Maintenance

·

12 min read

Annual Maintenance Plan: Playbook for Maintenance Teams

Stop wasting time on avoidable breakdowns. One yearly plan keeps work under control.

Your maintenance crew works under pressure every day, while production expects stable output, Management expects lower cost and technicians want clear tasks instead of chaos.

Random calls shape the schedule, failures arrive during busy hours, spare parts sit in the wrong place. The same equipment fails again and again.

A written annual maintenance plan changes this pattern. The team moves from reaction to a clear path for the whole year.

Why an annual maintenance plan matters

An annual maintenance plan connects daily work with long term business goals.

You decide in advance which assets receive attention, when work happens, and how results reach leadership.

Planned work reduces unplanned downtime and lowers emergency repair effort.

Industry reports show preventive maintenance reduces equipment downtime by around thirty percent and lowers total maintenance cost by more than ten percent.

A clear plan supports:

- Higher uptime on critical lines

- Safer operation of equipment and buildings

- Longer asset life

- Better use of technician time

- More reliable data for decisions

Key parts of an annual maintenance plan

A strong annual maintenance plan stays simple. Use these elements as a checklist.

- Asset inventory

- Risk and criticality view

- Task library

- Yearly schedule

- Ownership and roles

- Metrics and targets

- Review rhythm

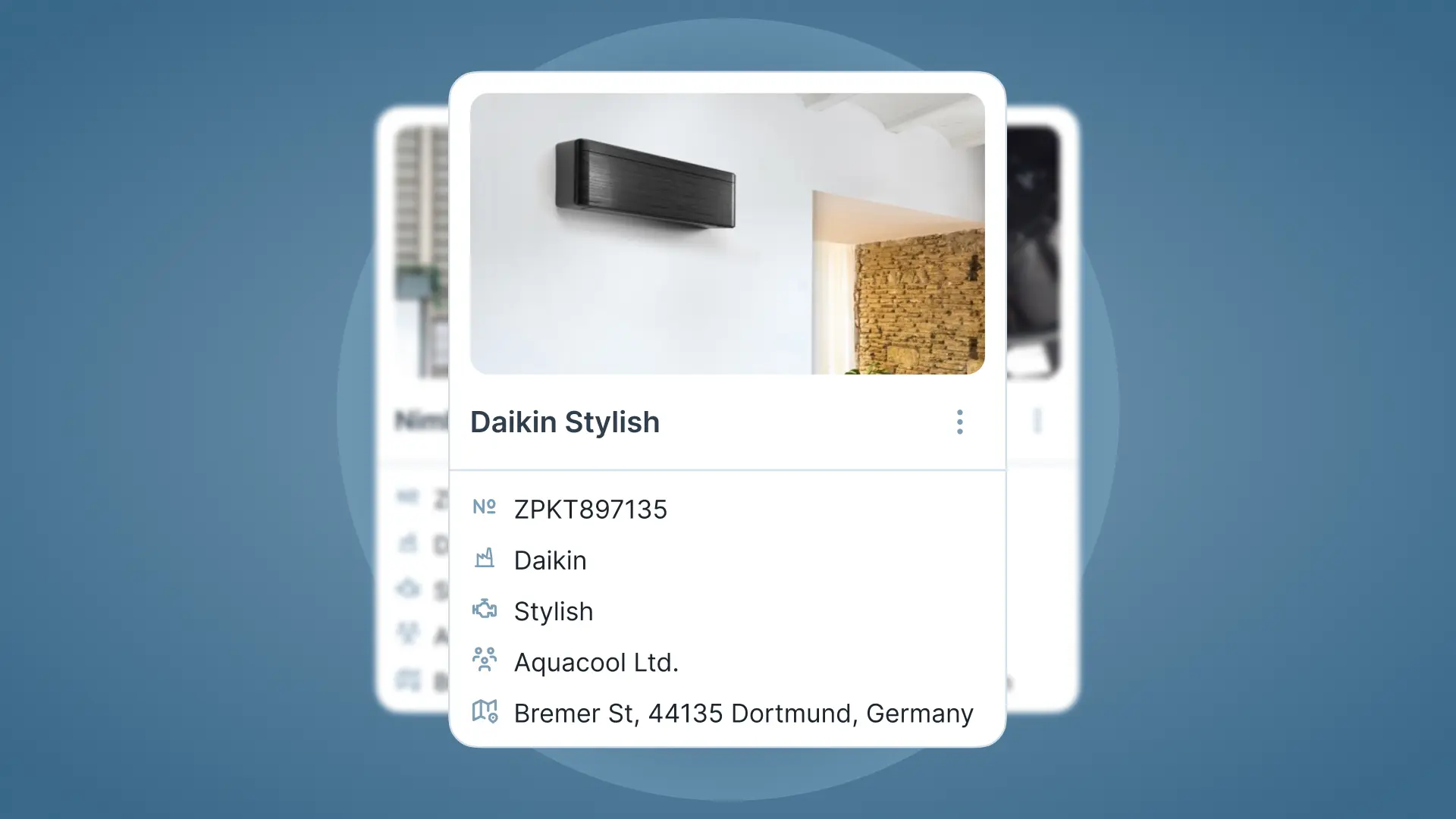

Asset inventory

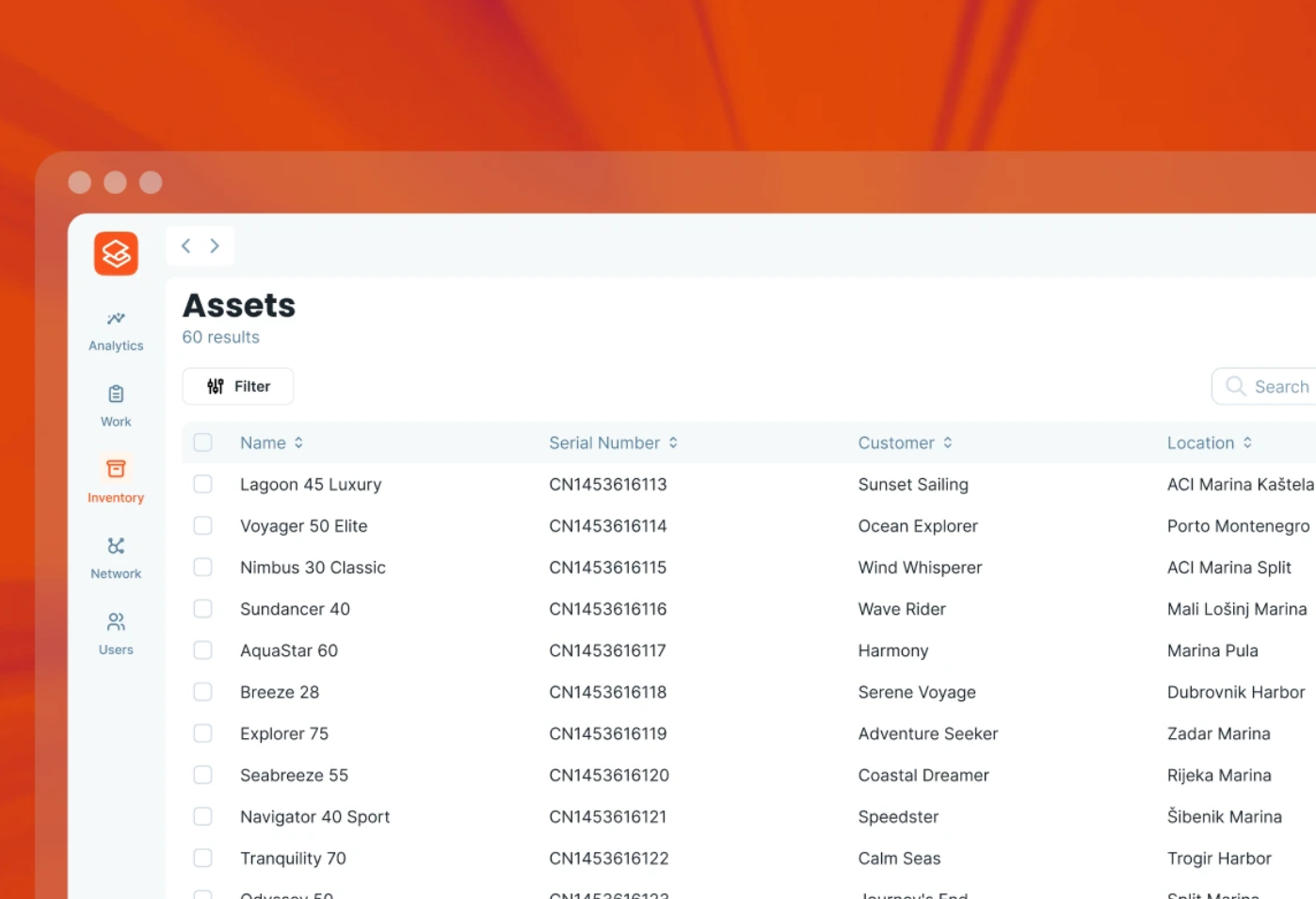

Start with an inventory designed for your plant or building, then group assets by location, line, and type. Include details required for planning.

