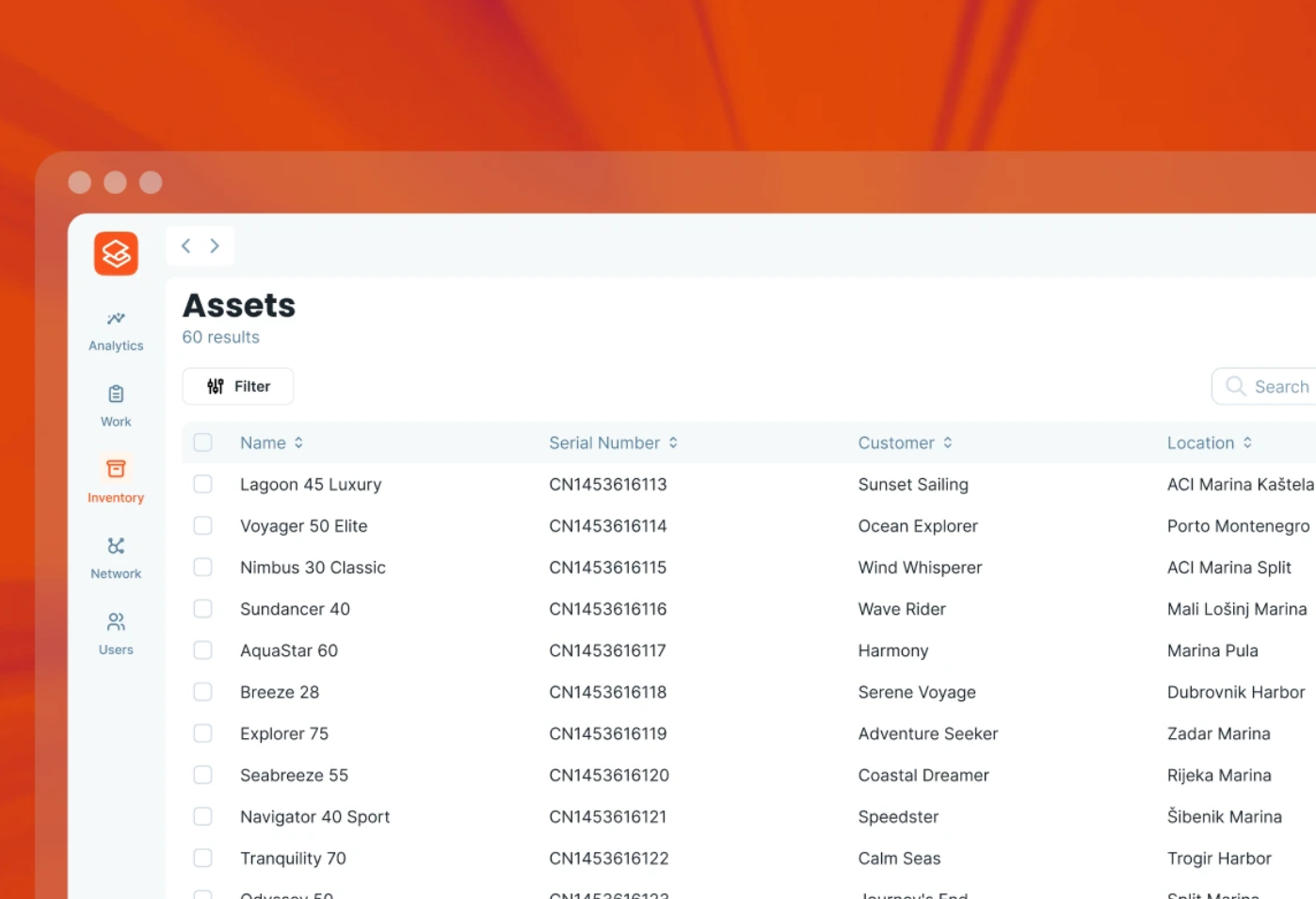

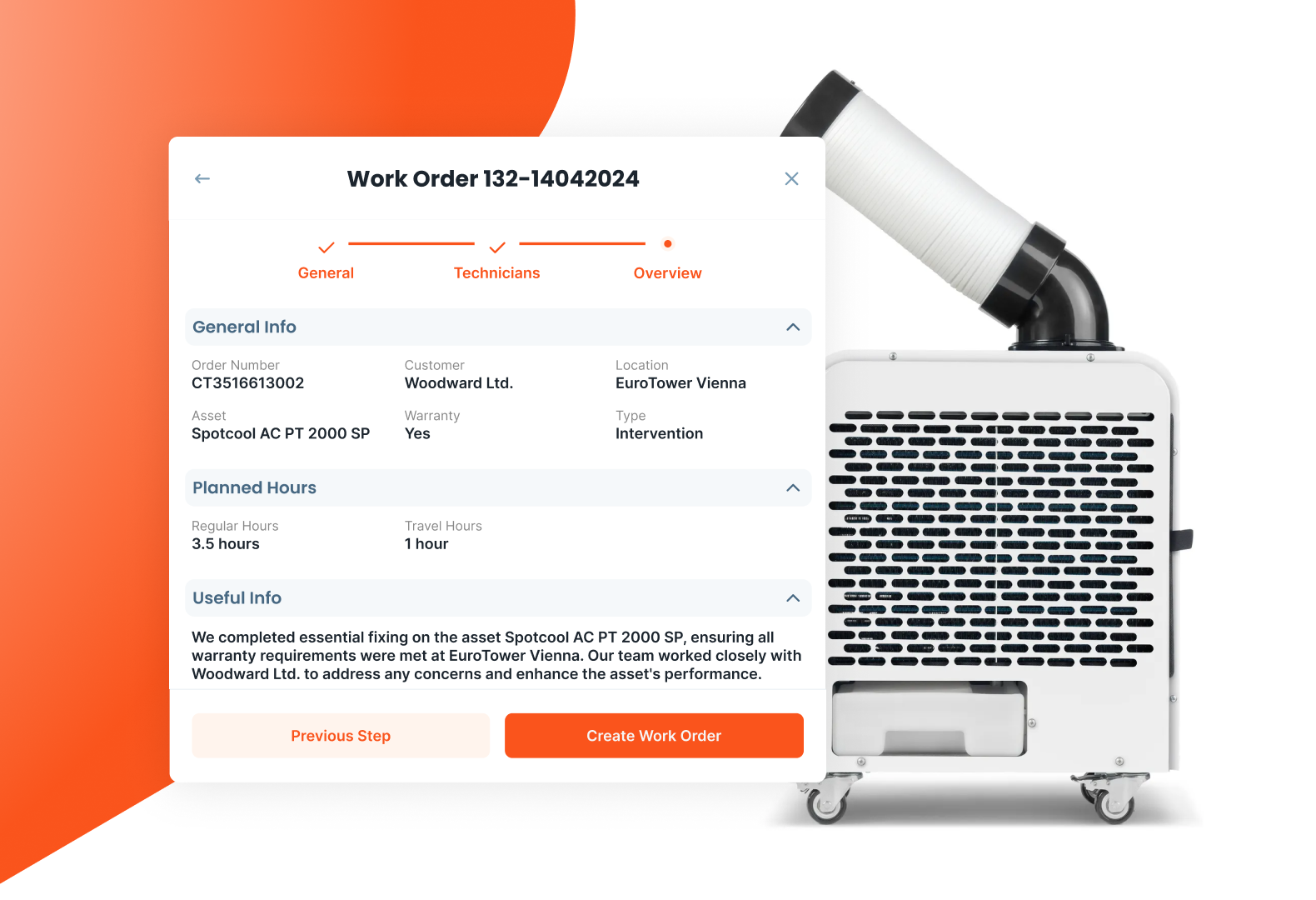

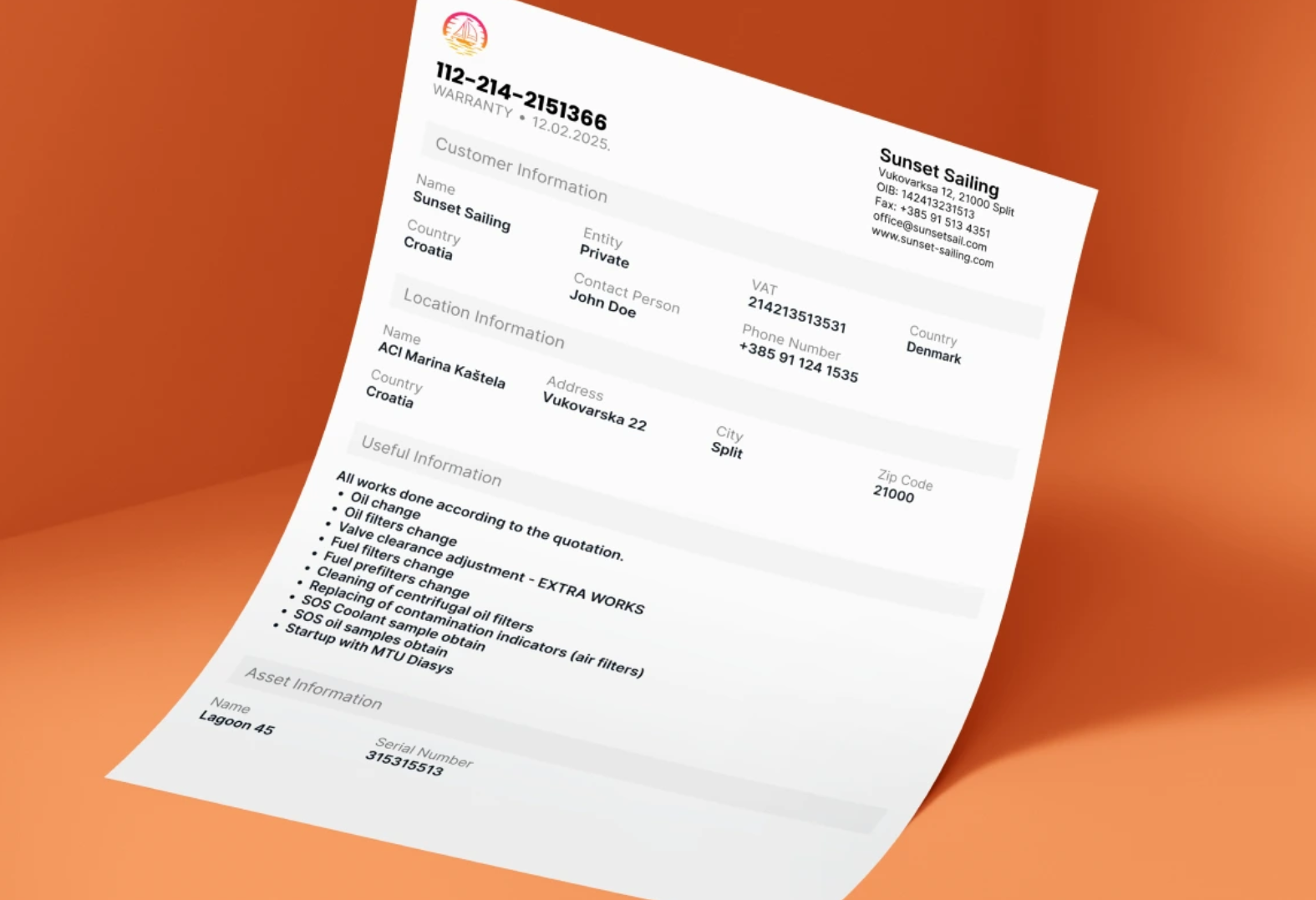

