Maintenance

·

16 min read

Digital Transformation in Maintenance

Digital Transformation

Digital transformation is a term that gets thrown around a lot, but let’s be honest — half the time people aren’t even sure what it means. Some think it’s just about installing AI, IoT or the newest maintenance software. Sure, tools like AI or a new CMMS can help. Nobody’s arguing that. But if all you do is throw technology at the problem, the real issues don’t go away. Digital transformation is a journey, not a destination. And in maintenance, that journey usually starts way before the software shows up — it starts with the basics: how work orders get passed along, how new techs are trained on the floor, and how breakdowns actually get reported.

And here’s the thing. Tech doesn’t fix messy processes. If your scheduling is all over the place or your team isn’t bought in, a new system won’t suddenly clean it up. I’ve watched companies spend big money on software, only for it to sit there unused. Why? Because nobody explained how to use it, or the culture just wasn’t ready for change. At the end of the day, the tool itself wasn’t broken — the way it was introduced was.

Another trap a lot of organizations fall into is digitizing bad processes. If a workflow is broken, making it digital just makes the problems move faster. Imagine a technician putting bad data into a CMMS. The reports will still be wrong, only now they look more official. Managers end up making bad decisions because the foundation wasn’t fixed first. That’s why before going digital, you need to step back: where are the bottlenecks? Where do jobs get delayed? What data is missing? Fix that first, then bring in the tech.

Data is the other side of the story. Without accurate, reliable information, even the most advanced system becomes useless. But when your processes actually work and your data isn’t all over the place, that’s when the software starts to help. Repairs get done faster, surprises happen less often and the planning finally starts to make sense.

Here’s the thing: digital transformation isn’t about jumping on the newest trend. It’s about your people — their routines, their habits, and if they’re ready to change. Tech can give a hand, but at the end of the day, it’s just a tool. The real work? Getting your team ready, tightening up your processes, and taking it step by step on the journey.

