Maintenance

·

19 min read

Reliability Centered Maintenance (RCM)

At Serwizz we’ve worked with several maintenance companies and we’ve met many maintenance teams. They all face a common challenge: how to keep equipment running smoothly without overspending time or resources. Downtime can affect not only how your production works but also the safety and affect customer satisfaction. That’s why we suggest using Reliability Centered Maintenance (RCM). RCM is a strategy that helps organizations focus on what really matters: reliability, safety and performance.

RCM isn’t just another maintenance buzzword. It's a data-driven approach that helps you understand your assets, identify potential failures and decide how to prevent them. RCM helps you and your maintenance team to make smarter, evidence-based decisions.

At its core, RCM changes the way we think about maintenance. It shifts the focus from simply fixing problems to understanding them. As mentioned in our other blogs, we switch from reactive to preventive maintenance mode. If you manage to do RCM in the right way it will help you increase uptime of your equipment and lower the costs.

In this guide, we’ll describe what is Reliability Centered Maintenances and explain how it differs from traditional maintenance strategies. We will also show how you can successfully implement it in your organization.

What Is Reliability Centered Maintenance?

Reliability Centered Maintenance (RCM) is a structured process which helps you determine the most effective maintenance strategy for each asset in your organization. RCM helps you find the balance, based on equipment’s function and risk of failure. So you should maintain equipment only when it needs attention. To achieve this ask these questions:

- What is the asset supposed to do?

- How can it fail?

- What happens when it stops working?

- What can we do to prevent that issue in the future?

Why RCM Was Created

RCM was first developed in the aviation industry in the 1960s. Traditional maintenance techniques were not good for more complex aircraft systems. The old approach where components were replaced at fixed intervals was no longer effective. Engineers realized that many parts were being replaced too early. Other parts were left until they stopped working.

The new approach was focused on function and consequence. The goal was simple:keep systems reliable and reduce maintenance costs. After this approach was successfully introduced with aircraft, RCM also became an important part in other industries such as manufacturing, energy, transportation and facilities management. RCM was giving consistent and measurable results.

The Main Goal of RCM

Reliability Centered Maintenance aims to preserve system functionality.

An effective RCM program helps you:

- Identify critical assets and prioritize them.

- Understand failure modes and their consequences.

- Apply the best maintenance actions (preventive, predictive or corrective).

- Optimize resources.

RCM brings structure and clarity to your maintenance efforts.

The Core Principles of RCM

There are four main principles of Reliability Centered Maintenance. We will give an overview of each one of these.

Function-Oriented Approach

The first principle of Reliability Centered Maintenance is understanding what your equipment is supposed to do. We suggest that you define the purpose for each asset. It can be simple: cooling air, producing parts or transporting materials. After that you can start planning your maintenance.

Once the function is clear, the maintenance team can focus on keeping that function available and reliable. This mindset helps teams avoid unnecessary maintenance work.

Failure-Focused Mindset

The second principle is dealing with the fact that every system will stop working at some point. You should understand how and why failures happen. After that try to take the right preventive actions.

You can connect this with our FMEA analysis. Try to analyse potential failure modes and try to identify weak points in your system. If possible try to do this, while the system is working well. If you understand the cause of each issue, you will be able to predict and prevent it.

Data-Driven Decisions

You should create your RCM strategy on real data rather than assumptions. Check your maintenance logs, performance history and inspection reports to make better decisions.

We suggest using modern maintenance tools like CMMS or IoT sensors. They can help you collect and interpret the data. With these tools you can schedule maintenance based on condition and performance trends.

Safety and Efficiency First

RCM strives to keep your maintenance team safe. Some issues are not a problem for production but also can lead to accidents or environmental risks.

When you use RCM, you will make maintenance decisions based on risk, not just cost.

How RCM Differs from Traditional Maintenance

Our experience while working in a field with a maintenance team showed that many companies still work in a traditional mode. They replace parts after a certain number of hours or days, no matter their condition. This preventive approach can reduce some issues but often it’s just unnecessary maintenance work and wasted resources.

Reliability Centered Maintenance does things smarter. RCM focuses on the actual condition of each asset and is not doing maintenance just because time has passed. This helps you prioritize work based on risk and impact, not routine.

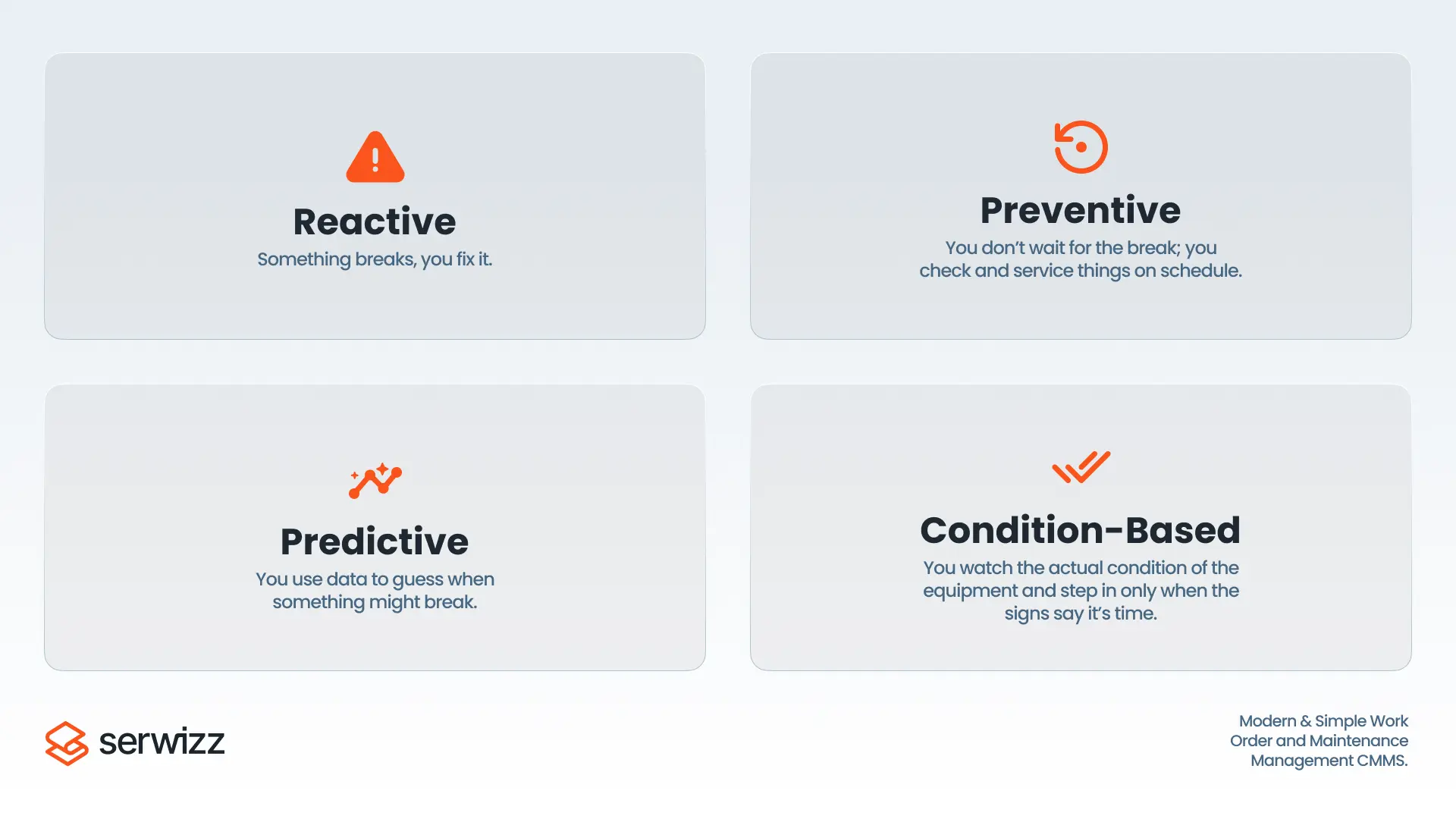

Reactive, Preventive, and Predictive Maintenance Compared

To understand RCM better, we will compare it to other maintenance types:

| Maintenance Type | Description | When Maintenance Happens | Main Advantages | Main Drawbacks |

|---|---|---|---|---|

| Reactive Maintenance | Fix equipment only after it fails. | After a failure occurs. | Simple, low upfront cost. | High downtime, safety risks, unexpected repairs. |

| Preventive Maintenance | Regular, scheduled maintenance regardless of condition. | Based on time or usage intervals. | Predictable schedule, reduces some failures. | Can cause over-maintenance and wasted labor or parts. |

| Predictive Maintenance | Uses data and sensors to predict when maintenance is needed. | Based on condition monitoring and performance data. | Minimizes unnecessary work, reduces downtime. | Requires technology and skilled analysis. |

| Reliability Centered Maintenance (RCM) | Focuses on reliability, risk, and function of each asset. | Based on asset criticality and real operational data. | Balanced, cost-effective, improves safety and performance. | Takes time to plan, analyze and set up correctly. |

You can read more about these different maintenance types in our blog.