Helpful fields:

- Asset name and code

- Location

- Manufacturer and model

- Age and expected life

- Maintenance history

- Frequent problems

This inventory gives structure for decisions about strategy and task frequency.

Risk and criticality view

Not every asset deserves the same attention. Focus effort where failure hurts most.

For each asset, rate:

- Safety impact

- Environmental impact

- Production impact

- Customer impact

- Replacement or repair cost

Assign a simple criticality level.

For example:

- A assets, highest impact

- B assets, medium impact

- C assets, low impact

Use this view when you choose maintenance strategy and intervals.

Task library

Next, prepare a repeatable library of maintenance tasks.

Include tasks such as:

- Visual inspections

- Cleaning and lubrication

- Functional tests

- Calibration

- Component replacements

- Safety checks

For each task, define:

- Asset or asset group

- Required skill

- Typical duration

- Required tools and materials

- Short work instructions or a checklist

- Safety notes

A clear task library supports consistent work across shifts, new team members learn faster and supervisors schedule work with more confidence.

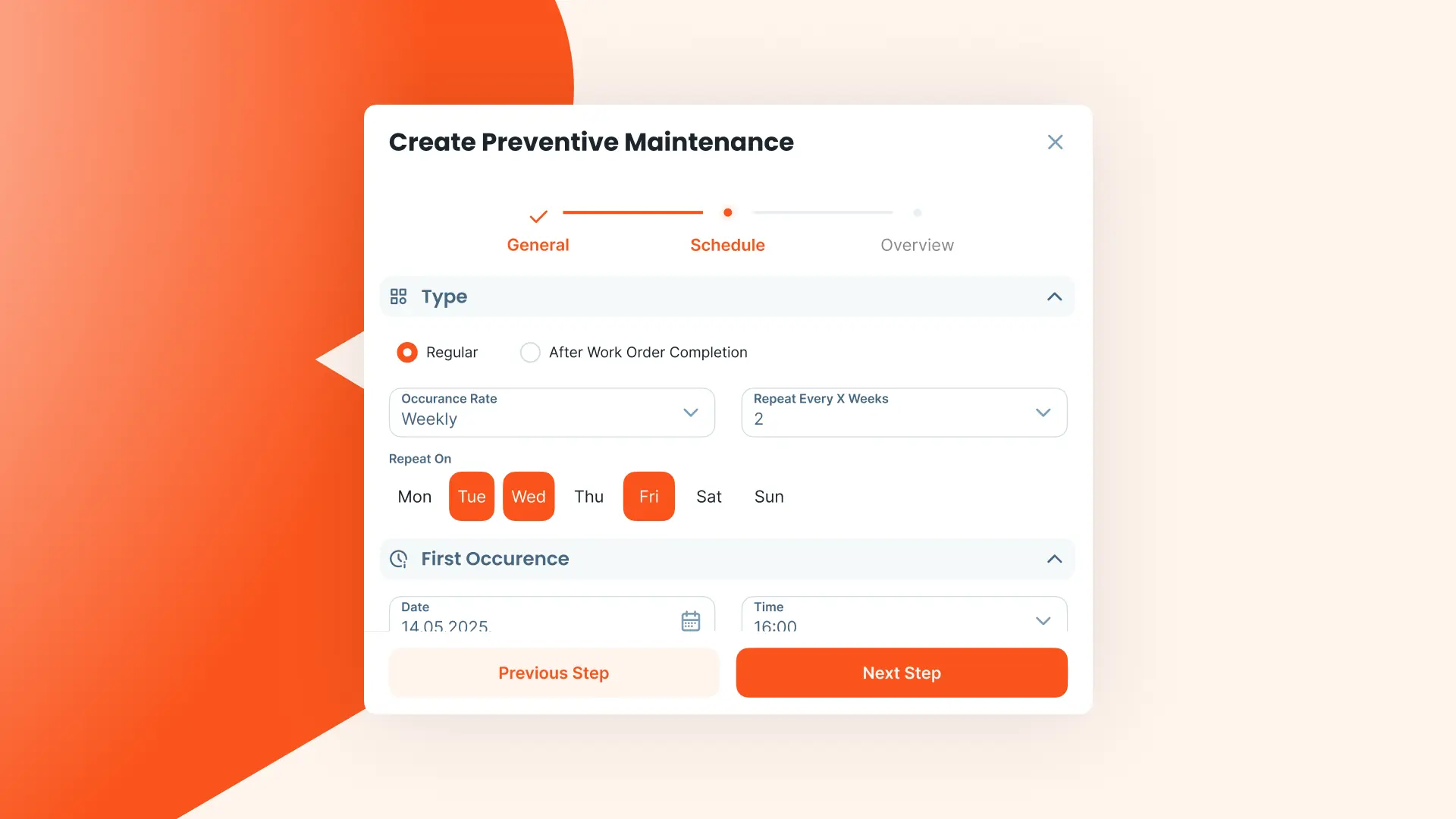

Yearly schedule

The yearly schedule answers one key question, what happens during each part of the calendar.

Break the year into:

- Daily tasks

- Weekly tasks

- Monthly tasks

- Quarterly tasks

- Twice per year tasks

- Annual tasks

- Shutdown tasks

Spread work so busy periods do not overload the team, group tasks by area to reduce walking time and link every job to an asset and an owner.