Digital Transformation in Maintenance

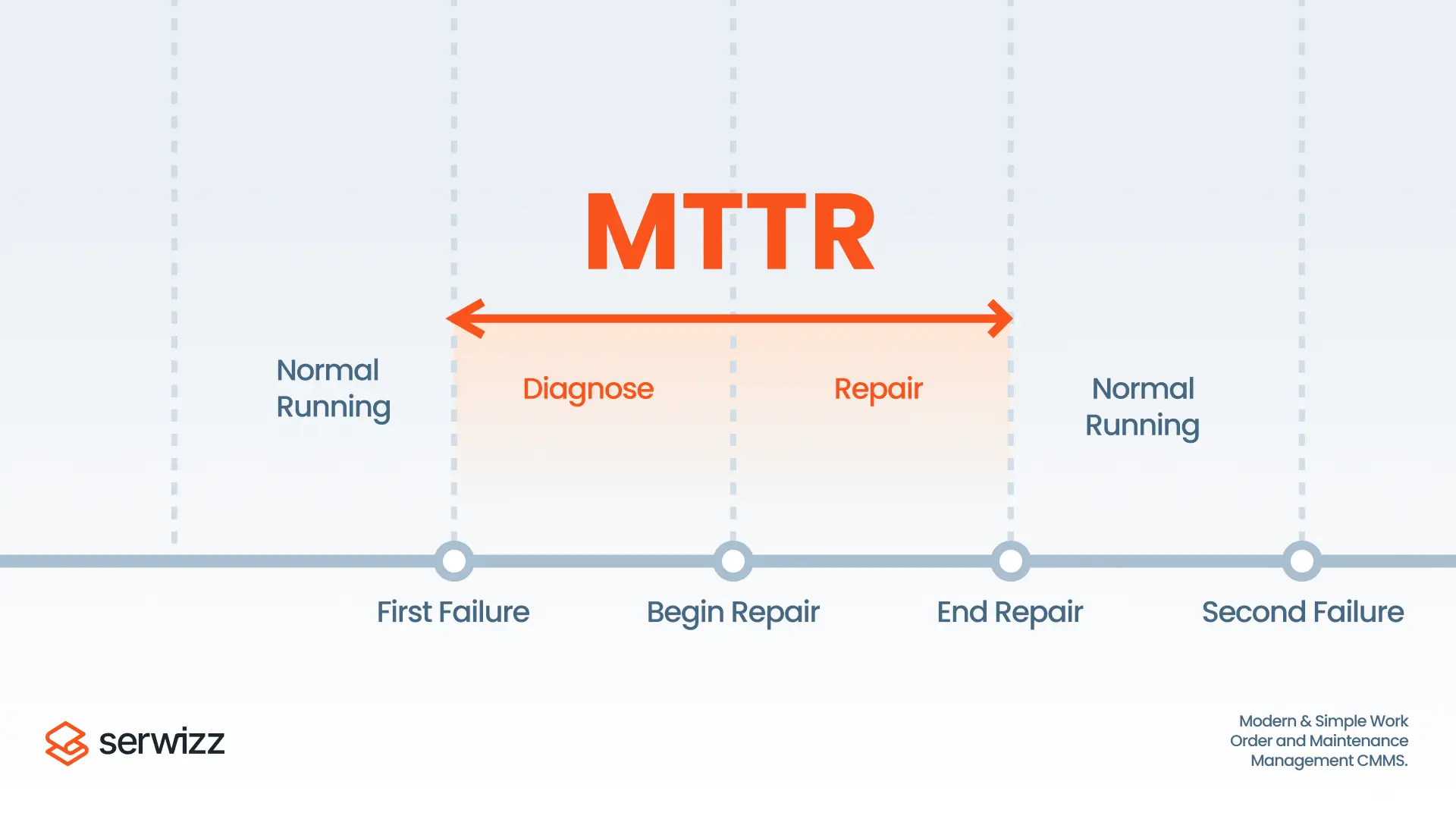

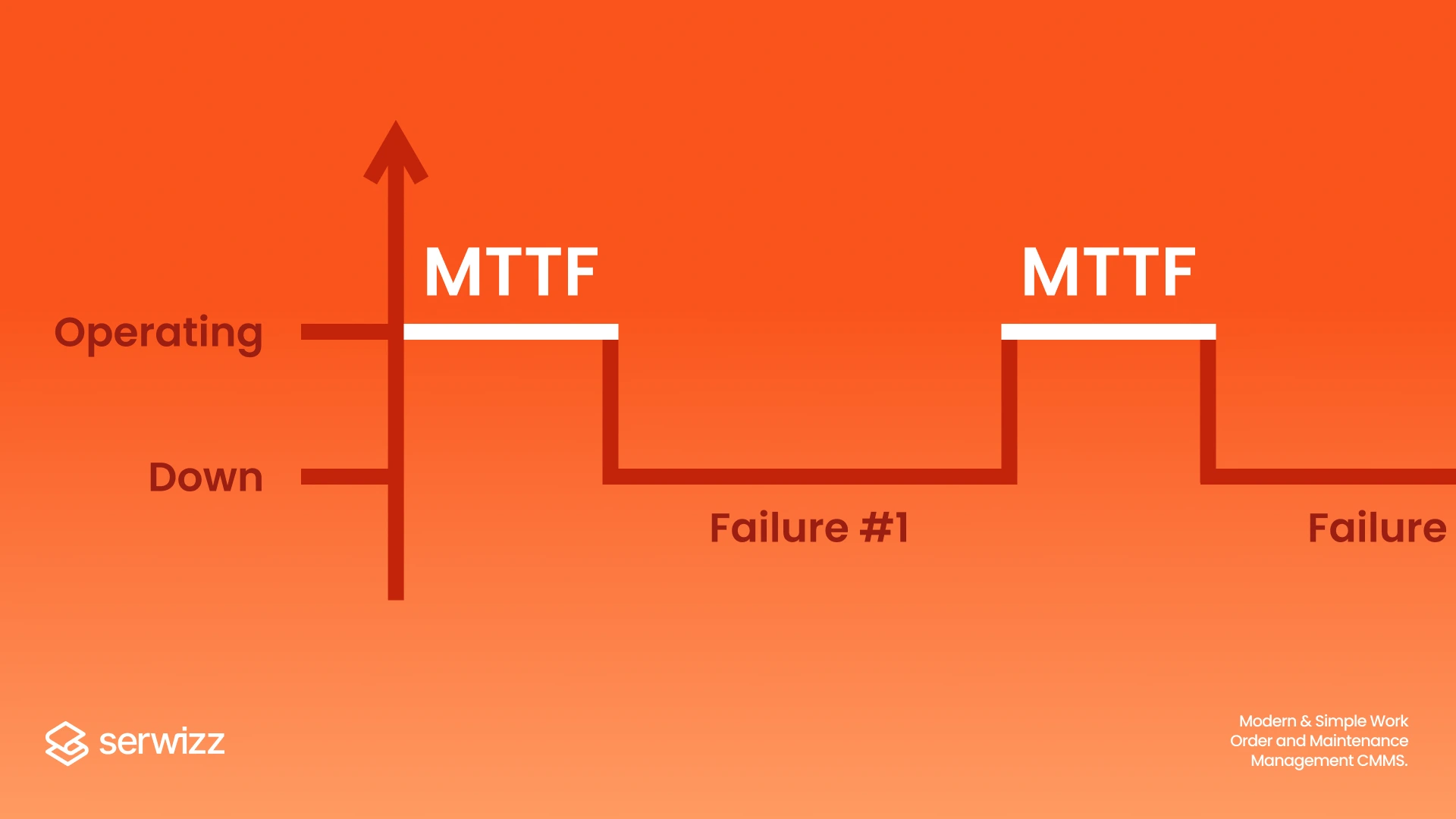

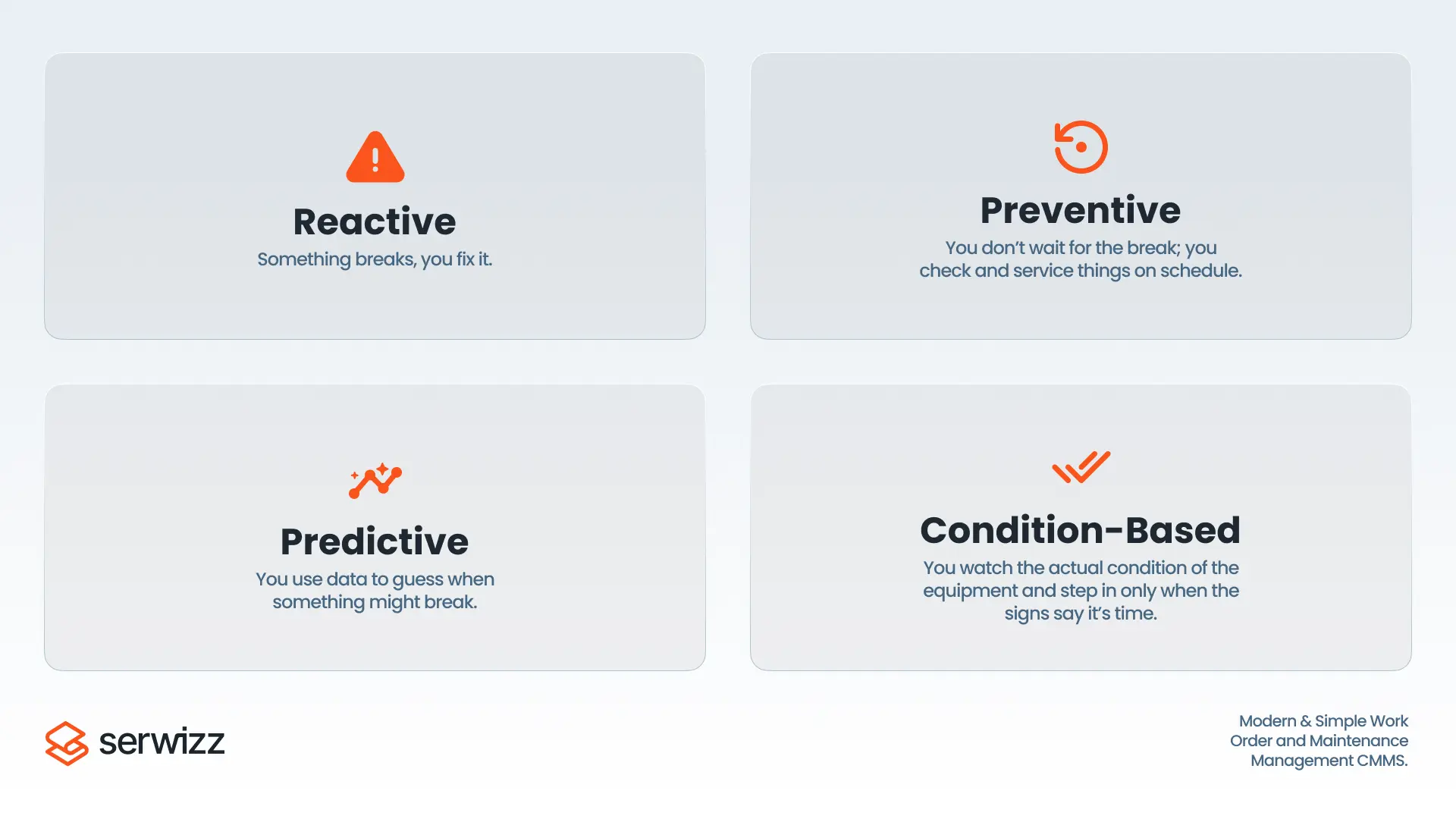

Maintenance has always been about keeping machines running and avoiding big surprises. The thing is, nowadays, digital tools are becoming a big part of that. Teams aren’t just fixing breakdowns anymore — they’re trying to spot problems before they happen. I’ve seen it happen on the floor: a sensor notices a motor vibrating more than usual, and the team swaps it out before it shuts down the line. That’s the move from reactive to predictive maintenance. It’s a big shift, but it really works.

Digitizing how you manage maintenance changes how people do their jobs day to day. Simple stuff can get automated, and real-time data helps teams plan instead of constantly putting out fires. IoT sensors are a great example — they track temperature, vibrations, or pressure and feed that info into one system. Then software can look for patterns that hint at trouble. The team gets a heads-up, schedules the repair, and everything keeps running smoothly. No chaos, no frantic calls at 2 a.m., and fewer costs down the line.