As shown above, RCM combines the best elements from all three strategies. It combines the logic of preventive and predictive maintenance but additionally it aligns maintenance activities with real business priorities.

The Real-World Impact of RCM

We have noticed that companies that use RCM often see measurable benefits. Their maintenance is more proactive, and less reactive. Their equipment lasts longer and resources are used more effectively.

More importantly, RCM helps teams work with purpose. Every maintenance task has a reason behind it. No more guessing or doing work “because we’ve always done it that way.”

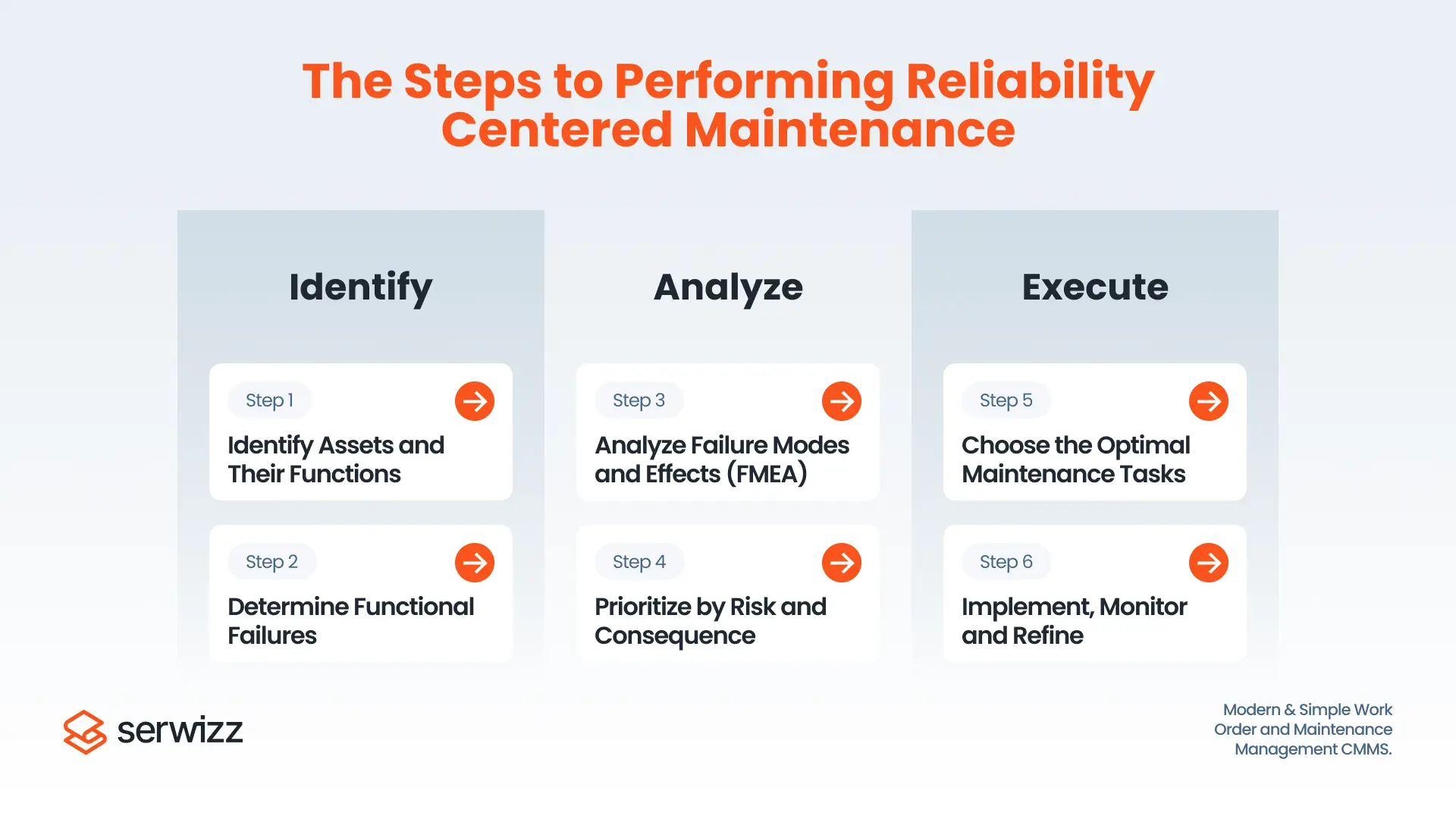

The Steps to Performing Reliability Centered Maintenance

We’ve seen a few of our clients put RCM into action with great success. Follow these steps and you will understand your equipment better.

Step 1 – Identify Assets and Their Functions

Make a list of your assets. Every machine, system or component that you use. Once listed, define what each asset is supposed to do. This means identifying both its primary functions (its main job) and secondary functions (such as safety, environmental protection or comfort).

Tip: Keep your definitions simple and specific. For example, instead of saying “compressor,” define its purpose: “compress air to 8 bar pressure for the production line.”

Step 2 – Determine Functional Failures

Next, ask yourself: How can this asset fail to perform its function?

A “functional failure” can relate to partial performance or safety issues. One good example is an air conditioner that is blowing air, but has issues with cooling.

Step 3 – Analyze Failure Modes and Effects (FMEA)

Try to combine RCM with Failure Mode and Effects Analysis (FMEA). FMEA detects what could go wrong, why it might happen and what would happen if it did.

For each possible issue determinate:

- The cause

- The effect

- The severity and likelihood.

This analysis helps you define your maintenance priorities.

Step 4 – Prioritize by Risk and Consequence

RCM helps you prioritize issues based on their risk, which combines both probability and consequence. Issues in your system are not equally critical. Some are minors while the others can stop your whole production.

Try to organize your maintenance team to focus on critical areas first. Knowing the risk factor you can have a maintenance plan that is efficient and aligned with business goals.

Step 5 – Choose the Optimal Maintenance Tasks

Once you understand which failures matter most, decide the best maintenance actions to prevent or control them.

These can include:

- Preventive tasks – such as regular inspections.

- Predictive tasks – such as temperature trends.

- Corrective actions – redesigning or replacing parts that are problematic.

These actions help you prevent the most important issues.

Step 6 – Implement, Monitor and Refine

Last step, start using your plan.Implement the chosen maintenance tasks, assign responsibilities and track results.

