Maintenance

·

12 min read

How to Reduce Maintenance Costs

Maintenance costs are quite a big part of operational budgets. For many companies, they present a certain challenge. Often, they are too high when we need to repair something, and on the other side, risky when there are budget restrictions. The good news is that there are practical ways to lower maintenance costs without impact on your reliability or performance.

In the last couple of years, with inflation, maintenance costs have also increased. Spare parts are now more expensive, delivery time is longer and having skilled technicians is also becoming a challenge. All of this makes smart maintenance planning more important than ever.

In this blog, we’ll look at proven strategies that help businesses save money while keeping equipment and assets in top condition.

Maintenance Cost Factors

Maintenance costs are impacted by several factors:

| Factor | Why it drives cost |

|---|---|

| Labor | The time technicians spend on inspections, repairs and paperwork. |

| Parts & materials | Cost of replacement components and spare parts. |

| Downtime | Every hour of unplanned downtime means lost productivity and revenue. |

| Energy use | Poorly maintained equipment often consumes more energy. |

| Emergency repairs | Unplanned interventions are almost always more expensive than planned work. |

If you know these cost drivers, it will be easier for you to assess what to improve.

Objectives of Maintenance Cost Management

The main goal of maintenance cost management at first sight is to reduce the cost. But the real goal is to manage maintenance smarter. The key objectives are:

| Objective | Benefit |

|---|---|

| Make equipment reliable | The longer the equipment works, the costs will be lower. |

| Cut unplanned downtime | The less time machines sit idle, the better the workflow. |

| Use resources wisely | Get the most out of your people, your spare parts and your budget. |

| Keep things safe & compliant | Good maintenance prevents accidents and avoids unnecessary fines. |

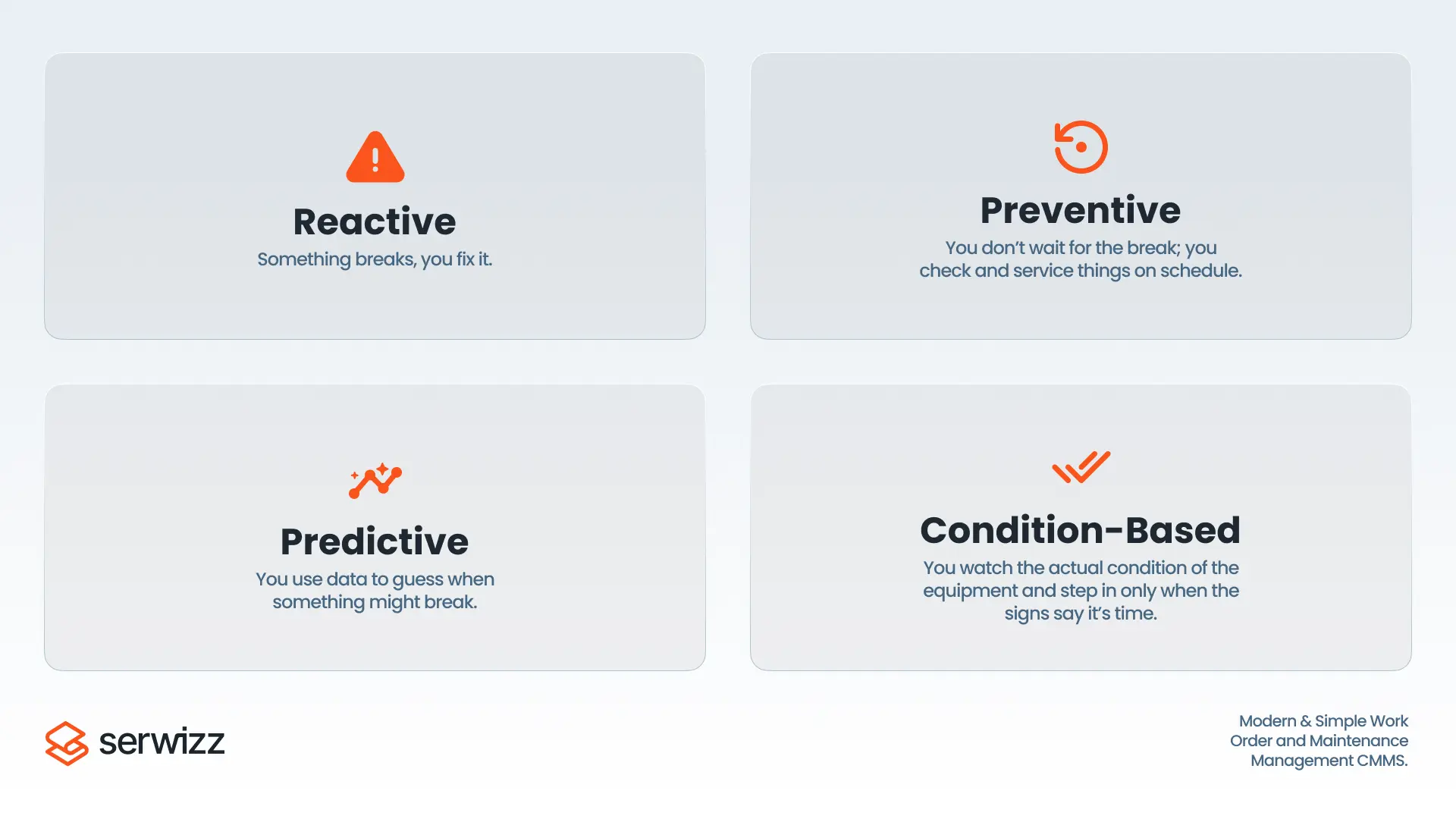

| Think long term | Shifting from reactive to preventive maintenance, and staying ahead of problems. |

Train Your Team

If you want to save on maintenance, start with your team. Provide them proper education and training. It doesn’t have to be complicated or expensive. If they get familiar with the equipment, they will be able to detect issues earlier. In that way you will avoid bigger problems.