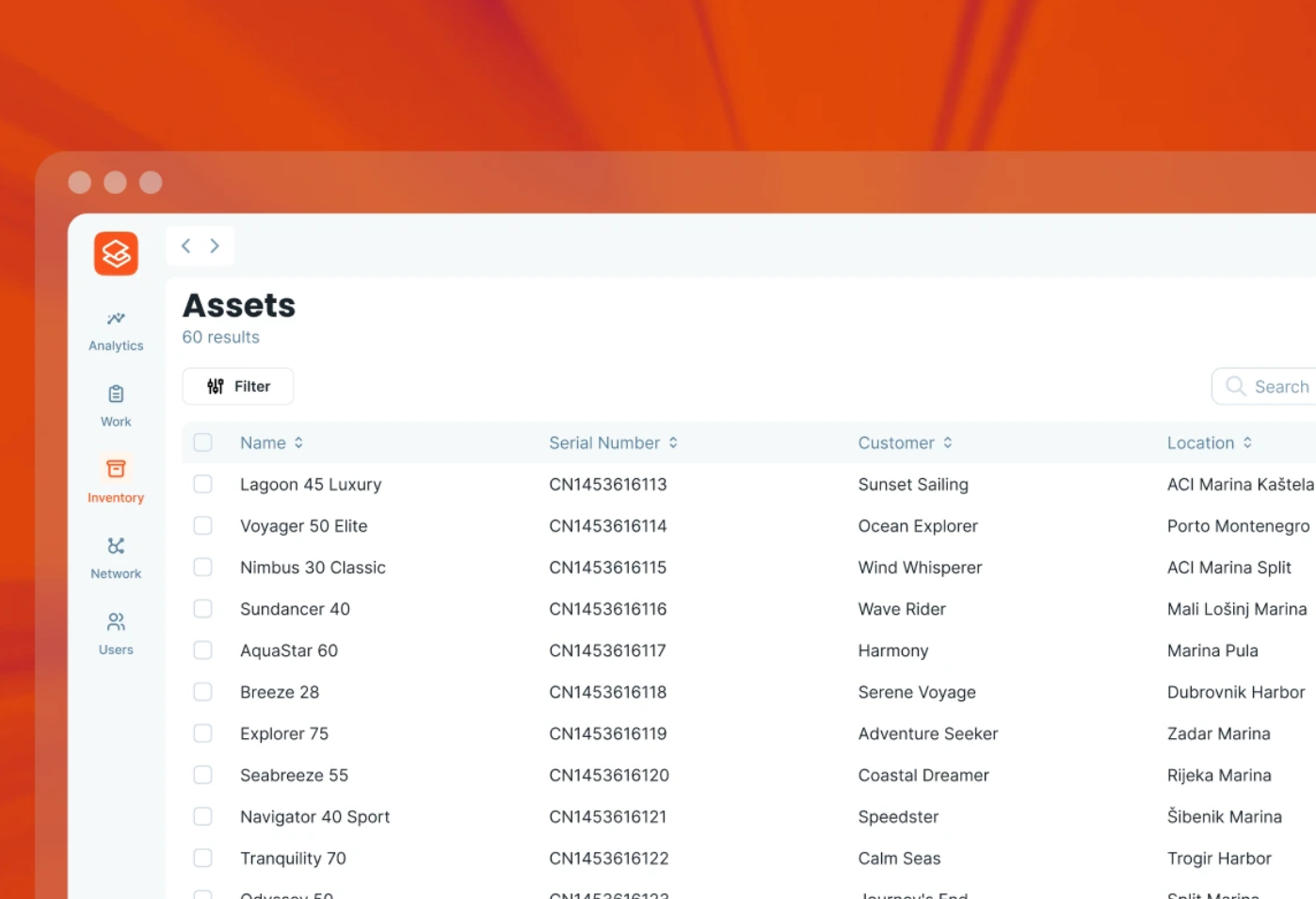

Centralizing information helps a ton too. No more hunting through spreadsheets or stacks of paper. Everything’s in one place. You can spot which machines need work, set up preventive schedules, and get reports that actually tell you something useful. It also means less time buried in admin work and more time doing meaningful tasks — fixing things, checking equipment, making sure everything stays up and running.

Here’s the big picture: digital transformation in maintenance means teams don’t have to sit around waiting for something to break. Regular checks, fixing things on time, and catching issues early start to feel normal instead of lucky. Tech helps a lot, but the real difference comes from how people do their work, how the processes are set up, and whether anyone’s actually paying attention to what the machines are trying to tell you.

At the end of the day, it’s not about fancy software or chasing the latest tech fad. It’s about your team, the habits they’ve built and being willing to change how maintenance gets done. The tools can help, sure, but the real work is still in people and processes.

Benefits of Digital Transformation

Digital transformation isn’t just about fancy software — it can turn maintenance from a necessary cost into a real advantage. The benefits show up everywhere: efficiency, savings, and even safety improvements on the floor.

Optimized Equipment Uptime

You know the first thing that changes? Machines actually stay running. Real-time monitoring keeps them within safe limits, so there are fewer nasty surprises and the equipment lasts longer. I’ve seen crews plan their days without constantly chasing breakdowns — it’s a huge relief when things start running like that. Less downtime keeps production smoother, schedules on track, and money in the budget.

Maintenance History Tracking

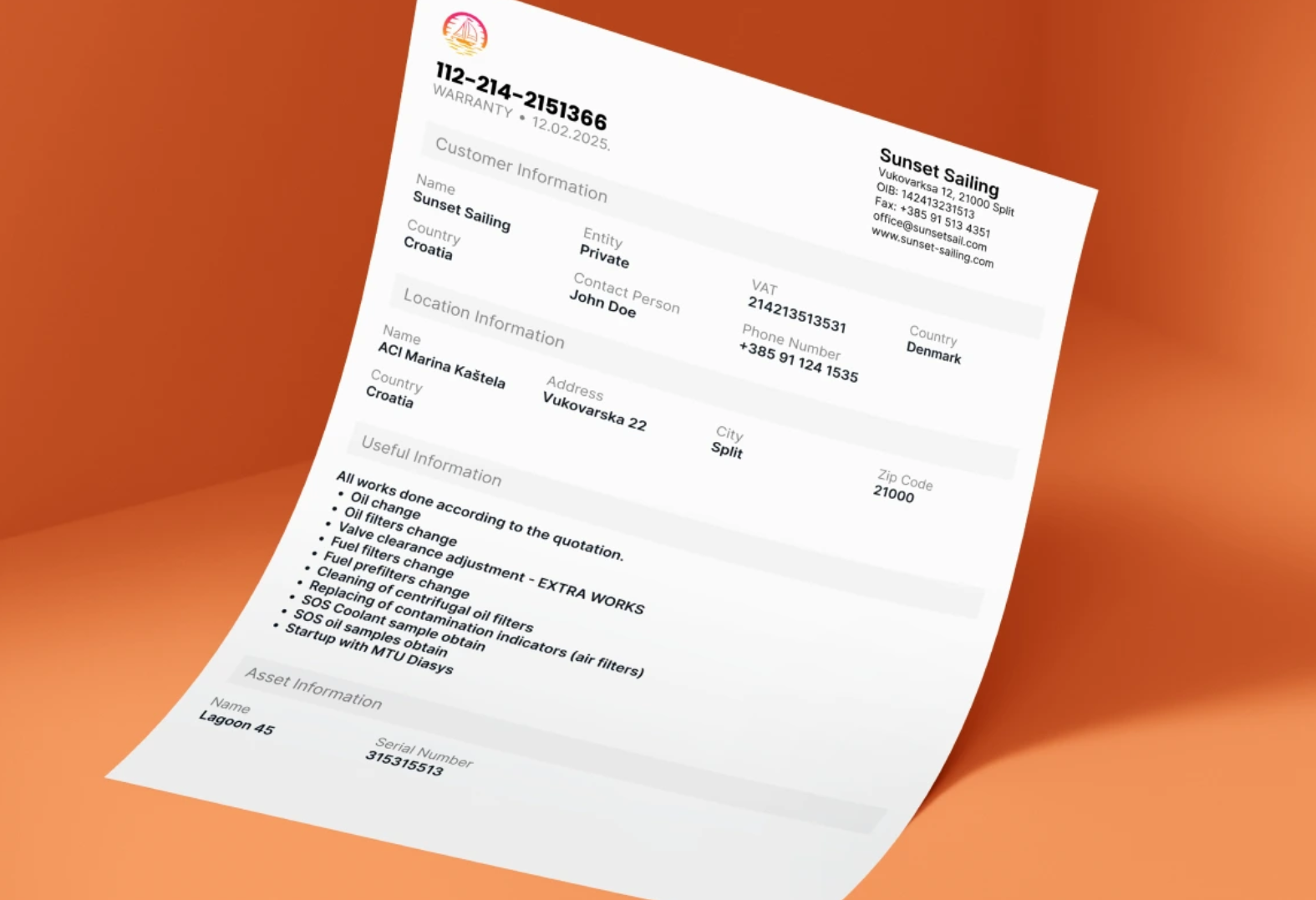

Keeping good records really helps. A maintenance log that actually gets updated makes life on the floor a lot easier. You can see what’s been done, what’s coming up, and which machines have been giving trouble. It also helps when regulators stop by. You can show them the work, no scrambling for papers. Once the team sees the data is solid, deciding what to do each day gets a lot easier.