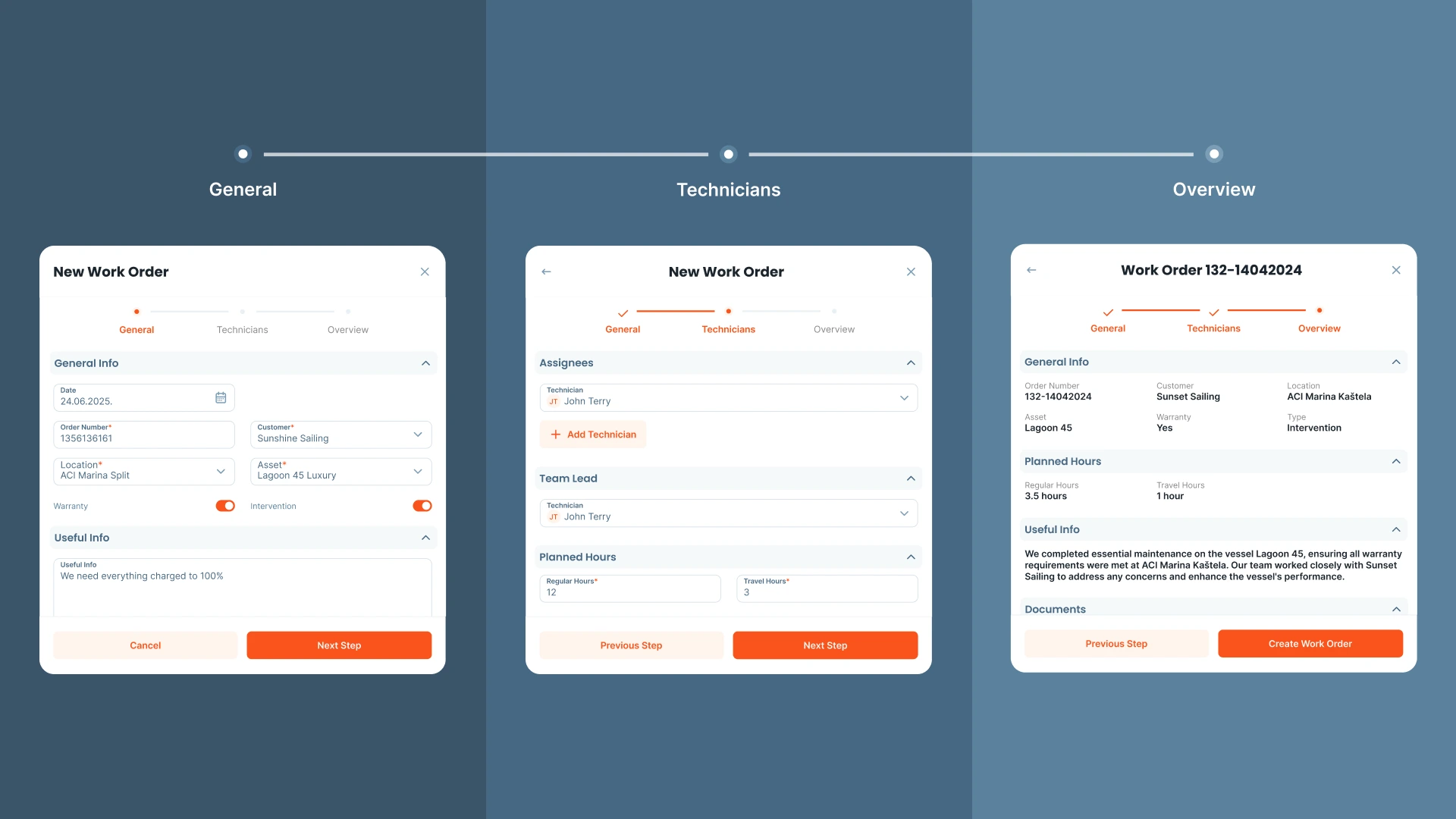

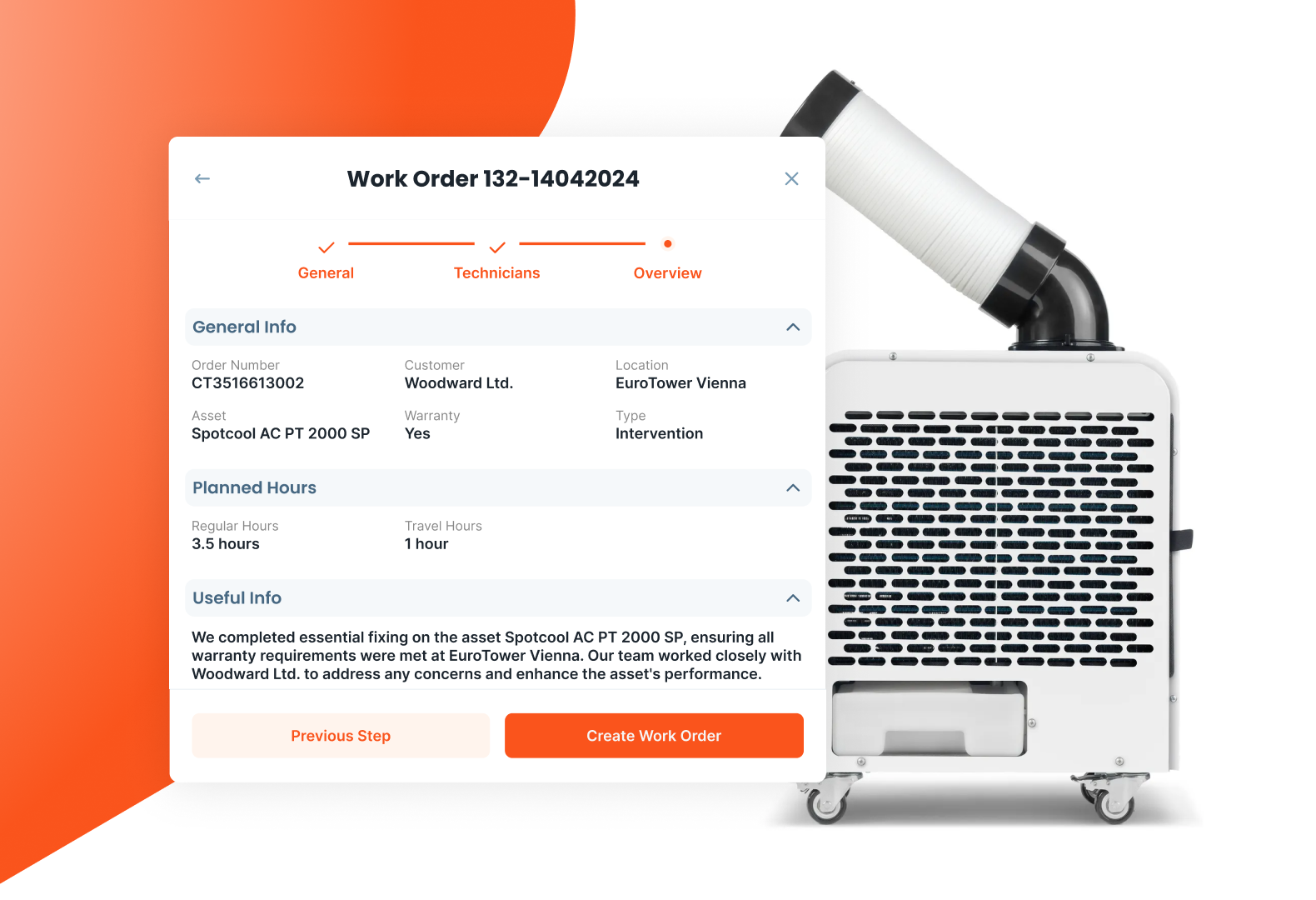

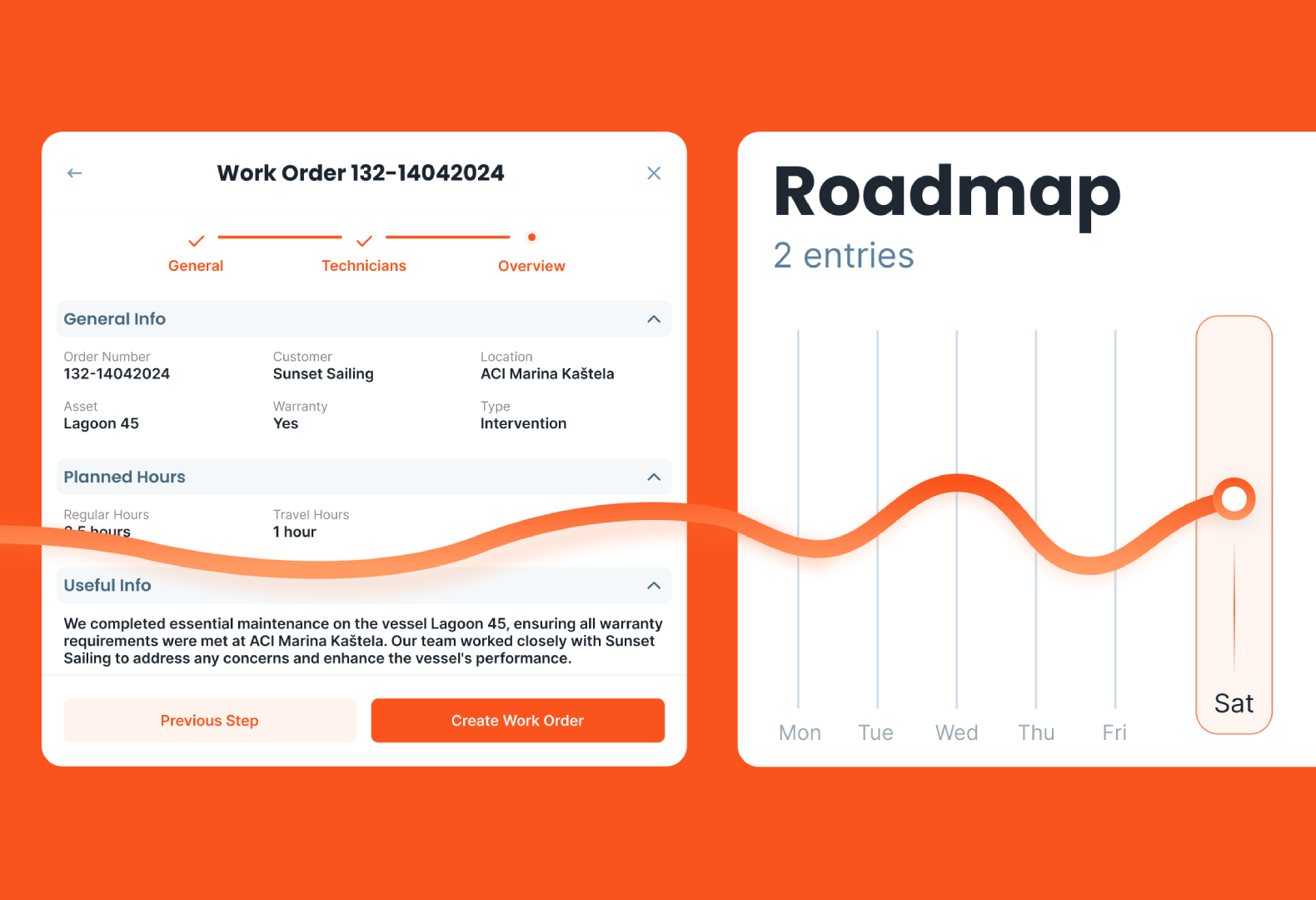

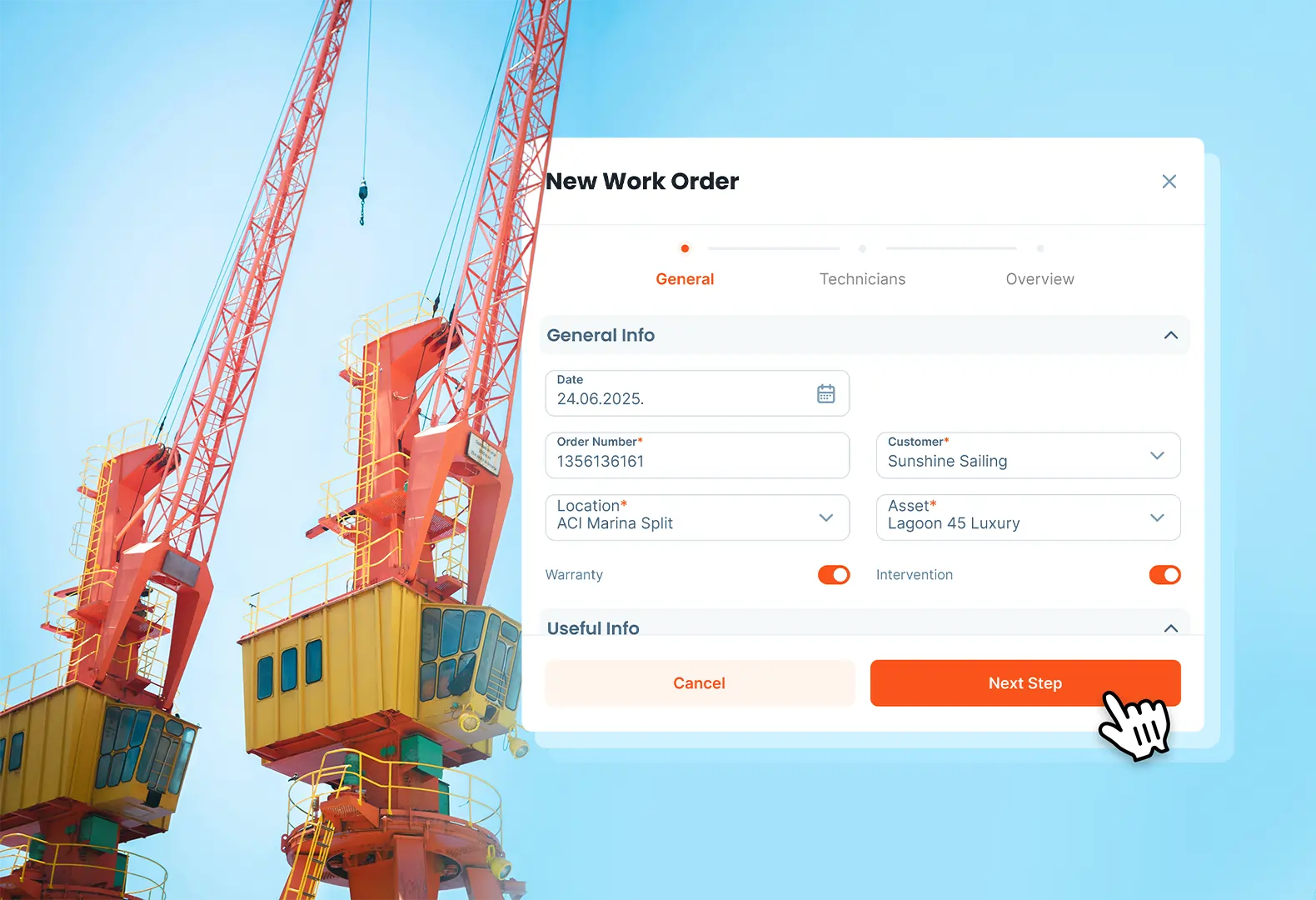

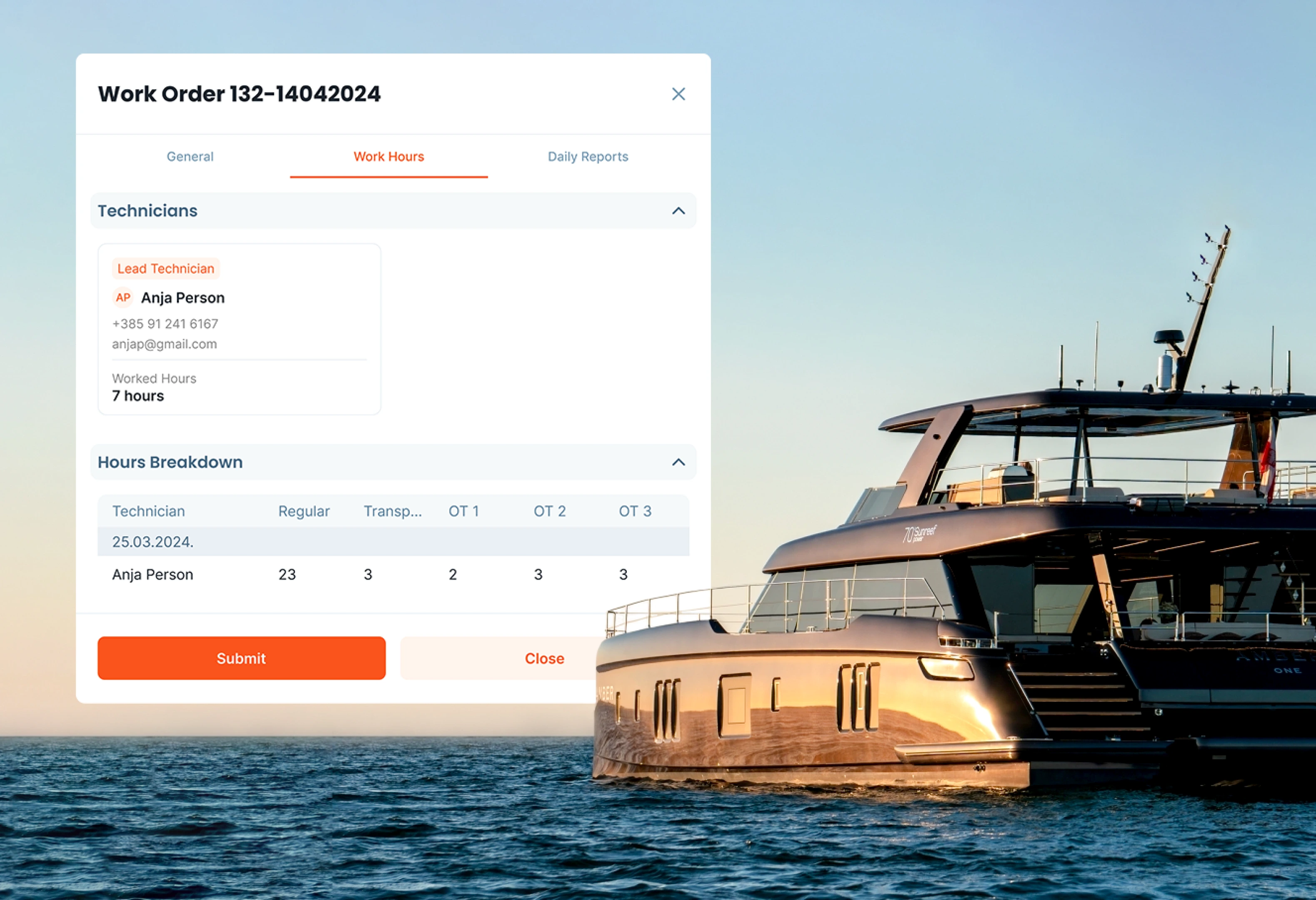

Use a CMMS to schedule work orders, log inspections and monitor asset performance.

RCM is part of a continuous improvement cycle. Review data regularly and adjust your strategy.

Benefits and Challenges of RCM

RCM can bring your team structure and better decision-making, but it can also be scary. It might sound complicated to the team.

Key Benefits of RCM

Some of the main benefits include:

- Improved reliability. Equipment performs better and lasts longer.

- Lower maintenance costs. You reduce unnecessary work and spare parts.

- Increased safety. By identifying failure risks early, you can protect your team and your operations.

- Higher uptime and productivity. Less downtime means smoother operations.