Example of simple training:

- Establish procedures and ensure your new team members gets familiar with them during the onboarding

- Use sharing session, where lesson learned will be presented from previous good or bad experience

- reminding the team about basic safety rules and regular inspection steps

Here is one real world example. In many warehouses, forklifts should be checked on a daily basis. Operators are educated to check if there is oil leak, tier damage or some strange noise. Once the education is done, it will take only a few minutes daily to perform inspection checks. And those minutes can prevent bigger issues.

In the end, the cost of training is quite small, compared to the cost that could happen during the downtime or the mistakes the team can make.

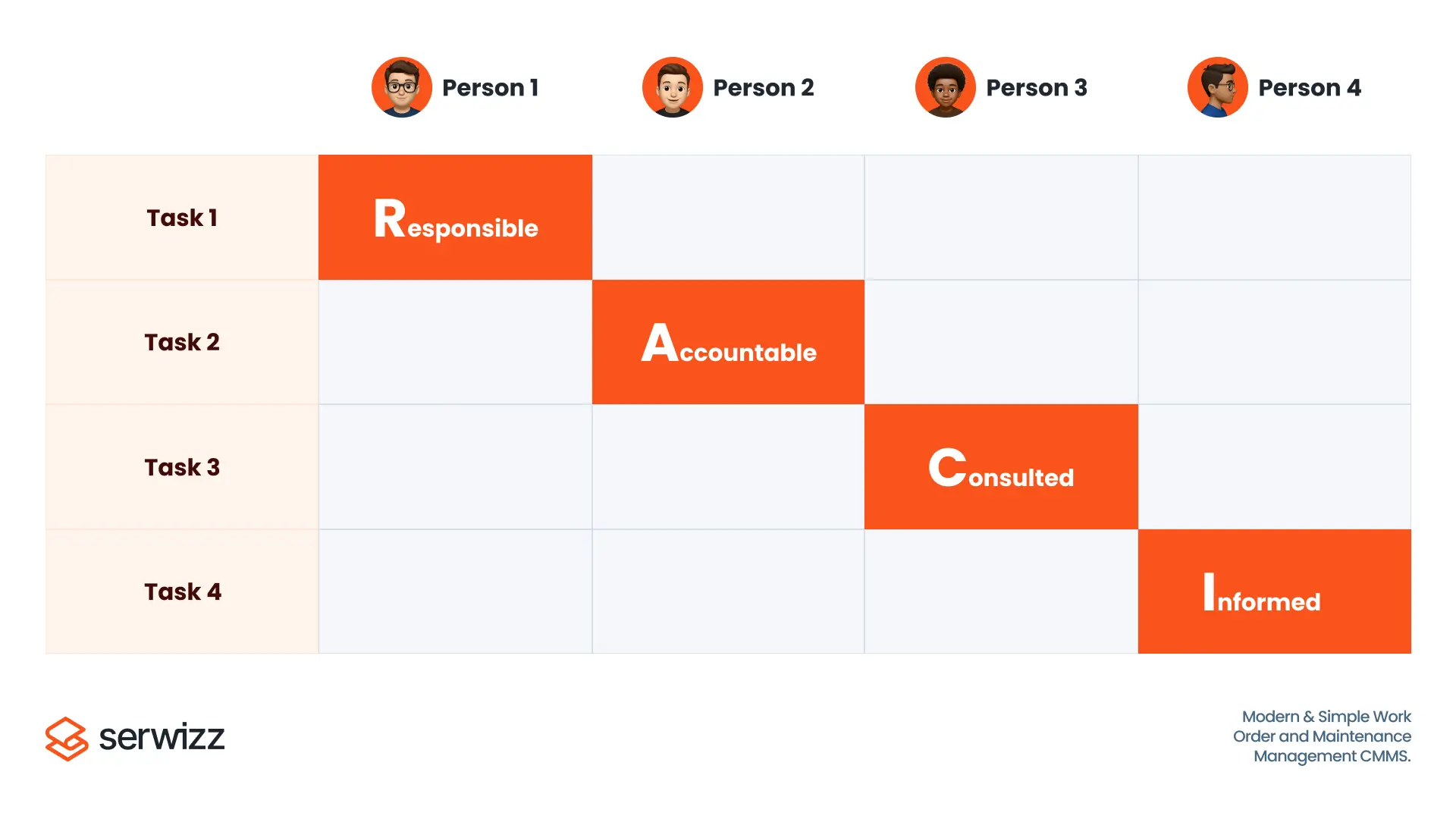

Prioritize Tasks

There are different priority levels for each maintenance task. Some tasks are urgent and require immediate attention. Some of them can even wait for tomorrow. Determining the right priority will help your team to focus on important things, and not waste time or things that are not blockers.

A simple way to start is by looking at which machines are critical to your operations. Then, make sure those get checked and fixed first. Less important tasks can follow on a regular schedule.

A good example to show why priorities are important is production flow. In the flow one machine might be critical, and if it stops working, the whole production will stop. That’s why you should give this machine the biggest priority, and focus on its inspection and repair. If that one is working well, your workflow is safe. Other machines in the flow are not that critical and can have medium priority, because if they stop working, flow can continue.

Prioritization approaches help you waste time on minor issues while bigger problems are standing there, costing you more.

Optimize the Maintenance Schedule

One of the challenges you might face is to find the balance between doing the maintenance too often, or too late. If you do it too often, you will waste time and money. If you do it too late, you will run into bigger problems.

Track your equipment performance. Based on data, determine which equipment requires daily check and which can be checked once a week. With this information, you can make better schedules and optimise your team allocation. All of this will result in less downtime and less cost.

Monitor Equipment Condition

In order to avoid bigger problems, you should monitor your equipment. Detecting strange noise, increased temperature or unusual vibration. All of these are often signs of a bigger problem.

