Maintenance

·

28 min read

What is MTTR?

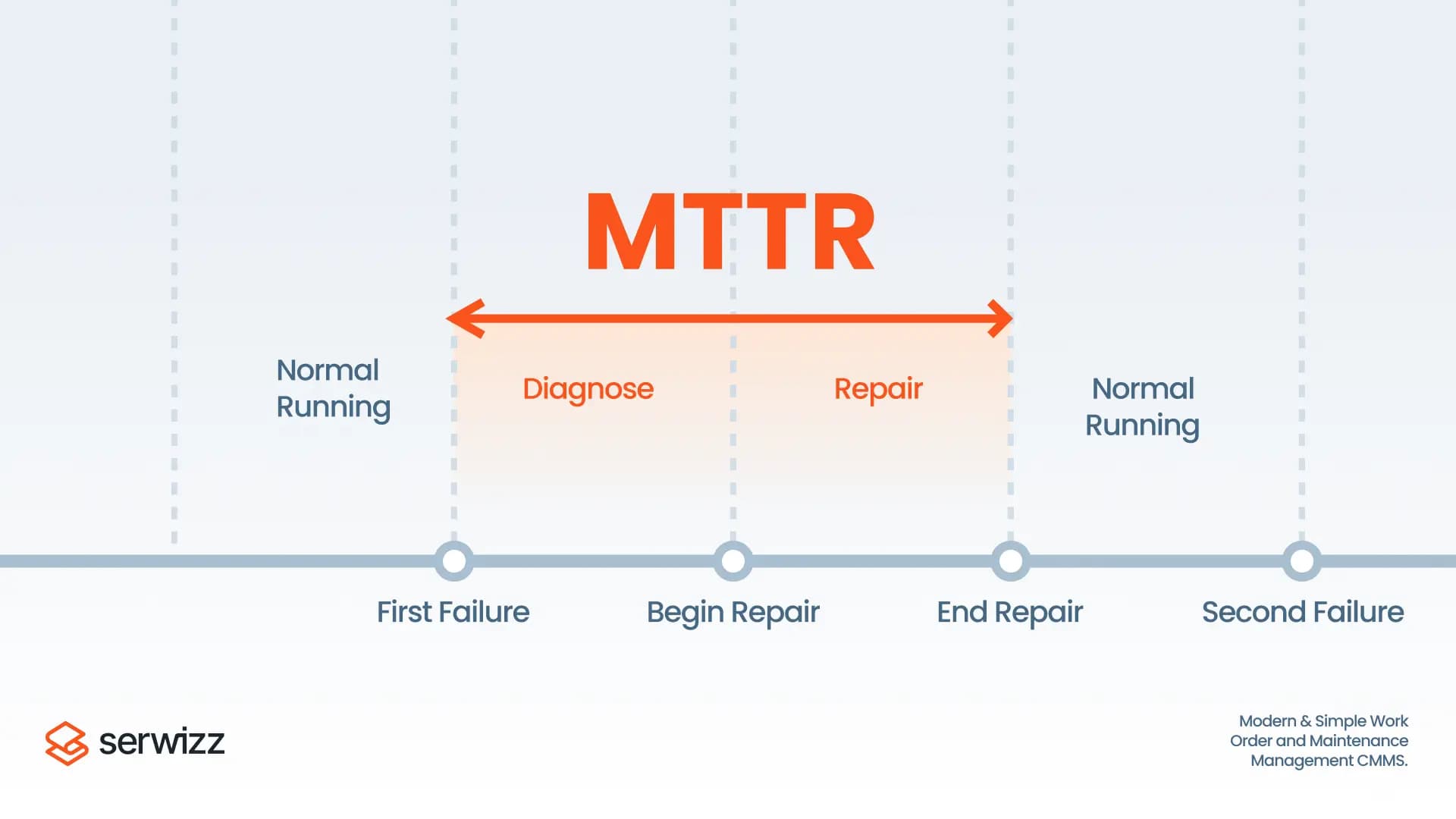

To begin with, MTTR or by its full name - Mean Time to Repair is another quite important measurement in preventive maintenance. In measures (on average) how long it takes your team to repair a piece of equipment or system after it stopped working.

If you are coming from the maintenance world, you are familiar with issues in production, when machines stop working. Sometimes one piece of equipment that stopped working can cause the entire production line to stop. Or imagine in the middle of summer, your air-condition system stops working, and all your employees have issues with health and productivity. In short, even a small system outage can become a bigger problem.

Downtime results with loss of money, but also with stress, frustration and unhappy customers. In order to avoid that, many companies started using MTTR. It helps them to measure and improve how fast will their equipment be up and running again.

If you manage to understand MTTR, you can react faster when things stop working but also make better plans for the future. You can allocate resources more effectively and make more reliable maintenance plans. In the sections ahead, we’ll dive deeper into what MTTR is, how to calculate it and explain why it matters in every maintenance strategy.

What is MTTR?

MTTR is not just a number in a maintenance report. It provides you the answer to the question - when will something be working again, once it’s stopped working.

MTTR includes all the steps in the repair process:

- Detecting the issue: Recognizing that equipment isn’t working properly.

- Diagnosing the problem: Understanding what is wrong and why.

- Gathering resources: Collecting tools, parts and the documentation.

- Repairing the equipment: Performing the actual fix.

- Testing and verifying: Ensuring the equipment is working again.

MTTR focuses on fixing the problem and not on prevention. Unlike metrics such as MTBF (Mean Time Between Failures), which measure how long equipment will work before it stops working, MTTR focuses on recovery after a problem is detected.

There are a few misunderstandings about MTTR:

- MTTR measures more than actual repair time. It measures total time from when the equipment stopped working, until it’s back online

- Lower MTTR is not always better. Of course, you want to fix the issue as soon as possible. But keep the quality level high. If you fix something quickly, you might repeat the problem.

- MTTR doesn’t stop issues. Also, it doesn’t replace preventive maintenance but it will help you improve the repair time.

- If you understand MTTR and use it, you can help your team to improve the repair process and reduce the down time.

How to Calculate MTTR

Calculating MTTR is simple. It’s important to understand what this measure tells you and which parameters to take. MTTR measures the average time your team spends fixing an asset that stopped working and getting it back to work.

The formula for MTTR is:

MTTR = Total Downtime / Number of Repairs

- Total Downtime: The sum of all time spent on repairs during a given period.

- Number of Repairs: The total number of repairs in that period.

Example: Let’s say you have a production machine that stopped working three times in a month:

- First breakdown: 4 hours to repair

- Second breakdown: 6 hours to repair

- Third breakdown: 5 hours to repair

- The total downtime is: 4+6+5=15 hours.

- The number of repairs is 3

- MTTR is: total hours (15) / total number of repairs (3)

Our MTTR is in this case 5. This means, on average, it takes five hours to fix this machine.

It’s important to define what you include in downtime:

- Include: Time from when the equipment stops working until it is fully working again. This includes finding a root cause of a problem, waiting for spare parts, fixing and testing.

- Exclude: Scheduled maintenance or preventive work. Machines are not working in that period, but you’ve planned this.

Types of MTTR

1. Mean Time to Repair (Classic Definition)

This is the standard MTTR that we focus on in this blog. This measure is applicable on physical assets, like machinery or HVAC systems. The metric tracks the time from failure detection to full restoration.

Example: A conveyor belt stops working. Your maintenance team identifies the problem, replaces a motor and tests the system. The total time spent is MTTR.

2. Mean Time to Recovery (MTR)

In IT and digital systems, a similar measure is used - Mean Time to Recovery. It focuses on putting the system back to normal. It includes:

- Detecting system outages

- Diagnosing IT issues

- Applying patches or reboots

- Restoring user access and functionality

Example: A server crashes during business hours. The IT support team detects the issue, performs the backup and ensures all apps are working. The total downtime is MTR.

3. Mean Time to Resolution (also MTTR in IT/Service Contexts)

In IT customer support, MTTR means Mean Time to Resolution. This measures the average time to resolve a ticket, incident or request.

Example: A software bug in applications causes an issue for users. The support team finds the issue, and creates a fix. The time from ticket creation to resolution is MTTR.

4. Mean Time to Respond (MTTR Variant)

Mean Time to Respond, measure the time from issue is addressed after it has been discovered. Often is used in service-level agreements (SLAs) where response time is critical.

Example: A technician receives an alert that a machine in building B is not working. The time that takes technician to come from building A to building B is s Mean Time to Respond.

If you understand the difference, you can easily choose MTTR for your industry or equipment type. While the core principle is the same: measuring how quickly a problem is resolved.

Why is MTTR Important?

Some of you might wonder, why do we need one more calculation. Don’t we have enough numbers already. The thing is, MTTR will affect your daily operations and costs, so it would be really beneficial to understand its importance.