Reduced Maintenance Costs

Catching problems before they blow up saves cash. Predictive maintenance keeps emergency repairs down and makes the most out of your parts and crew. I’ve seen it firsthand: avoiding just one big breakdown can save thousands, sometimes way more, depending on the machine. It’s not a theory; it actually happens on the floor.

Better Decision-Making

When your machines start sending real-time info, everything on the floor changes. The team can see problems as they pop up and react before they become a mess. IoT keeps the data flowing, and AI can flag patterns that crews might not notice. That early warning helps the team schedule repairs at the right time instead of just guessing. Fewer surprises, faster fixes, and a team that feels like it’s actually running things — not just reacting all the time.

Other key benefits include:

- Less downtime

- Lower costs

- Longer equipment lifespan

- Improved safety

- Optimized maintenance processes

- Improved maintenance practices

- Better communication (via mobile and tablet apps, improving access to information)

In short, digital systems save money and create value. They help the team get more done and do it better. That usually means happier customers and more business coming in.

Challenges of Digital Transformation

Sure, digital transformation sounds great on paper. But making it actually work? That’s another story. Teams hit all sorts of roadblocks — things that slow work down, or even stop it dead in its tracks. Knowing what’s coming can save you a lot of headaches.

Employee Resistance

Getting everyone on board? Yeah, that’s not easy. Lots of techs have been doing things the same way forever, and suddenly you drop a new digital tool on them — it can freak people out. Some folks worry they might lose their jobs. Others just stick to old habits — feels safer that way. I’ve watched it happen: a new system goes in, and the team barely touches it for weeks because they’re unsure what to do. Honestly? Getting people on board is often harder than dealing with the tech itself. Bring staff in early. Show them how the tools actually make their work easier. Give them training that fits their day-to-day. Skip that, and resistance is almost guaranteed.

Leadership Inertia

Another big hurdle is leadership inertia. Some company leaders like the idea of being digital, but they’re not ready to commit fully. It’s easier to work in the business than in the business. Day-to-day stuff usually takes over, and thinking about the bigger picture? That often gets shoved aside. I’ve seen plenty of digital projects flop because companies get excited about the newest flashy tools but forget to see if they actually fit how people work. Without leaders rolling up their sleeves and putting in the time, digital transformation just doesn’t happen.

Budget Constraints

Money’s tight — always. Most maintenance teams are busy keeping the lights on and machines running, so finding extra cash for new digital tools can be a real headache. Software, hardware, training and integration can get expensive fast. You really need to plan carefully and have a clear story for why the investment is worth it.

Integration Challenges

Getting new tools to play nicely with old systems? That’s a headache. A lot of teams are still stuck on spreadsheets or old platforms that don’t talk to each other. The data gets trapped and nobody really sees the full picture. Usually, it works best to tackle it slowly. Start swapping in new platforms one at a time. Pull the data together as you go and don’t expect everything to work perfectly from day one. It takes a while, and yeah there will be little victories along the way that keep people motivated.

Lack of Technical Knowledge

Finally, not every team has the chops for big digital projects. Maintenance crews know their machines and buildings inside out, but picking the right tech, setting it up, and keeping it running? It can feel pretty overwhelming. A tech partner who’s been through it before can really help. They show the team how to work the new tools into everyday routines without turning everything upside down.

Implementing Digital Transformation

Making digital transformation actually work? That’s more than just buying some new software. It takes planning, a bit of patience and figuring out what really works for your crew. One approach might click for one team and completely flop for another. There’s no magic formula.

Start with a clear strategy

The first step is figuring out a plan that actually makes sense for your team. That might mean thinking about different approaches like outcome-based or condition-based maintenance. The key is knowing how digital tools will support your maintenance work so changes stick long-term.

Take it slow

Big, sudden changes rarely work. Start small. Try out a pilot project and see what works. Learn as you go, make tweaks along the way and don’t try to change everything at once that usually just causes headaches on the shop floor. Move step by step: from manual processes to partial automation, then to full automation when the team is ready. Pilot projects also show value early and tracking metrics from day one is a must.