Educate your team to detect these signs and identify the issue early. Doing this can save a lot of time and prevent expensive repairs. Simple tools like checklists or basic monitoring devices can help. They don’t have to be fancy. The key is using them regularly. Regular checks prolong your equipment life and reduce surprises.

Use Data to Identify Savings

Monitoring and recording how your equipment works can help you detect where to save the money.

Things you can monitor:

- Downtime

- Repair frequency

- Recurring issues

Analyse these factors and detect patterns. You might notice some machines stop working more often or that some suppliers are better than the others. When you know the patterns you can do corrective actions.

That includes:

- Adjusting schedule

- Educating the team

- Changing supplier

Remember, small changes like this, can help you avoid bigger costs in the future.

Use High-Quality Replacement Parts

If you decide to buy cheaper spare parts, that might be a good idea and a better option at first sight. But, if you look long term, you will have to buy them more often, because it’s more likely they will stop working and maybe even harm the other components.

If possible, try to invest in high-quality parts that are usually more reliable. By doing that, you will prolong the life of your equipment and avoid unplanning. repairs. In total, less downtime should mean more money saving.

Recently we met one factory owner who told us how his company switched to cheaper belts to save money. Unfortunately, after a few months, those belts started to have issues, and had to be repaired or even replaced more often. Some belts even damaged nearby components. The factory owner learned the lesson the hard way, and switched back to more expensive, but higher-quality belts. After some period he noted that breakdowns rate decreased significantly and overall costs were lower.

Cheap vs. High-Quality Parts

| Aspect | Cheap Parts | High-Quality Parts |

|---|---|---|

| Initial Cost | Low | Higher |

| Lifespan | Short | Longer |

| Failure Risk | High | Low |

| Impact on Other Components | Can cause damage | Minimal risk |

| Total Long-Term Cost | Often higher | Usually lower |

Manage Your Inventory Wisely

One of the challenges you might face is storage. Having too many spare parts will cost you money and require more space. The thing is, some of those spare parts you might not even need for months. On the other side, you would like to have the right spare parts available, especially those which take more time to deliver.

The solution for this problem is having the balance. To achieve it, you should track wichs parts you need more often, and then ensure you always have them ready. For those rarely used, you can order them as needed.

Good inventory management helps:

- To avoid last minute purchase

- Control Cost

- Allocate the team

Automate Where Possible

Maintenance tasks often repeat. For example tracking tasks, writing schedules or reports, all of these you have to do all over again. Especially if you do it the old school way. With paper and pen. Or by using spreadsheets.