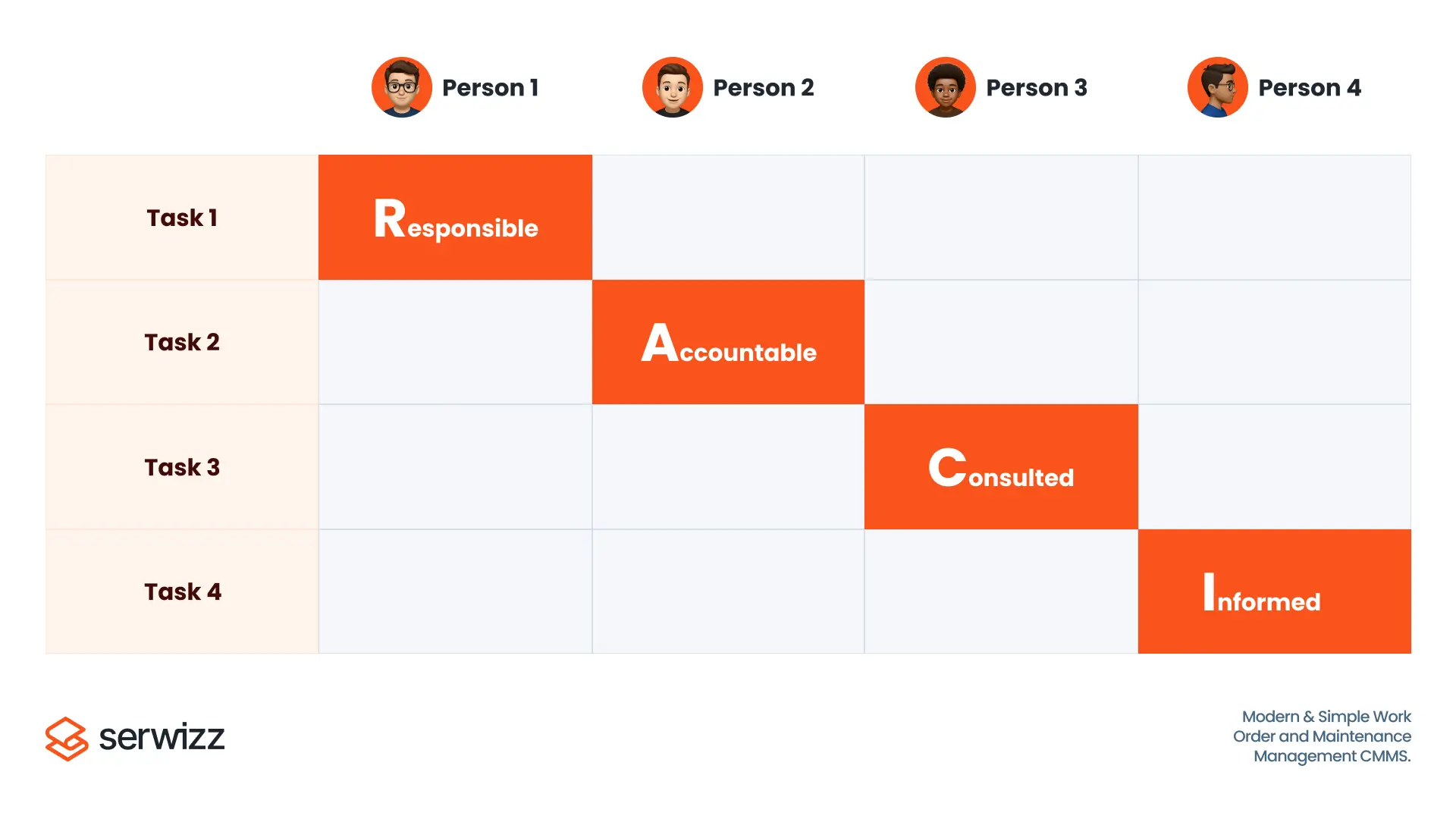

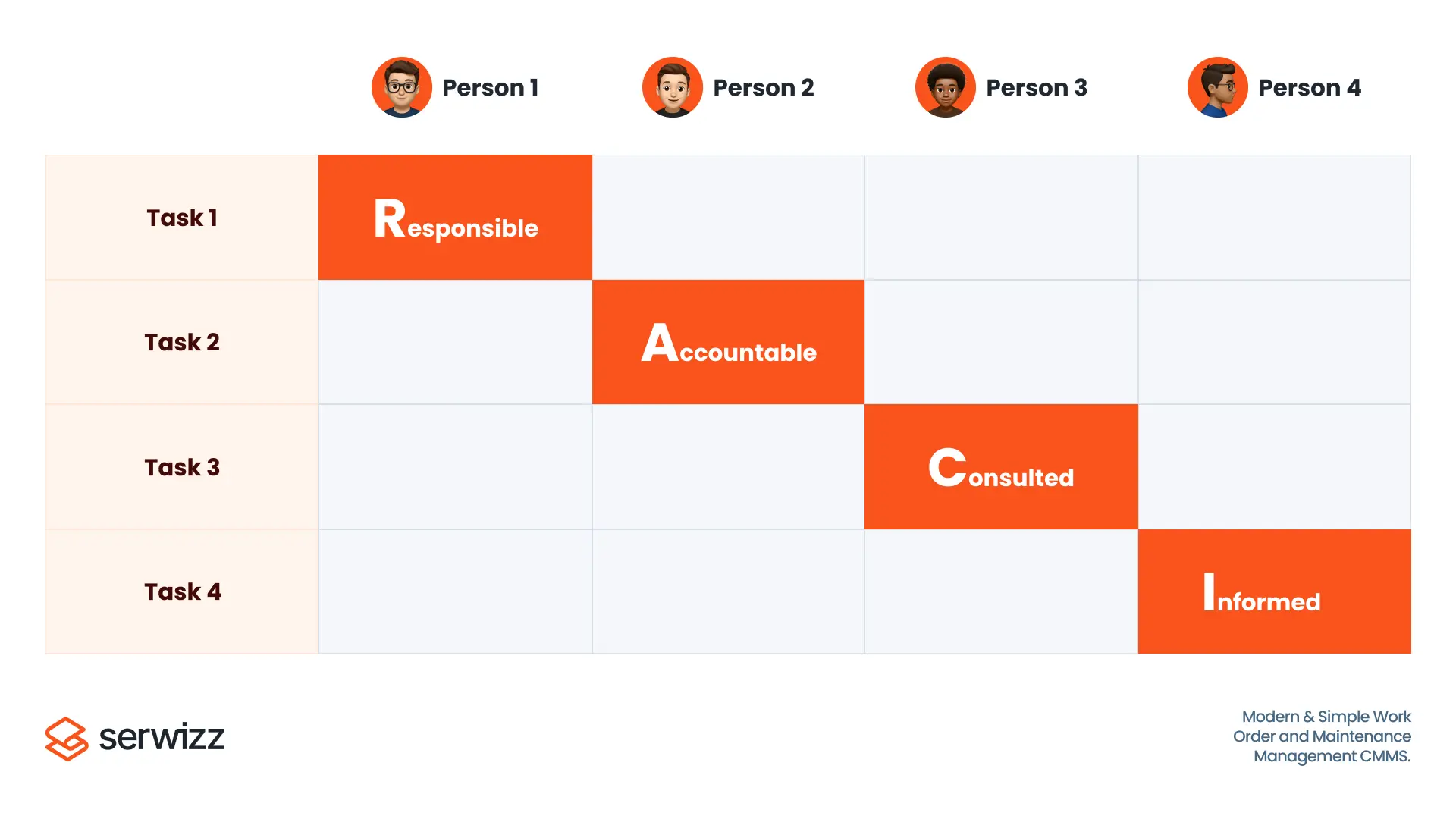

Ownership and roles

An annual maintenance plan needs clear owners.

Assign:

- A maintenance owner for each asset or area

- A planner or coordinator

- A main contact for operations

Make ownership visible in the plan and include names instead of only role labels.

This approach supports accountability and faster decisions.