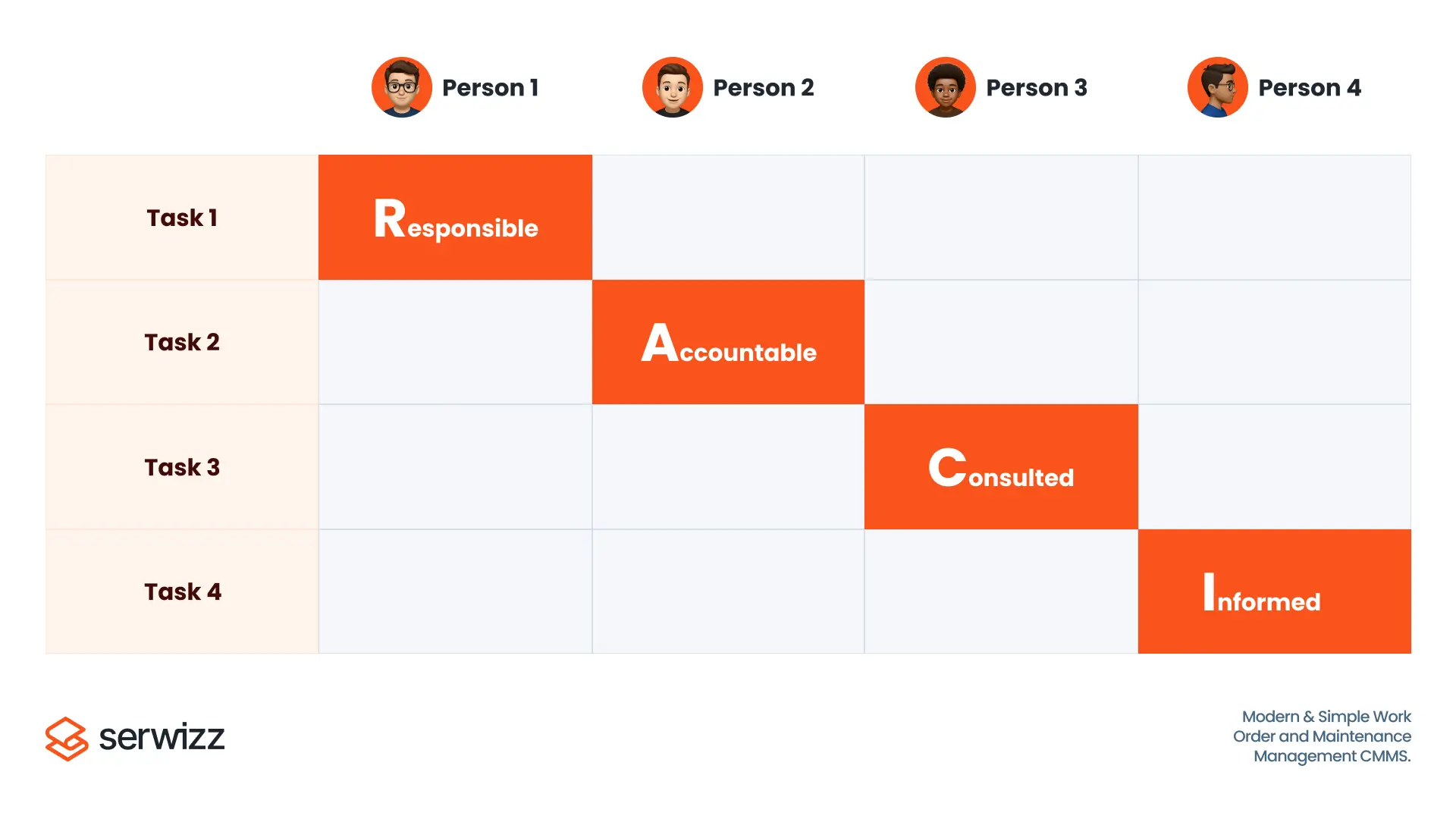

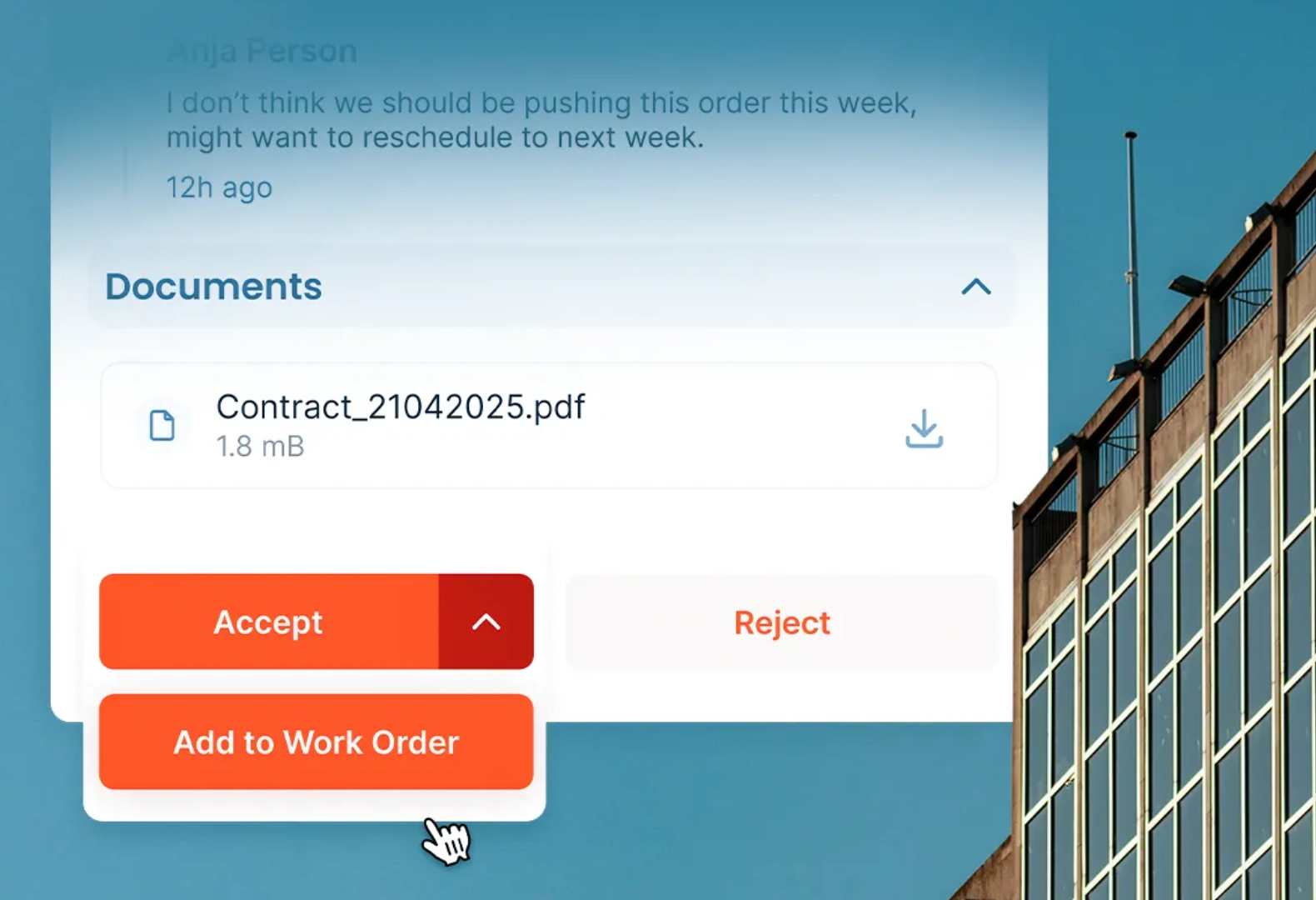

Get employees involved from day one

Getting employees involved from the start is huge. Digital transformation only works if people are on board, so their participation matters. That means including maintenance leaders in strategy talks, giving hands-on training with new tools, and setting up ways for the team to share ideas. Everyone should see how the changes make their own work easier, not just help the company.

Make the training fit each role, so no one feels lost. Switching to digital maintenance shakes things up. It touches a lot of people and changes how they do their work. Some people will push back — and that’s okay. You’ve got to be straight with them - explain why this change is happening and what it actually means for their work. Let the team help plan things, give them room to figure stuff out and stick around to lend a hand when things get messy. That’s usually what helps things run smoother and keeps everyone from feeling lost.

Choose the right partner

A digital transformation partner isn’t just a software vendor. They should guide your team, answer questions and offer ongoing support. A good partner actually knows the maintenance world and what you’re trying to do. They stick around for the long haul. Jump in to help the team figure out the tools. Make sure people can actually use them and don’t expect it all to go smoothly at first.