1. Minimizing Downtime and Boosting Productivity

When your machine stops working, each minute is crucial. Each minute equipment is down, meaning your costs are higher. In the production line, one asset that stops working can cause whole production to stop. In the IT sector, system down means all employees are on hold with their tasks.

MTTR helps you detect how long these interruptions last. By knowing MTTR you can adjust your plans to be more effective, and you can optimize your resource allocation.

2. Cost Control

As mentioned in the previous chapter. One asset down, means your cost is higher. How come? You have to send an emergency team, order spare parts quickly, maybe even pay overtime. If you track MTTR you can improve inefficient processes and avoid stops in production.

Example: If your team needs 7 hours to fix one specific asset, you can analyse MTTR for that asset. Analysis might show you that it takes that long because the spare part is in a warehouse that is far away. Or maybe your procedure to fix the asset is not clear to the whole team. If you recognize and fix these problems, your MTTR might approve.

3. Safety Considerations

Sometimes issues with equipment or assets are more than just a frustration. In medicine for example, they can cause significant danger for patients. If you know your MTTR, you can prepare by having additional equipment ready and your team focuses on fixing faulty assets, without the pressure.

4. Customer Satisfaction and Service Levels

For businesses that serve clients directly, MTTR affects more than internal operations—it impacts customers. In IT services, a prolonged system outage frustrates users and erodes trust. In manufacturing, issues in production affect delivery time.

You should aim to keep MTTR low. In that way you show your customers that you are responsive, reliable and able to handling problems efficiently. It builds confidence and strengthens your reputation.

5. Insight into Maintenance Effectiveness

MTTR can provide you feedback if your maintenance model is working well. If MTTR is high, it can indicate that your team lacks skill, that you as a company use inefficient processes or that you have issues with low quality equipment. Monitor MTTR and try to figure out the root cause of the issue. That will improve your process and make the team more efficient.

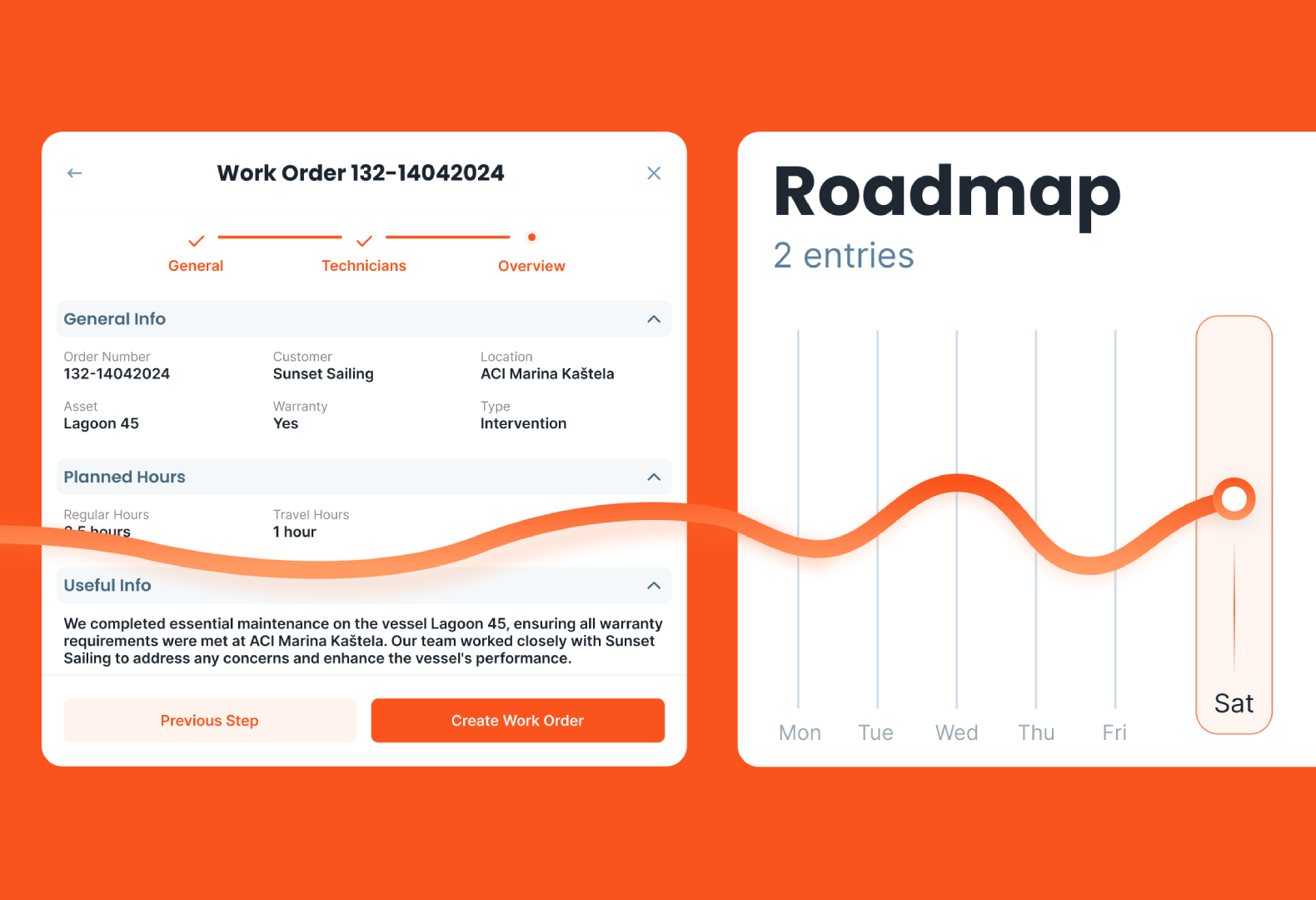

Benefits of Tracking MTTR

Now that you know MTTR and how to calculate it, let’s go to the next step. Real benefit of this measure comes if you track it for a longer period of time. MTTR can provide you insights and here some of the key benefits.

1. Better Planning and Scheduling

If you know your MTTR, you can make better or more realistic plans. Team managers can focus on scheduling maintenance tasks, ordering spare parts on time and planing team allocation.

Example: If you know that repairing a key equipment takes 5 hours, and that machine is rarely used in the afternoon, you can plan an afternoon shift, and have downtime when utilization is low.

2. Smarter Resource Allocation

MTTR helps you detect why it takes that much longer to fix a broken asset. It can show that spare parts are hard to find or that team is not fully provided with needed training. My understanding this you can invest in spare parts management or additional training.

3. Stronger Reliability Program

MTTR often brings more questions.

- Why do some machines take longer to repair?

- Are some assets often having issues?

- Can preventive or predictive maintenance help prevent issues?

These questions can help you improve your maintenance programs over time.

4. Benchmarking Performance

MTTR can help measure performance of your team, quality of your assets. You can compare:

- Which machines take longer to repair?

- Which technicians resolve problems fastest?

- Which vendors have more quality parts?

This benchmarking helps you make decisions better.

5. Improved Communication with Stakeholders

MTTR can help you describe not just quality but in quantity way what is improved. This can be important to your C-level or to customers. Instead of saying, “We’re doing repairs faster,” you can say, “We reduced our MTTR from six hours to four in the last quarter.” By using these phrases you can show the benefits of your team work.

Challenges in Measuring MTTR

In theory, MTTR is just another calculation. Track downtime, divide by the number of repairs and you’re done. In reality, measuring MTTR can be tricky. Many maintenance teams run into challenges:

1. Inconsistent Data Collection

One of the biggest challenges is how downtime is tracked. If your team forgets to log start and end time, or if you use different methods for logging, you might have MTTR that gives you wrong information, or misleading results.

2. Different Interpretations of “Repair Time”

Not every organization defines MTTR the same way. Some count only the “hands-on” repair time, while others include waiting for parts, approvals, or even travel time. Without a clear, shared definition, comparing MTTR across teams or facilities becomes nearly impossible.

3. Overemphasis on Speed Over Quality

As said earlier, it is important to have MTTR lower, but under one condition. That you keep the quality level high. Nobody wants incomplete or low-quality fixes or that you have to repeat the fix.

4. Influence of External Factors

Sometimes repair time is slowed down by factors outside the maintenance team’s control. Examples include:

- Waiting days for a spare part to arrive

- Delays in getting vendor support

- Approvals from management or safety checks

These external factors can make MTTR higher. But it’s important to understand that in this case technicians are not the problem.

5. One-Size-Fits-All Doesn’t Work

Not all assets are created equal. Repairing a complex production machine may naturally take longer than fixing a light fixture. Comparing MTTR across very different types of assets can create unrealistic expectations if the context isn’t considered.

How to Improve MTTR

Improving MTTR will result in a faster and smarter repair process. Additionally, your team will make machines back up and running, without affecting the quality. Here are some ways to lower MTTR.