- Smarter resource planning. With RCM, you know where to spend your time and budget.

Example: A client of ours owns a small factory. Their machines usually ran fine, but maintenance was only done once a month on a set schedule. After introducing RCM, they started checking the most critical equipment more often and reduced the level of maintenance on less important assets. Just a few months later, they noticed something amazing: unplanned downtime dropped by about 20%.

Common Challenges in RCM

Like any structured process, RCM can be challenging at first. The most common challenges include:

- Time and effort to set up. RCM requires careful planning, asset analysis and training. It will require some time to set it up, but looking long term it’s worth it.

- Data availability. Some companies don’t have enough data at the beginning. We suggest they use CMMS to collect and organize data.

- Team alignment. You have to make sure your whole team understands and accepts RCM. Maintenance teams and management must work together to make it effective.

- Initial investment. Training and setup require time and money, but soon you will see savings and benefits.

How to Overcome These Barriers

We suggest you start with small steps

- Begin with your most critical assets.

- Use CMMS software to track progress and capture data automatically.

- Train your team.

- Communicate clearly. Help everyone see how RCM supports safety, reliability and productivity.

Once the first results appear, it becomes much easier to get full organizational support.

Implementing an RCM Program

So far we have explained to you the theory of Reliability Centered Maintenance. In this chapter we will explain how to use it in the real world. We suggest that you gather your team and start with small steps.

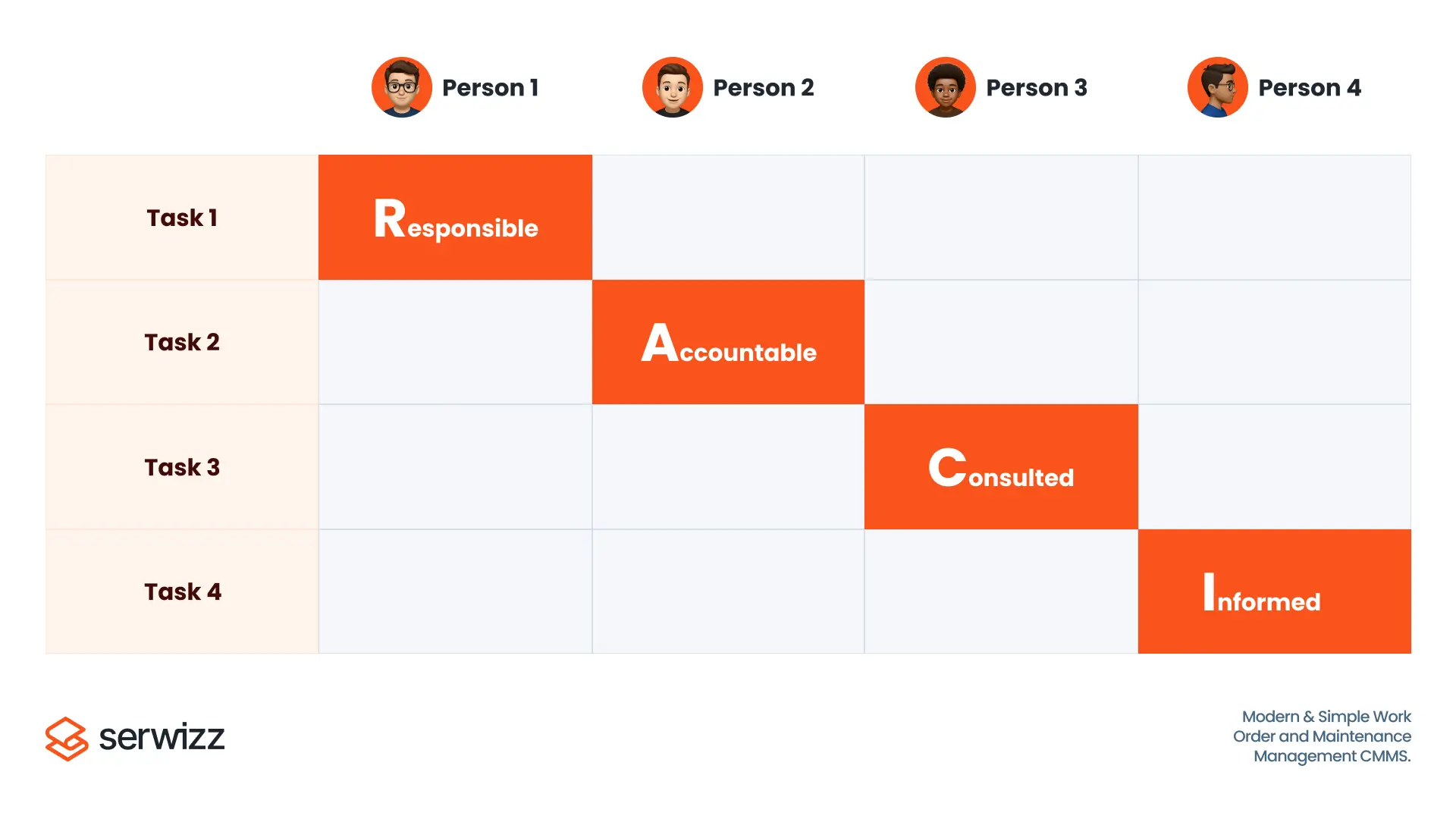

Building the Right Team

RCM works best when everyone is included.