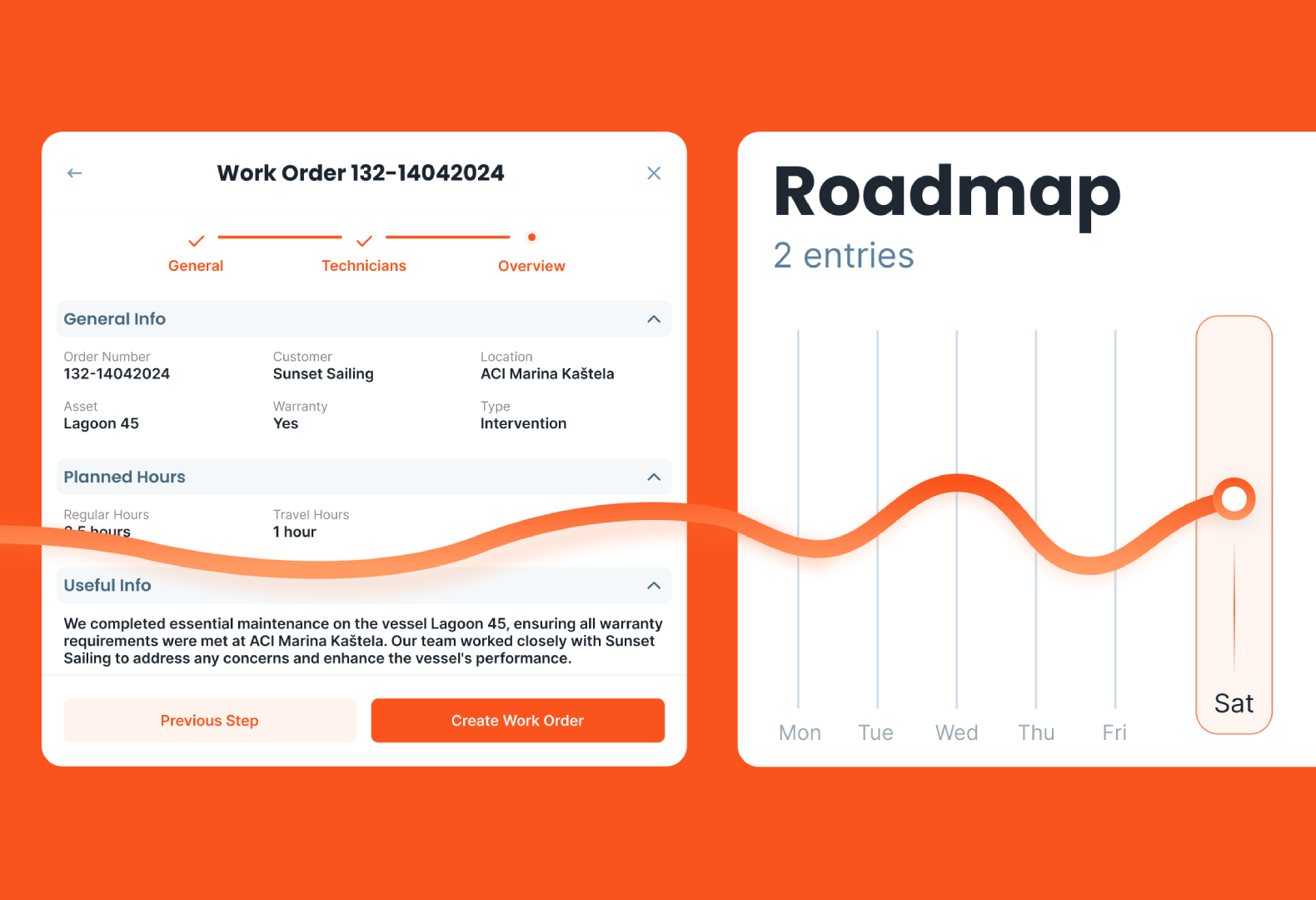

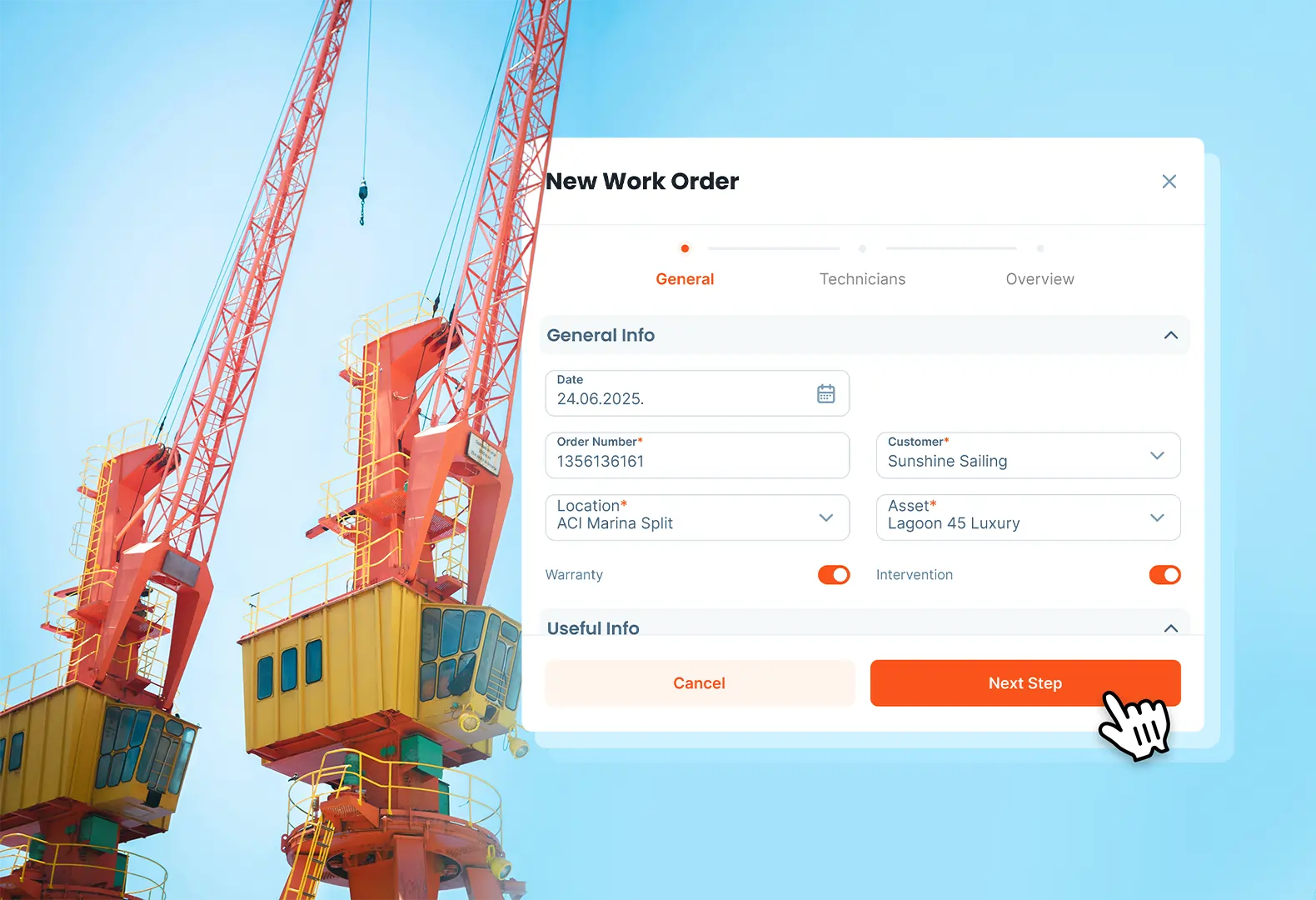

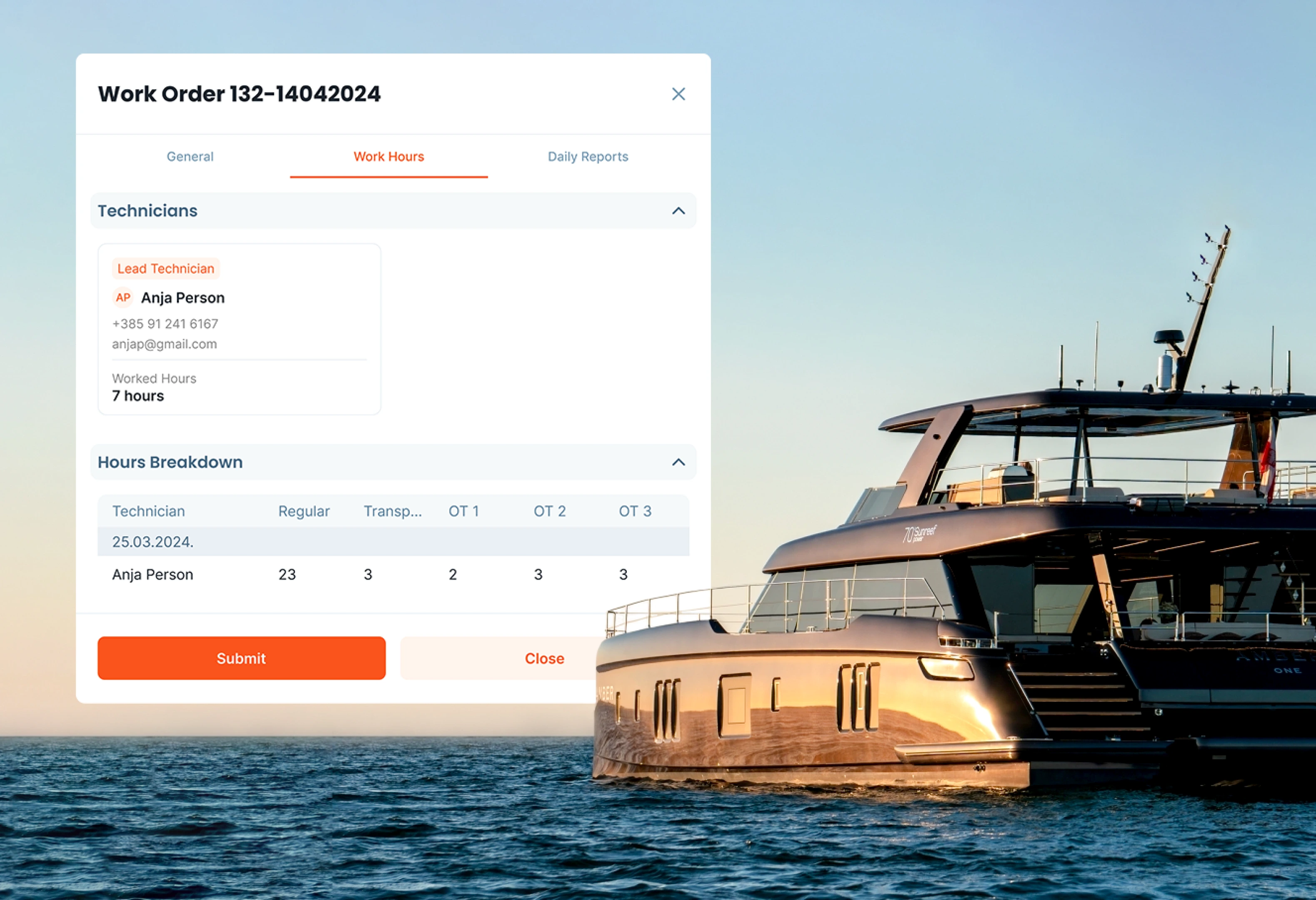

With CMMS you can store all SOPs in one place and your team can access it via phone or tablet. You can link maintenance tasks to related SOPs and make a standardisation in your process. Each work order can include a step-by-step guide, ensuring the job is completed the same way every time.

Centralized SOP management also simplifies version control. When a process changes, you can update the document once and the whole team will have the updated version in a few seconds. This prevents outdated instructions.