1. Invest in Training and Cross-Skilling

If your team is well trained and educated, they will be able to resolve the issues faster. Try to avoid situations when only one person has the knowledge. It increases the risk of issue “on hold” in case he is not available.

Tip: Conduct regular knowledge-sharing sessions and courses to refresh your team knowledge.

2. Build a Strong Spare Parts Strategy

Often, waiting for spare parts affects MTTR. Ensure you have the spare parts ready in the warehouse, especially for crucial assets.

Tip: Use your maintenance data to identify which assets have more failures and keep their spare parts ready.

3. Standardize Repair Procedures

If your repair procedures are the same within the team, that can improve your MTTR. You can use for example standard operating procedures (SOPs), checklists and documentation. These simple tools can help your team to be more efficient.

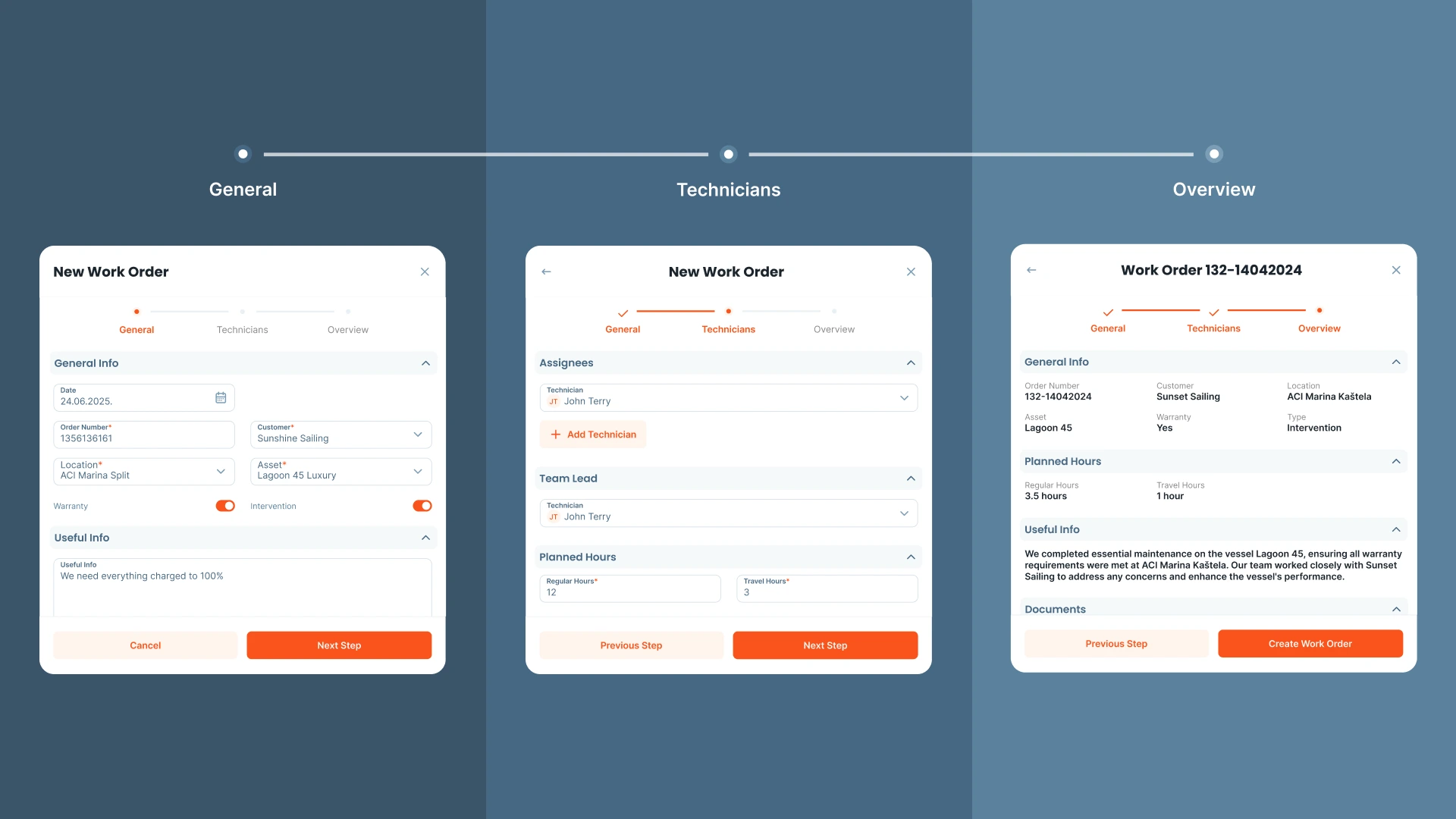

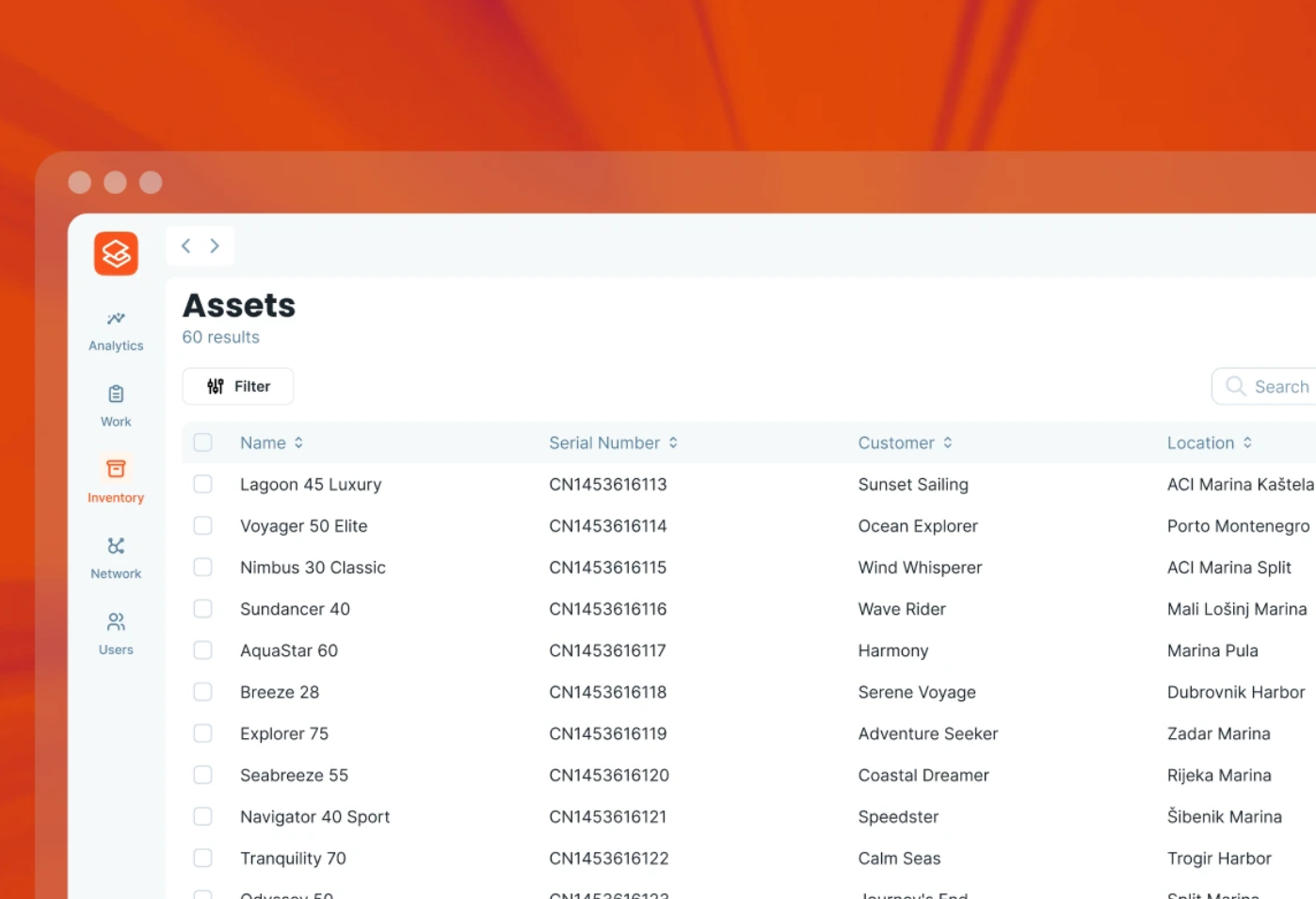

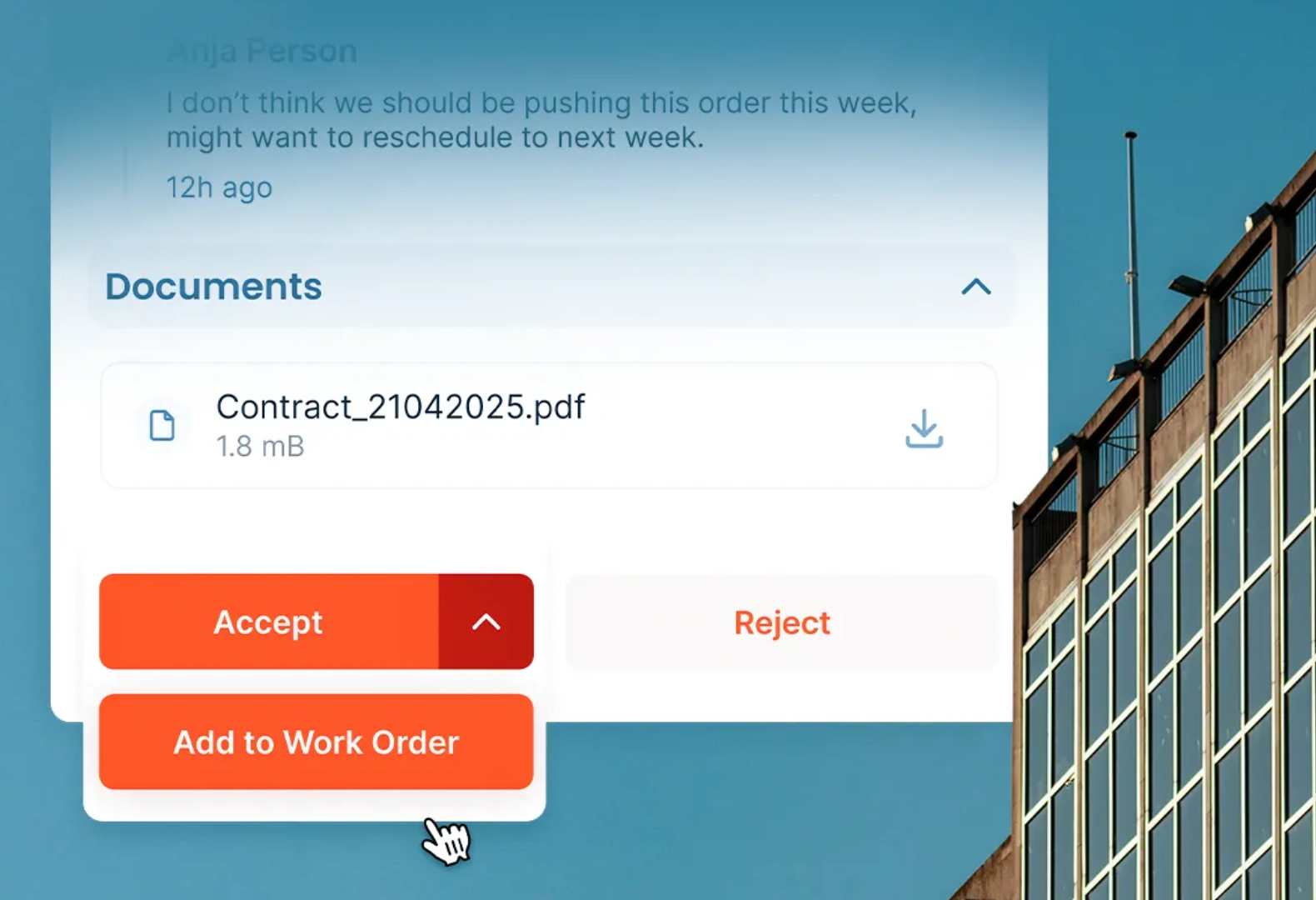

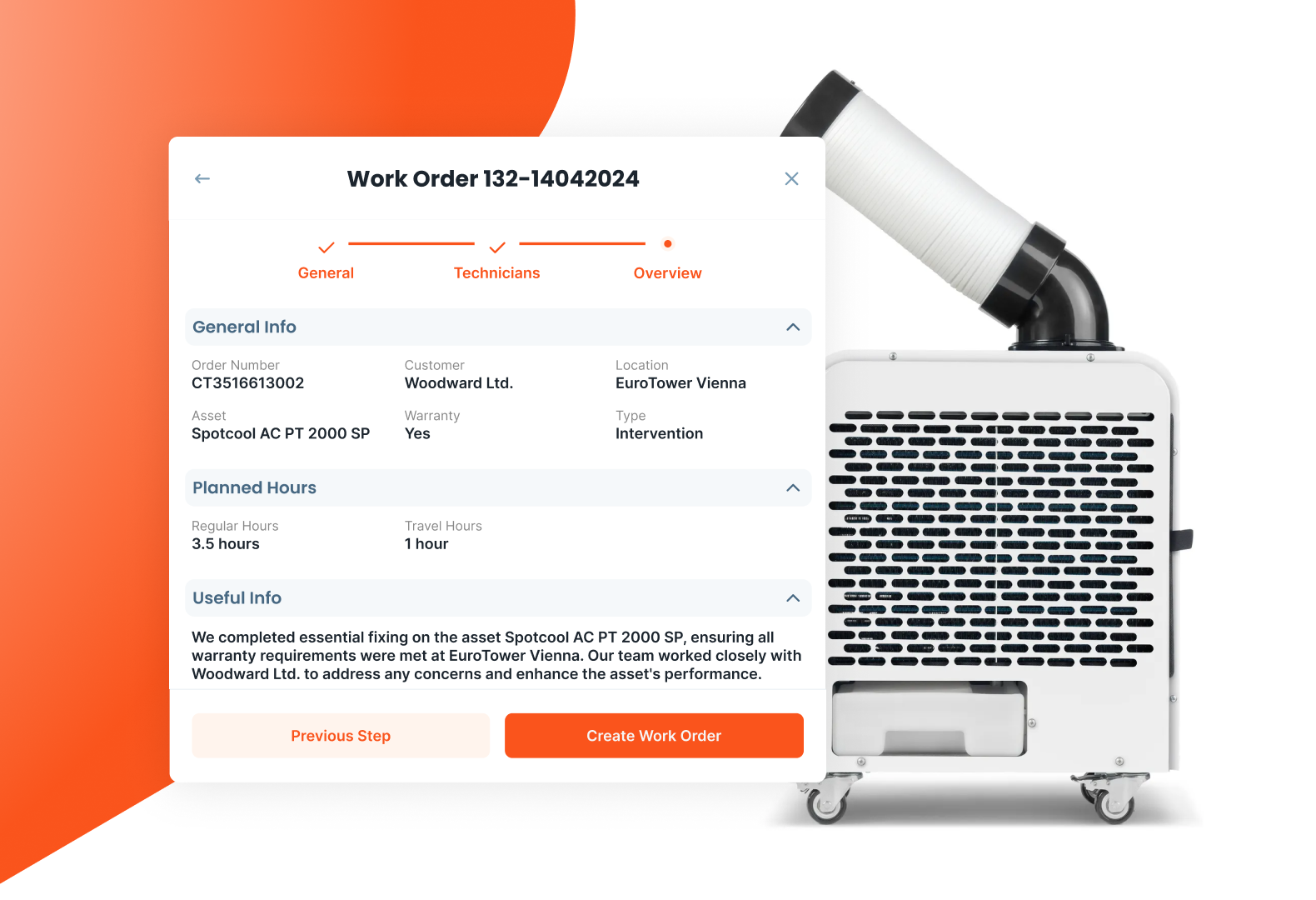

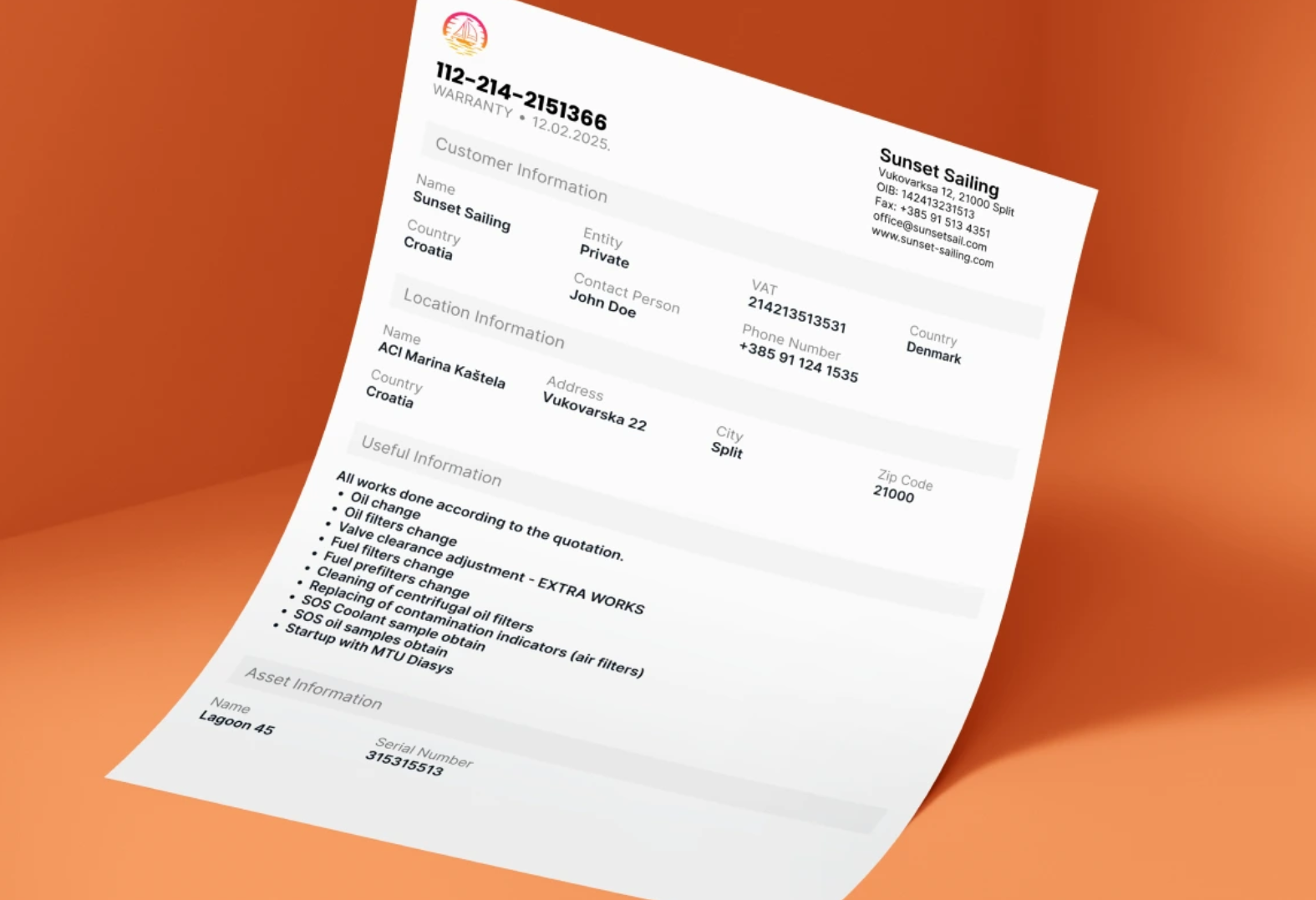

Tip: Keep procedures accessible. For example use CMMS or mobile apps so anyone can access needed information within seconds.