Your core RCM team usually includes:

- Maintenance technicians who know the assets.

- Engineers or planners who can analyze failures and design tasks.

- Operators who use the machines every day.

- Managers or supervisors who provide direction and support.

It’s important to make everyone feel part of the process.

Using Technology to Your Advantage

When you combine RCM with simple digital tools like a CMMS, it’s easier to plan and track maintenance work.

You can also use small smart sensors to watch things like temperature or vibration, so you can spot problems early before they cause bigger issues.

Setting Metrics for Success

RCM is only effective if you can measure the results. Some key metrics to watch include:

| Metric | Usage |

|---|---|

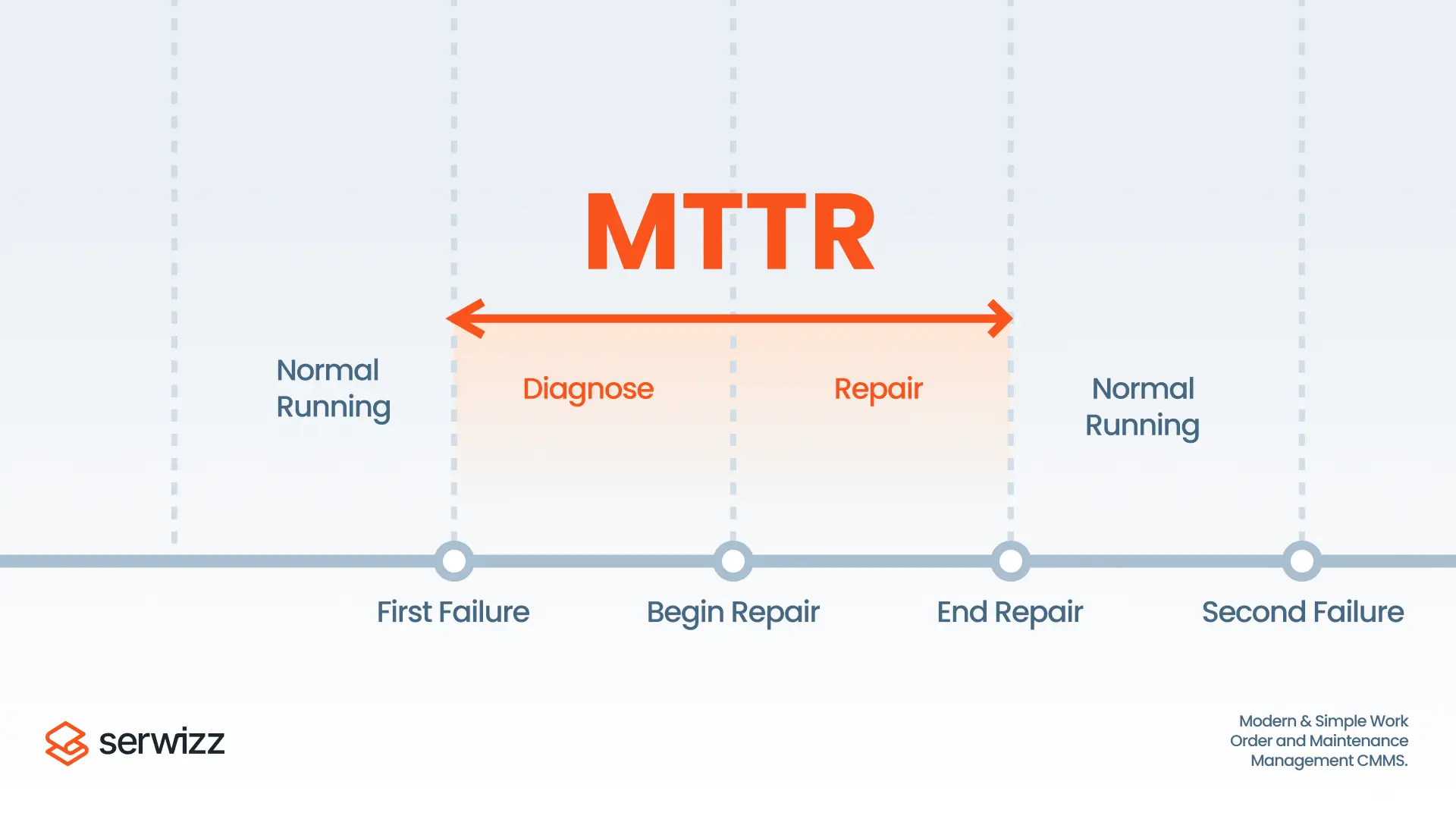

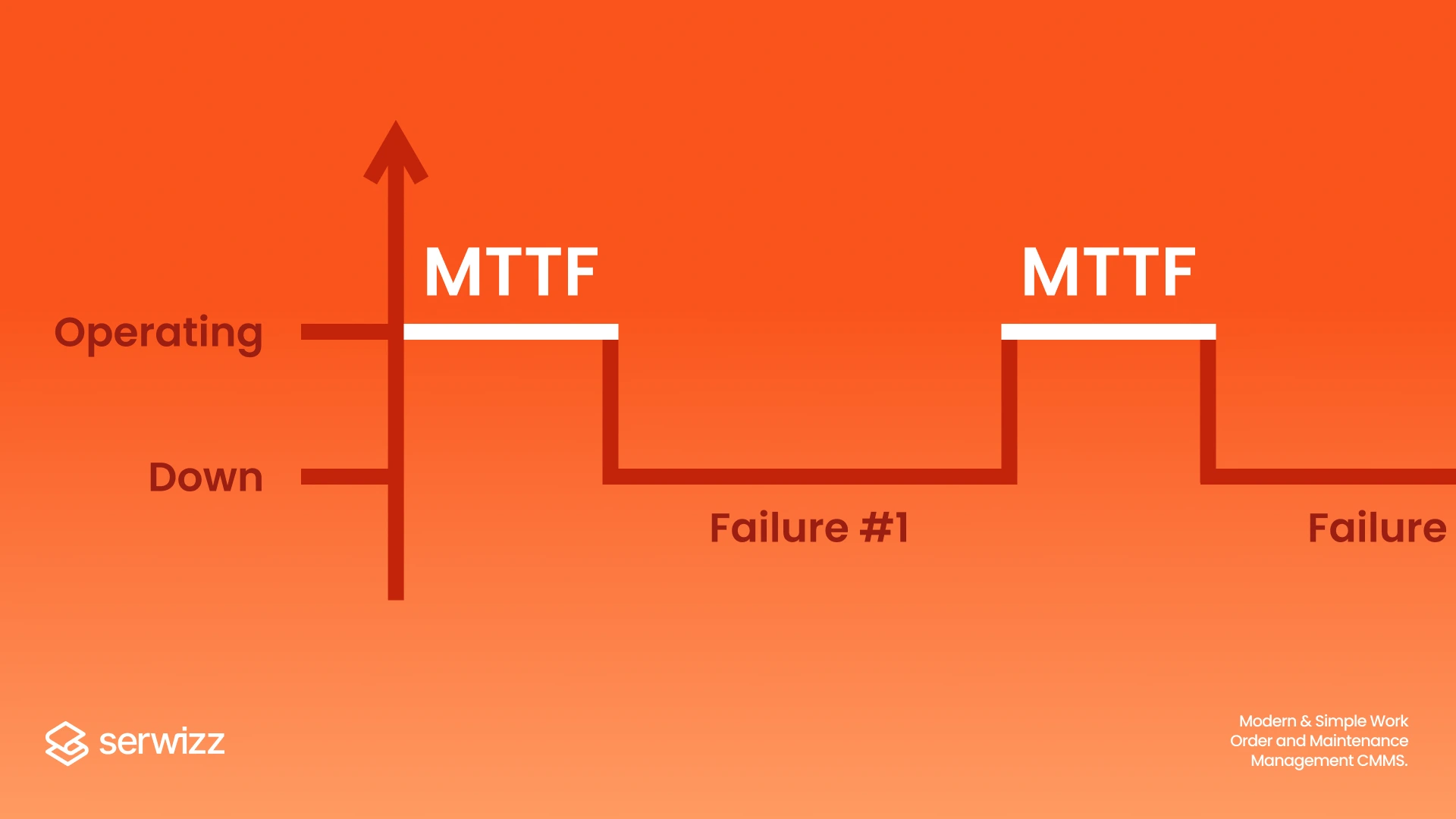

| MTBF (Mean Time Between Failures): | Measures how long assets operate before they stop working. |