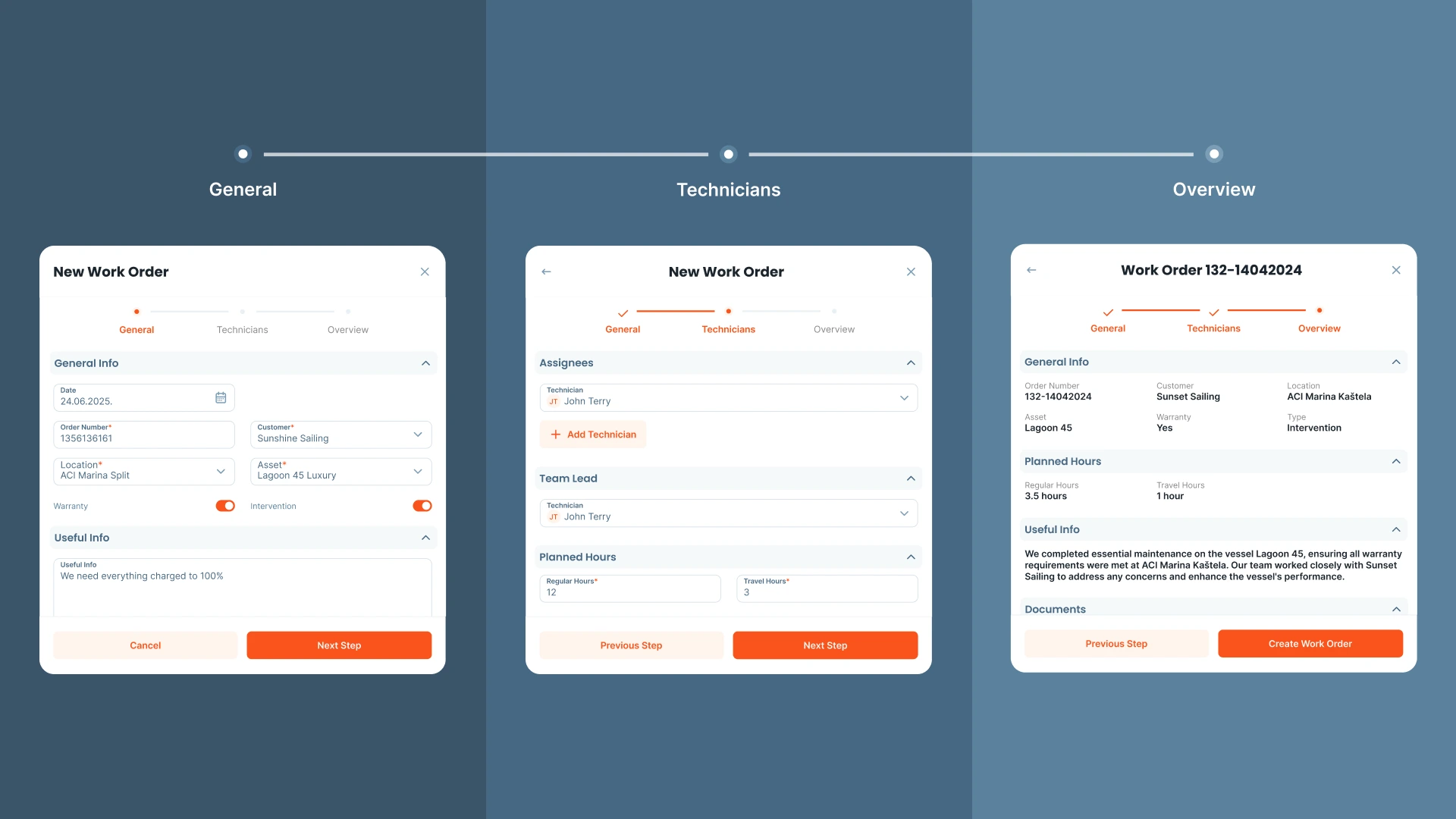

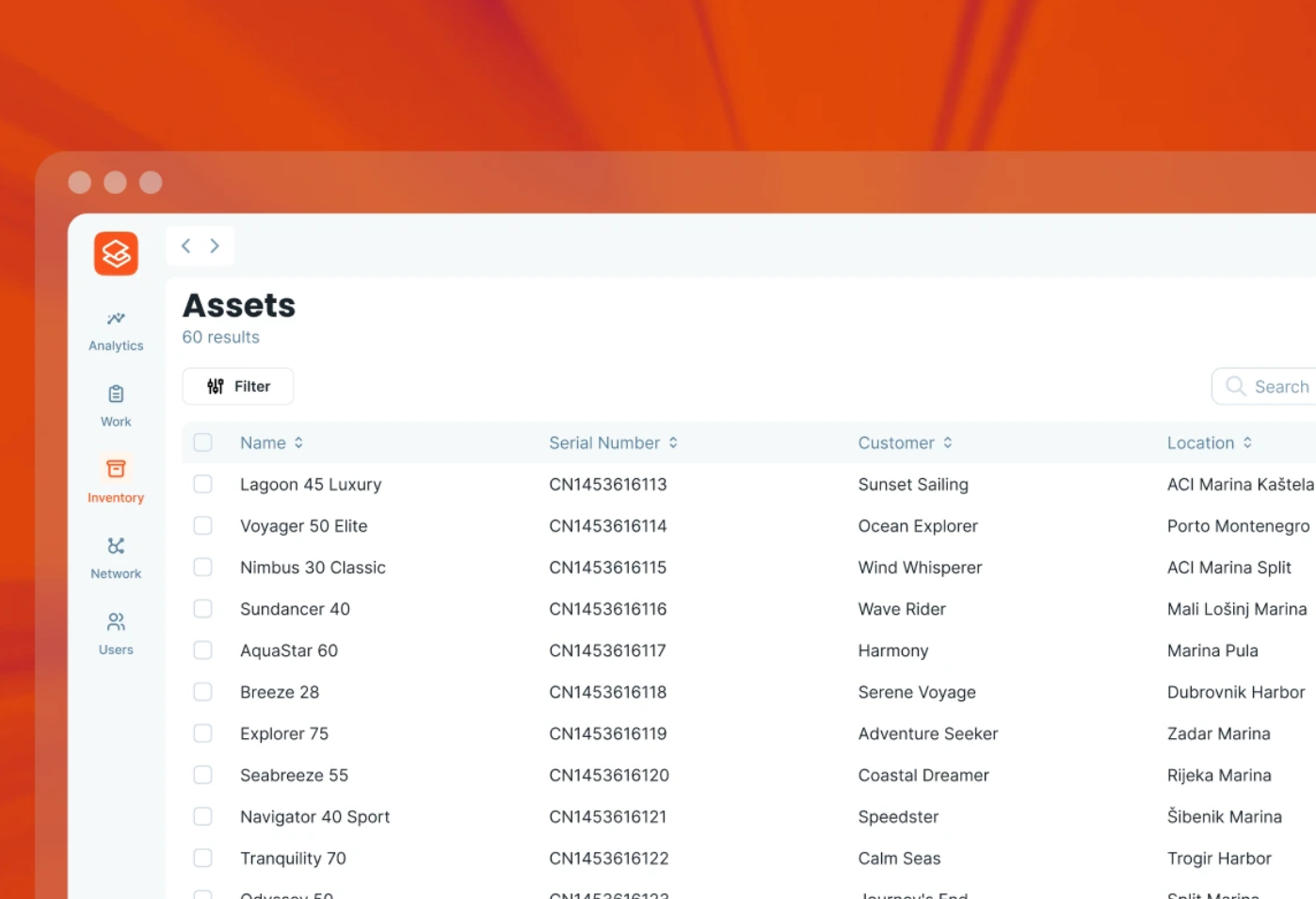

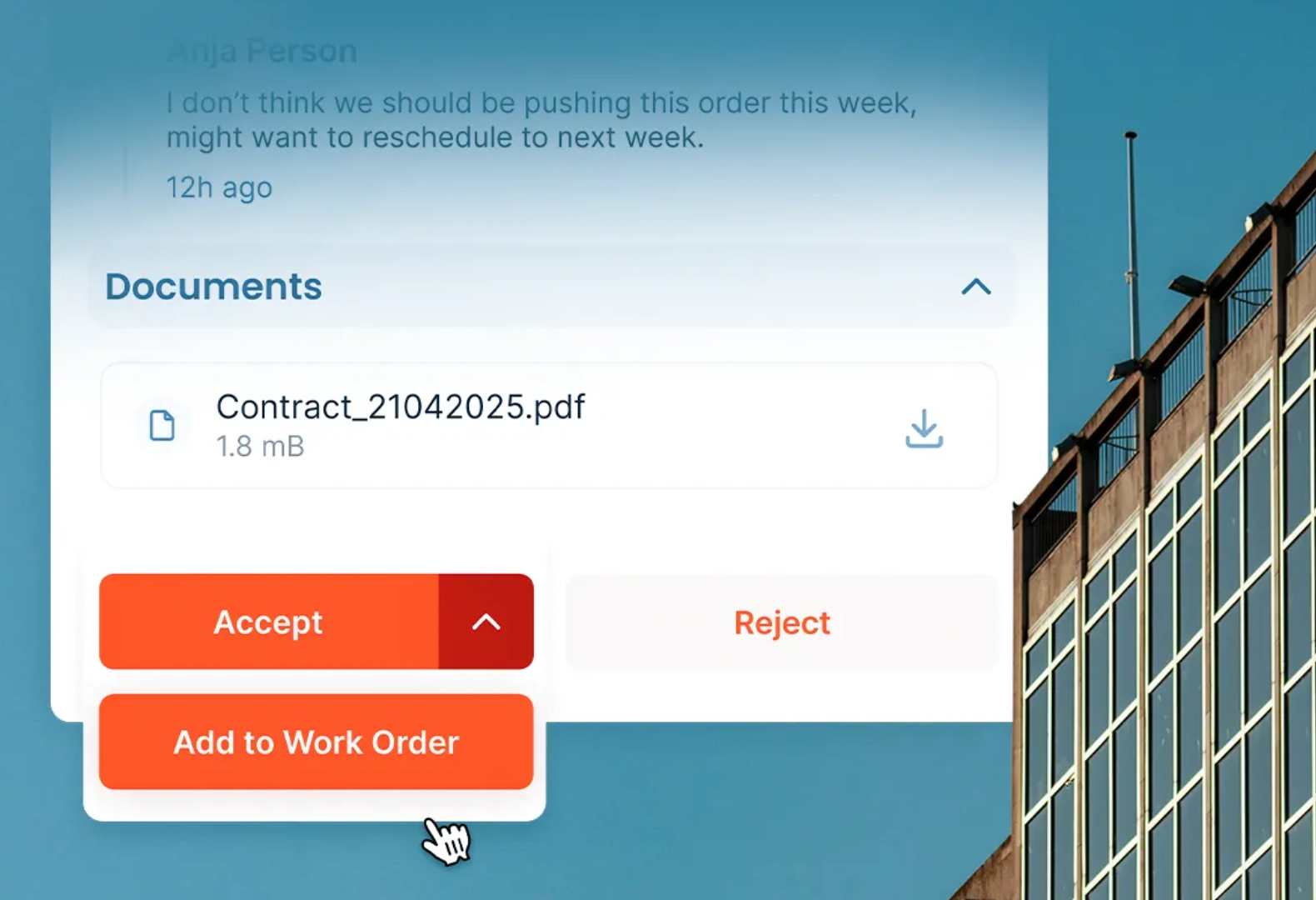

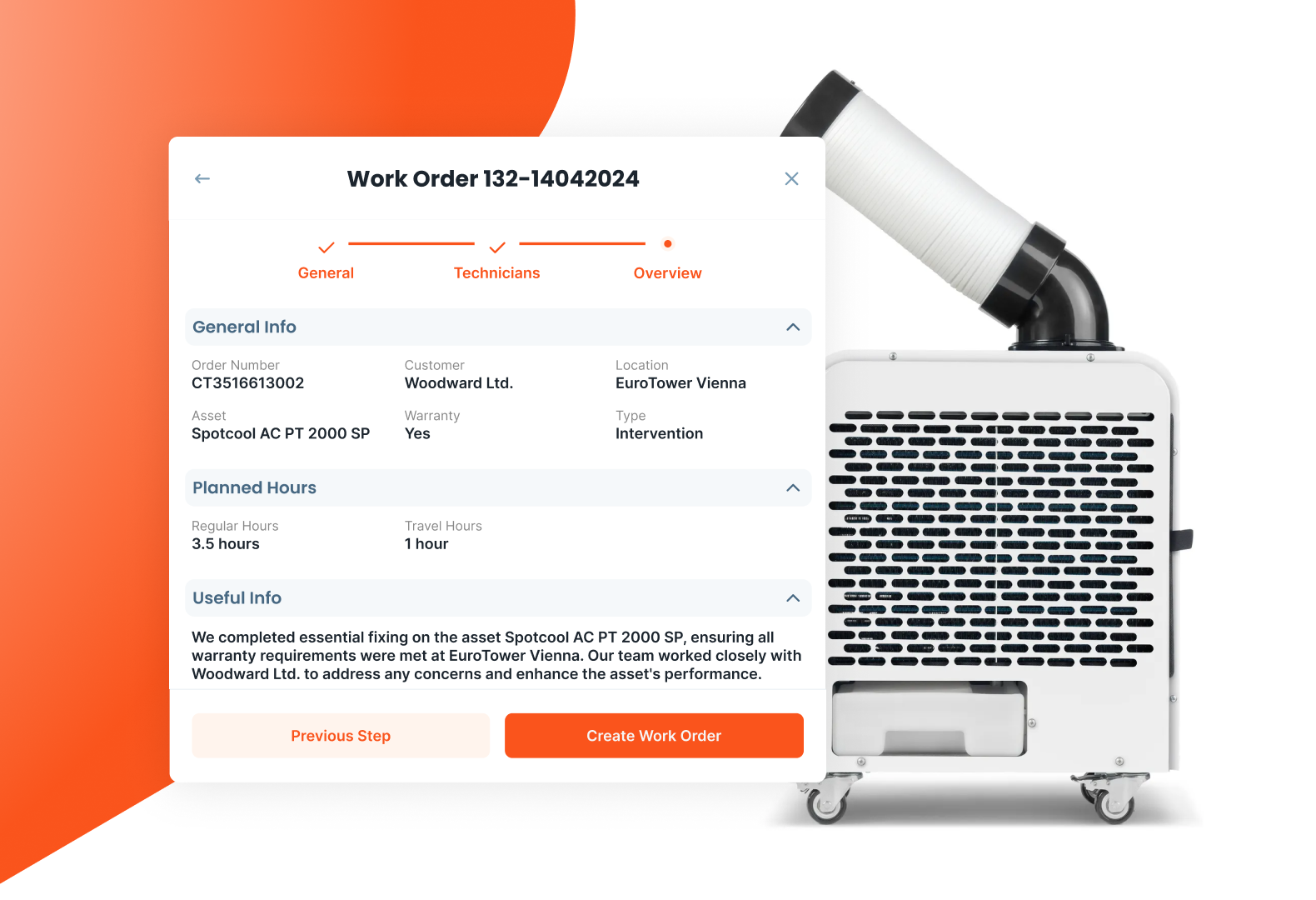

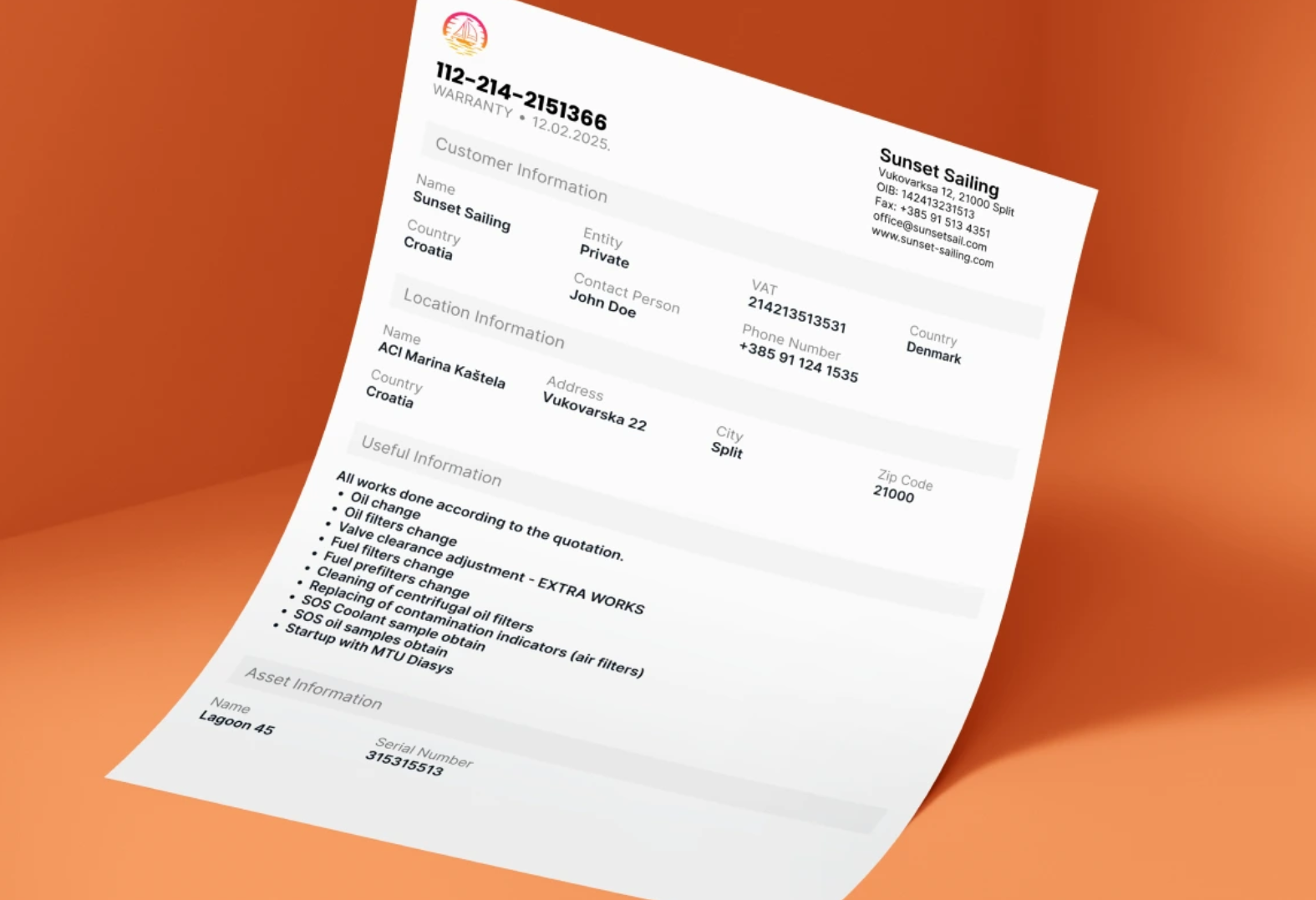

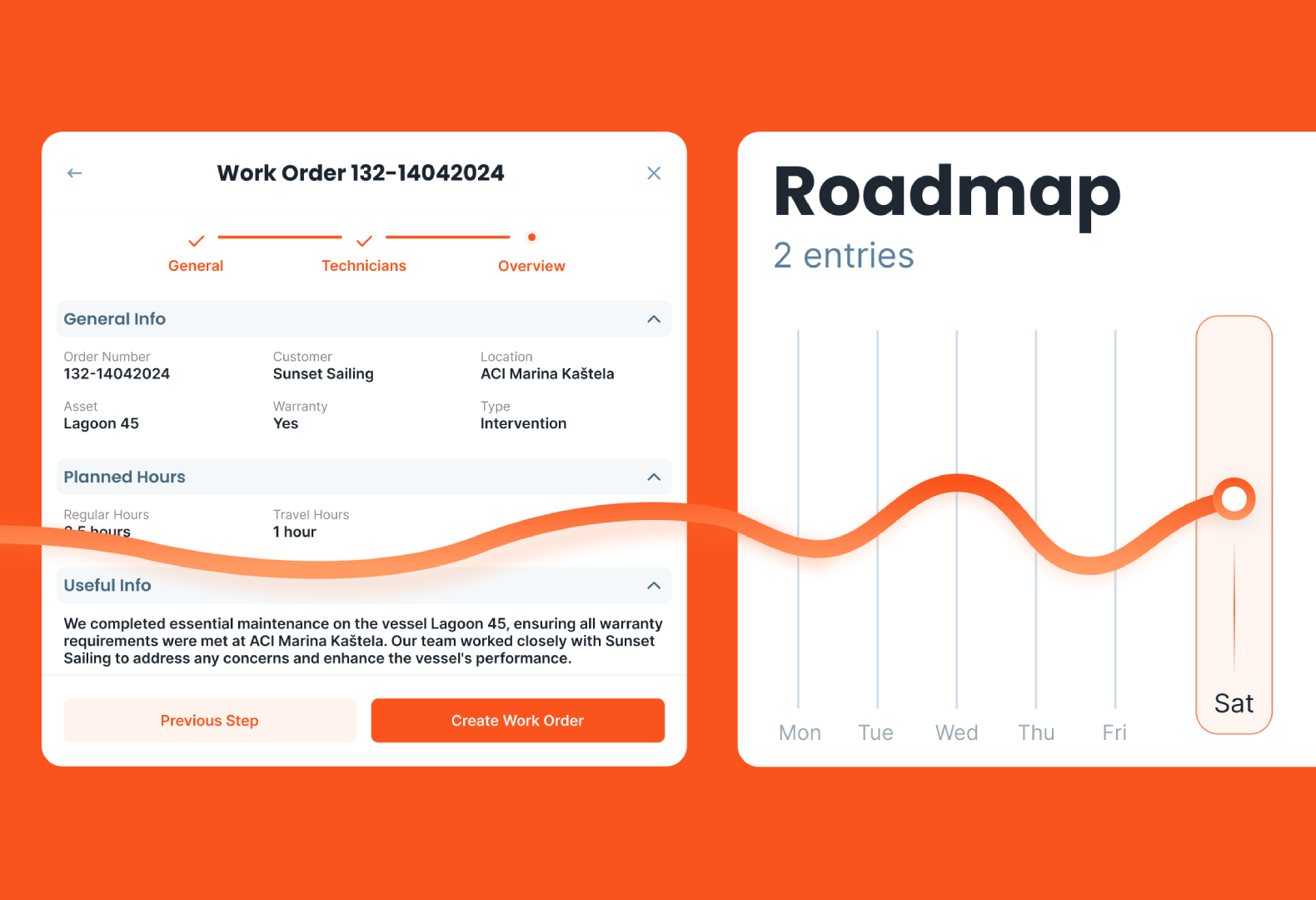

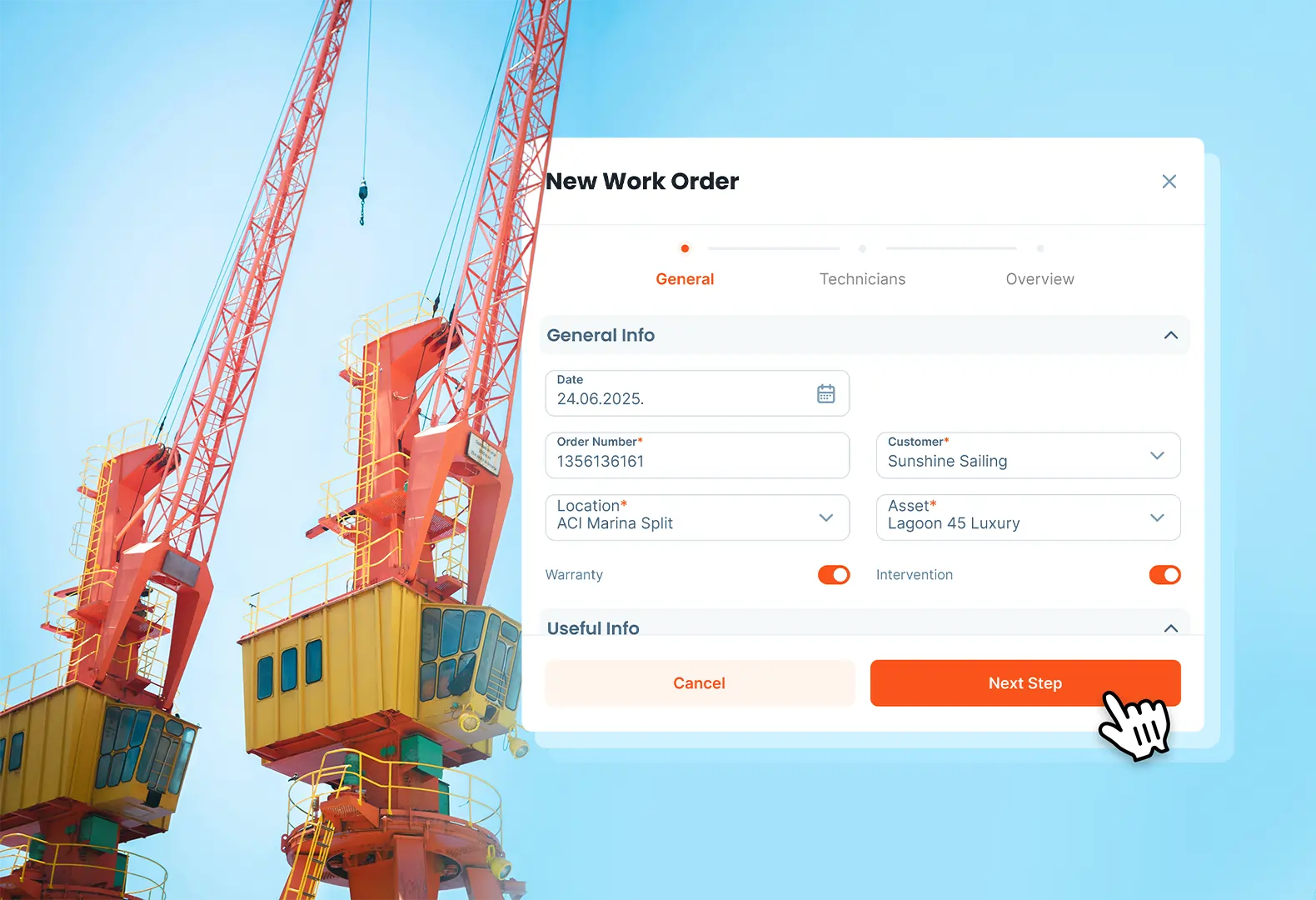

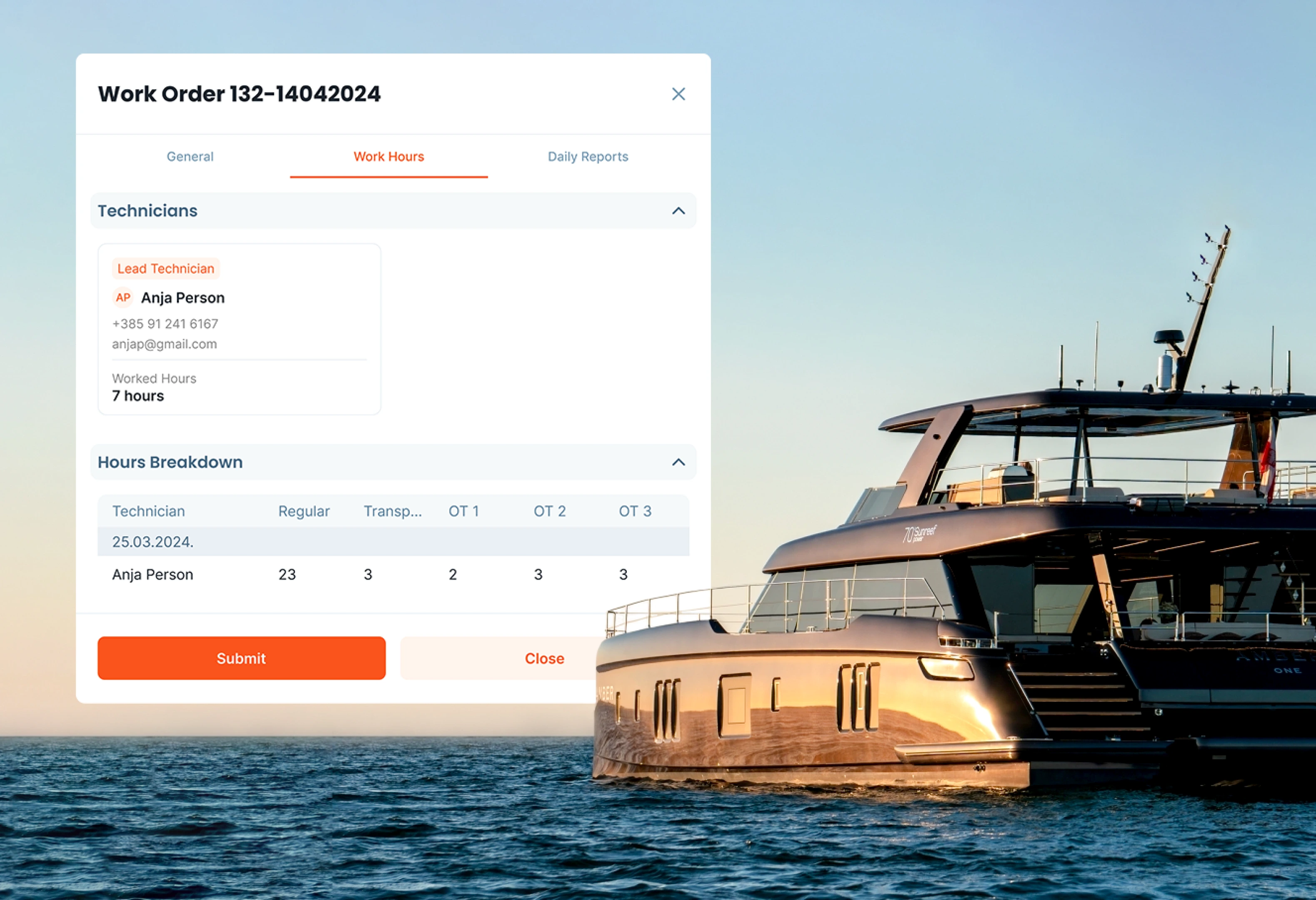

Luckily, with digital transformation and the right software, such as Serwizz, you can automate a lot of processes. Serwizz, as a CMMS tool, can help you create schedules, allocate people, send reminders, and have all the important data in one place. In the application.

Some of the benefits automation offers:

- Less paper work

- Less forgotten tasks

- Less admin work -> more “real” work

- Better efficiency

- Better insights

- Lower costs

Maybe to better understand, imagine you own a ship service company, and you have 50+ spreadsheets, for each vessel that you maintain. If you miss to enter the date correctly, you might forget something. A CMMS like Serwizz removes this risk. By using Serwizz, you can get automatic reminders for overdue tasks and you can assign work instantly, without chasing people with emails or calls.

Conclusion

Reducing maintenance costs is the art of managing and planning the work smartly. It is not about cutting costs wherever you can. Choose the right approach, as we’ve shown in our blog, and you can make your equipment more reliable, your team more focused and your cost lower.

Start small with small steps. First educate your team, set priorities, track and monitor, and in the end use the data that you have. Day by day, and you will notice more savings and less issues and downtime.

And if you want to make the whole process easier, a CMMS tool like Serwizz can help. From scheduling and tracking to automation and insights. Serwizz CMMS has all of these in one place, so you can focus on the work that matters.