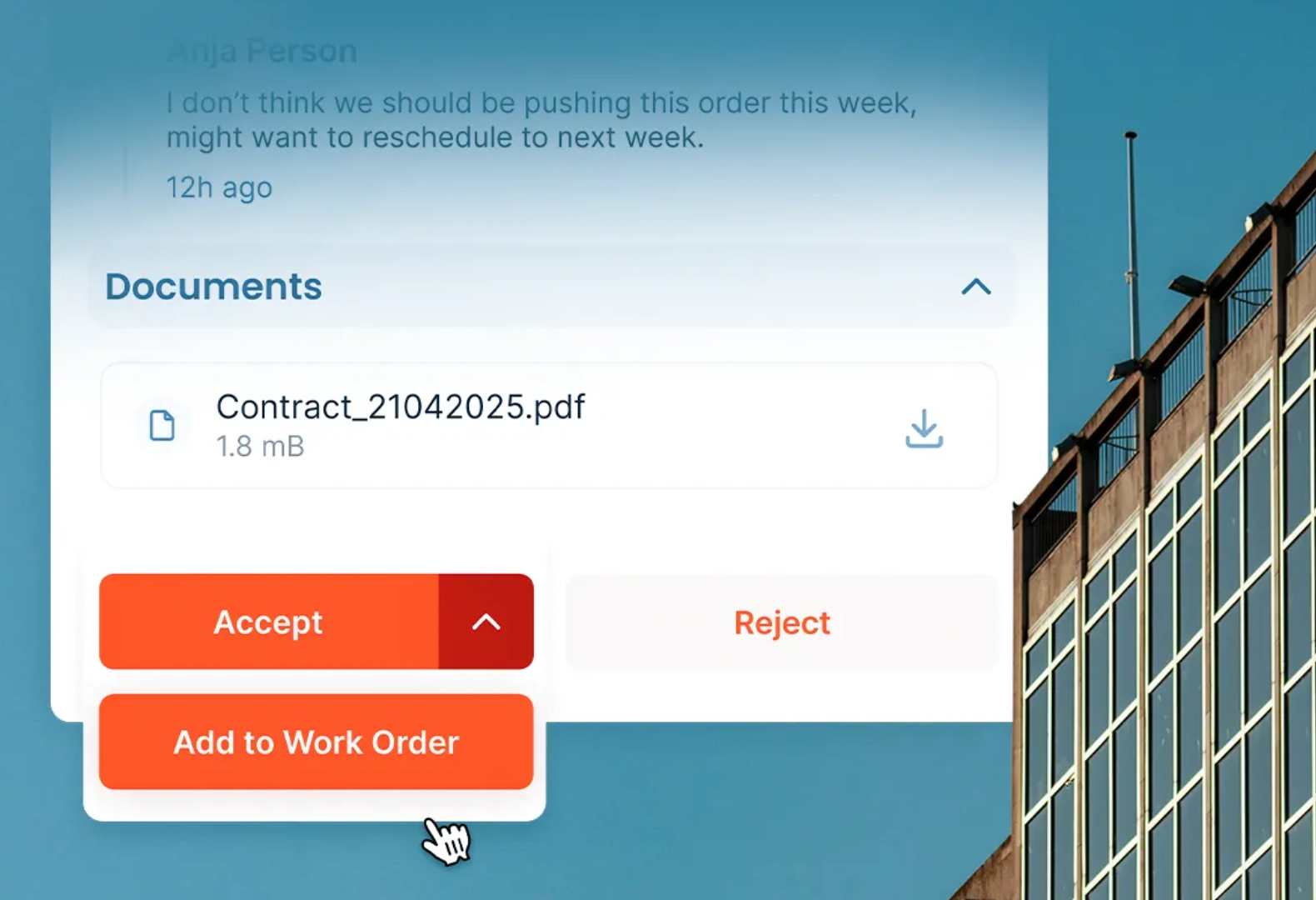

Tracking completion through a CMMS builds accountability and transparency. Supervisors can see when a task was finished and by whom. They can check notes and give the approvals.

Integrating SOPs into a CMMS such as Serwizz not only supports consistency and compliance but also saves time on administrative tasks. It keeps your team aligned, your equipment properly maintained and your operations running efficiently.

Building a Culture of Reliability Through SOPs

SOPs should be more than just checklists for you and your team. Try to make it part of your company’s culture. Try to educate your team that following a procedure is there to help them in everyday work, rather than controlling them. Maintenance then should focus on doing the task things the right way, every time.

A strong SOP culture builds trust. Your team knows what’s expected of them, while you as a manager can focus on the results. SOP puts safety into first place, making it a priority for the team. SOP also provides you reliability: equipment work better and downtime drops.

SOP also results in faster onboarding of new team members. When procedures are written clearly, new team members can learn by doing and not just by watching. The result is confidence, teamwork and smoother operations.

SOPs is a document, but if used correctly, it helps in forming a company culture.

Conclusion

Your team may not have any SOP. Maybe they don’t even know what SOP is. Don’t worry. Try to educate them and choose one small task, like the monthly HVAC filter cleaning. Ask your technician to and write down how you actually do it, step by step. Test it, fix what doesn’t work and try it again.

Soon you will see the benefits, and probably you will write more SOPs. That will result in clear and simple procedures that your team can use in everyday work. Remember, that the goal isn’t to create folders with paperwork. The goal is to help your team be more confident and do the job safely. If you achieve that, the work will be smoother and you will notice less downtime.

Start small, keep it real and stay consistent. That’s how strong SOPs grow, one job at a time.