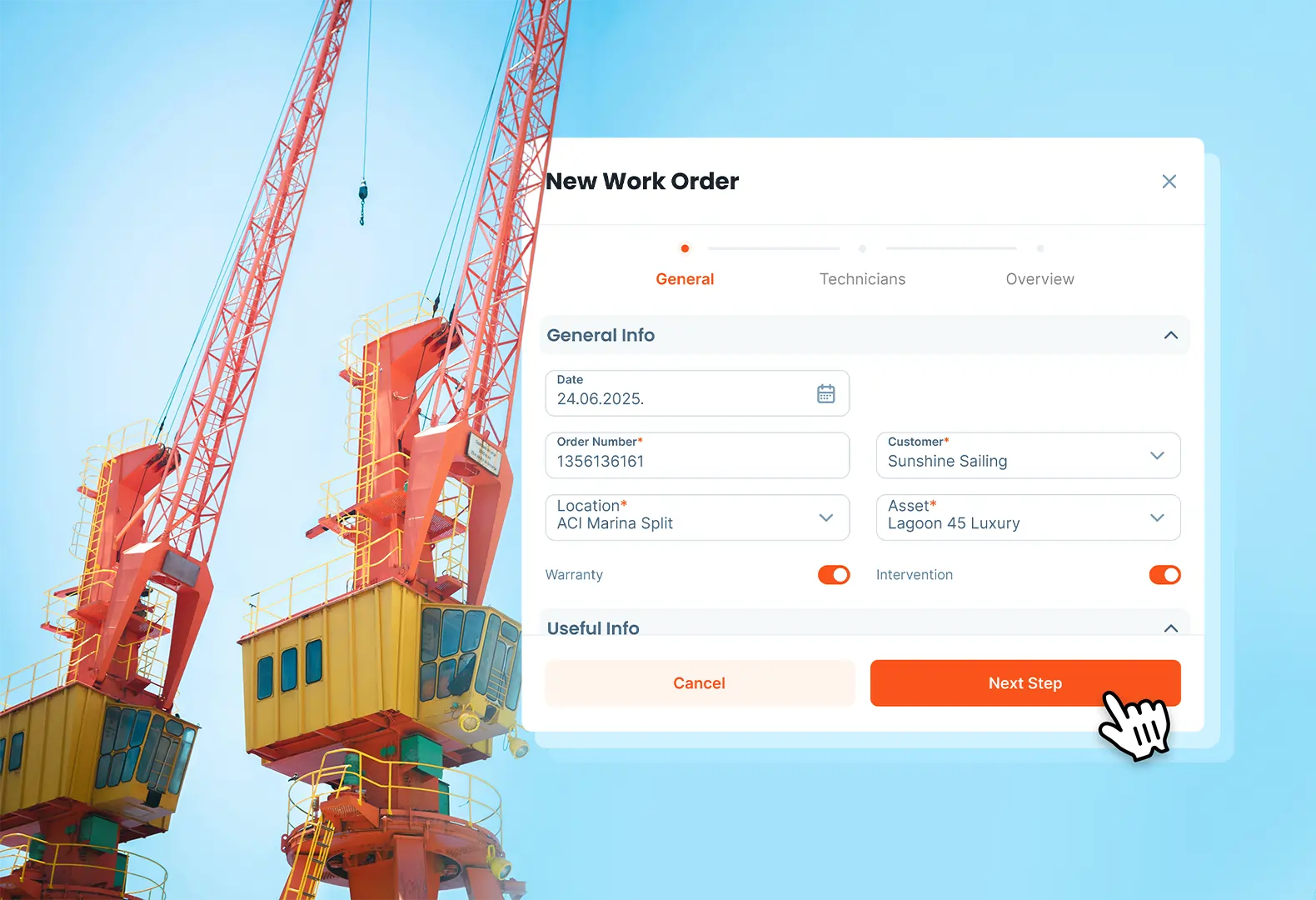

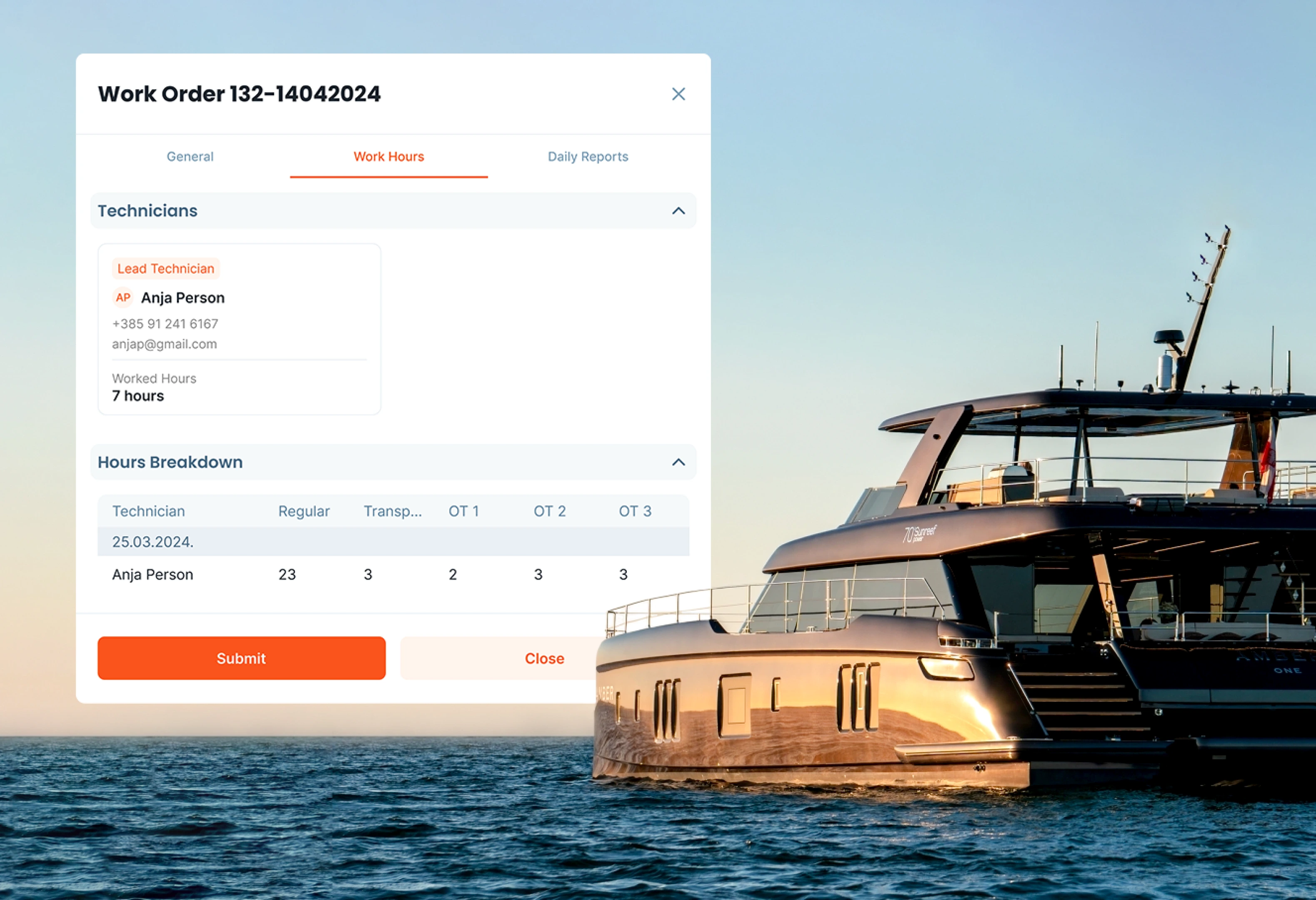

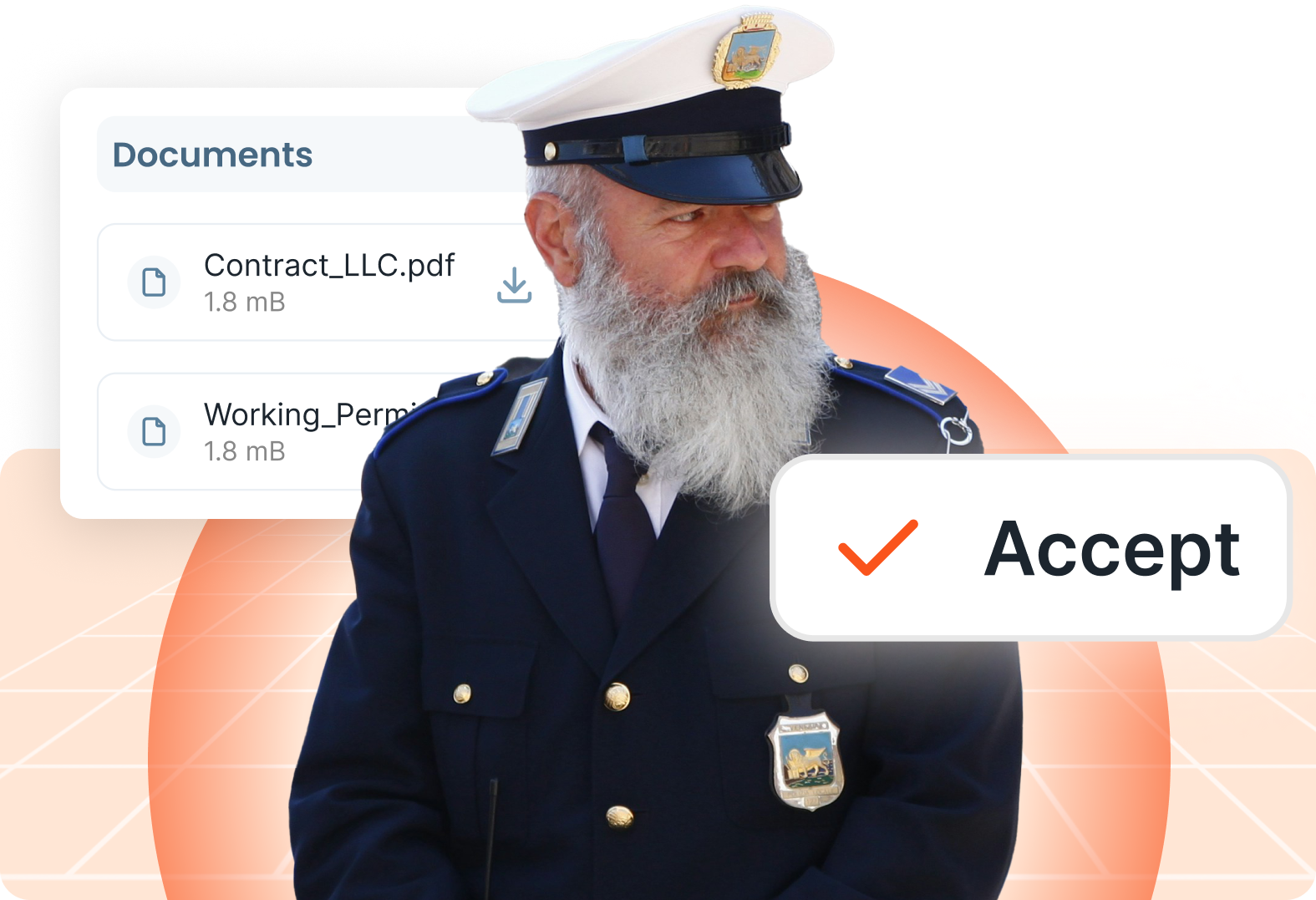

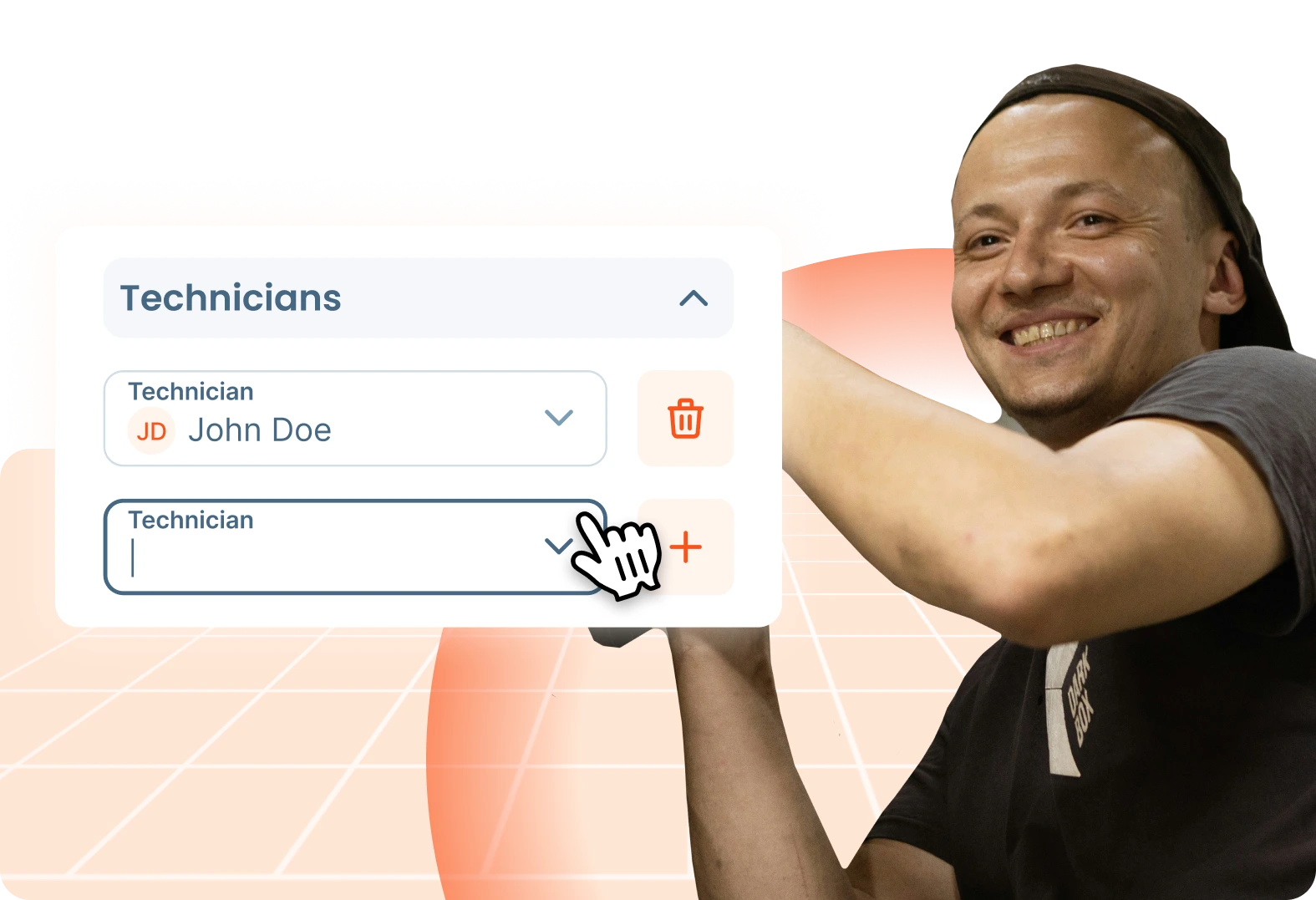

4. Use Technology (CMMS, Sensors, Mobile Tools)

CMMS (Computerized Maintenance Management System) such as Serwizz can help you track downtime, log repair history and indicate recurring issues. Sensors and IoT devices can also send indications about faulty equipment.