| Uptime percentage | The ratio of operating time to total available time. |

| Maintenance cost per asset | Helps identify where resources are used efficiently or wasted. |

| Work order completion rate | Track maintenance task performance. |

We suggest that you choose two or three metrics that are most important to your company, at first. Later you can add more metrics.

Examples of RCM in Action

Reliability Centered Maintenance is applicable in many industries, especially where equipment stability is important.

Manufacturing: Reducing Unplanned Downtime

One of our clients in the manufacturing industry often had problems with a packaging line that stopped without warning. To fix the issue, they’ve decided to apply RCM.

The team performed FMEA analysis and identified where the issues started. Issues were then prioritised. They added quick condition checks at the beginning of each shift and monitored the main motor. After some time, issues became rare and production became more stable.

HVAC Systems: Improving Comfort and Efficiency

One of the facilities teams we spoke to had issues with their HVAC system. They’ve noticed recurring cooling problems during the summer. They used RCM to study the root cause and discovered that blocked filters cause most of the issues.

Instead of scheduling filter changes by calendar date, they started checking filter conditions weekly. They also adjusted inspection routines for fans and motors. As a result, their energy bills were lower and the HVAC system performed better.

Marine Sector: Managing Critical Equipment Safely

Recently we met with the CEO of a power generation plant. His team used RCM to take better care of its turbines. The team found the parts that were most likely to cause problems and started checking their temperature and oil condition to detect issues early.

They prevented unexpected issues and kept the workers safe. Over time, the company was able to do maintenance less often without taking risks, saving both time and money.

How CMMS Supports RCM

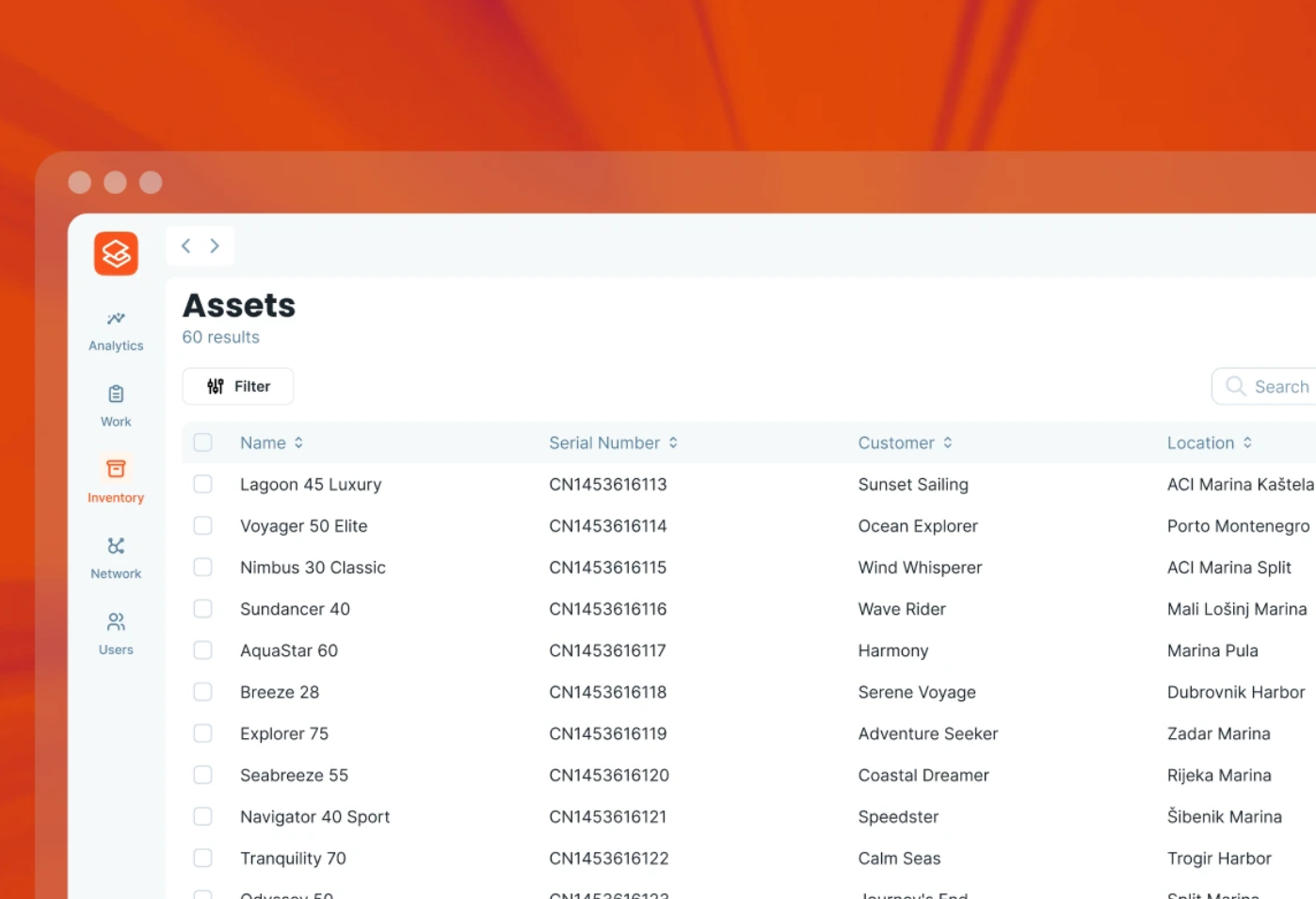

Even the best maintenance plan can be better when combined with CMMS. CMMS helps you organize everything:

- Maintenance schedule

- Maintenance checklists

- Failure history

- Spare parts

RCM gives you the strategy. CMMS gives you the tools to make it happen.