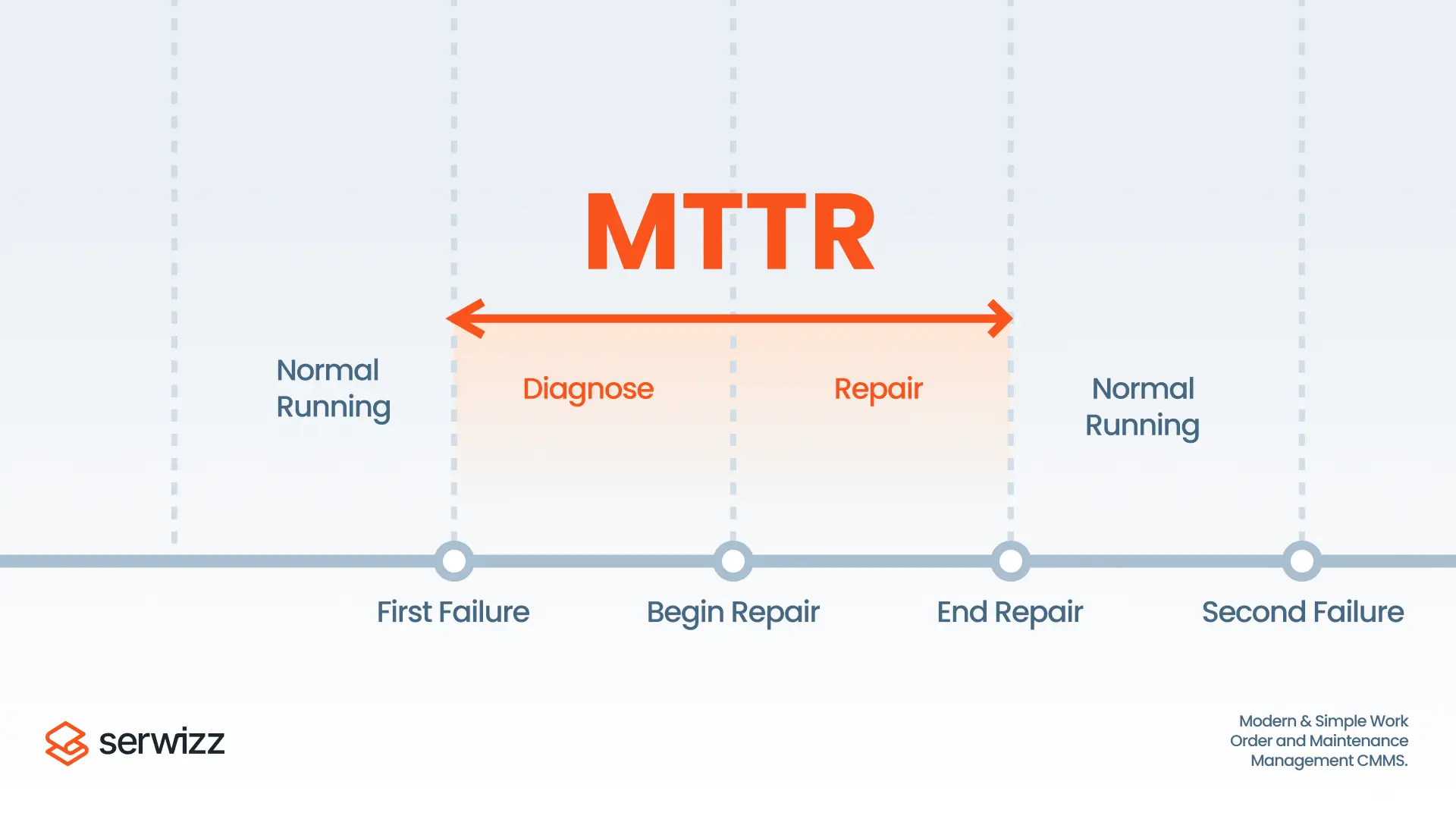

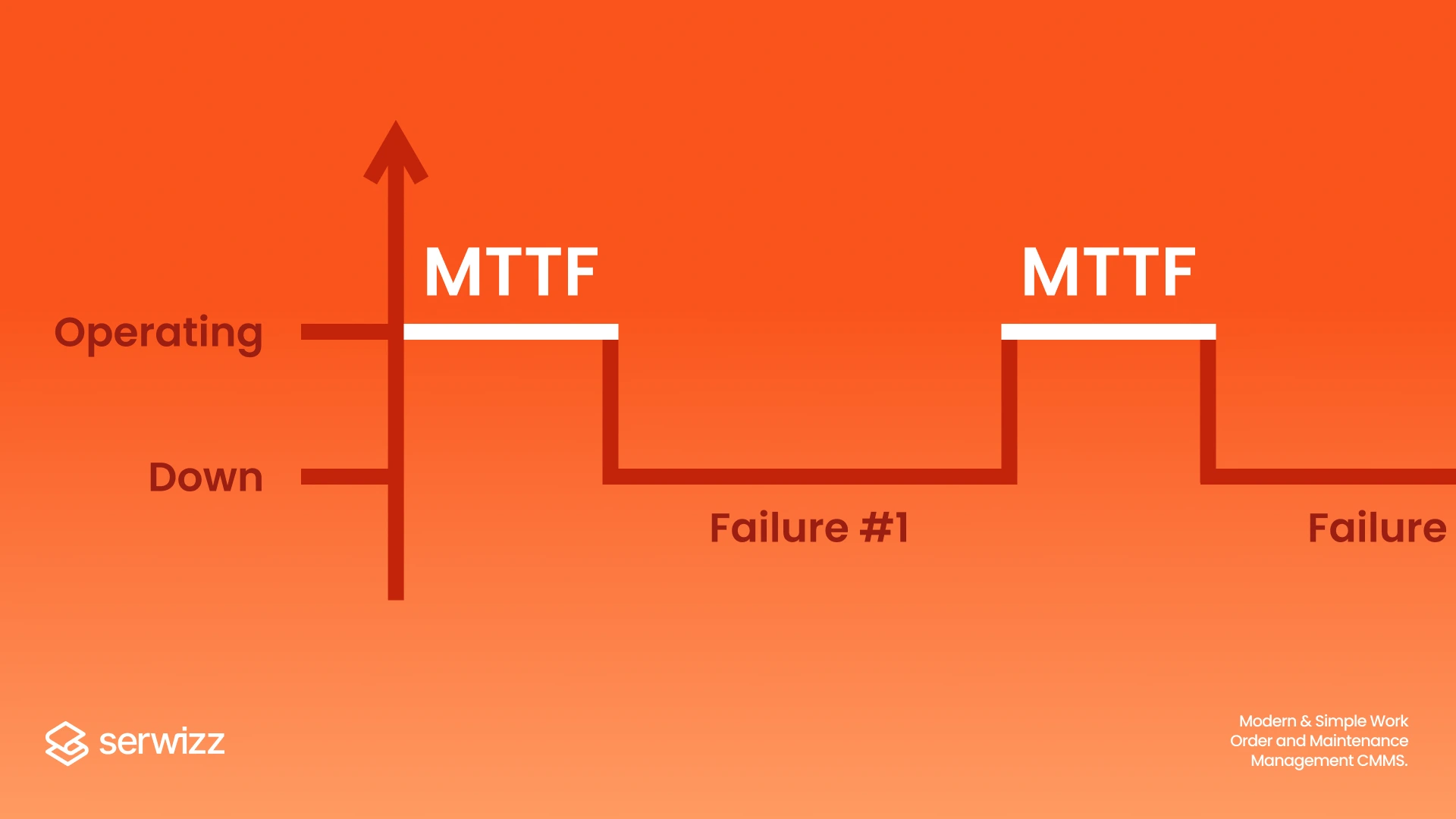

Metrics and targets

Measurement keeps an annual maintenance plan honest.

Useful metrics:

- Share of planned work versus reactive work

- Completion rate for preventive tasks

- Mean time between failures

- Mean time to repair

- Downtime hours per line or asset

- Maintenance cost per asset or per unit of output

Industry data links strong preventive programs with lower unplanned downtime, lower emergency repair cost, and longer asset life.

Select a short list of metrics aligned with your business goals and review numbers with operations and leadership each month and quarter.

Review rhythm

An annual maintenance plan evolves with your site, business priorities shift, assets age and new lines arrive.

Set a simple review rhythm.

Weekly:

- Check upcoming tasks and resource gaps

- Confirm completion of critical work

Monthly:

- Review metrics and major failures

- Adjust tasks with low value

Quarterly:

- Review criticality levels

- Change task frequency when failure patterns shift

- Move resources between lines when needed

Annual:

- Review the full asset list and strategies

- Compare budget with actual cost

- Plan training for technicians

- Confirm the annual maintenance plan for the next cycle

Step by step annual maintenance plan

Follow these steps to build or refresh your annual maintenance plan.

1. Define goals for the year

Start from business goals for the next twelve months.

Examples:

- Higher throughput on one priority line

- Fewer delivery delays

- Stronger safety record

- Lower maintenance cost per unit

Write one short sentence for each goal and keep those sentences visible while you plan tasks and schedules.