Tip: Start with small steps. Use CMSS to log repair time.

5. Encourage Collaboration and Knowledge Sharing

Encourage your team to help each other and share tips and tricks. Use help manuals and documentation, and store them in CMMS.

Tip: Conduct “lessons learned” sessions, and write down useful tips.

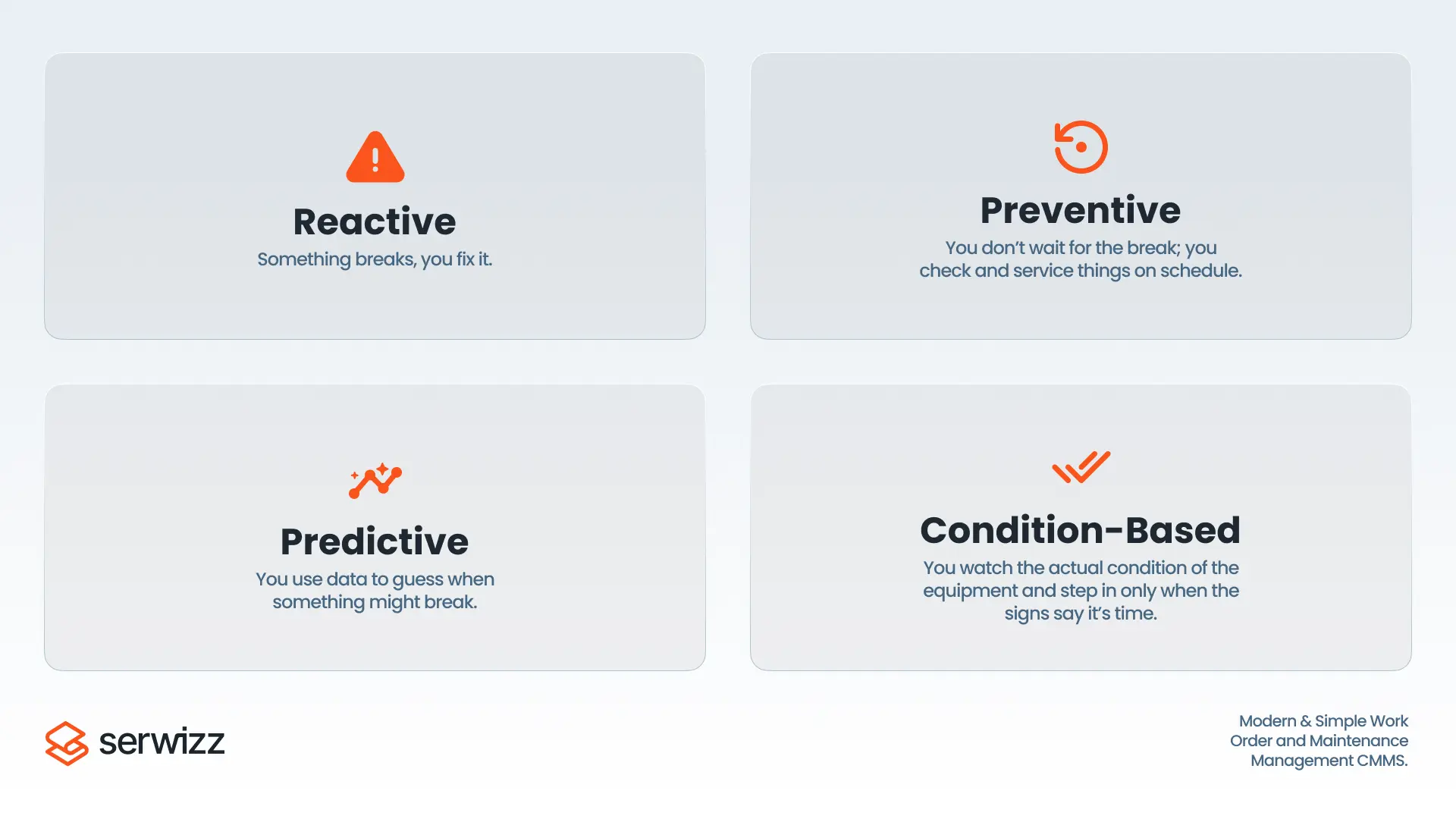

6. Integrate Preventive and Predictive Maintenance

Preventive and predictive maintenance help you keep the equipment working. That means less issues and lower MTTR.

Tip: Use MTTR data to identify which assets deserve extra preventive care.

MTTR vs. Other Maintenance Metrics

MTTR is a powerful metric, but we suggest you use it with other maintenance metrics. Together, these metrics can give you the whole picture of your business. They can determine the quality of your equipment and processes .

MTTR vs. MTBF (Mean Time Between Failures)

- MTTR measures how long it takes to fix something once it stops working.

- MTBF measures the average time equipment works before it stops working again.

Example: One asset stops working after 200 hours (MTBF). You need 4 hours to repair it (MTTR). Knowing these numbers help you calculate uptime and downtime.

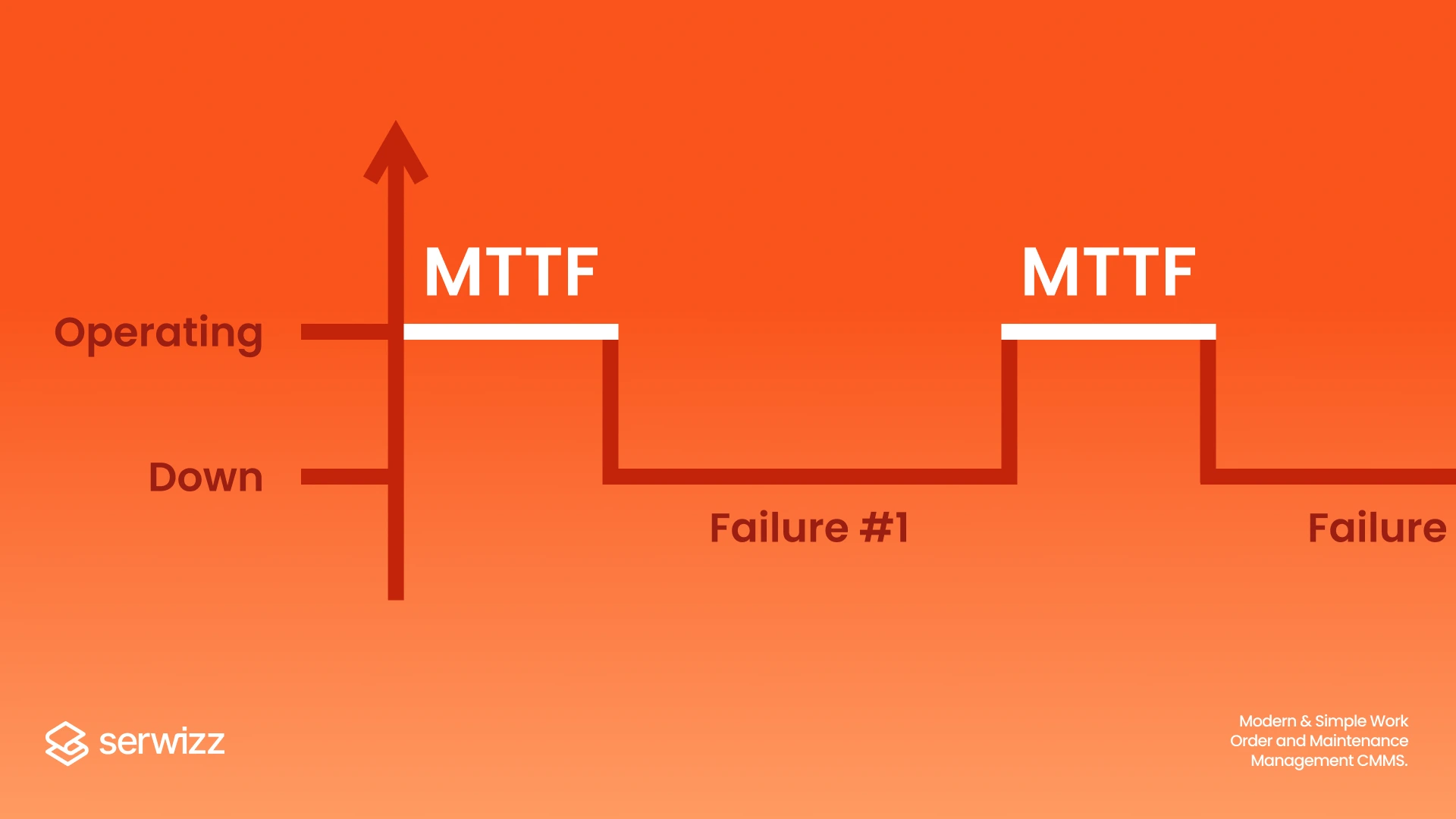

MTTR vs. MTTF (Mean Time To Failure)

- MTTR applies to assets that can be repaired.