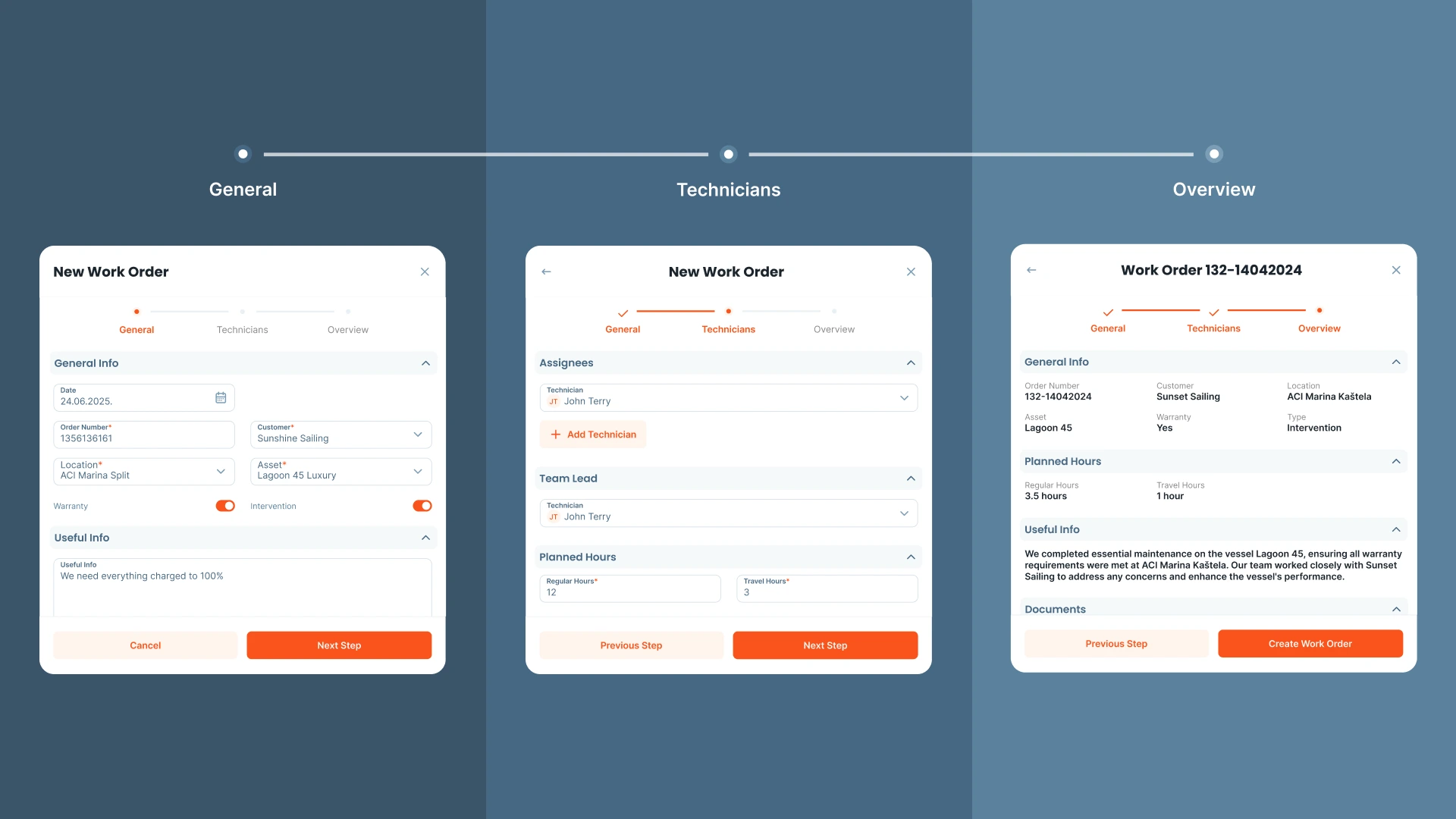

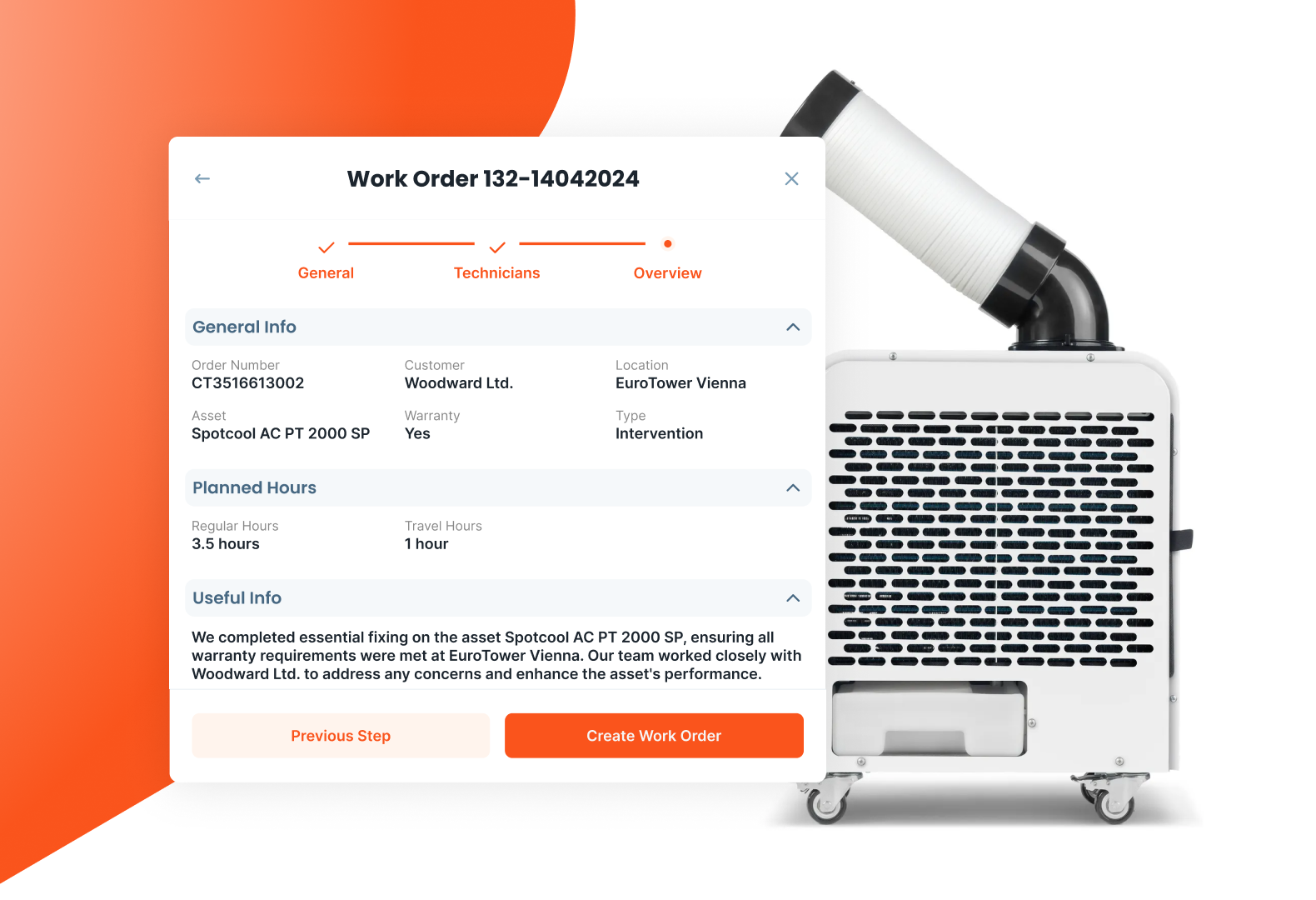

Remember: it’s a journey, not a destination

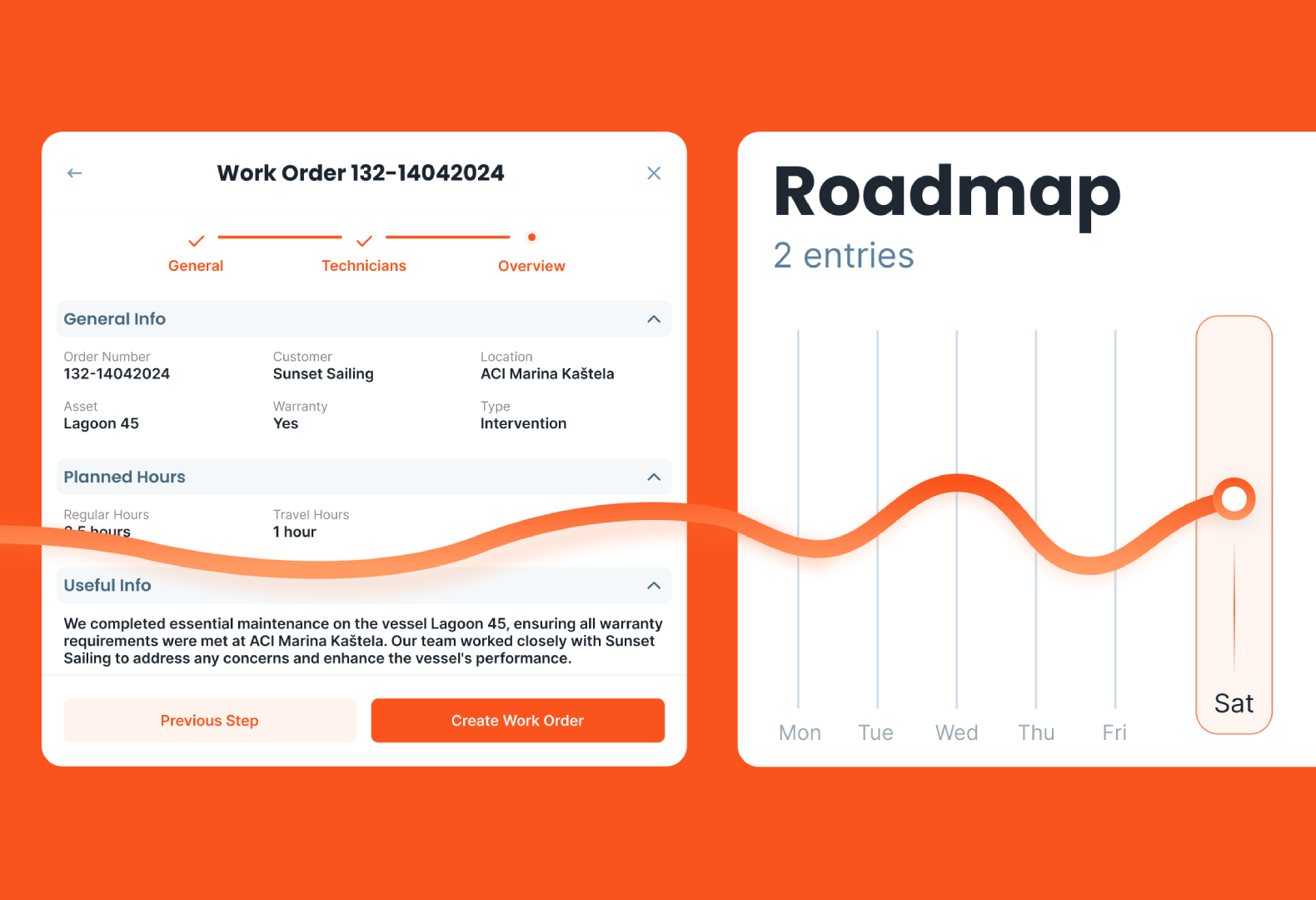

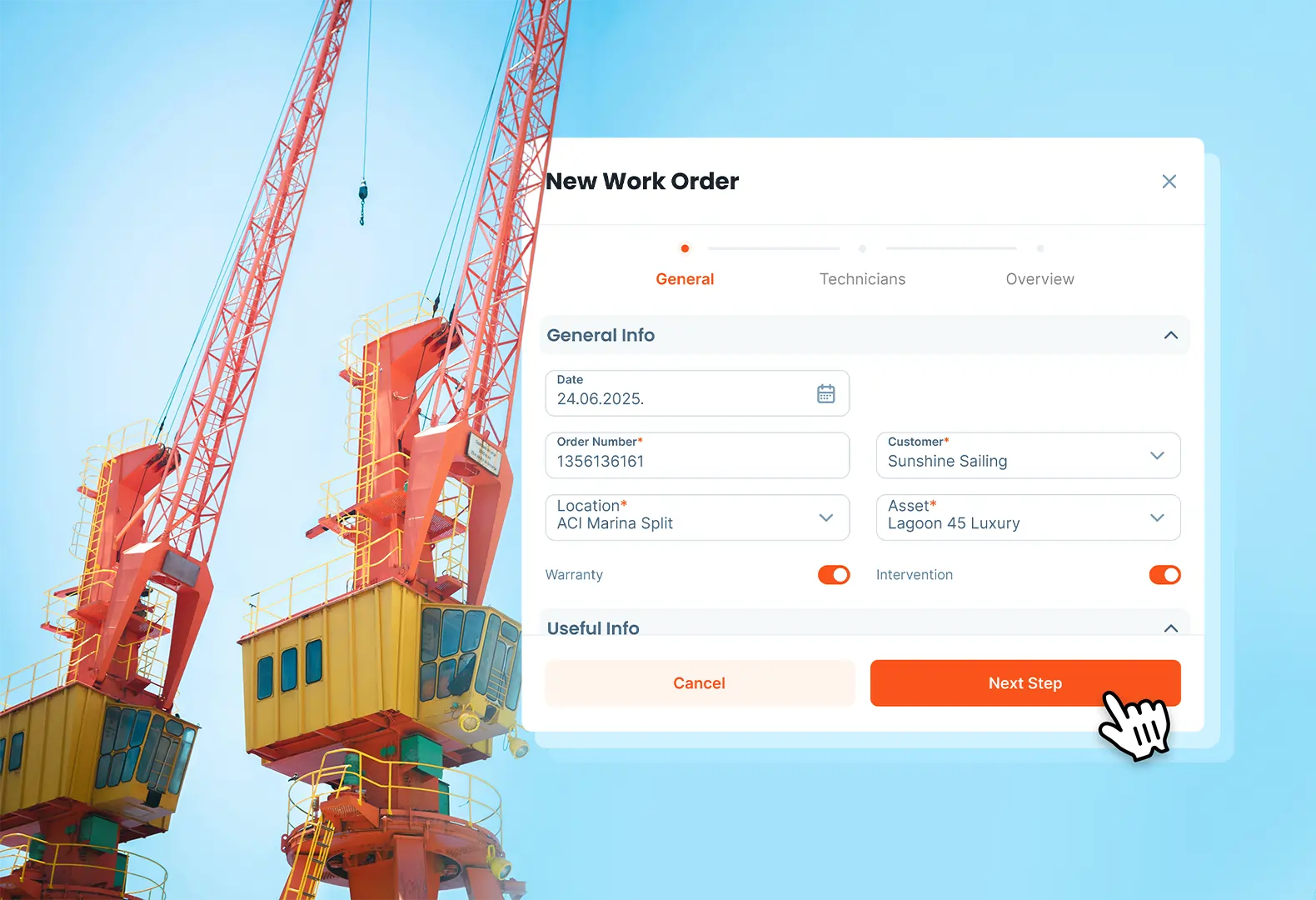

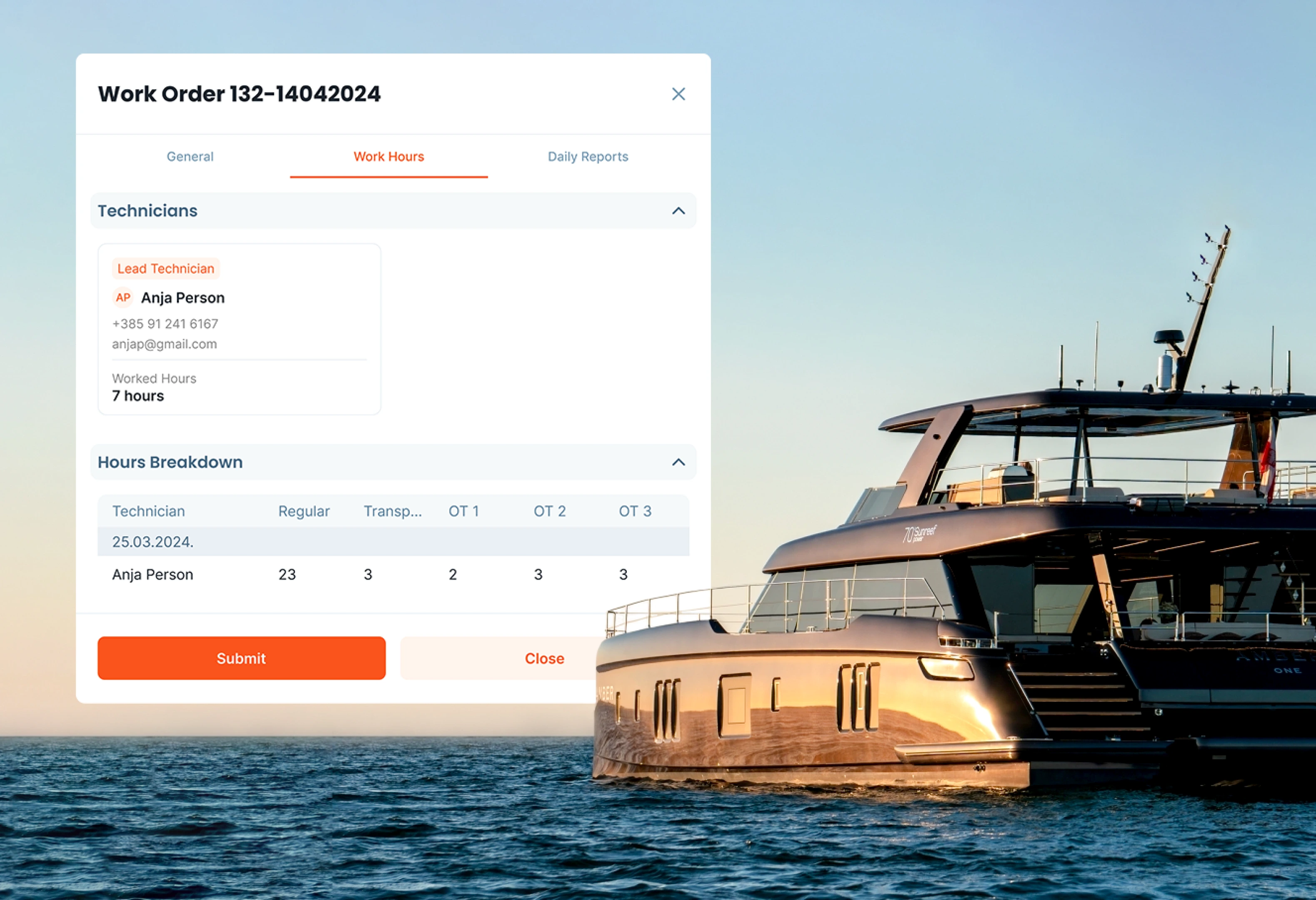

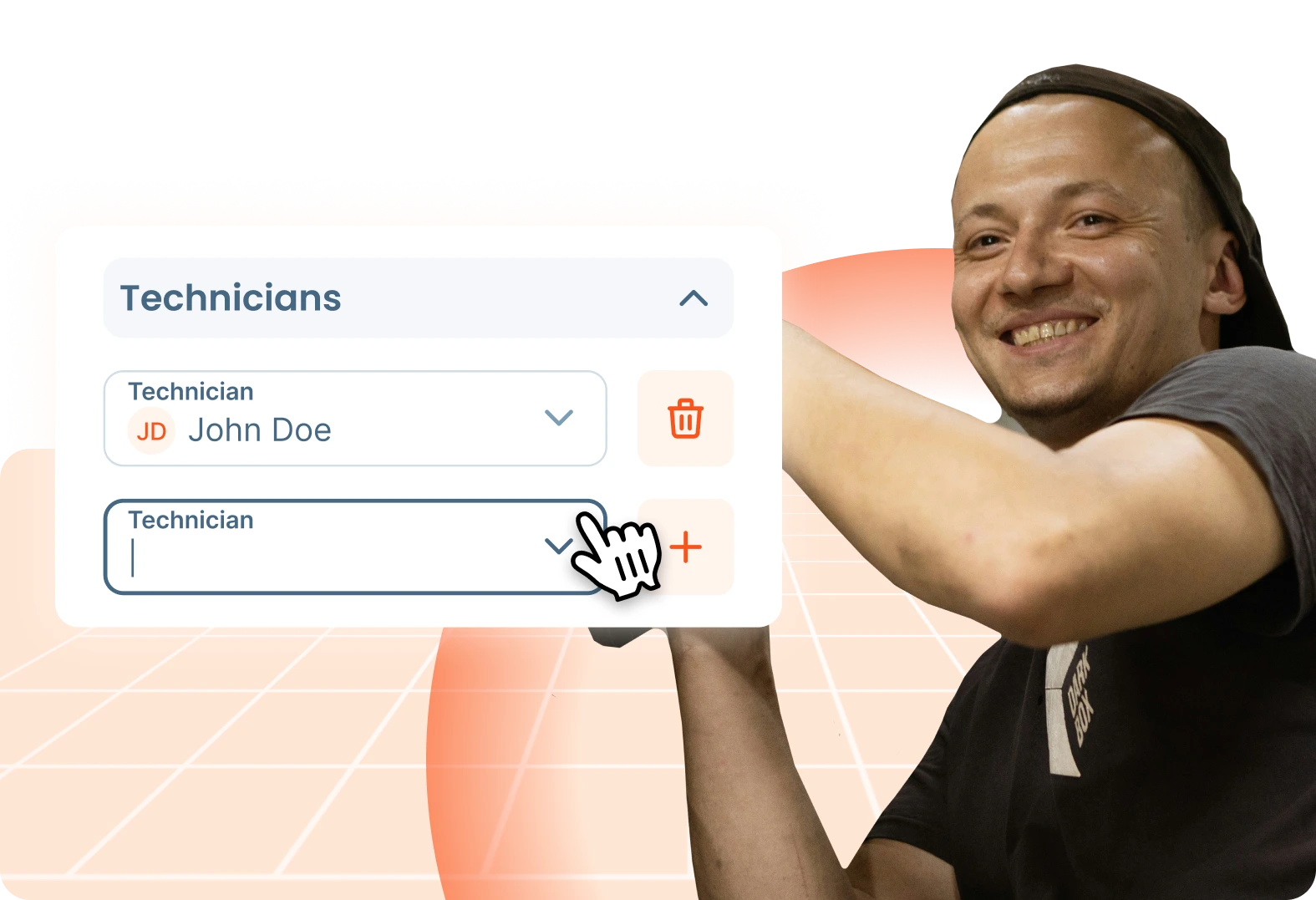

Digital transformation isn’t something that stops once the system goes live. Digital transformation keeps going. You’ll need support, updates and a way to check that the tools are actually helping day-to-day. A good CMMS, like Serwizz CMMS, can really help out: it lets you see what’s happening with assets in real time, stay on top of preventive maintenance, manage work orders more smoothly,and make smarter decisions with the data you’ve got.

Conclusion

Digital transformation is changing how maintenance teams work, for real. It’s not just about fixing breakdowns anymore. These days, teams can sort of catch problems before they happen. They keep things running, most of the time without surprises and adjust how they work as they go, though, you know, it’s not always perfect. Everyone has a part to play: techs, supervisors, managers… all of them. Take it slow, roll out changes in little chunks and before long, downtime doesn’t feel like the usual headache anymore.

Digital tools can make life easier, sure, but only if people actually use them. Teams start getting more from the machines, finish jobs a bit quicker and sometimes finally stop making the same mistakes again and again. It takes time, and it takes everyone paying attention, but it can really make a difference.

And it doesn’t just help the team — the folks using the equipment notice it too. That builds trust, keeps customers happy, and helps the business grow a little at a time.

It’s definitely not a quick fix. Honestly, it’s not simple either. Technology is there to help people get things done — it doesn’t run the show by itself. Take it step by step. Involve your team. Get the right partners who know what they’re doing and adjust as you go. Do all that, and you can handle the changes, stay competitive and keep things running without too many headaches. Even when the unexpected pops up.