2. Map assets and criticality

Use the asset inventory and risk view.

For each asset group, note:

- Criticality level

- Current failure patterns

- Current maintenance approach

Highlight assets with frequent failures or long repair times, mark assets with strong safety or environmental impact. Give these groups more structure in the annual maintenance plan.

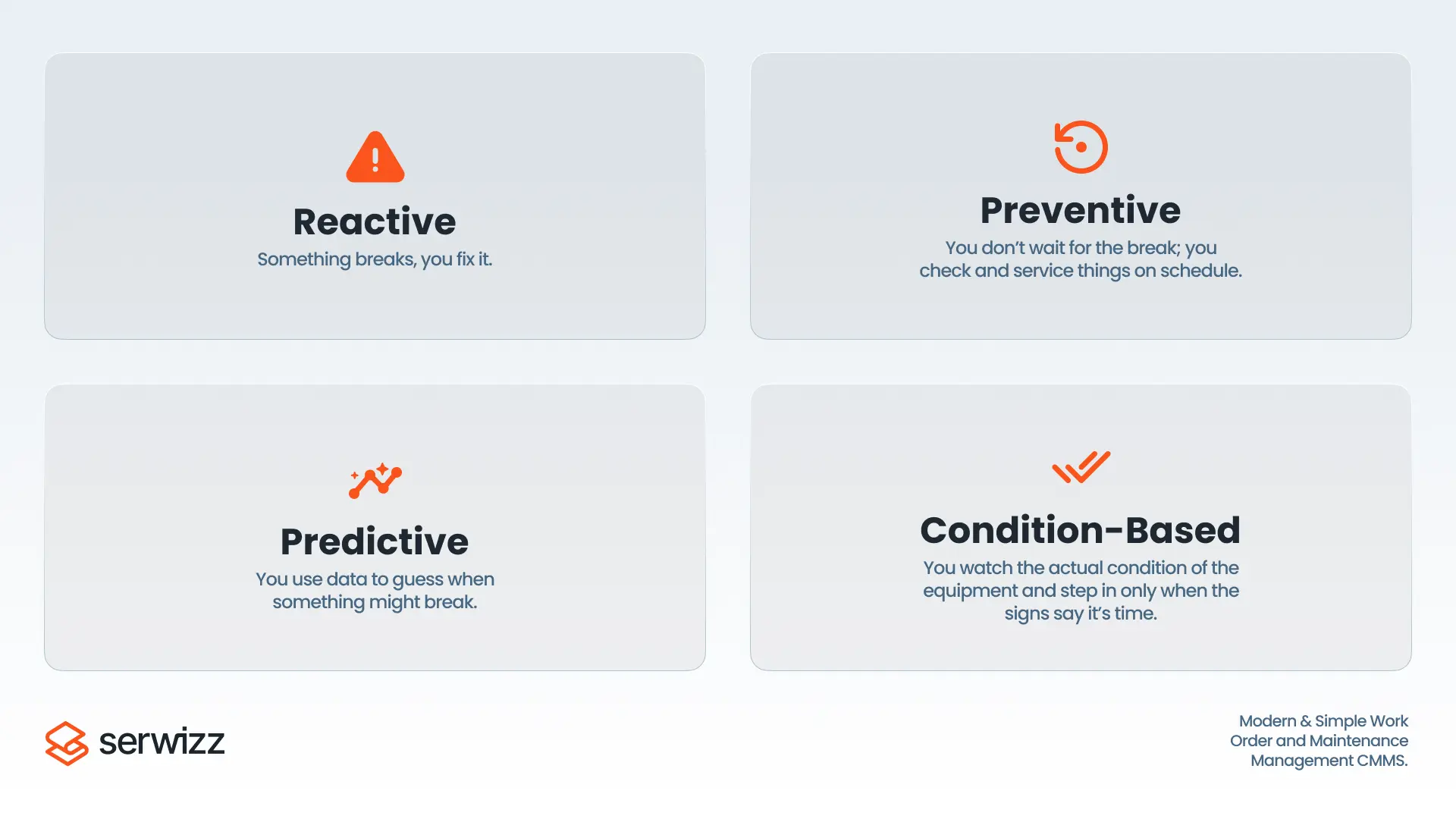

3. Choose maintenance strategies

Select a maintenance strategy for each asset group.

Common options:

- Run to failure for simple, low risk equipment

- Time based preventive maintenance on a calendar

- Usage based maintenance driven by hours or cycles

- Condition based maintenance driven by inspections or sensor data

Match the approach to risk, impact, and data quality. Avoid over maintenance on low impact assets and missed inspections on critical equipment.

4. Build the task library

Connect tasks from your library to each strategy.

Example for a production line motor:

- Monthly visual inspection and cleaning

- Quarterly vibration and temperature check

- Annual alignment check

- Replacement of bearings after a set number of hours or cycles

Keep instructions short and practical and link tasks to checklists or standard procedures.

5. Build the yearly calendar

Now spread tasks across the year.

Use this sequence:

- Place annual and shutdown tasks first and align with planned stops

- Add quarterly tasks

- Add monthly tasks

- Add weekly and daily routines

Balance workload across weeks and avoid heavy work during peak production where possible.

For each task, specify:

- Target week or day

- Expected effort

- Required skills

- Spare parts needs

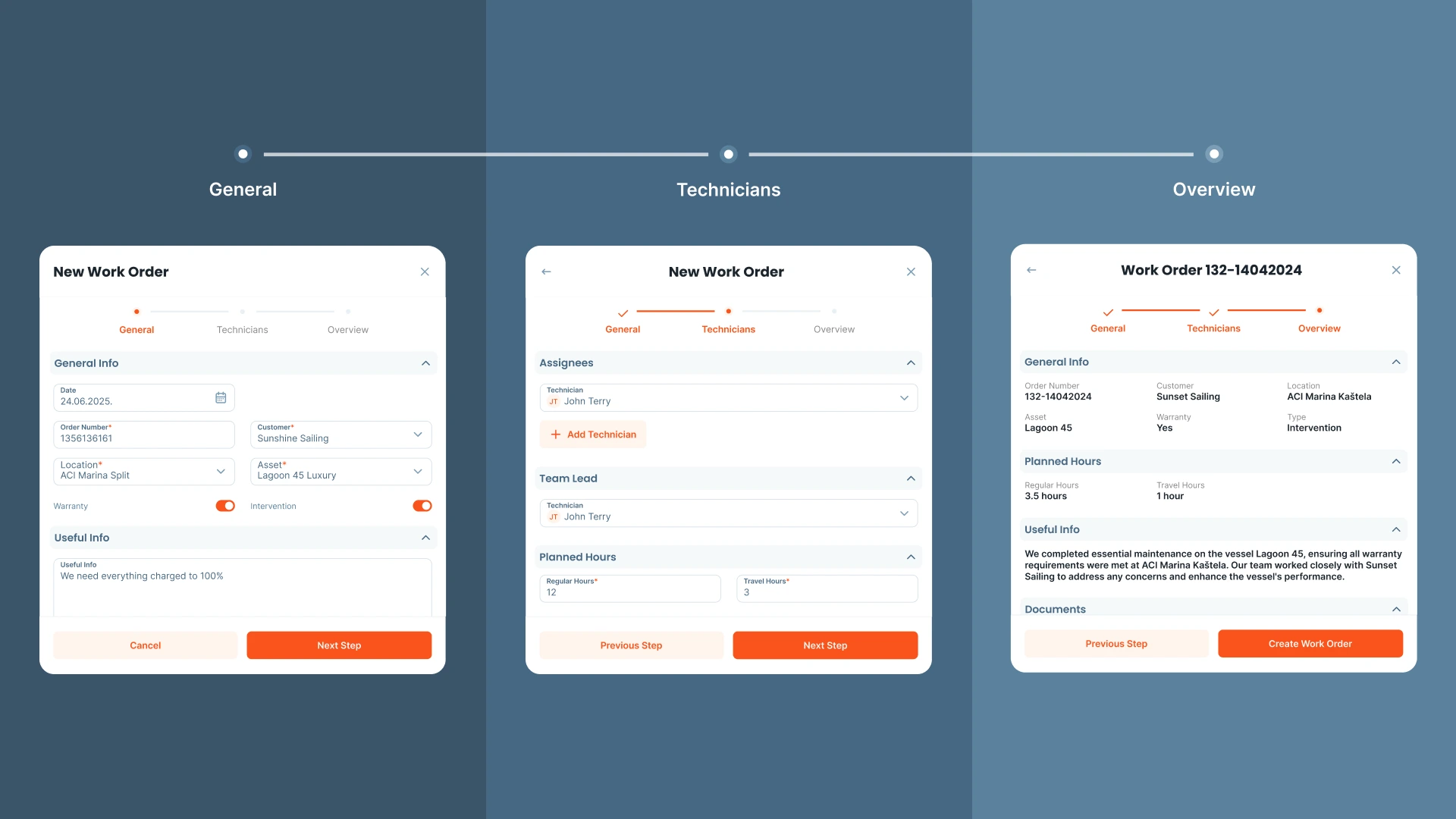

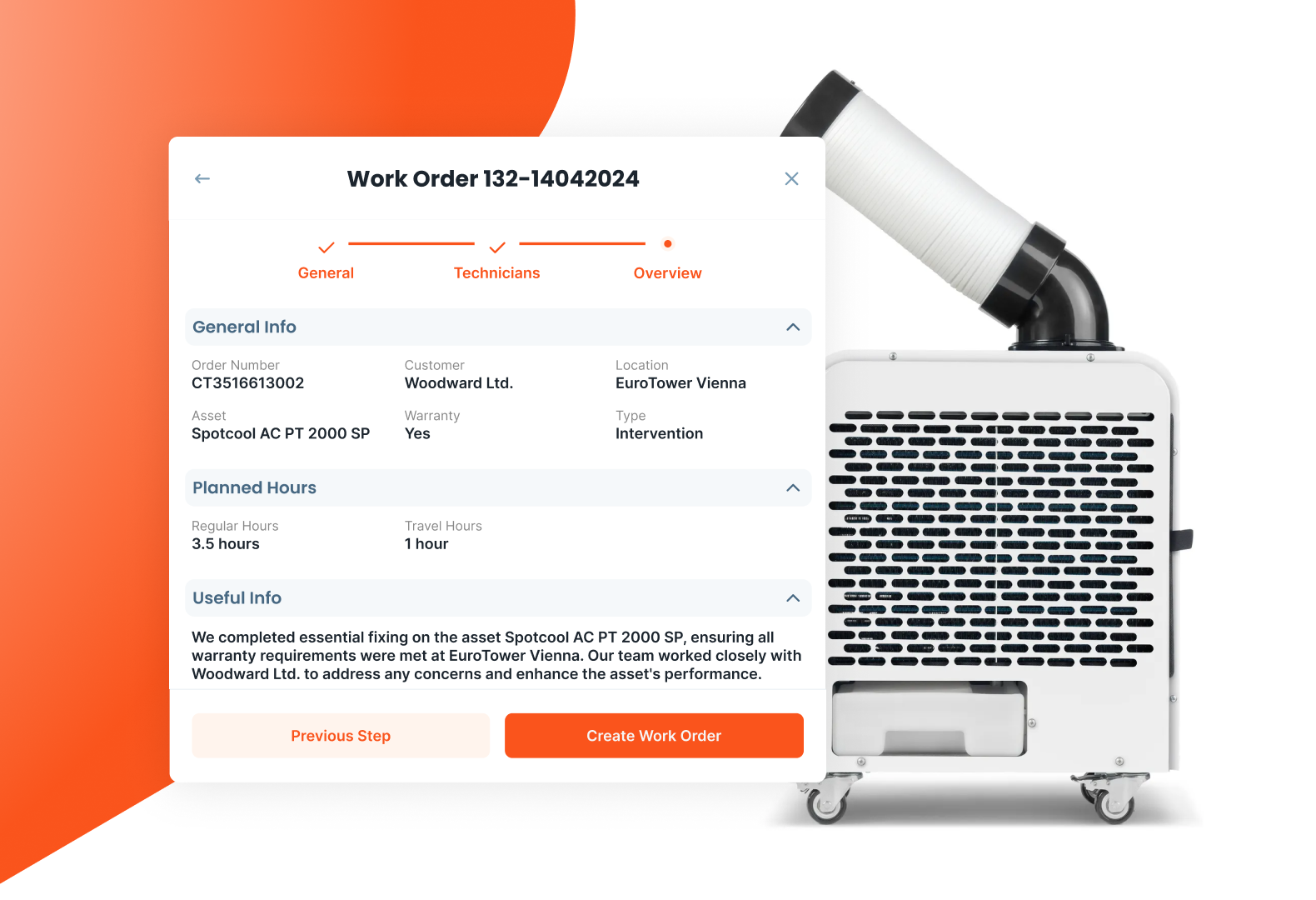

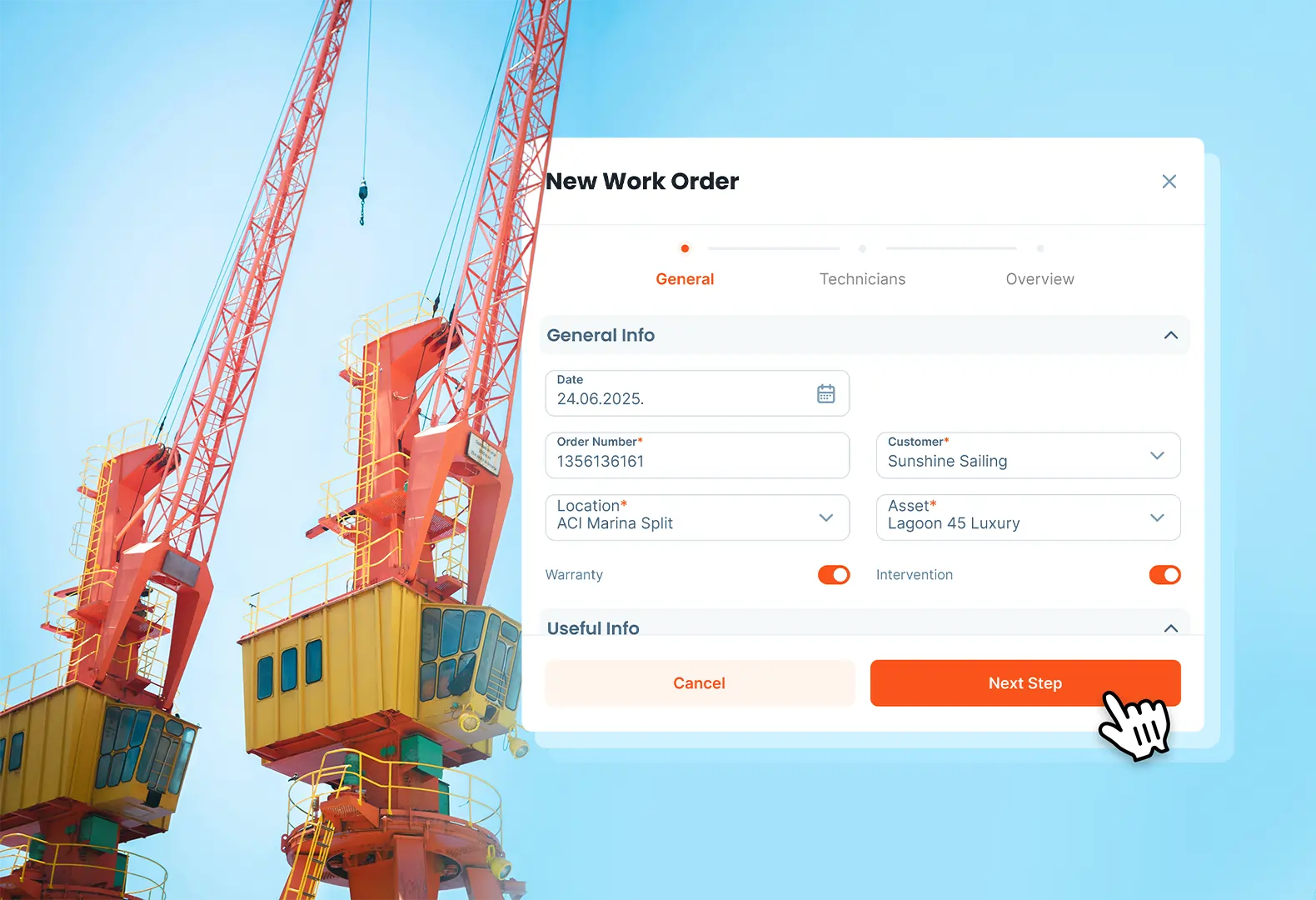

Many teams move this information into a maintenance system so everyone follows one schedule and one source of truth.

6. Assign ownership and workflows

Assign ownership at three levels:

- Overall plan owner, often the maintenance manager

- Area or line owners

- Task level owners and backup owners

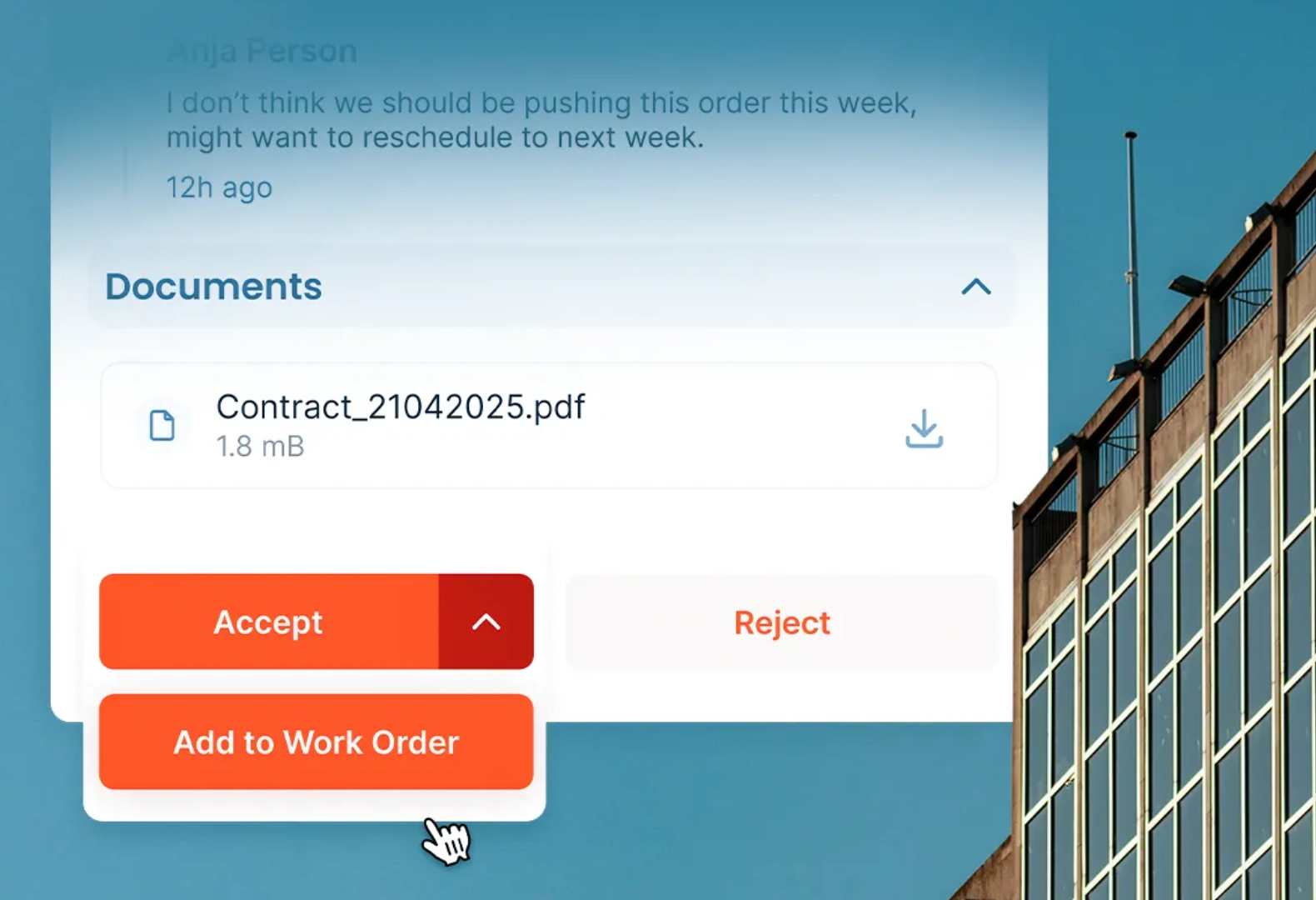

Describe workflows in simple language:

- How operations sends requests

- How planners turn requests into work orders

- How technicians add notes after work

- How completed work feeds reports and history

Clear workflows reduce conflict when pressure rises.

7. Review, learn, and adjust

At the end of each month, review:

- Planned versus completed preventive work

- Number of reactive jobs

- Root causes for major breakdowns

At the end of each quarter, adjust:

- Task frequency

- Criticality levels when business impact changes

- Resource allocation between lines

Small adjustments keep the annual maintenance plan relevant and effective.

Example annual maintenance schedule

Use this schedule as a starting draft and adapt detail to your site and assets.