- MTTF applies to assets that can not be repaired and must be replaced.

Example: A lightbulb has an MTTF of 10 000 hours. Once it stops working, you replace it. By contrast, a motor might stop working every 5 000 hours (MTBF) and take 3 hours to repair (MTTR).

MTTR vs. Availability/Uptime

Availability is often calculated using both MTTR and MTBF:

Availability = MTBF / (MTBF + MTTR)

This formula shows how much time equipment is available for use. The lower your MTTR, the higher your availability.

Example: Your machine works 100 hours (MTBF) and you need 5 hours to fix it (MTTR), availability is:

100/(100+5)=95.2%

This means your machine is available more than 95% of the time.

How These Metrics Work Together

Individually, each metric tells you one segment of performance. If you look them all together, you will get a complete view of reliability:

- MTBF and MTTF tell you how often issues happen.

- MTTR tells you how fast you fix the issue.

- Availability will tell you the time equipment is actually in use.

When to Use MTTR (and When Not To)

MTTR can be really powerful if used in the right way . However, it can also be misleading if applied in a wrong way.

When MTTR is Most Valuable

-

Critical Assets with High Impact

MTTR is especially useful for equipment or assets where each minute is critical. That includes safety-critical systems in navigation or medicine. -

Identifying Bottlenecks in the Repair Process

If you are tracking MTTR during some period, you might notice where delays occure. Are repairs taking too long because of missing parts? Or troubleshooting takes too long because you don’t have good documentation? MTTR helps with these pain points. -

Building Service Level Agreements (SLAs)

In IT and service industries, MTTR is often written into SLAs. For example: “We guarantee to restore service within 4 hours.” Measuring MTTR ensures you’re meeting commitments and maintaining customer trust. -

Benchmarking Teams or Facilities

Comparing MTTR across assets or locations helps highlight best practices. If one facility consistently repairs faster, what are they doing differently?

When MTTR Can Be Misleading

-

Focusing Only on Speed

Chasing a lower MTTR can lead to lower quality repairs. Sometimes taking a bit longer to fix something properly is more important than the speed. -

Very Different Asset Types

Comparing MTTR for complex equipment (like a turbine) with simpler systems (like a lightbulb) doesn’t provide meaningful insights. Context is everything. -

Preventive Maintenance Scenarios

MTTR doesn’t capture the benefits of preventive or predictive maintenance. It only measures after a failure has happened. Relying only on MTTR can give a false sense of security. -

External Delays Beyond Your Control

If downtime is extended because of vendor delays, shipping times for spare parts, or management approvals, MTTR leads you in the wrong direction.

Industry Examples & Case Scenarios

It’s easier to understand MTTR if we provide you with real-world examples.

1. Manufacturing Plant Equipment Breakdown

In a small workshop where packaging machines are used to seal boxes before shipping. One afternoon, one of the sealing machines stopped working.

- Downtime logged: 4 hours

- Repairs required: The maintenance team had to find a faulty belt, replace it and test the machine.

- Impact: During those 4 hours orders and deliveries were delayed.

The company tracked MTTR and discovered their paint point. It was waiting for spare parts. Stocking these parts in advance reduced repair time from 6 hours to just 2 hours.

Takeaway: MTTR highlights where better spare parts management can cut downtime dramatically.

2. Facilities Management – HVAC System Failure

In an office building, the HVAC system stopped working during a summer heatwave. With temperatures over 40 degrees Celsius, employees started to feel unwell and their productivity decreased.

- Downtime logged: 4 hours

- Repairs required: The maintenance team diagnosed a fault fan, replaced it and tested the system.

- Impact: Employee morale and productivity decreased during the issue.

The company noticed, thanks to the MTTR, that HVAC issues were recurring. Preventive maintenance schedules are adjusted to inspect fans more frequently.

Takeaway: MTTR data can guide preventive strategies that keep facilities running smoothly.

3. IT System Outage

A mid-sized company runs CRM software on cloud servers. One afternoon, the server crashed and the employees couldn’t access customer data.

- Downtime logged: 3 hours

- Repairs required: IT team diagnosed corrupted files, restored the system from backup and did a round of testing to ensure stability.

- Impact: Sales teams lose access to customer information delaying client calls and deals.

The company used MTTR to track how long it takes to restore services after failures. By improving backup processes and automating monitoring alerts, they’ve managed to reduce their MTTR from 3 hours to 1 hour.

Takeaway: In IT industry, MTTR directly impacts customer service and revenue opportunities.

Best Practices for Managing MTTR

Having lowerMTTR should not put a pressure on your team. It should help you remove the obstacles that slow repairs down, It should provide your team the tools, training and support they need to do the job right. Here are some best practices:

1. Focus on Continuous Improvement

An issue could be a chance to learn something. After a repair, ask your team: What slowed us down? Could we do it better next time? Questions like this can help you doing continuous improvement.

2. Communicate Clearly with Stakeholders

If some asset stops working, everyone wants to know how long it will take to fix. Be transparent. Share realistic repair time and regular updates. Clear communication reduces stress and builds trust with managers, employees and customers.

3. Set Realistic Targets

Not all equipment is equal. A broken light bubble might take a few minutes to repair, while a broken boiler could take much longer. Setting the same MTTR target for every asset can lead to frustration. Create different targets for critical vs. non-critical assets, or for simple vs. complex repairs.

4. Give Technicians the Right Tools and Information

If your team doesn’t have spare parts or documentation ready, delay might happen. Make sure repair manuals and spare parts are easy to access.

5. Use MTTR Data to Guide Strategy

Don’t just record MTTR and file it away. Look at the trends:

- Are certain machines always slow to repair?

- Do repairs take longer on night shifts than day shifts?

- Is one facility consistently faster than another?

How a CMMS Can Help with MTTR

If you want to improve your MTTR, we suggest using digital loos, such as CMMS (Computerized Maintenance Management System).

A CMMS helps you:

- Track downtime

- Keep repair histories in one place

- Manage spare parts

- Standardize procedures

- Improve communication in real time

With CMSS such as Serwizz, fixing things becomes easier and the team is focused on fixing the issue, rather than searching for information or approval.

MTTR FAQs

1. What does MTTR stand for?

MTTR stands for Mean Time to Repair. It measures the average time it takes to repair equipment or a system and get it running again after a failure.

2. How do you calculate MTTR?

The formula is simple:

MTTR = Total Downtime / Number of Repairs

For example, if your machine was down for 10 hours over 5 repairs, your MTTR would be 2 hours.

3. What is a good MTTR?

It depends on the type of equipment and industry. For small repairs, you might aim for minutes. For more complex assets, several hours might be normal.

4. Does a lower MTTR always mean better performance?

Not always. A quick repair is great, but it can cause mistakes. Sometimes a longer repair that solves the root cause is more valuable in the long run.

5. How is MTTR different from MTBF?

- MTTR = how long it takes to fix something.

- MTBF (Mean Time Between Failures) = how long equipment runs before it breaks again.

Together, they show both how reliable your equipment is and how fast you can recover when things go wrong.

6. Can MTTR be applied to all assets?

Not exactly. MTTR only applies to repairable assets. If something can’t be repaired and must be replaced (like a lightbulb), you would use MTTF (Mean Time To Failure) instead.

7. How can software help with MTTR?

A CMMS (Computerized Maintenance Management System), such as Serwizz can:

- Track downtime automatically

- Record repair histories

- Store spare parts lists

- Help teams communicate in real time

This makes the whole repair process faster and smoother.

8. Is MTTR useful on its own?

MTTR is powerful, but it should never be the only metric you track. Pair it with MTBF, MTTF, and availability for a complete picture of performance.

Final Thoughts

MTTR is not just another maintenance metric. It is an important tool that tells you how quickly your team can respond when something goes wrong, how smoothly your processes are and how prepared your team is.

A lower MTTR means fewer disruptions, less stress and happier customers. But it’s not just about speed. MTTR supports your team with the right tools, spare parts and information so they can repair equipment without any problem.

Combining MTTR with other metrics like MTBF, can help you get a full picture of your system’s reliability. Adding a tool like CMMS can help you even more to detect and improve trends.

Last, but not the least, MTTR helps you reduce downtime and make stronger connections with your customers.