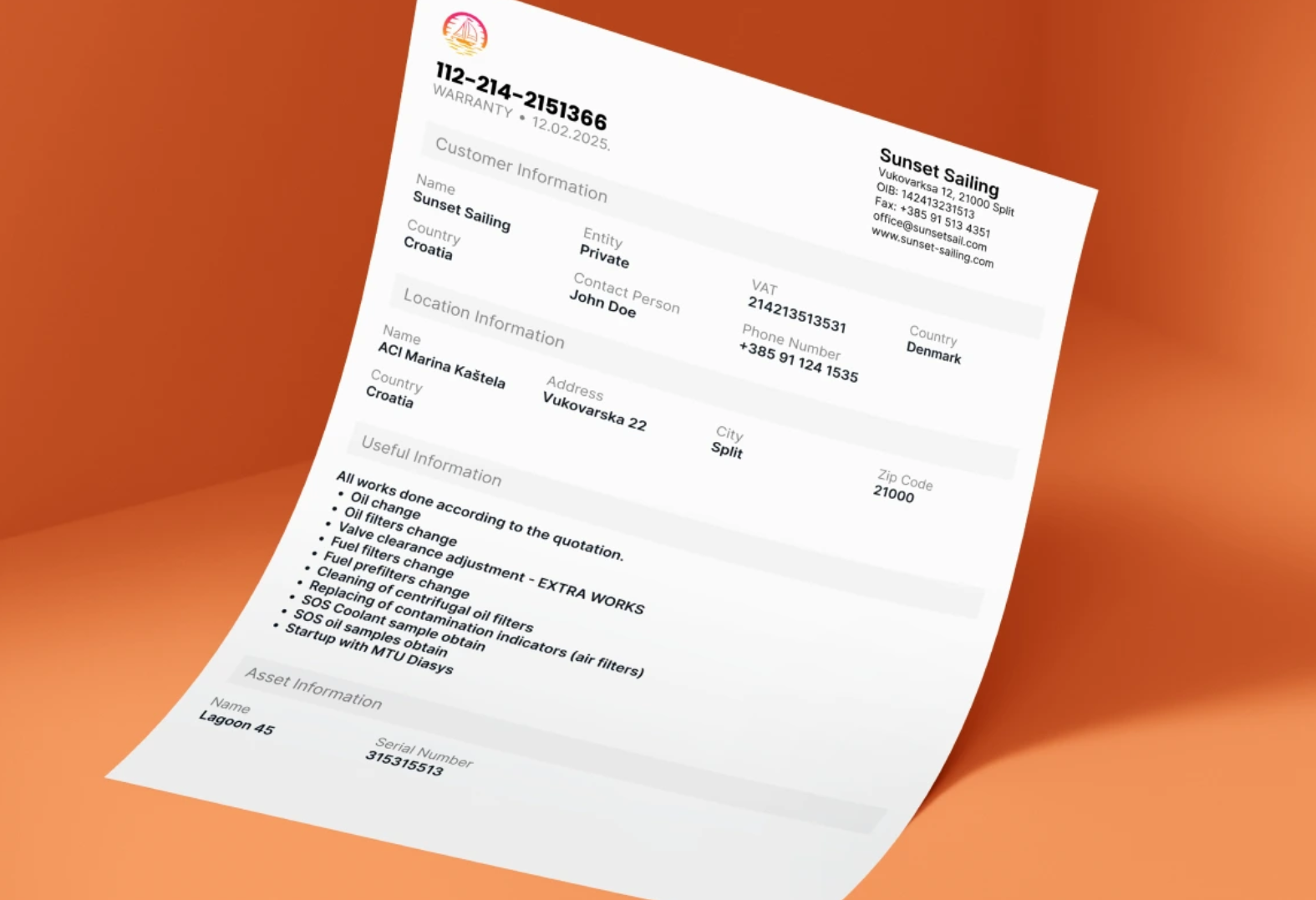

Bringing Structure to Your Maintenance Tasks

When you start applying to RCM, you’ll quickly realize how much data you need — work orders, inspection results, asset histories, and more. Doing all that on paper or spreadsheets can get messy fast.

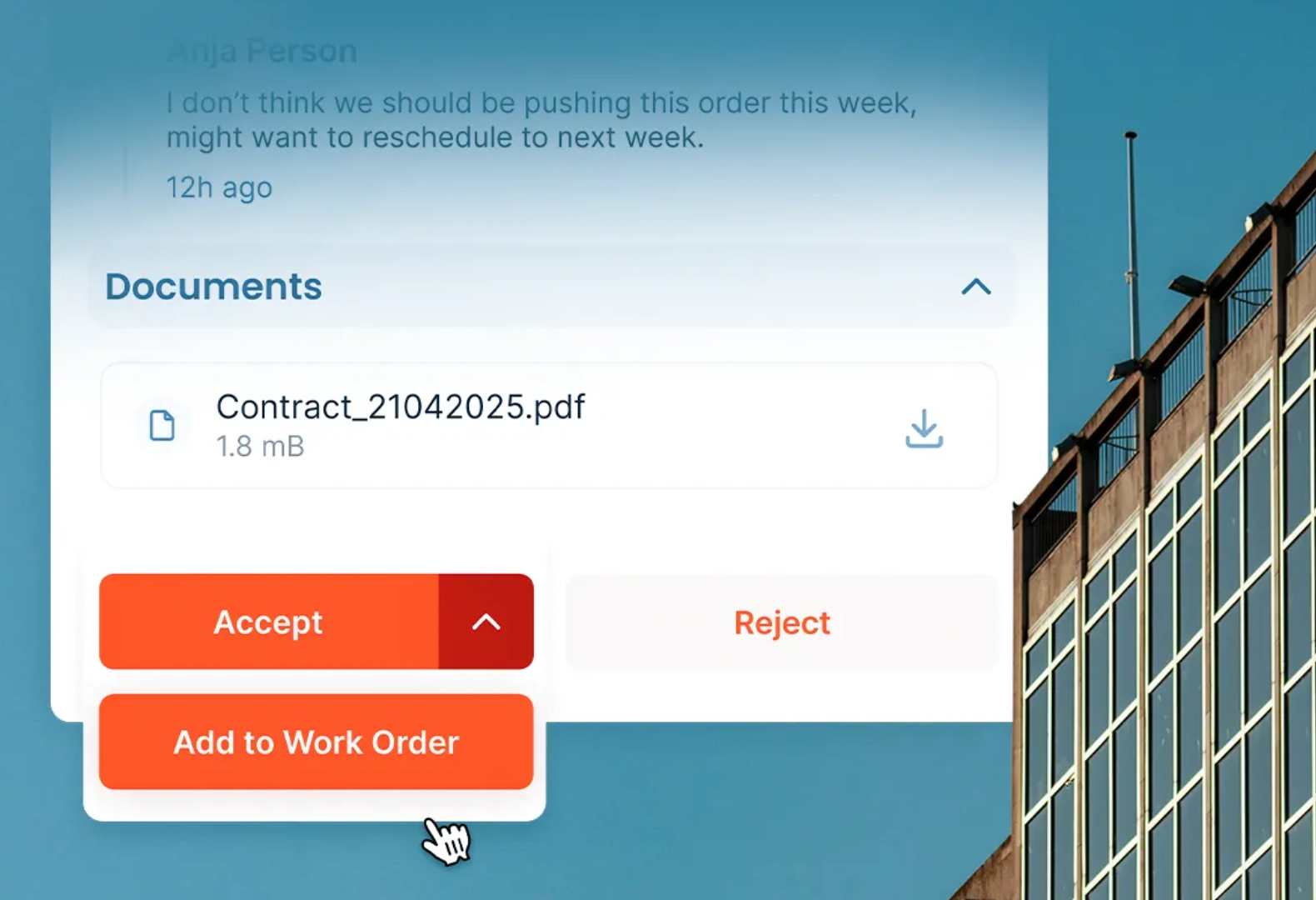

A CMMS keeps things organized. You can create maintenance tasks and assign them to technicians. No more spreadsheets.

Tracking Performance and Failures

CMMS stores all your maintenance history in one place. You then analyse the data and identify patterns: which assets have more issues, which parts are always replaced.

This data helps you decide where to focus your RCM efforts.

Connecting People and Information

RCM only works when everyone is on the same page. With a CMMS the whole team can have updates in real time. No more guessing who did what or when. You can track who completed each task, how long it took and what materials were used.

Turning Data Into Better Decisions

The biggest advantage of using a CMMS with RCM is the data analysis. Use the dashboards and graphs to have a clear picture of what’s working and what’s not. That’s how RCM becomes part of your everyday process. Simple, structured and supported by real data.

Final Thoughts on Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance is focused on doing the right maintenance, not more maintenance. It helps teams understand their assets, define the priorities and make better decisions.

RCM might sound complex at first, but it’s really about asking simple questions:

- What does this machine do?

- What causes the machine to stop working?

- What happens when it does?

- What can we do to stop that from happening?

Once you start thinking this way, everything changes. You switch from reactive to preventive mode. Your equipment lasts longer and your operations become smoother and safer.

At Serwizz, we’ve seen how RCM can transform maintenance teams. RCM in combination with CMMS can help you improve reliability, safety and performance.

If your goal is to reduce downtime, manage maintenance costs and keep your team focused on what truly matters, RCM is a great place to start.