Daily

- Walkthrough of production and utility areas

- Check for leaks, noise, heat, vibration, and unusual smells

- Confirm completion of yesterday work orders

- Record observations and minor issues in the maintenance system

Weekly

- Inspect guards, interlocks, and emergency stops

- Check lubrication points on key drives

- Inspect belts, chains, and rollers on conveyors

- Review backlog and close old requests

Monthly

- Inspect electrical panels and look for loose connections

- Test backup power where present

- Inspect air compressors, filters, and drains

- Check spare parts levels for high criticality assets

- Run a short safety talk for technicians

Quarterly

- Perform detailed inspections on A assets

- Test building safety systems and detectors

- Inspect roofs, drains, and exterior structures

- Check calibration of critical sensors and gauges

- Review key performance indicators with operations and leadership

Twice per year

- Service HVAC systems before peak seasons

- Inspect main pumps and valves

- Check structural elements and material handling systems

- Audit data quality in the maintenance system

Annual

- Review criticality ratings and update where needed

- Overhaul selected high impact assets

- Compare budget with actual spend

- Plan skills and training for technicians

- Review and update the annual maintenance plan for the next year

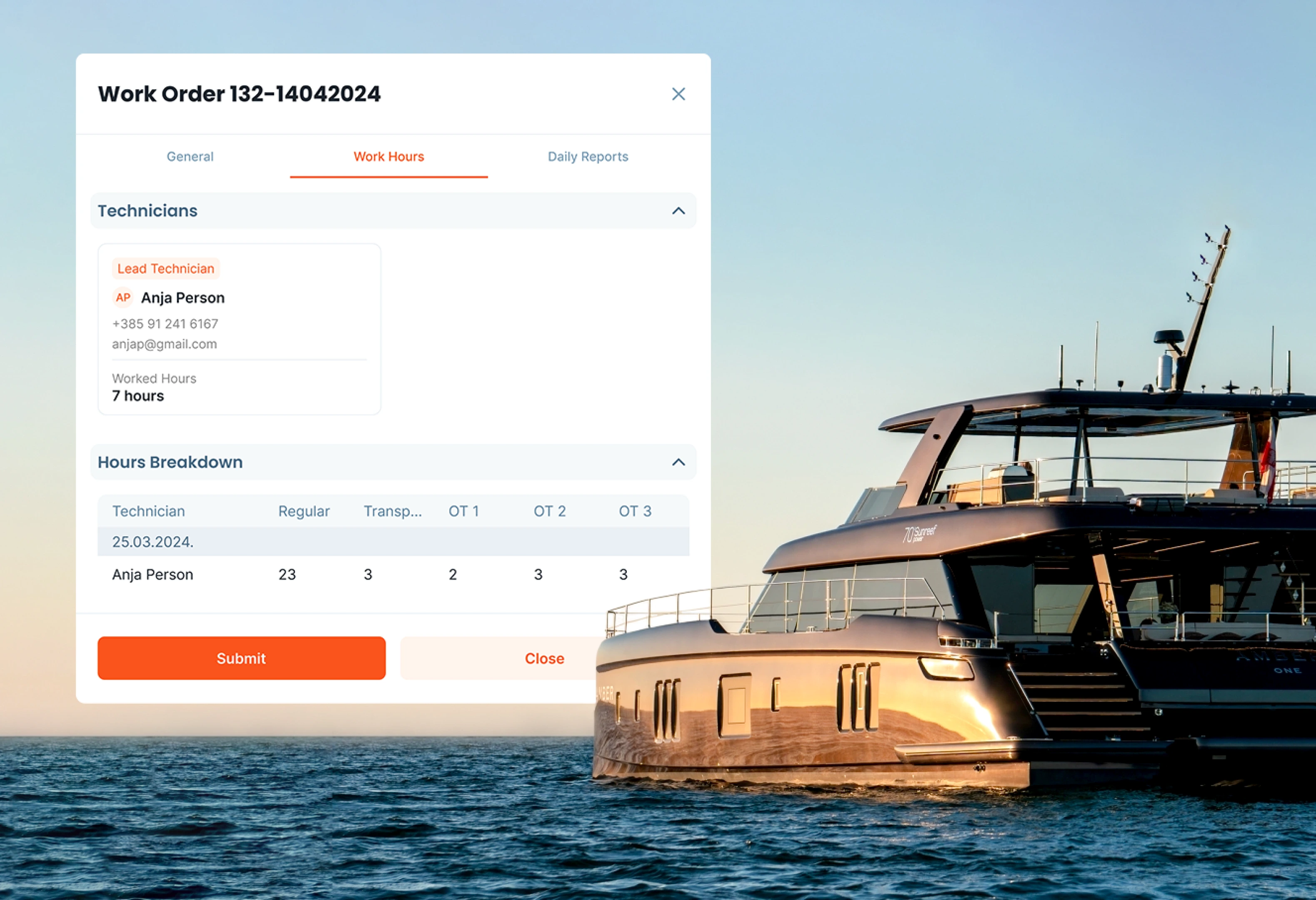

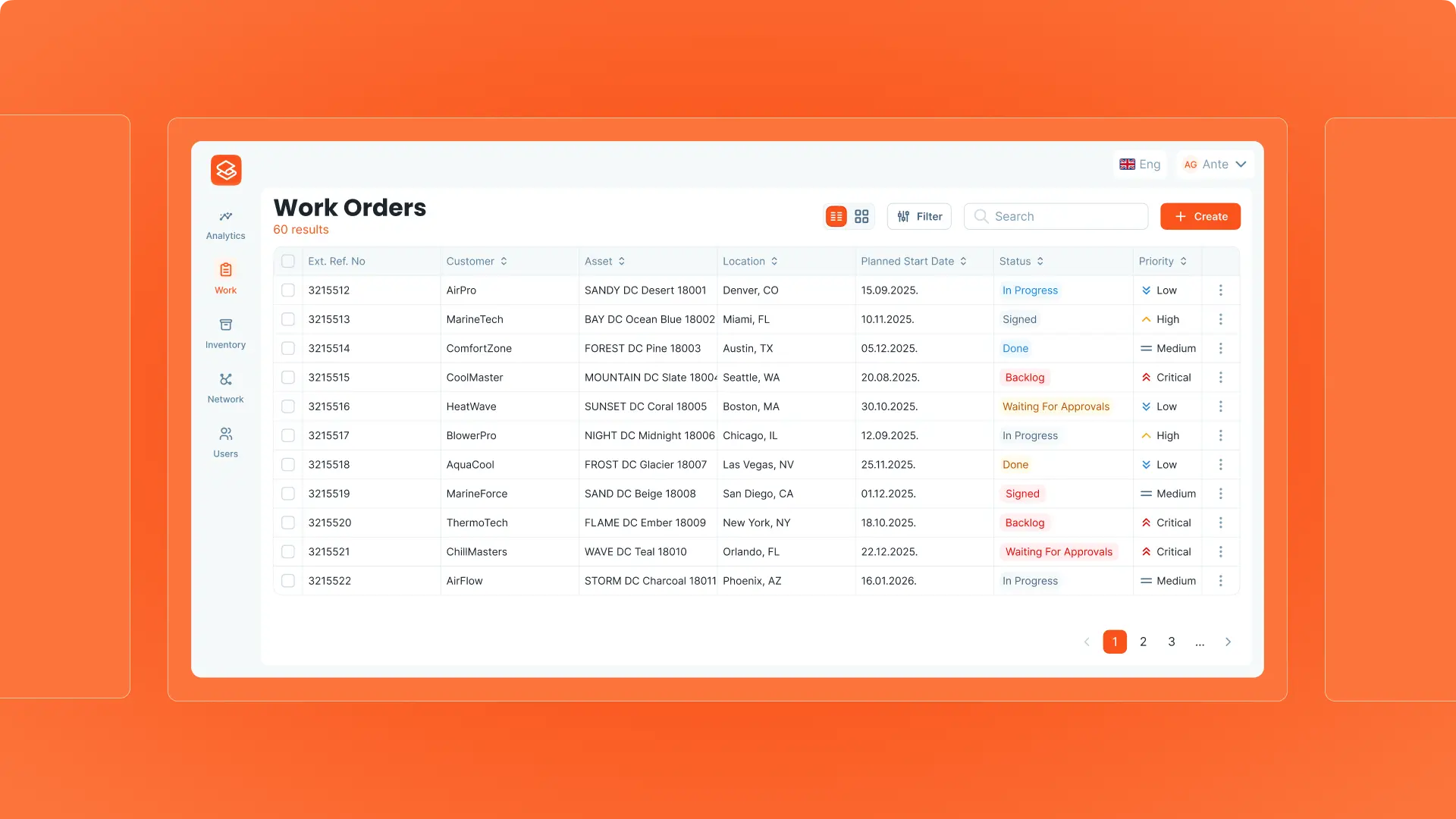

Using software to support your annual plan

Paper forms and basic spreadsheets struggle once asset numbers grow, work orders disappear, schedules drift out of date and reporting slows down.

A dedicated maintenance system keeps assets, tasks, schedules, and history in one place. Teams handle requests, work orders, checklists, and reports inside a single platform.

Serwizz focuses on needs of maintenance and service teams. The platform supports preventive schedules, work orders, asset records, and reporting in one structured view.

For more insight into preventive maintenance as a smart investment, read this guide on the Serwizz site.

Bringing your annual plan to life

Without a plan, each breakdown feels bigger than the last one, phones ring across shifts.

Production stops during the worst possible hour and the team spends energy on the same failures every month.

With a clear annual maintenance plan, work follows a visible path.

You know which assets matter most, you know which tasks stand in front of you this week. Numbers show progress instead of guesswork.

Start with one site, one line, or one asset group. Build a simple annual maintenance plan for the next twelve months and follow through on regular reviews.